Patents

Literature

84results about How to "Increase electrostatic attraction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

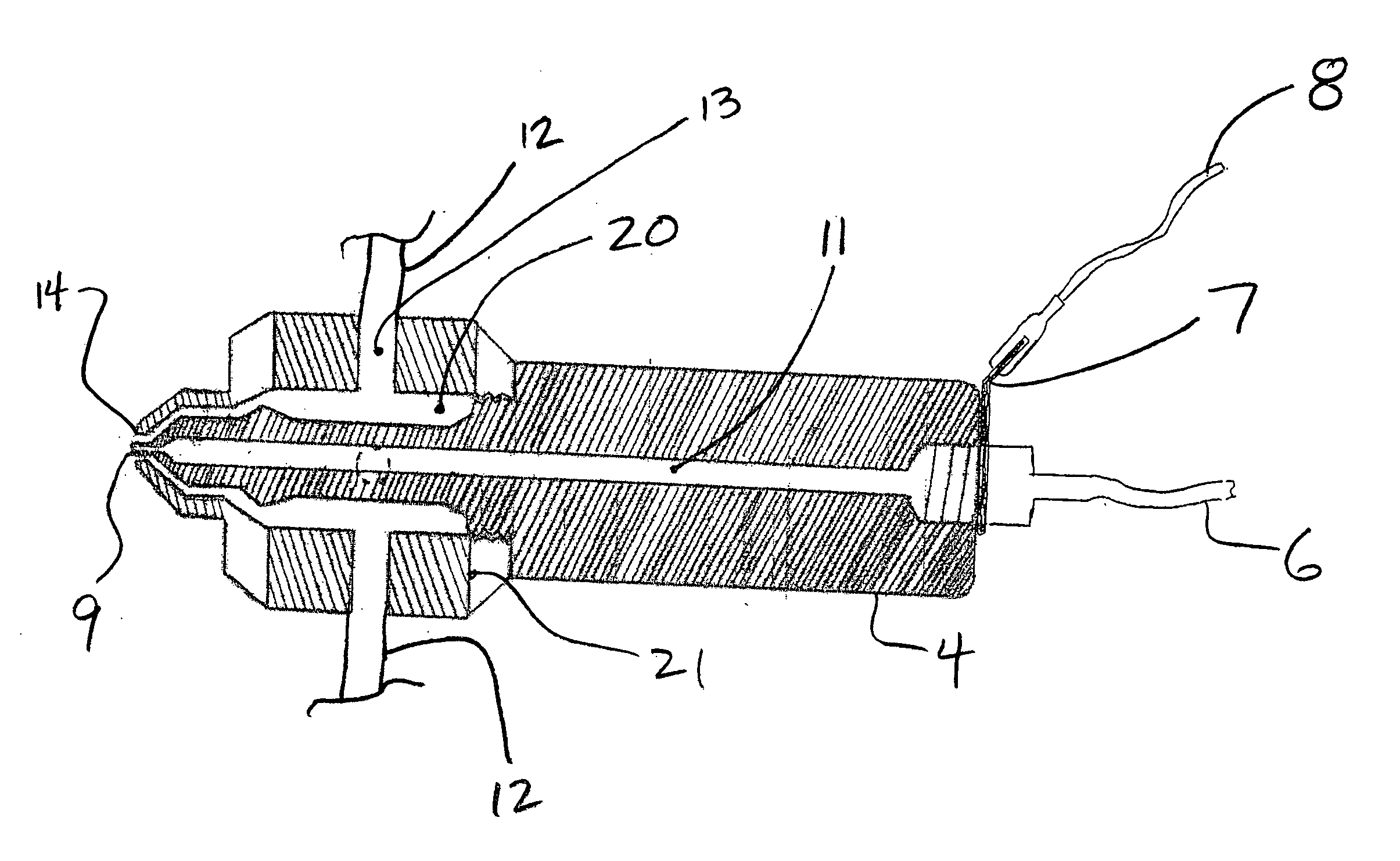

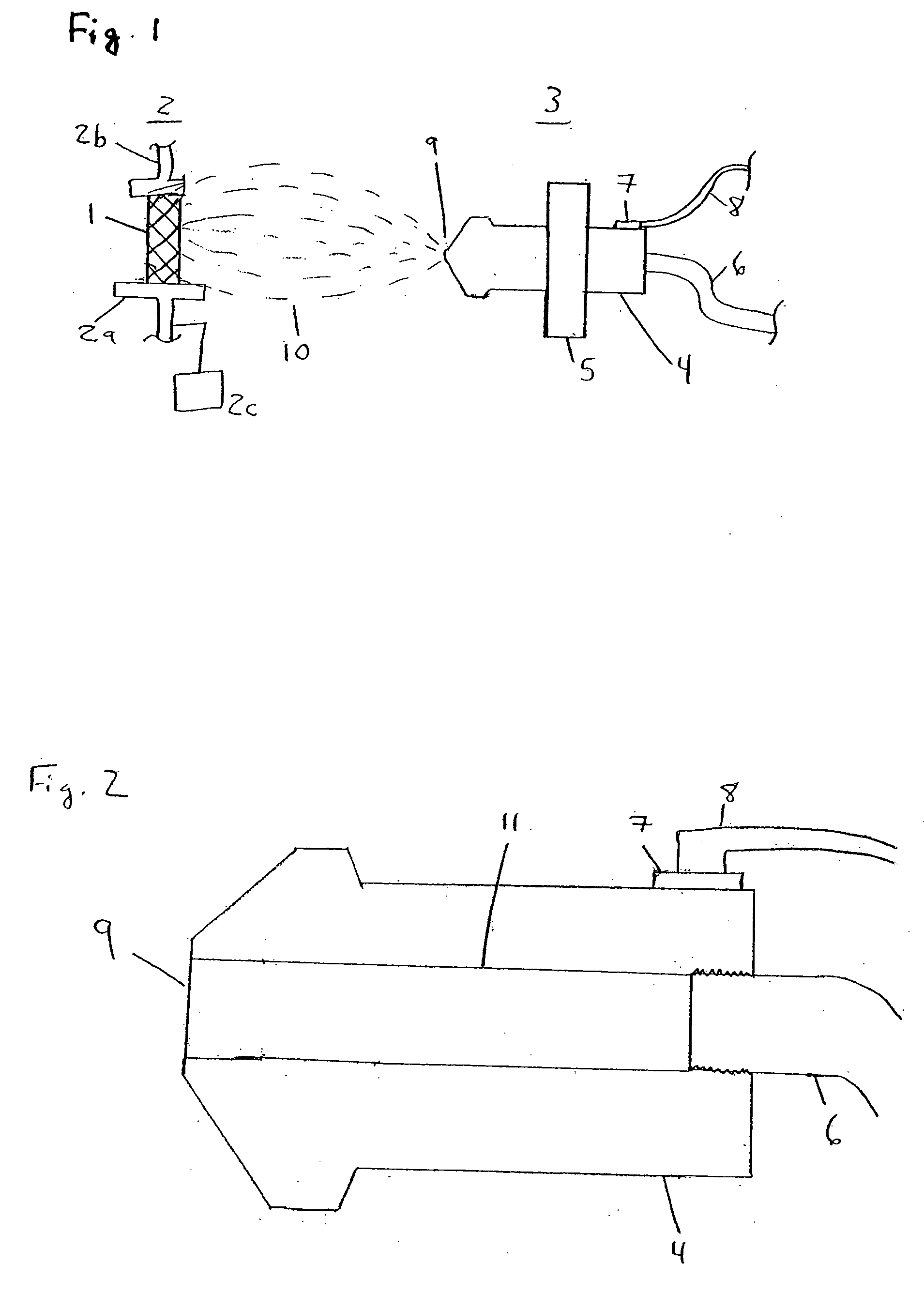

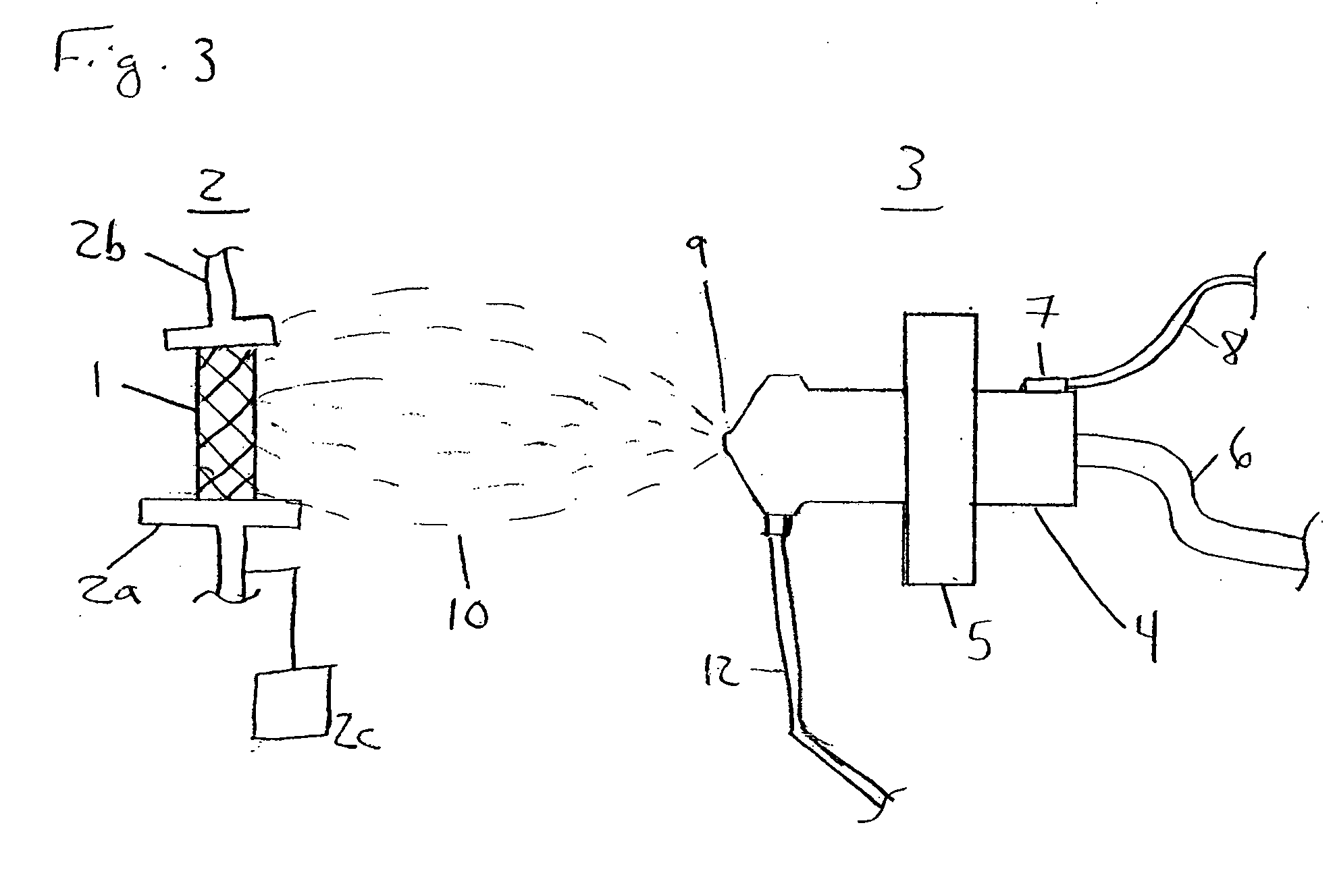

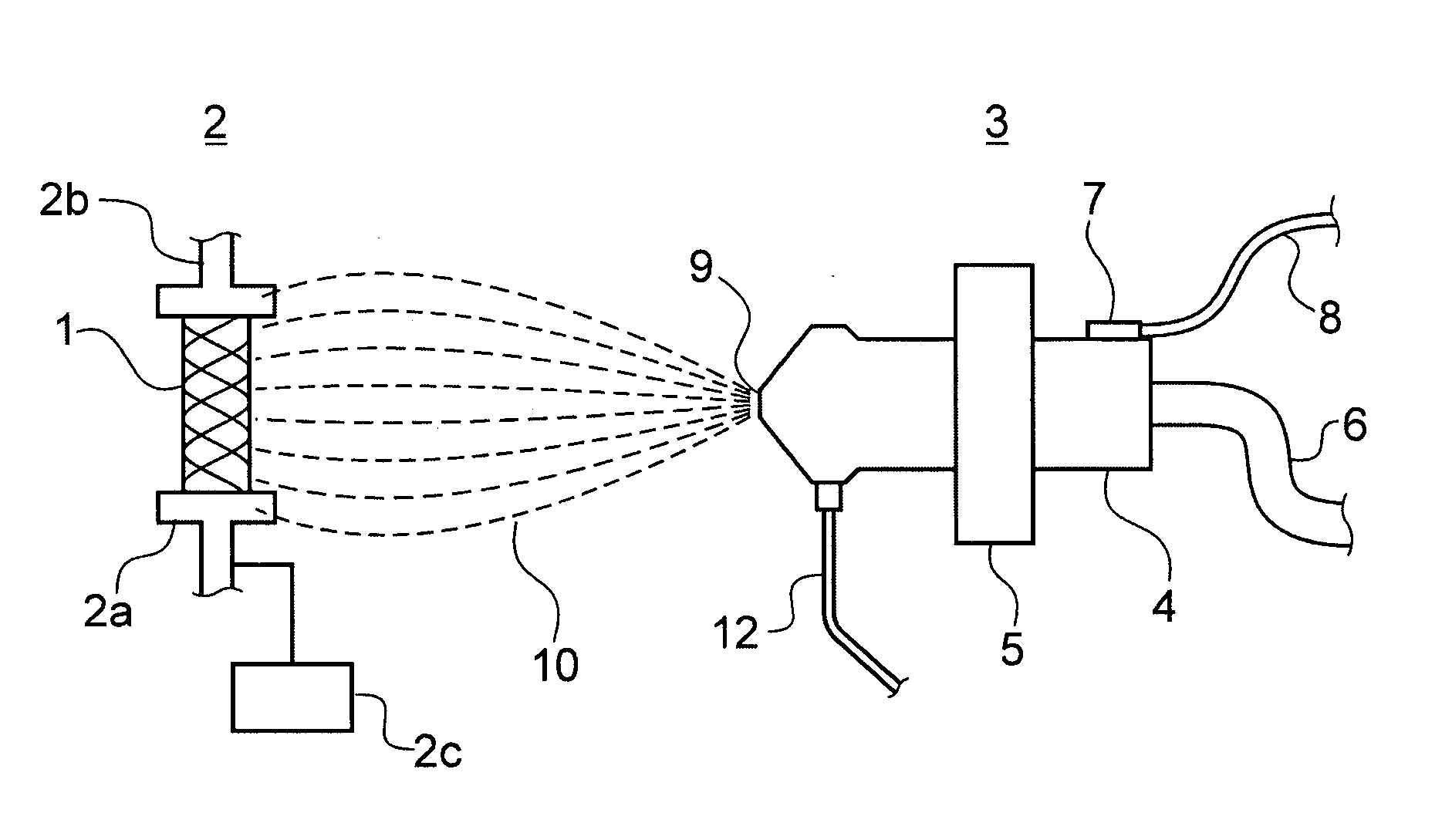

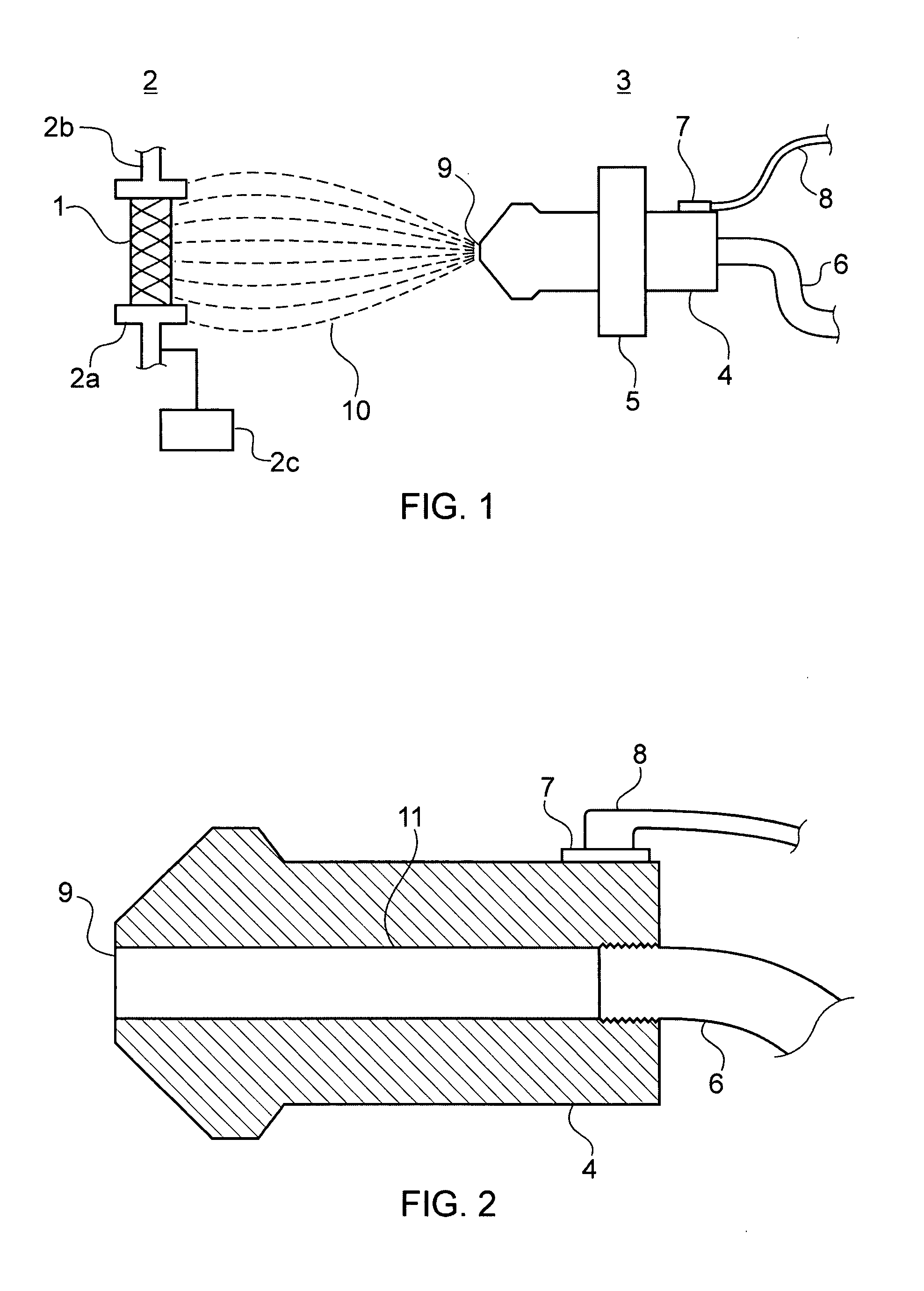

