Device and method for recycling rectification tail gas through evaporator condensation method

An evaporator and condensation method technology, which is applied in the field of rectification tail gas recovery and treatment, can solve the problems of inconvenient recovery method, unsatisfactory recovery efficiency, complex structure, etc., and achieve the effects of increasing air pressure, high heating efficiency, and convenient condensation recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

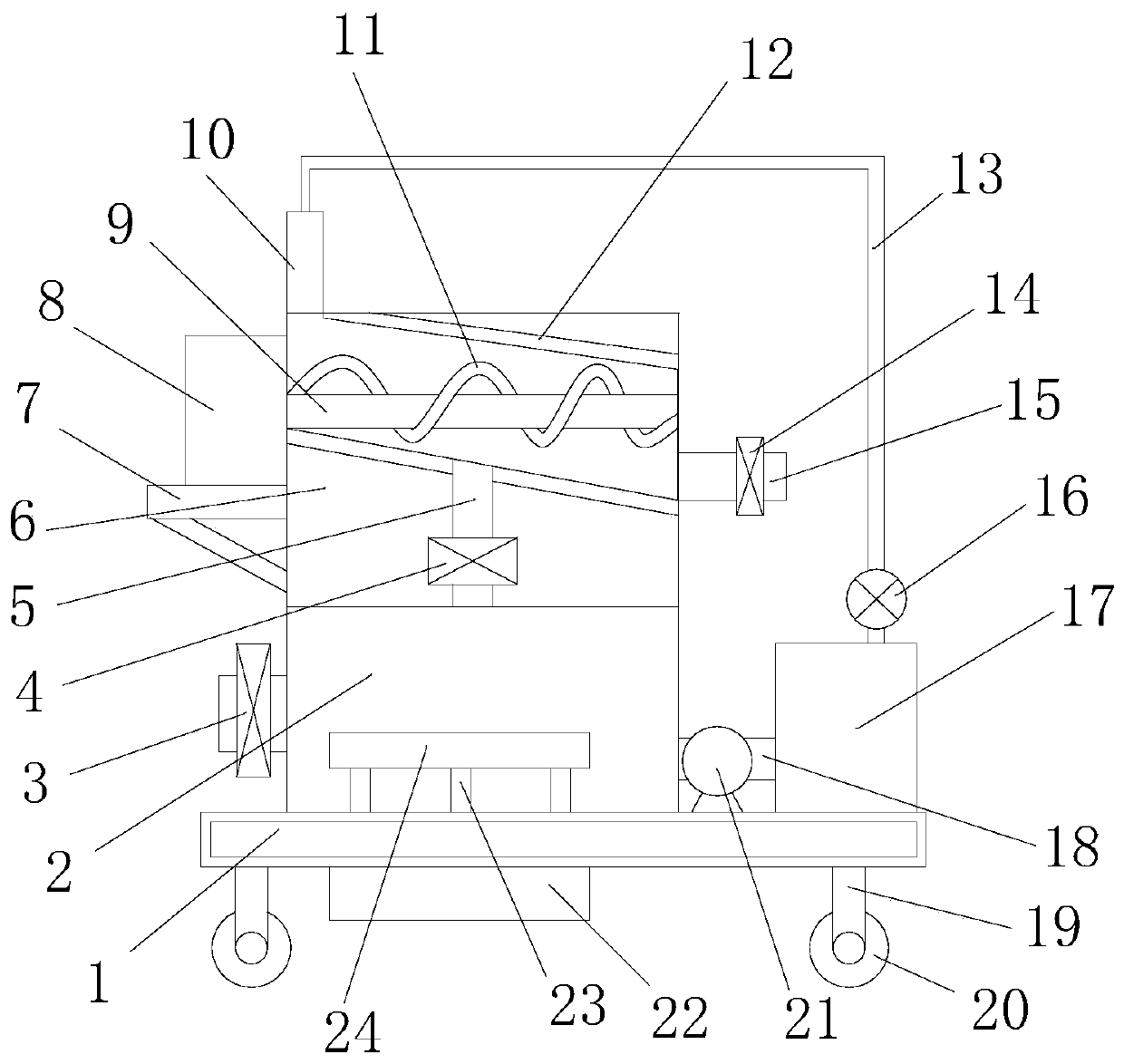

[0030] Embodiment one, with reference to figure 1 , one A device for recovering rectification tail gas by evaporator condensation method, comprising a base 1, a recovery tower 6 is arranged on the base 1, an evaporator 2 is arranged at the inner bottom of the recovery tower 6, and a condensation bin 12 is arranged at the top of the recovery tower 6, The top of the evaporator 2 communicates with the condensing chamber 12 through the connecting pipe 5, and the connecting pipe 5 is provided with a pressure relief valve 4; the base 1 is provided with a nitrogen tank 17, and the nitrogen tank 17 communicates with the evaporator 2 through a booster pipe 18, The booster pipe 18 is provided with a booster pump 21, and the booster pump 21 is fixed on the base 1; the present invention uses the mixture of high-pressure nitrogen and rectification tail gas to increase the pressure in the evaporator 2, and the stable physical and chemical properties of nitrogen ensure boosting security. ...

