High-efficiency diamond polishing agent and preparation method thereof

A diamond and polishing agent technology, applied in the field of high-efficiency diamond polishing agent and its preparation, can solve the problems of unusable polishing, narrow application range, poor polishing effect of petrographic analysis, etc., achieve good polishing effect, increase electrostatic attraction, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

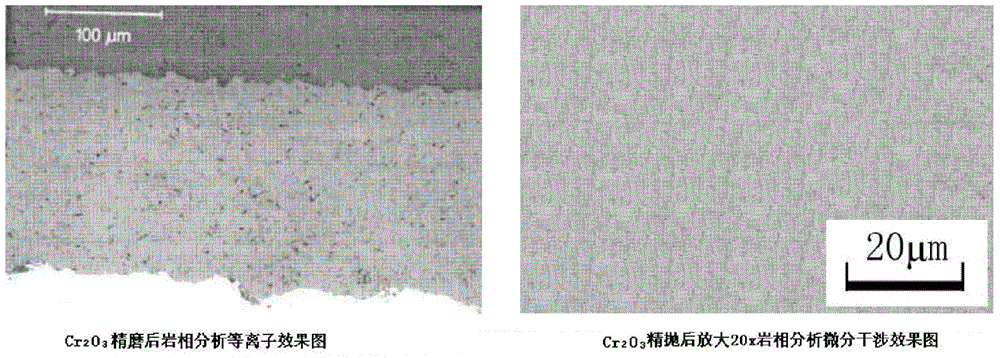

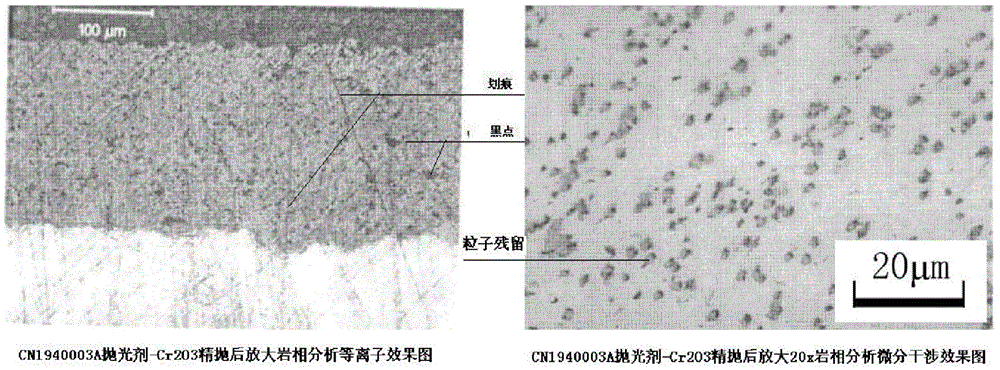

Image

Examples

Embodiment 1

[0038] A high-efficiency diamond polishing agent, which is prepared from the following raw materials in weight percentage:

[0039]

[0040] The particle size of the ultrafine diamond powder is 28 μm;

[0041] Described solvent is the ethanol aqueous solution that mass concentration is 20%;

[0042] The surfactant is sodium silicate and nonylphenol polyoxyethylene ether, and its mass ratio is 1:1;

[0043] Described wetting agent is acetone and stearic acid, and its mass ratio is 2: 1;

[0044] Described dispersant is glycerol and polyethyleneimine, and its mass ratio is 2: 1;

[0045] The strong acid is concentrated hydrochloric acid.

[0046] The ultrafine diamond powder is prepared through the following steps:

[0047] 1) Single crystal diamond is selected as raw material, and it is crushed by a counter-jet jet mill;

[0048] 2) Put the crushed diamond material into an electromagnetic ball mill and then crush it, and reshape the crushed diamond powder to carry out c...

Embodiment 2

[0052] A high-efficiency diamond polishing agent, which is prepared from the following raw materials in weight percentage:

[0053]

[0054] The particle size of the ultrafine diamond powder is 10 μm;

[0055] The solvent is water;

[0056] The surfactant is nonylphenol polyoxyethylene ether;

[0057] Described wetting agent is acetone and sherwood oil, and its mass ratio is 1: 1;

[0058] The dispersant is polyvinyl alcohol;

[0059] The strong acid is concentrated hydrochloric acid.

[0060] The ultrafine diamond powder is prepared through the following steps:

[0061] 1) Single crystal diamond is selected as raw material, and it is crushed by a counter-jet jet mill;

[0062] 2) Put the crushed diamond material into an electromagnetic ball mill and then crush it, and reshape the crushed diamond powder to carry out chemical purification, rinsing and classification;

[0063] 3) Put the graded diamond micropowder into a microwave drying oven to dry to obtain ultrafine di...

Embodiment 3

[0066] A high-efficiency diamond polishing agent, which is prepared from the following raw materials in weight percentage:

[0067]

[0068] The particle size of the ultrafine diamond powder is 40 μm;

[0069] Described solvent is ethanol;

[0070] The surfactant is fatty alcohol polyoxyethylene ether;

[0071] Described wetting agent is stearic acid and sherwood oil, and its mass ratio is 9: 1;

[0072] Described dispersant is sodium lauryl sulfate and polyethylene glycol, and its mass ratio is 5: 7;

[0073] The strong acid is sulfuric acid.

[0074] The ultrafine diamond powder is prepared through the following steps:

[0075] 1) Single crystal diamond is selected as raw material, and it is crushed by a counter-jet jet mill;

[0076] 2) Put the crushed diamond material into an electromagnetic ball mill and then crush it, and reshape the crushed diamond powder to carry out chemical purification, rinsing and classification;

[0077] 3) Put the graded diamond micropow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com