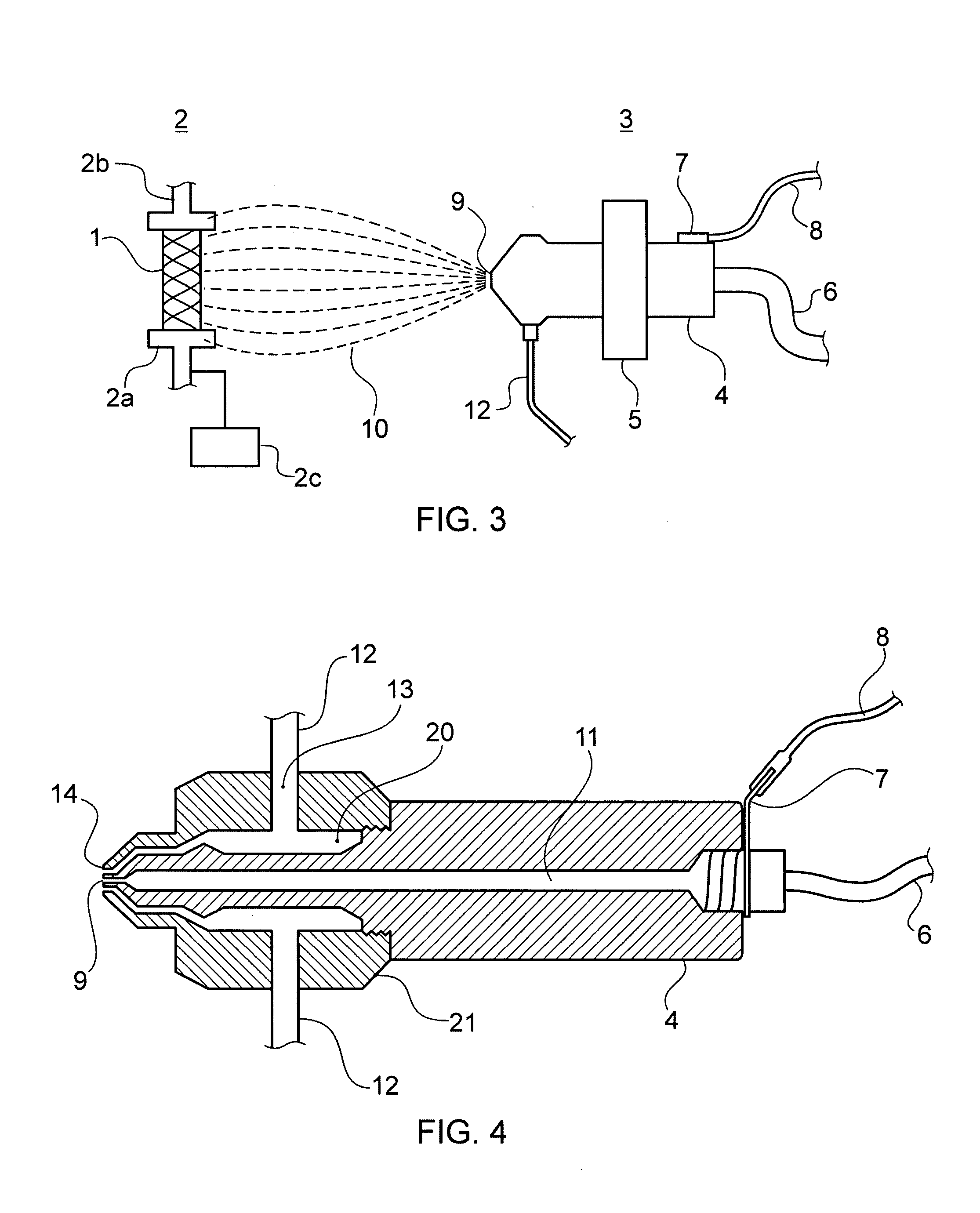

Apparatus and method for electrostatic spray coating of medical devices

ActiveUS20050175772A1Increased ionization increases the fraction of coating spray attractedIncrease electrode surface areaLiquid spraying plantsElectric shock equipmentsVoltage spikeSpray coating