Embodiment 2

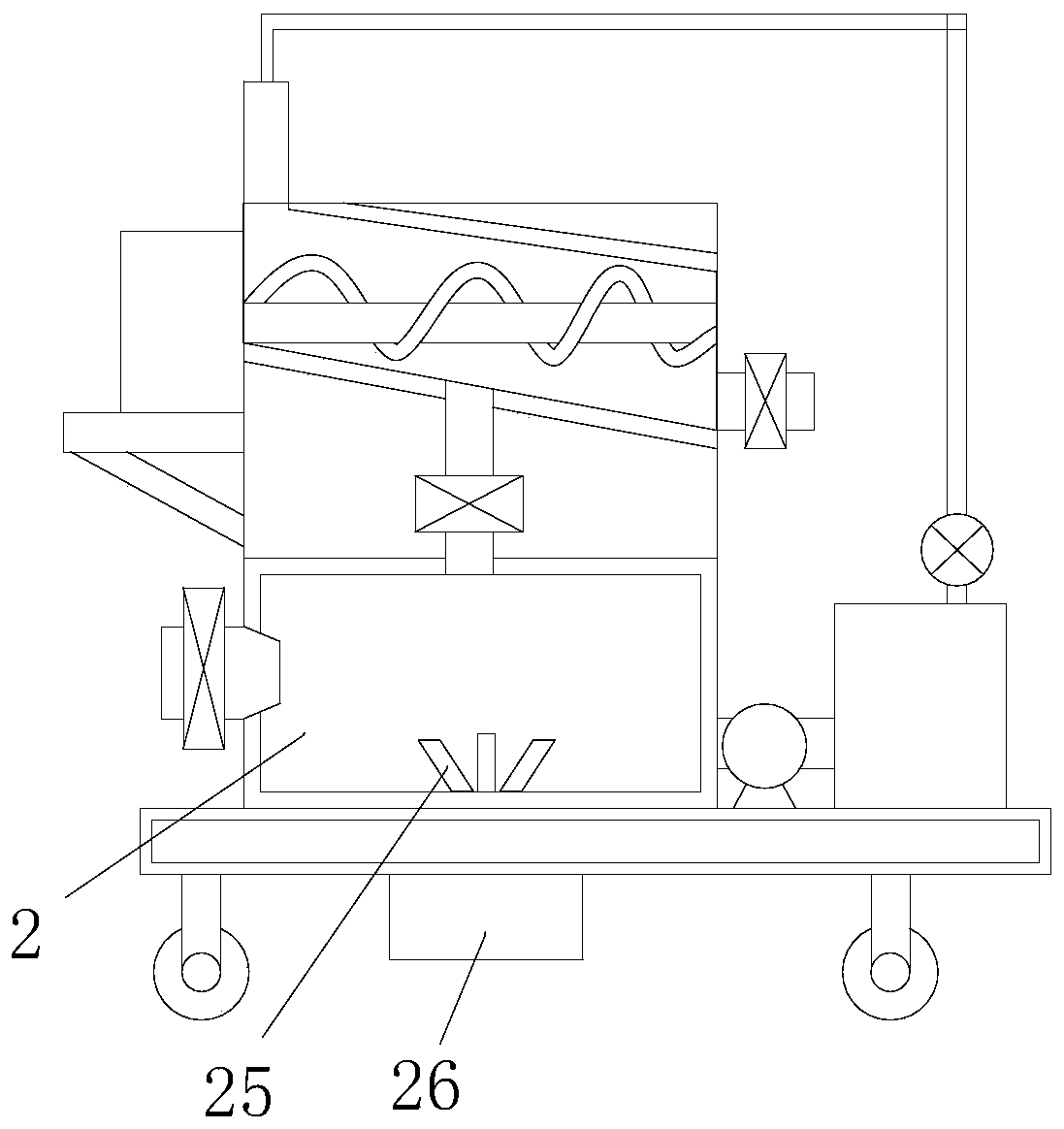

[0036] Embodiment two, refer to figure 2 The only difference between this embodiment and embodiment one is:

[0037] The inner wall of the evaporator 2 is a ceramic inner wall, and the bottom of the evaporator 2 is provided with a plurality of laser tubes 25, and the lower side of the base 1 is provided with a laser generator 26 connected to the laser tubes 25, and the laser tubes 25 are arranged in a divergent shape; Using laser to heat the rectification tail gas, the high heating efficiency makes the