Efficient boiled off gas (BOG) after-condenser

A flash gas and condenser technology, applied in the field of high-efficiency flash gas (BOG) recondensers, can solve the problems of low condensation efficiency, complex equipment, and difficult control, and achieve sufficient condensation, simplified operation, and reduced flow dead ends. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

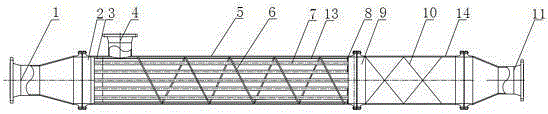

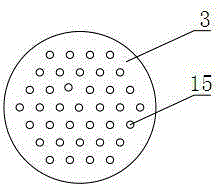

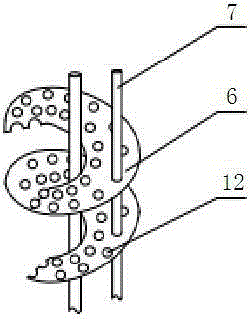

[0024] Such as Figure 1 to Figure 4 As shown, a high-efficiency flash gas (BOG) recondenser includes a first shell 5, a second shell 14, an LNG inlet 4 located on the first shell 5, and a The tube plate 3 and the supporting grid 8 at both ends of the housing 5 are connected to the BOG inlet 1. A plurality of microporous tubes 7, a distance rod 13 and a spiral are arranged between the tube plate 3 and the supporting grid 8. The deflector 6, the spiral deflector 6 is provided with a tube hole 12, the tube plate 3 is provided with a tube sheet tube hole 15, the surface of the microporous tube 7 is provided with micropores, the microporous tube 7 and the fixed The distance rod 13 passes through the tube hole 12 on the spiral baffle 6 and is fixed in parallel between the tube plate 3 and the supporting grid 8; one end of the second shell 14 is connected to the first shell 5 through a connecting flange 9. The other end is connected to the LNG outlet 11, and a static mixing unit 10 ...

Embodiment 2

[0027] Such as Image 6 As shown, on the basis of Example 1, the micropore diameter of the microporous tube 7 is 10 μm, and the arrangement angle between the microporous tubes is 30 degrees. One end of the microporous tube 7 is connected to the tube on the tube plate 3. The plate tube hole 15 is butted, the other end is movably overlapped with the supporting grid, and the end on the side of the supporting grid is blocked; the microporous tube and the tube plate are connected by thread.

Embodiment 3

[0029] On the basis of Example 1, the micropore diameter of the microporous tube 7 is 60 μm, and the arrangement angle between the microporous tubes is 45 degrees. One end of the microporous tube 7 is connected to the tube plate tube hole on the tube plate 3. 15 butt joint, the other end is movably overlapped with the supporting grid, and the end on the side of the supporting grid is blocked; the microporous tube and the tube sheet are connected by thread.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com