An apparatus and method for electrostatic spray deposition of small targets, such as medical devices like stents. The apparatus includes a target holder which applies a first electrical potential to the target, and an electrostatic dispensing nozzle which applies a second potential sufficient to attract the coating fluid from the nozzle toward the target. Because the entire dispensing nozzle is conductive, the coating fluid may receive a greater charge than may be obtained with internal electrode-type nozzles. Electrostatic attraction of the coating fluid to the target is enhanced by the combination of higher charge density imparted to the coating fluid by the conductive nozzle, and application of a momentary voltage spike to the target to provide consistent conductivity between the target and its holder, thereby ensuring the target is presents the full first potential applied to the holder. The voltage spike may also be used independently of the conductive nozzle.

Owner:BOSTON SCI SCIMED INC

Apparatus and method for electrostatic spray coating of medical devices

ActiveUS7241344B2Increased ionization increases the fraction of coating spray attractedIncrease electrode surface areaLiquid spraying plantsElectric shock equipmentsVoltage spikeSpray coating

An apparatus and method for electrostatic spray deposition of small targets, such as medical devices like stents. The apparatus includes a target holder which applies a first electrical potential to the target, and an electrostatic dispensing nozzle which applies a second potential sufficient to attract the coating fluid from the nozzle toward the target. Because the entire dispensing nozzle is conductive, the coating fluid may receive a greater charge than may be obtained with internal electrode-type nozzles. Electrostatic attraction of the coating fluid to the target is enhanced by the combination of higher charge density imparted to the coating fluid by the conductive nozzle, and application of a momentary voltage spike to the target to provide consistent conductivity between the target and its holder, thereby ensuring the target is presents the full first potential applied to the holder. The voltage spike may also be used independently of the conductive nozzle.

