A degreasing oil recovery device and control method

A recovery device and control method technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of lubricating oil waste, a large amount of oil mist, etc., to prevent waste, reduce pollution, and improve recycling efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

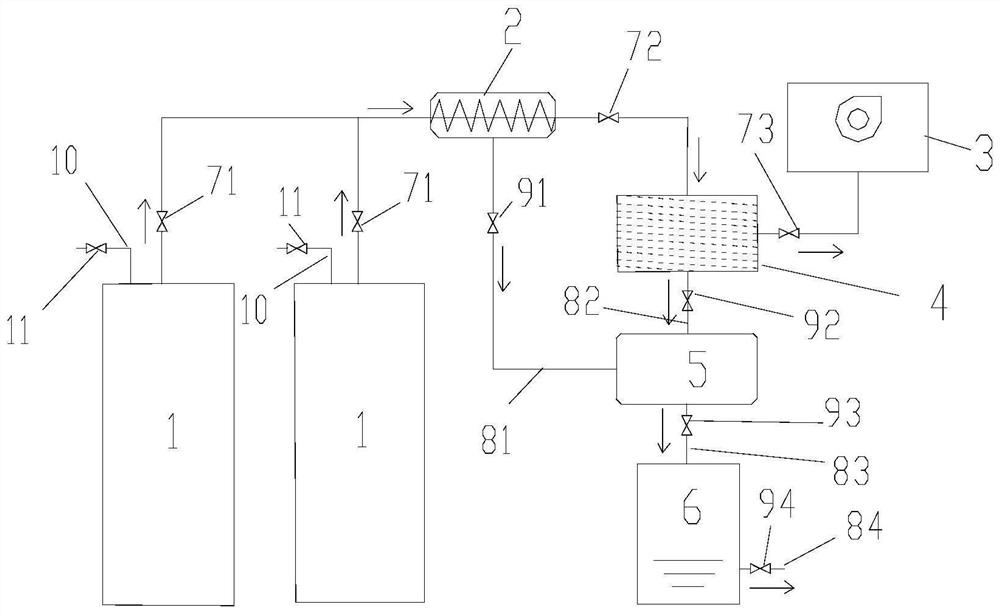

[0060] Such as figure 1 Shown, the present invention provides a kind of degreasing oil recovery device, it comprises:

[0061] Degreasing equipment 1, used to degrease the heat exchanger;

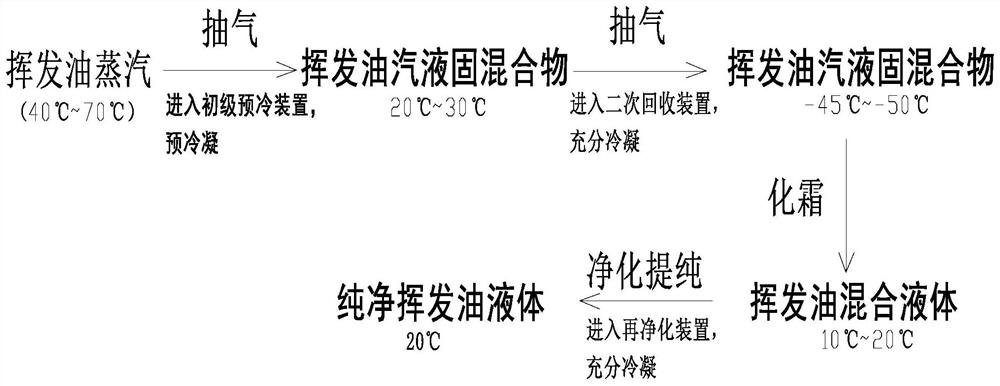

[0062] The primary pre-cooling device 2 is in communication with the degreasing equipment 1 so that the oil and gas in the degreasing equipment 1 can be introduced into the primary pre-cooling device 2, and the primary pre-cooling device has a closed first internal cavity , and can reduce the temperature in the first internal cavity to separate oil and gas;

[0063] Air extraction system 3, capable of communicating with the primary pre-cooling device 2, so as to perform suction on the primary pre-cooling device 2, so as to reduce the pressure in the first internal cavity of the primary pre-cooling device 2 .

[0064] In the present invention, by setting the primary pre-cooling device connected to the degreasing equipment and the air pumping system capable of communicating with and pumpin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com