rectification tail gas quickly vaporized, which is convenient for subsequent condensation and recovery.

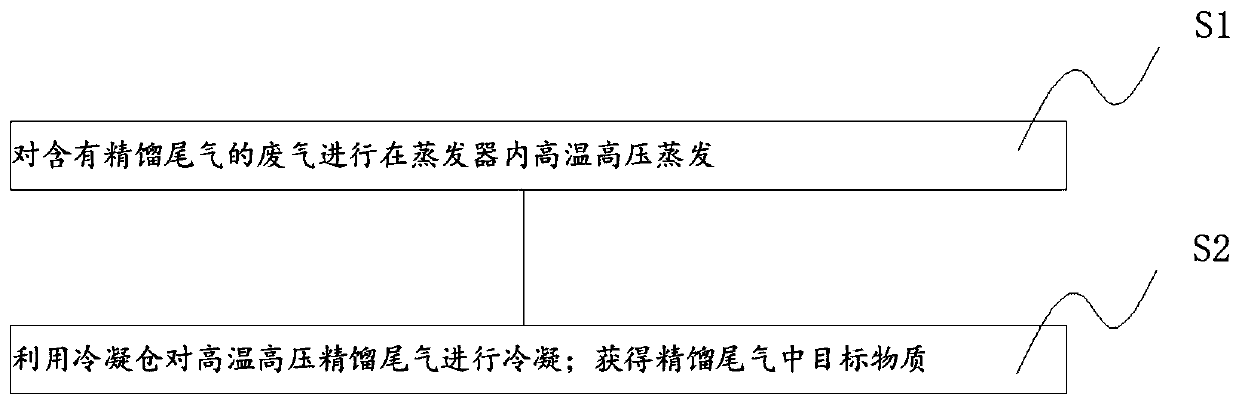

[0038] see image 3 : the method that evaporator condensation method reclaims rectification tail gas in embodiment one and embodiment two, comprises the steps:

[0039]S1. Evaporate the waste gas containing rectification tail gas at high temperature and high pressure in the evaporator;

[0040] S2. Condensing the high-temperature and high-pressure rectification tail gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com