Owner:BOSTON SCI SCIMED INC

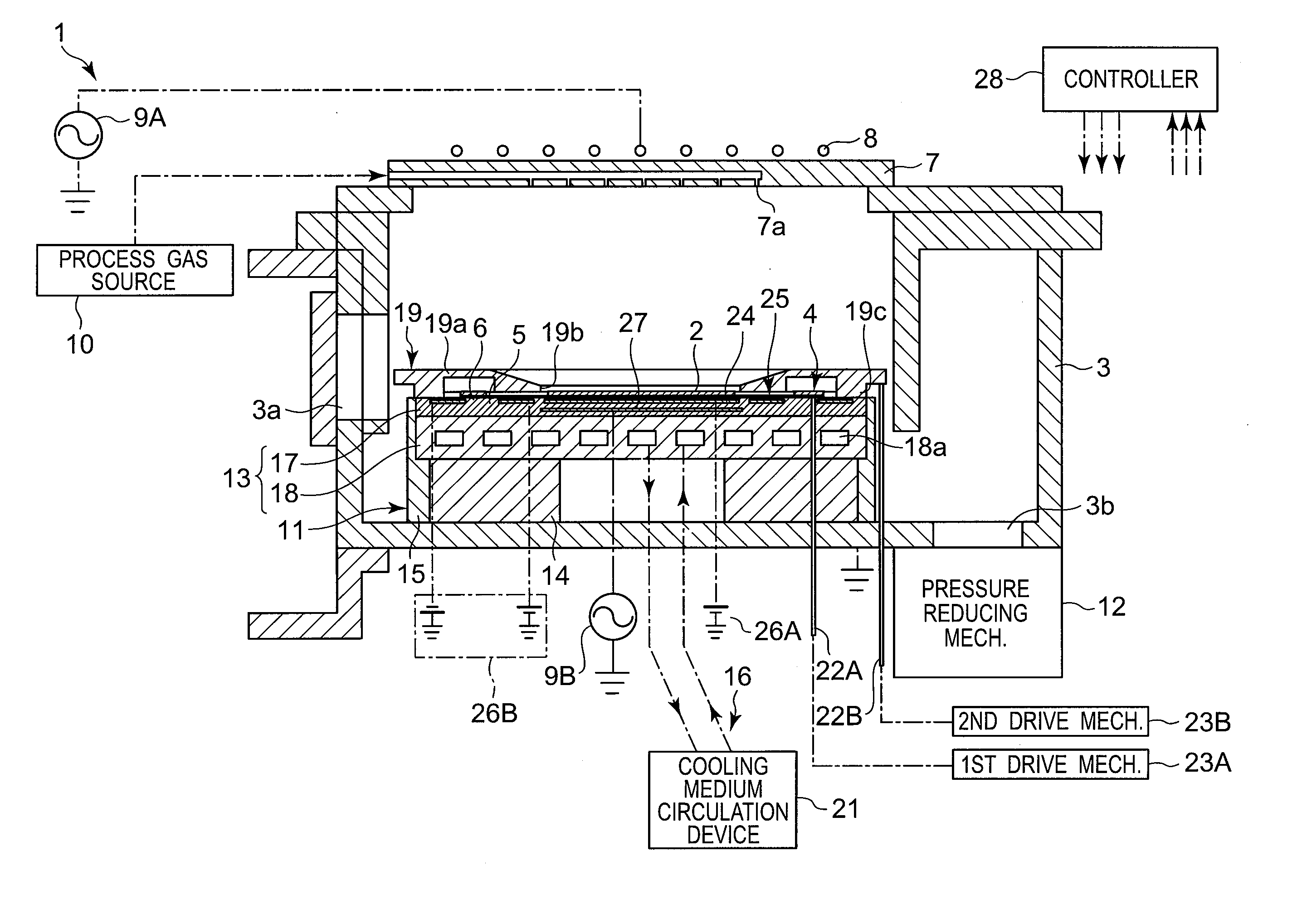

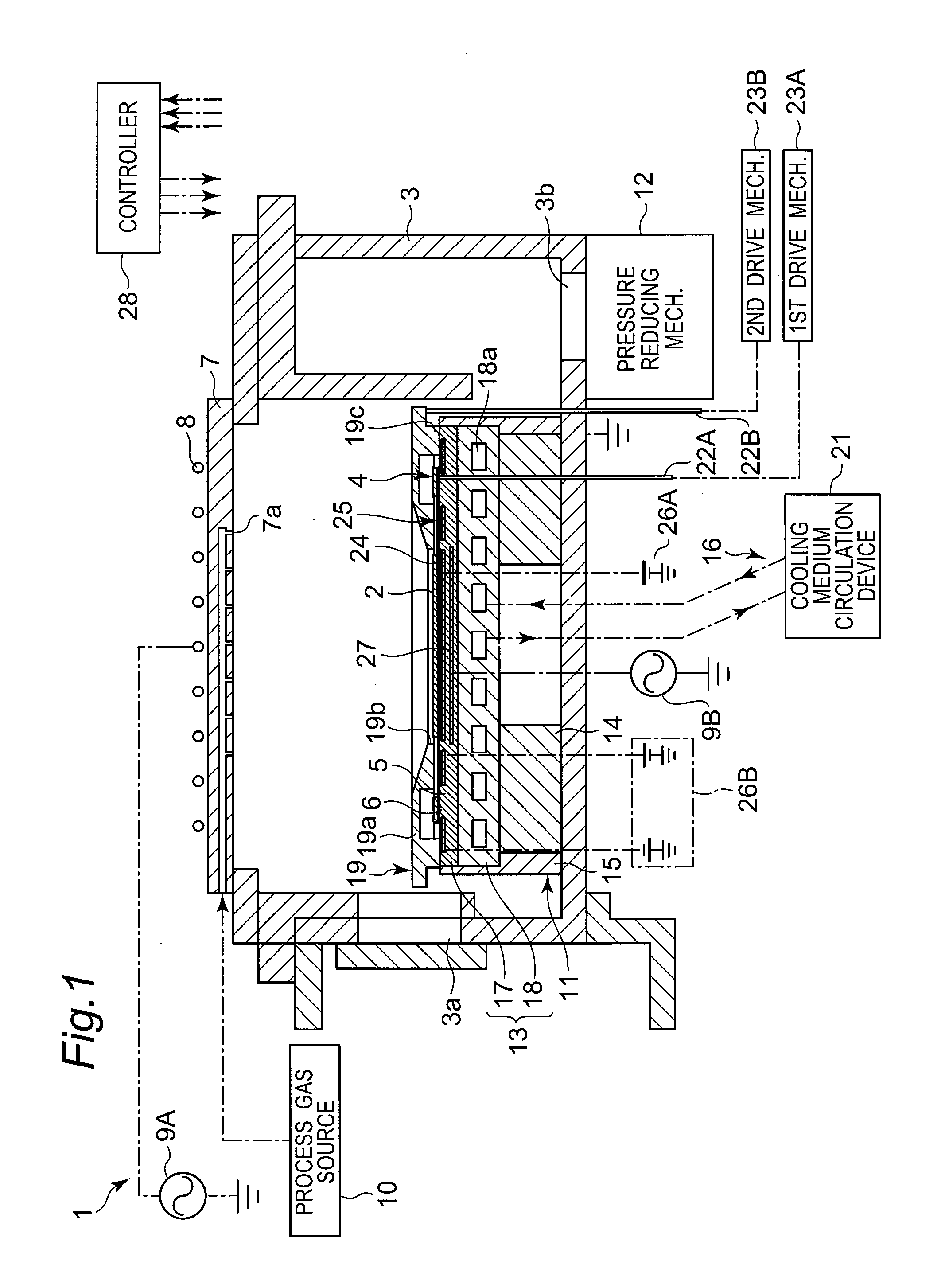

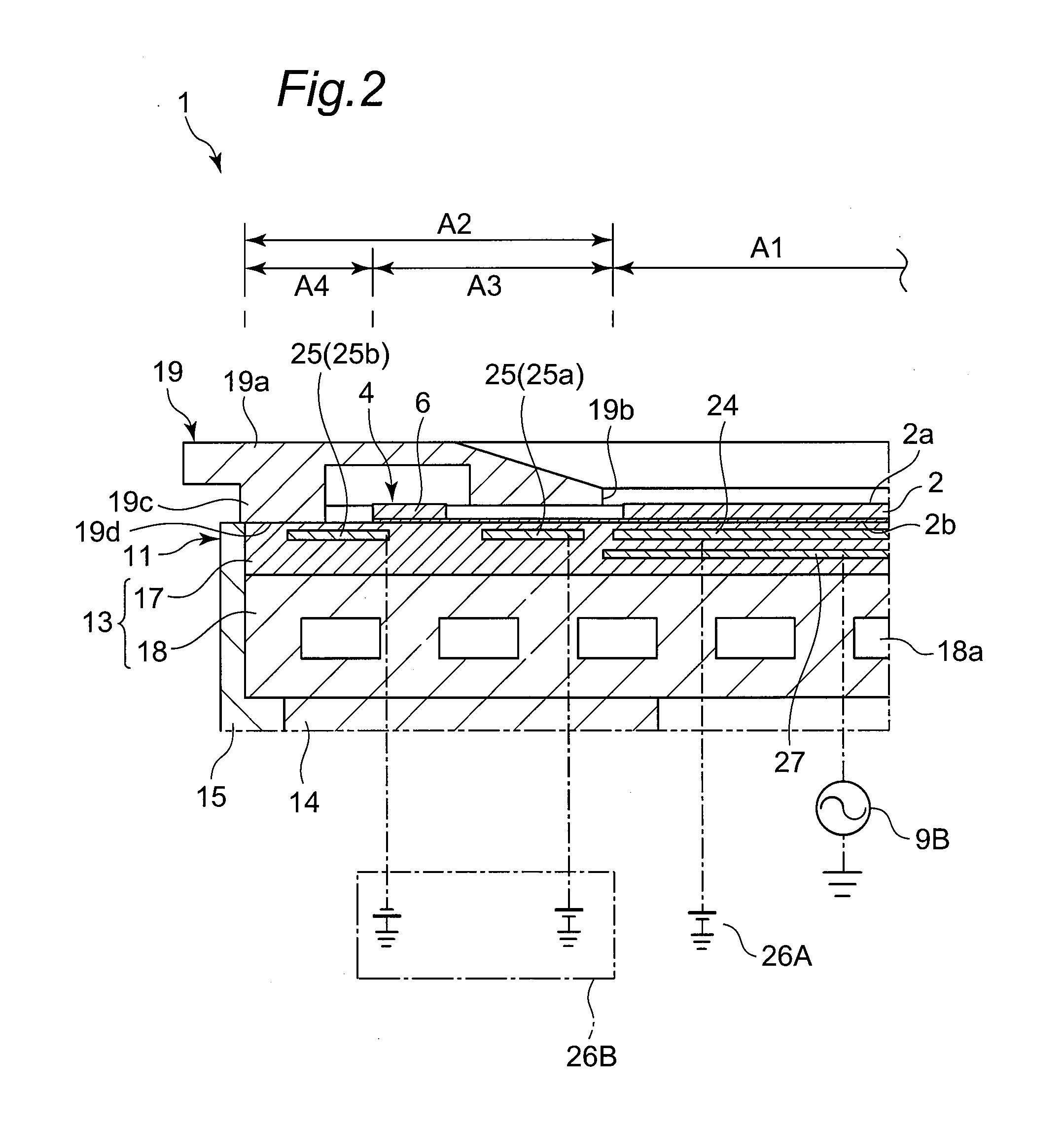

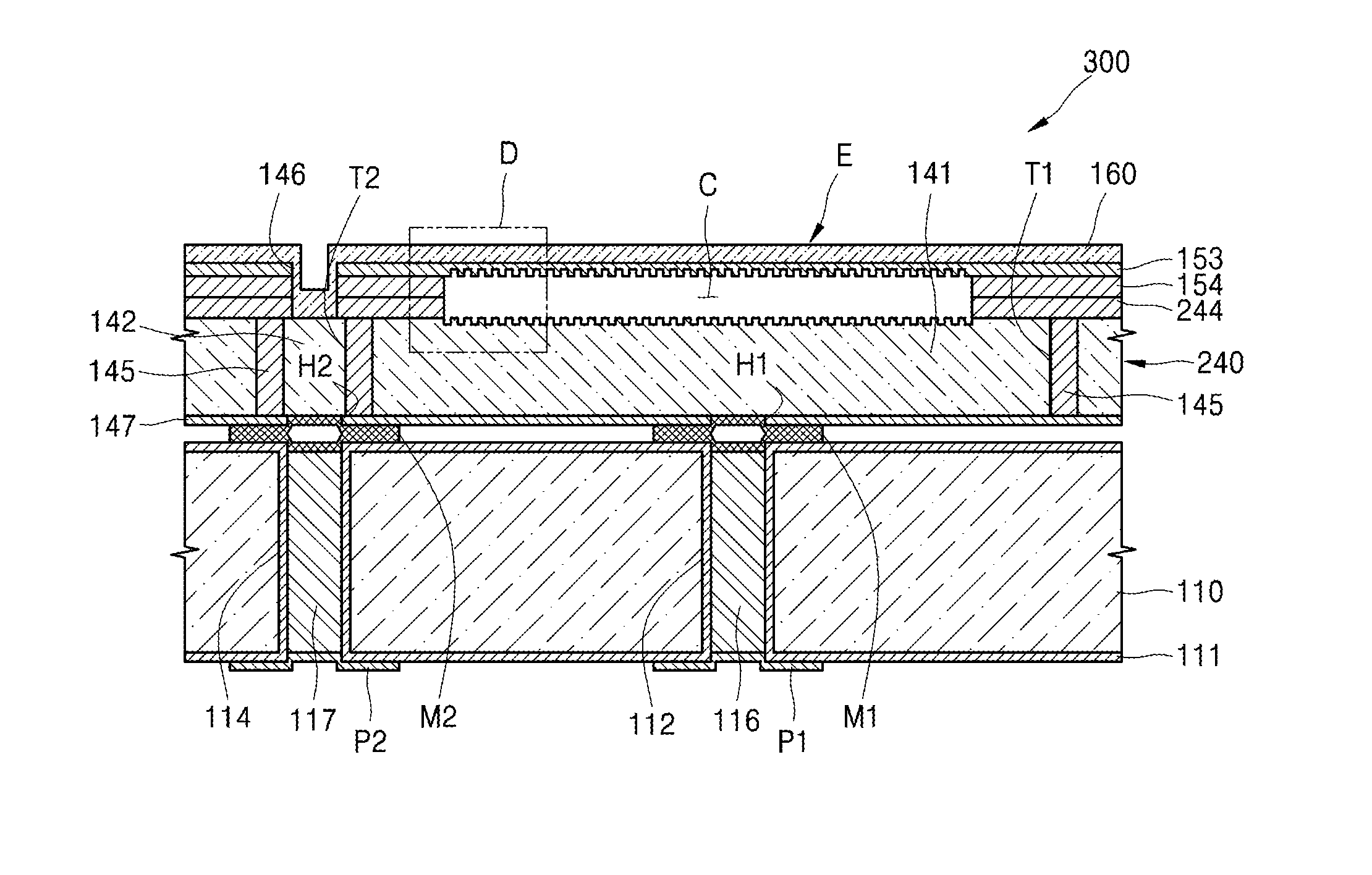

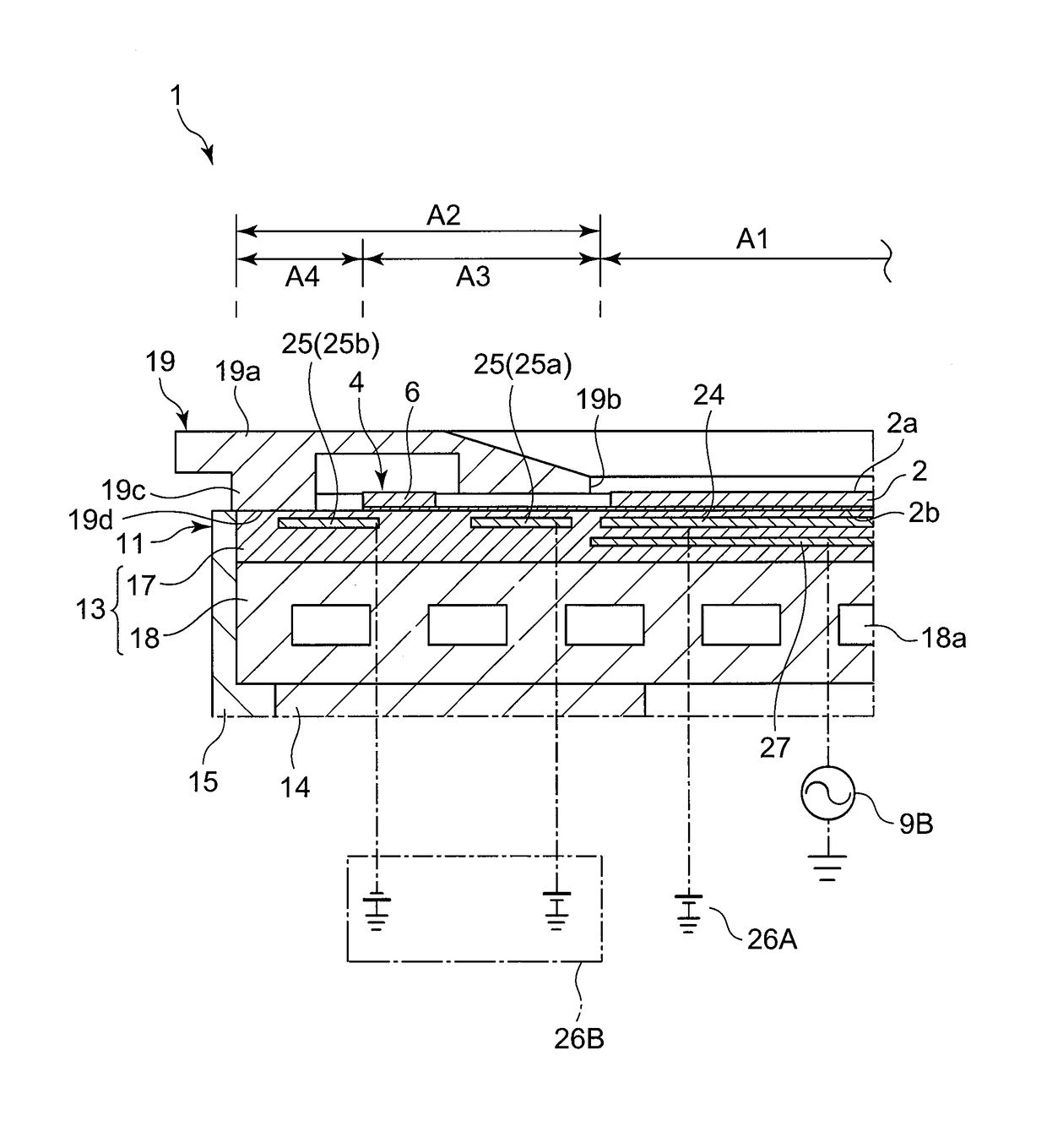

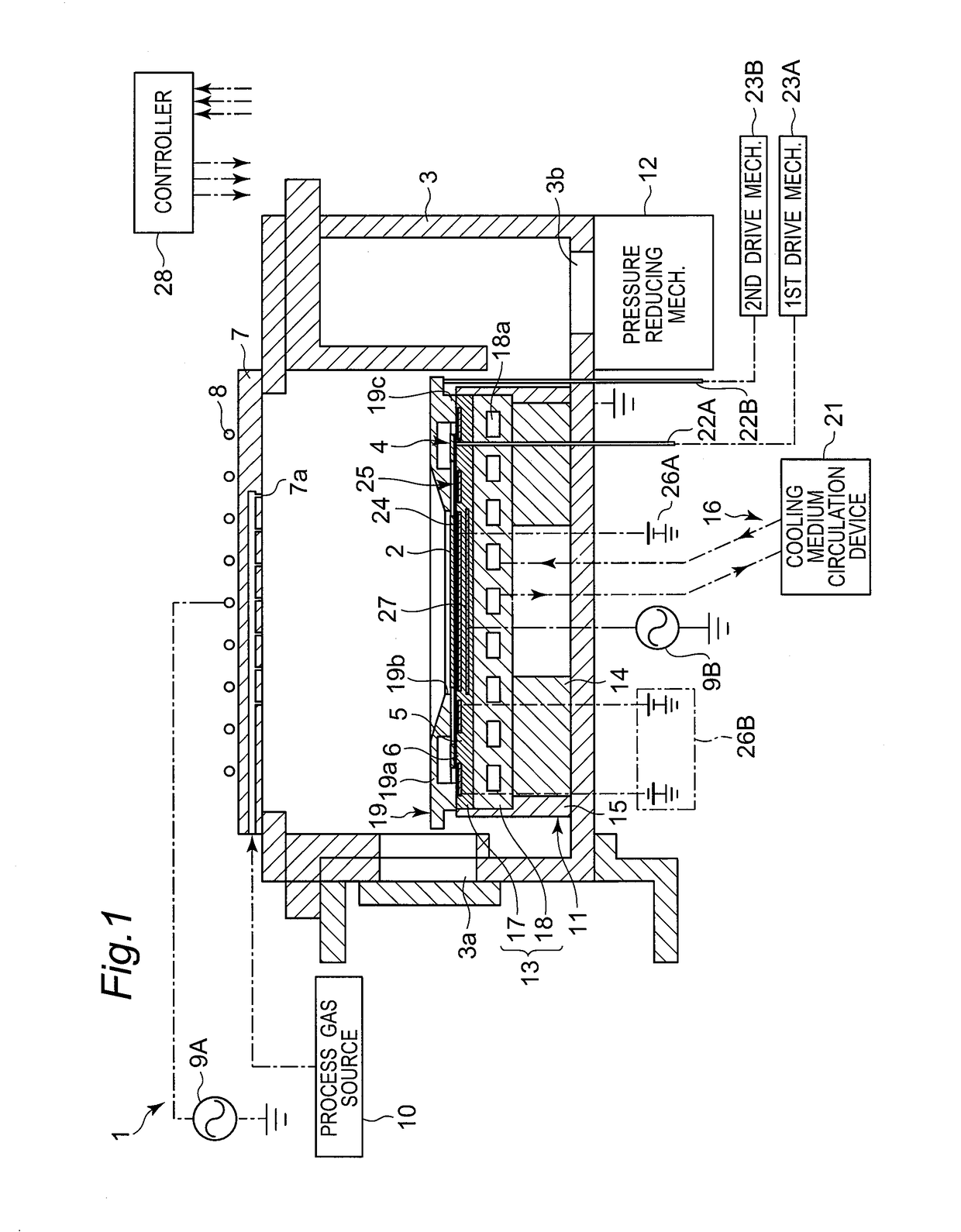

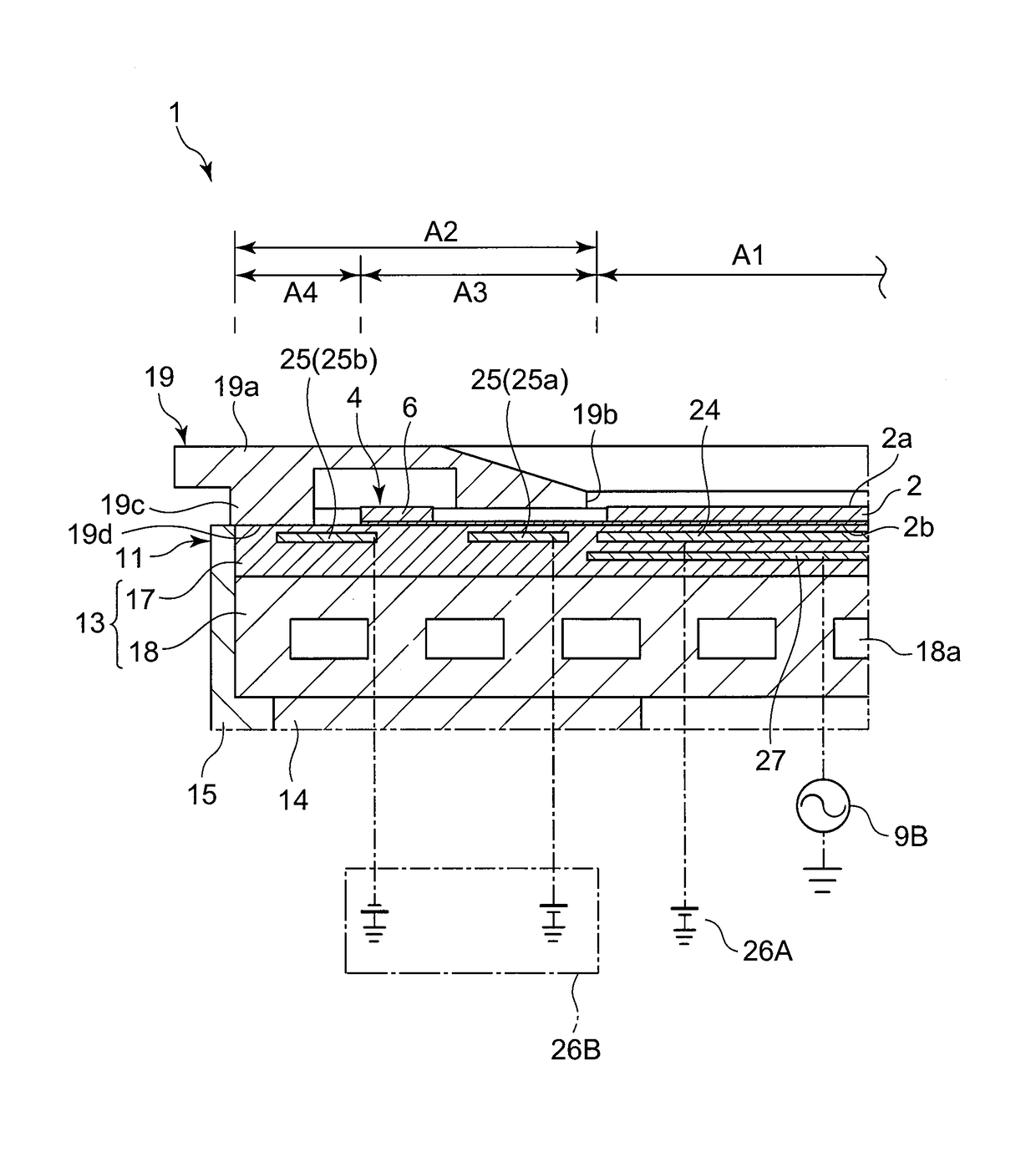

Plasma processing apparatus and method therefor

ActiveUS20150122776A1Improve performanceLess influence on the plasma process performanceElectric discharge tubesDecorative surface effectsEngineeringDry etching

A dry etching apparatus plasma processes a wafer held by a carrier having a frame and an holding sheet. A electrode unit of a stage includes an electrostatic chuck. Adjacent to an upper surface of the electrostatic chuck, a first electrostatic attraction electrode and a second electrostatic attraction electrode are incorporated. The first electrostatic attraction electrode is of unipolar type and electrostatically attracts the wafer via the holding sheet. The second electrostatic electrode is of bipolar type and electrostatically attracts the frame via the holding sheet as well as a holding sheet between the wafer and the frame. Both of plasma processing performance and electrostatic attraction performance are improved.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

