Preparation method of barium sulfate-carbon aerogel composite support supported palladium catalyst

A technology of carbon airgel and composite carrier, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc. Reduced activity, affecting the industrial application of homogeneous palladium catalysts, etc., to achieve the effects of easy operation, short reaction time, and not easy to condense

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

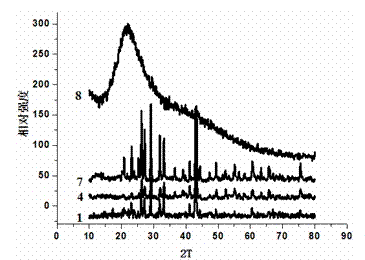

[0023] Dissolve 10g of glucose and 6g of polyvinylpyrrolidone (K30) in 60mL of water, then add 0.3g of Ba(OH) 2 ·8H 2 O, 0.2g potassium sulfate, transfer the mixed solution to a closed reaction kettle, react at 200°C for 5 hours, and obtain a columnar gel after the reaction. figure 1 (a), the gel was freeze-dried and calcined at 550°C for 3 hours under a nitrogen atmosphere to obtain a barium sulfate-carbon airgel composite carrier. The powder diffraction pattern is shown in figure 2 (1), it can be seen from the figure that (1) the peak of barium sulfate appears, and No. 8 has only the carbon peak (without adding Ba(OH) 2 ·8H 2 O and potassium sulfate prepared carbon gels), illustrating that BaSO 4 have been doped into the carbon gel.

Embodiment 2

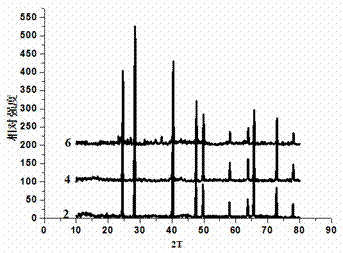

[0025] Dissolve 5.5g of sucrose and 0.5g of polyacrylamide (Mw: 2000000~14000000) in 20mL of water, then add 0.2g of barium chloride and 0.13g of ammonium sulfate, transfer the mixture to a closed reaction kettle, and react at 200°C After 5 hours, the cylindrical gel was obtained after the reaction. figure 1 (b), after lyophilization, the gel was calcined at 450°C for 2 hours under a nitrogen atmosphere to obtain a barium sulfate-carbon airgel composite carrier, and its powder diffraction pattern is shown in figure 2 (4), it can be seen from the figure that the peak of barium sulfate appears in (4), and there is only a carbon peak in No. 8, indicating that BaSO 4 have been doped into the carbon gel.

Embodiment 3

[0027] Dissolve 5g of lactose and 0.6g of polyacrylamide (Mw: 2000000~14000000) in 15mL of water, then add 10mL of acetic acid, 1.2g of barium nitrate, and 1g of potassium sulfate, transfer the mixture to a closed reaction kettle, and react at 200°C After 5 hours, a cylindrical gel was obtained after the reaction was completed, and the gel was freeze-dried and calcined at 600°C for 4 hours under a nitrogen atmosphere to obtain a barium sulfate-carbon airgel composite carrier.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com