Method and system for recovering volatile substances in wastewater

A technology for volatile substances and wastewater, which is applied in the field of recycling volatile substances in wastewater, can solve the problems of secondary pollution, poor cooling effect, high flow rate, etc., and achieve the effects of reducing the organic content of wastewater, facilitating condensation recovery, and high treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

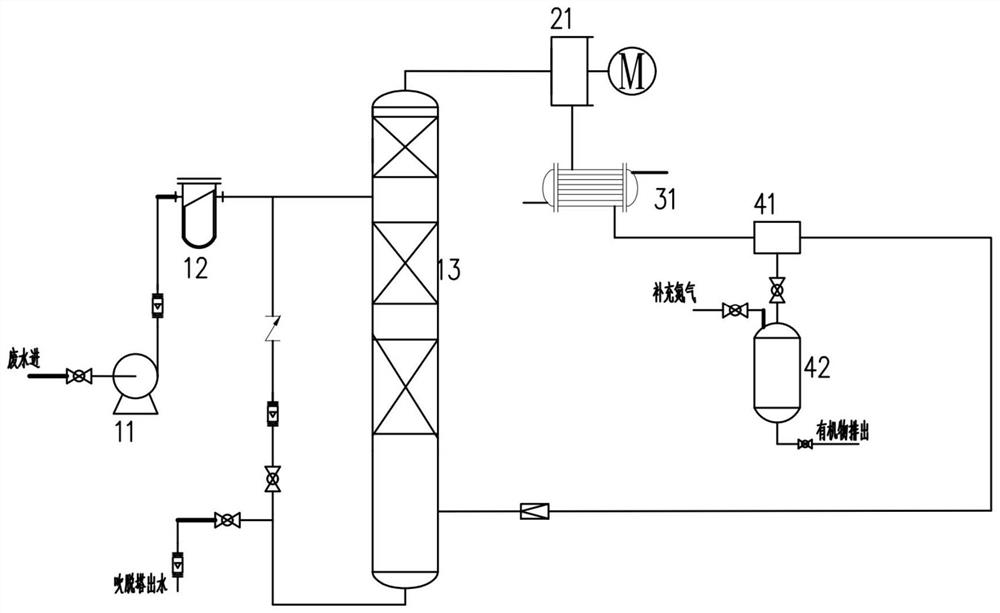

[0059] The present embodiment provides a system and operation process for recovering volatile substances in waste water, and the specific details are as follows:

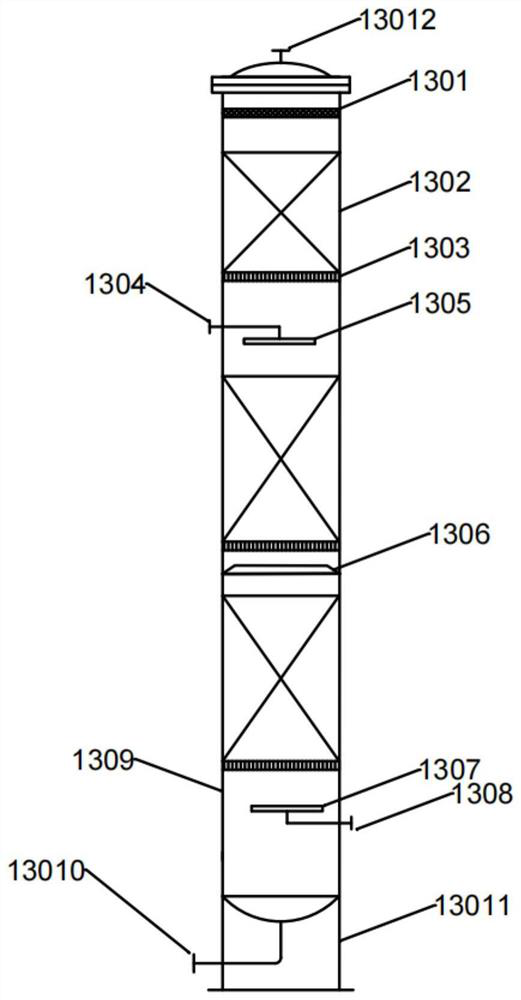

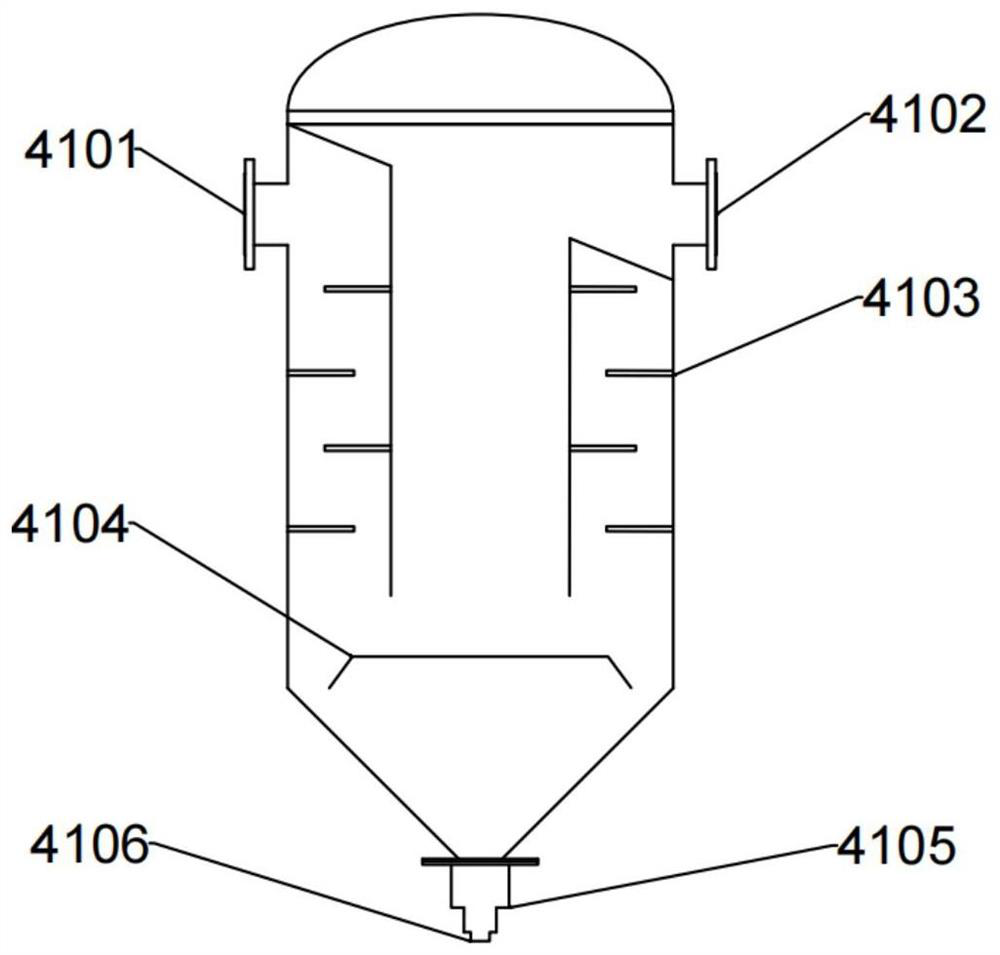

[0060] A system for recovering volatile substances in wastewater, comprising: stripping device, pressurizing device, condensing device and recovery device; wherein stripping device comprises waste water feed pump 11, waste water filter 12 and stripping tower 13, stripping device The tower 13 is composed of a skirt support 13011 and a tower body 1309; a waste water feed end 1304 is arranged in the upper part of the tower body 1309, a flow meter is arranged in front of the waste water feed end 1304, and the waste water feed end is connected to a nozzle-type water inlet distributor 1305; The stripping tower adopts regular corrugated metal mesh packing 1302. The gold mesh packing is provided with 2 to 4 layers according to the height of the tower. In this embodiment, three layers are set. The gold mesh packing 1302 is su...

Embodiment 2

[0070] The present embodiment provides a method for recovering methylene chloride in wastewater, which is realized by using the device provided in Example 1. The treatment object is the wastewater of a certain furan ammonium salt project, and the main component of the furan ammonium salt wastewater is 98.00 ~99.00wt% water, 0.8~1.5wt% dichloromethane, 0.03~0.05wt% furan ammonium salt, 0.05~0.08wt% furoic acid, 0.08~0.17wt% methoxyamine, 0.04~~0.20wt% other organic impurities . Specific steps are as follows:

[0071] S1: Open the gas condenser 31 to enter and exit the frozen brine, fill the liquid storage tank 42 with 0.70MPa (gauge pressure) nitrogen, and open the liquid inlet valve of the gas storage tank. Start the compressor 21. After the compressor 21 is fully started, open the inlet valve of the stripping tower 13, and adjust the nitrogen inlet flow to ensure that the tower pressure of the stripping tower 13 is between 0.01 and 0.02 MPa (gauge pressure). The gas runs st...

Embodiment 3

[0081] This embodiment provides a method for recovering 2-methyltetrahydrofuran in wastewater, which is realized by using the device provided in Example 1. The wastewater to be treated is the process wastewater of a certain 5-chloro-2-pentanone project. The main wastewater of this project is The ingredients are 91.5%-94.5% by weight of water, 5.0-8.0% by weight of 2-methyltetrahydrofuran, 0.3-0.5% by weight of 2-methylfuran, and 0.1-0.2% by weight of other organic impurities. Specific steps are as follows:

[0082] S1: Open the gas condenser to enter and exit the frozen brine, fill the liquid storage tank with 0.70MPa (gauge pressure) nitrogen, and open the air intake valve of the gas storage tank. Start the compressor. After the compressor is fully started, open the inlet valve of the stripping tower, and adjust the nitrogen inlet flow to ensure that the tower pressure of the stripping tower is between 0.01 and 0.02MPa (gauge pressure), and the gas runs stably for 10 minutes....

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com