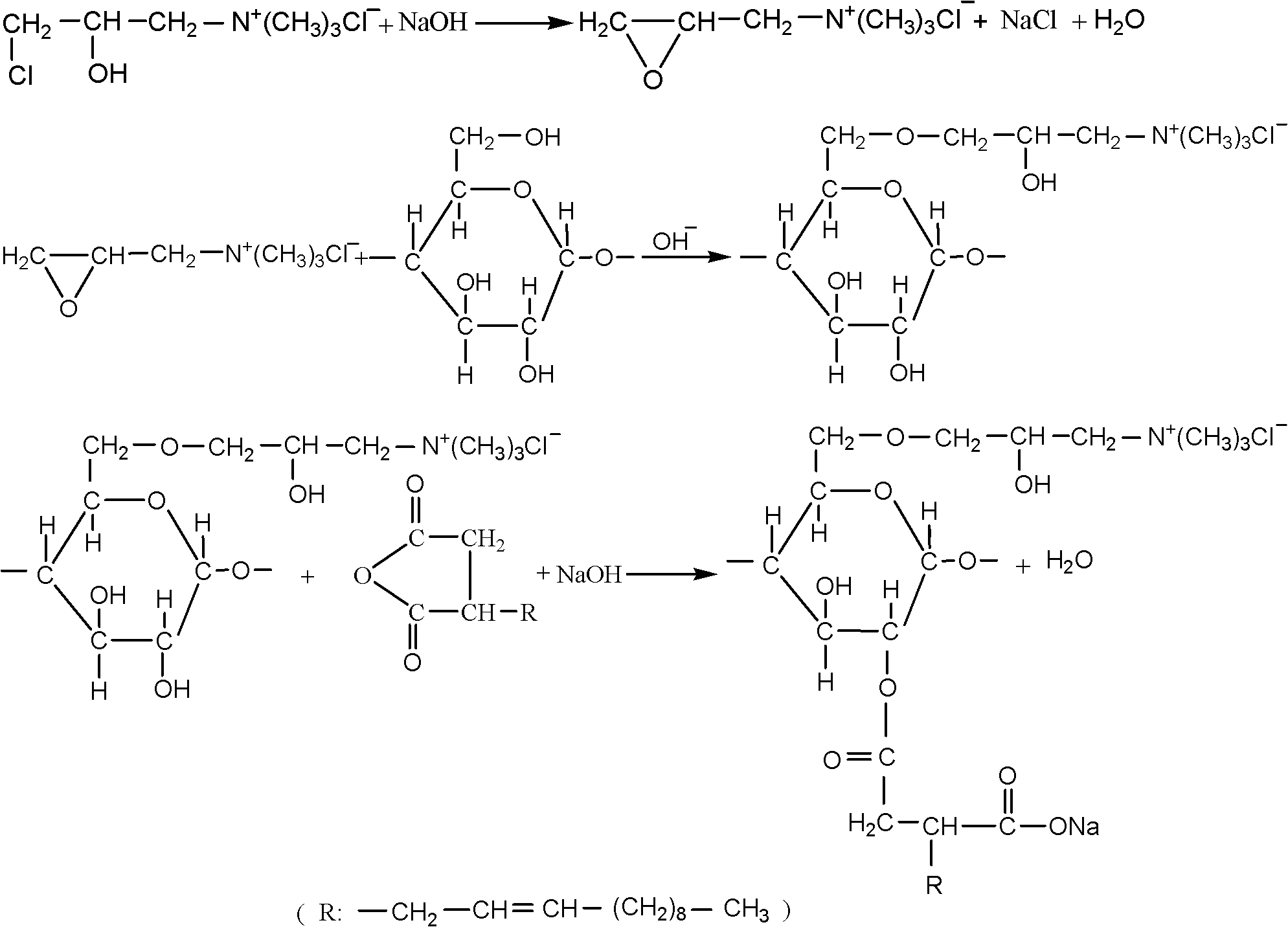

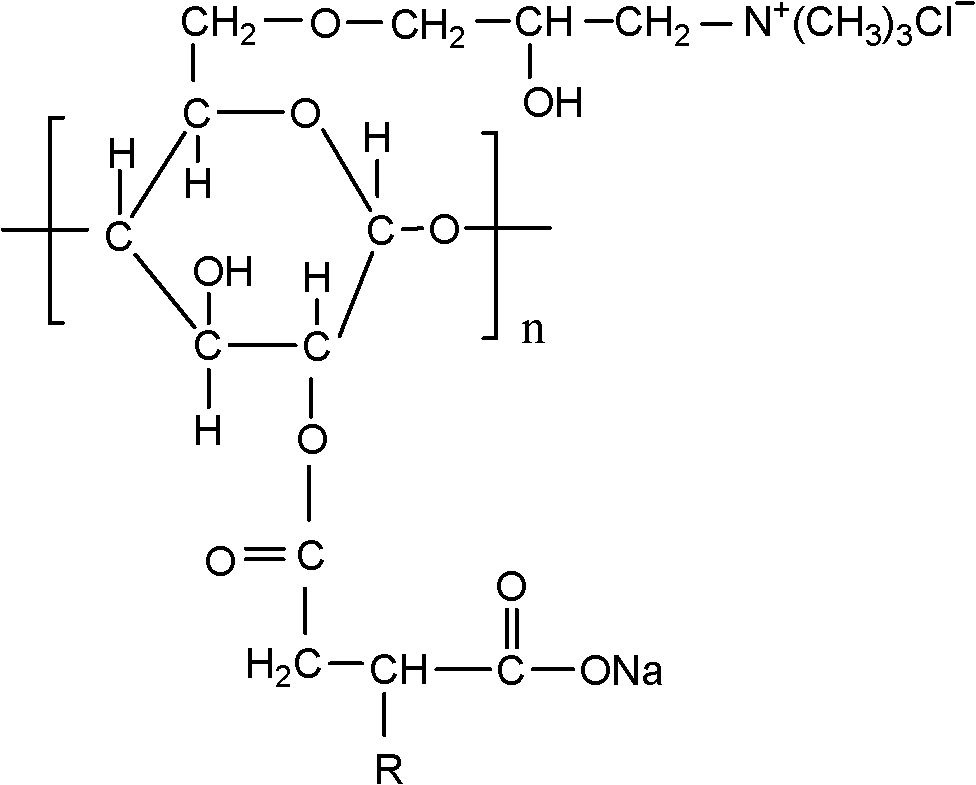

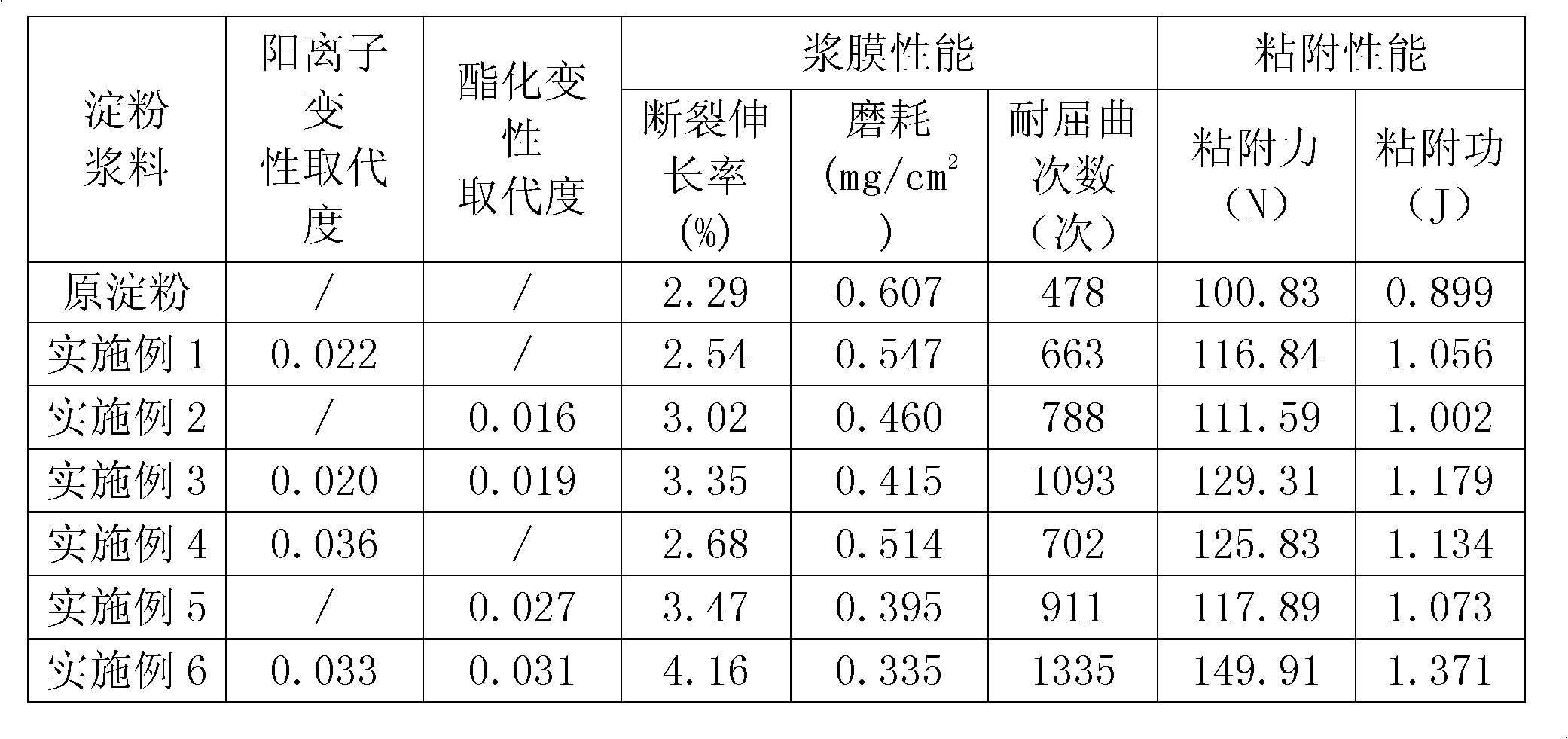

Method for synthesizing composite modified starch slurry

The invention discloses a method for synthesizing composite modified starch slurry, belonging to the technical field of methods for synthesizing the modified starch slurry applied to starching of spinning warps. The method comprises the following steps of: firstly carrying out positive ion modification on starch by utilizing quaternary ammonium type positive ion etherifying agent 3-chlorine-2-hydroxypropyltrimethylammonium chloride to synthesize positive ion starch, and carrying out an esterification reaction between the synthesized positive ion starch and dodecenylsuccinic anhydride so as to synthesize positive ion-dodecenylsuccinate composite modified starch slurry. According to the method for synthesizing the composite modified starch slurry, disclosed by the invention, positive ion groups and ester group which is large in volume and provided with vinyl group are introduced in a starch macromolecular chain so that film performances of the starch slurry is remarkably modified, and adhesion performance of the slurry to synthetic fibers such as terylene can be improved, thus starching requirements of warps, especially the terylene and the like, are better met. The method for synthesizing the composite modified starch slurry, disclosed by the invention, can be used for starching warps of fibers such as cotton, linen, mucilage glue and terylene / cotton, terylene / linen, terylene / mucilage glue through a common sizing machine or a high-speed sizing machine.

Owner:芜湖迅腾新材料有限公司 +1

Method for treating biological filler from waste hollow fiber ultrafiltration membrane or microfiltration membrane as matrix

InactiveCN108341481AHarm reductionLow costTreatment with microorganism supports/carriersIn situ polymerizationUF - Ultrafiltration

The invention relates to a method for treating a biological filler from a waste hollow fiber ultrafiltration membrane or a microfiltration membrane as a matrix, wherein a raw material of the biological filler adopts the waste hollow fiber ultrafiltration membrane or the microfiltration membrane, according to the source and the pollution situation of the raw material of the biological filler, different physical or chemical cleaning methods are adopted, and the surface roughness, the initial microbial amount or the hydrophilic property of the raw material of the biological filler can be controlled by a surface hydrophilization modification method or nano material in-situ polymerization modification method, so that the biological filler has a faster film-hanging speed compared with a conventional the biological filler; according to the source and the pollution situation of the raw material of the biological filler, a path of recycling of the waste hollow fiber membrane is realized, and hazard of waste polymers to the environment can be greatly reduced. Through use of the waste hollow fiber membrane for the preparation of the biological filler, the preparation cost of the filler can begreatly reduced, and the preparation cost of the filler is mainly due to the cost of the raw material of the biological filler and energy consumption during the preparation process.

Owner:TONGJI UNIV

Electrostatically adsorptive sheet and display using same

ActiveCN104379346AStay non-adhesiveImprove electrostatic adsorption capacityStampsCoatingsPolymer scienceThin membrane

This electrostatically adsorptive sheet (iii) is obtained by laminating an adsorptive sheet (i) which comprises a resin film layer (A) that is provided with an adhesive layer (C) on one surface, and a supporting layer (ii) which comprises a resin film layer (B). The resin film layer (A) of the adsorptive sheet (i) and the resin film layer (B) of the supporting layer (ii) are bonded with each other by electrostatic adsorption.

