Grading type condensing device for coal/biomass pyrolysis equipment

A biomass pyrolysis and condensation device technology, which is applied in the field of condensation technology, can solve the problems that liquid products cannot be graded, affect the liquid product graded purification and high-value utilization, and achieve low condensation costs, improve separation and purification, and high-value utilization Utilization and operation are safe and reliable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

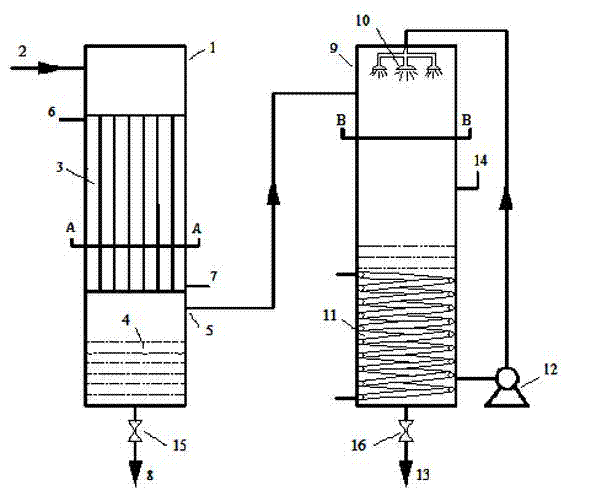

[0020] See figure 1 Take the staged condensing device for coal and biomass pyrolysis equipment with an oil production capacity of 500kg / h as an example. The device includes a falling film condenser and a spray condenser, and a falling film condenser and a spray condenser. The condensers are connected in series.

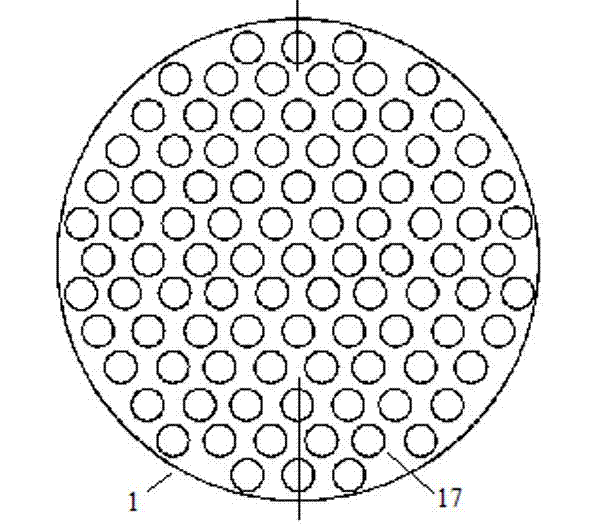

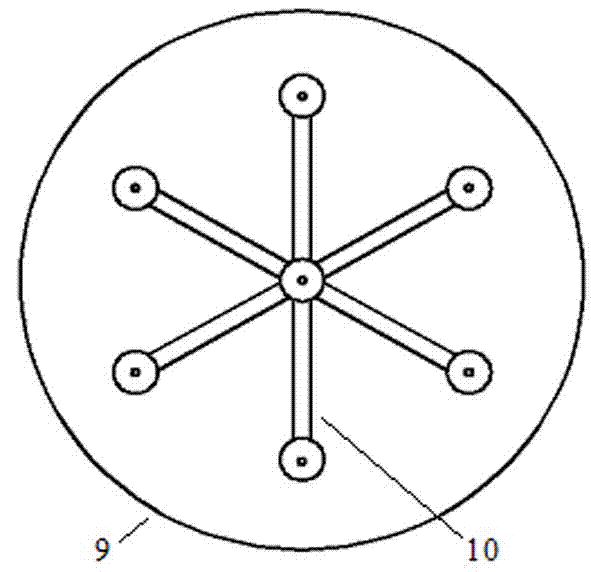

[0021] The body 1 of the falling film condenser is cylindrical, the upper side of the body 1 is provided with a pyrolysis steam inlet 2, and the middle part is provided with a tubular indirect heat exchanger 3, see figure 2 , The lower part is the liquid storage section 4. The upper side of the falling film condenser in the upper part of the liquid storage section 4 is provided with an air outlet 5; the upper side of the tubular indirect heat exchanger 3 is provided with a cooling water outlet 6, and the lower part A cooling water inlet 7 is provided on one side, and a first-stage liquid product outlet 8 is provided at the bottom of the body 1 of the falling film condens...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com