Owner:YUPO CORP

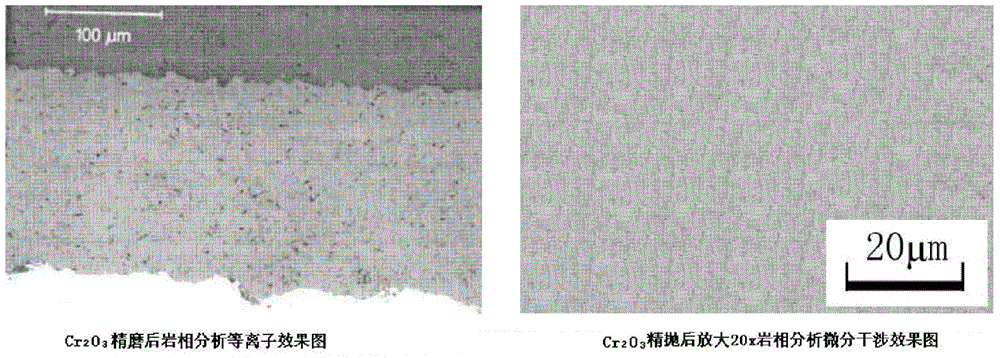

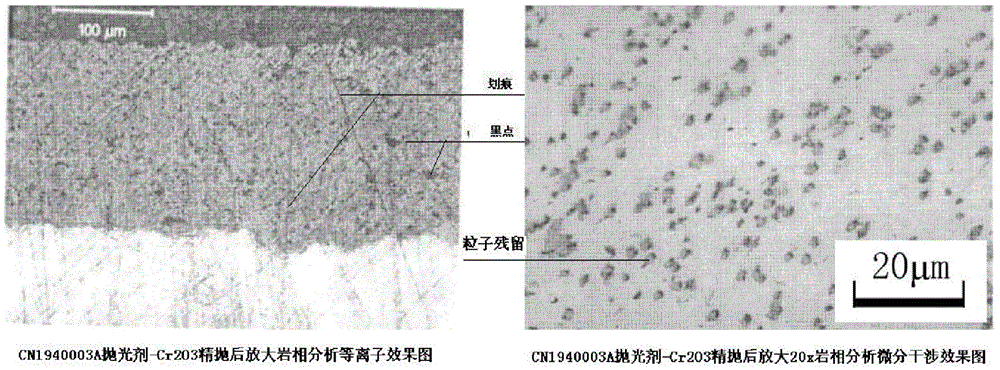

High-efficiency diamond polishing agent and preparation method thereof

ActiveCN104059539APlay a buffer roleImprove polishing effectPolishing compositions with abrasivesOctahedronHigh carbon

The invention discloses a high-efficiency diamond polishing agent which is prepared from the following raw materials in percentage by weight: 5-20 percent of ultra-precision diamond micro powder, 10-20 percent of ethyl orthosilicate, 20-30 percent of solvent, 0.2-0.8 percent of strong acid, 10-30 percent of surface active agent, 10-25 percent of wetting agent, 5-15 percent of dispersing agent and 0.1-5 percent of PH conditioning agent. According to the high-efficiency diamond polishing agent, the diamond micro powder is subjected to surface modification by using ethyl orthosilicate, so that a silicon dioxide coating layer is formed on the surface of the diamond micro powder, and during polishing, the coating layer plays a role in buffering the diamond micro powder on the inner layer; through performing multiple times of crushing and shaping on the diamond micro powder and improving surface modification process, the morphology of the diamond micro powder is closer to an octahedron; the prepared polishing agent has a better polishing effect to high-hardness metal materials such as high-carbon steel, also has a better polishing effect to crisp and hard materials such as Cr2O3, ceramics, jade and quartz, and is capable of completely preventing the damage on the surface of a material to be polished, and free from generating scratches, black points, and particle surface residues during polishing.

Owner:武汉三灵新材料有限责任公司

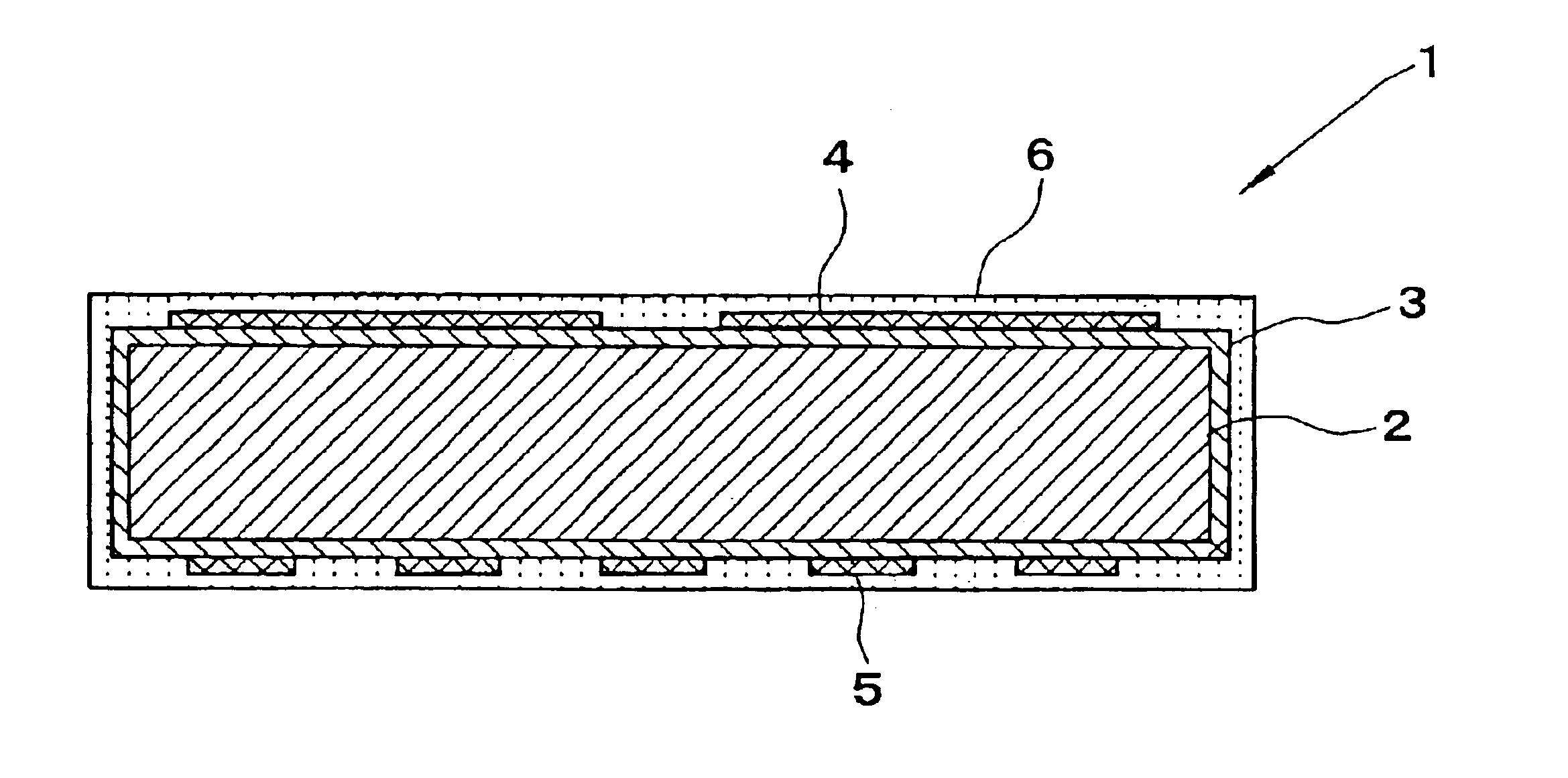

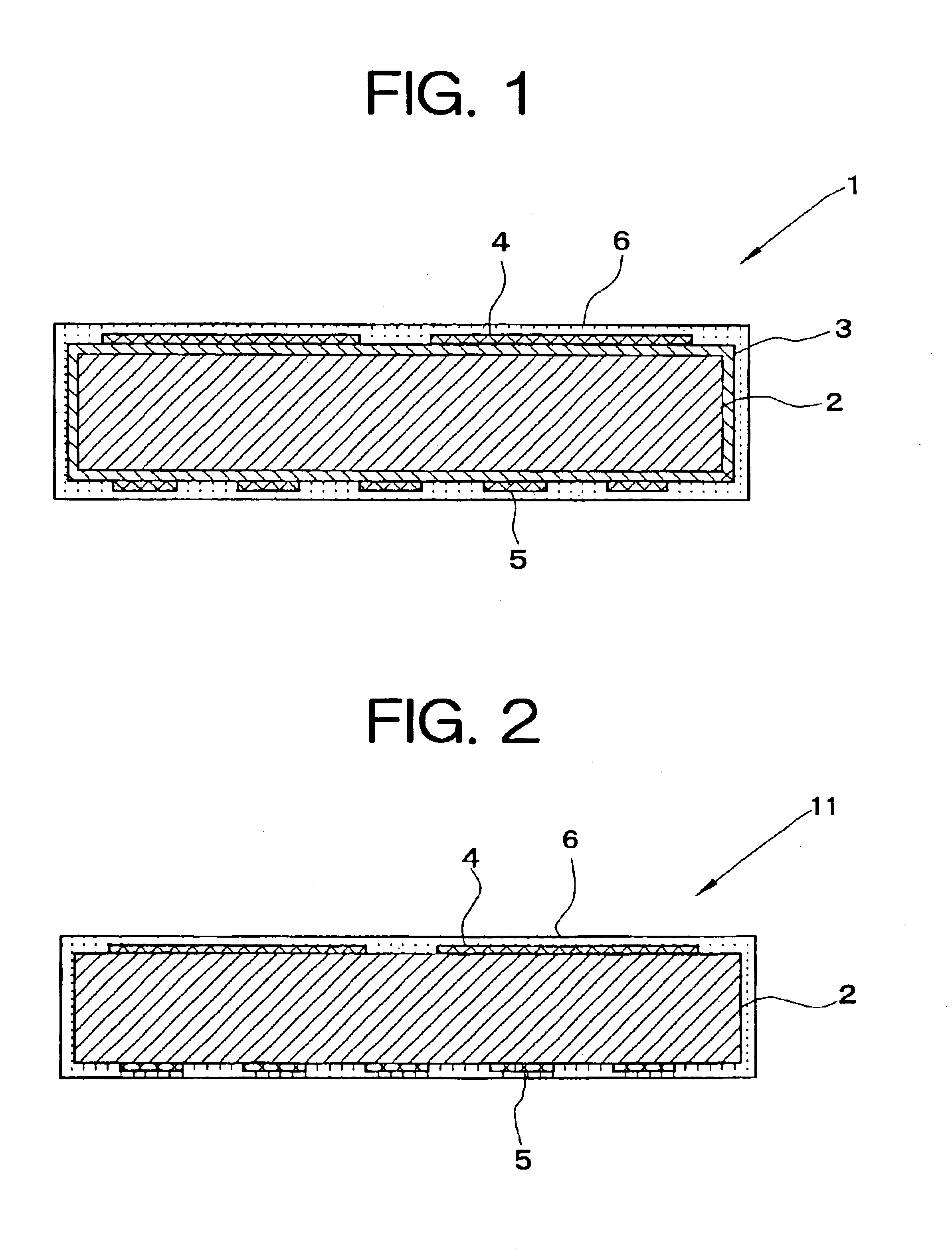

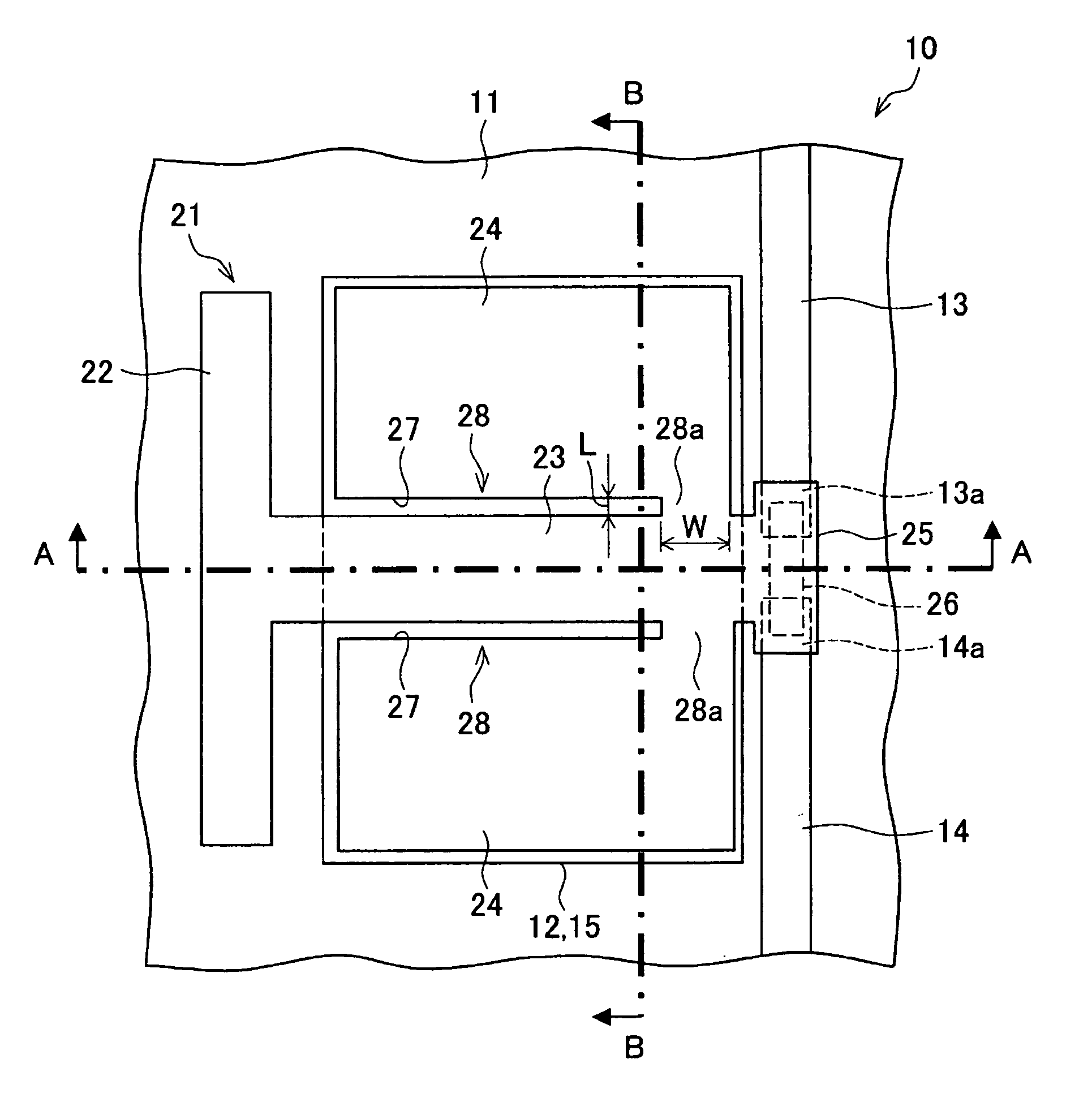

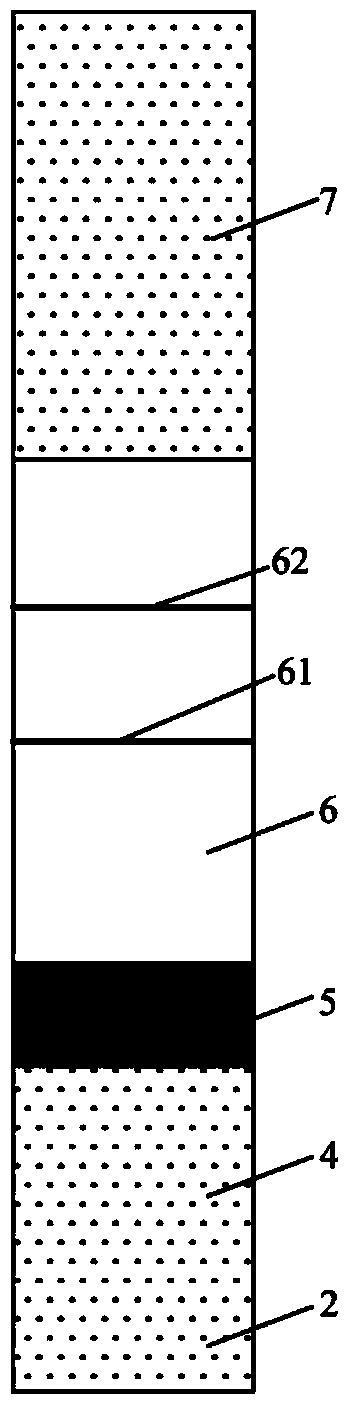

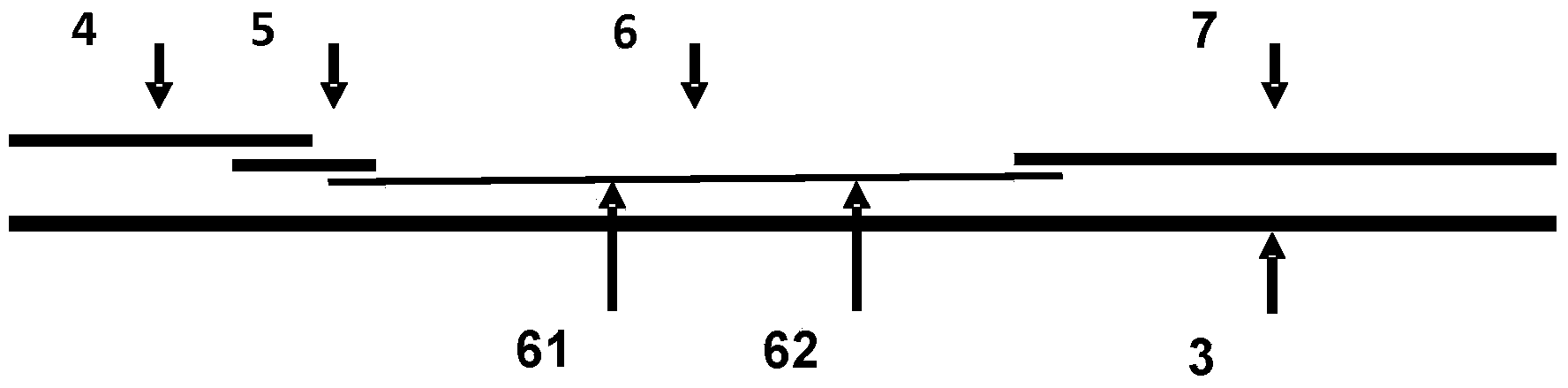

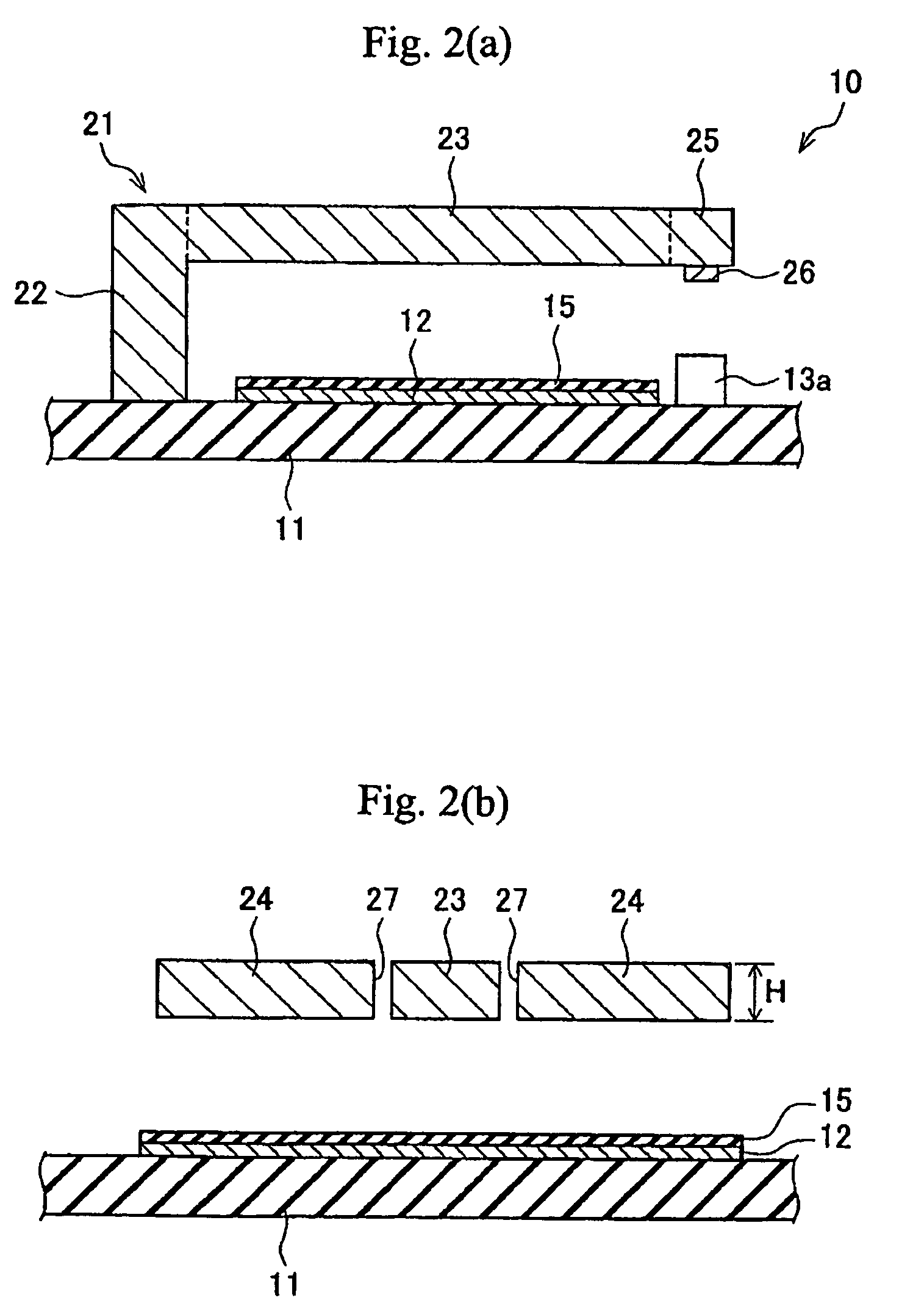

Heating apparatus with electrostatic attraction function

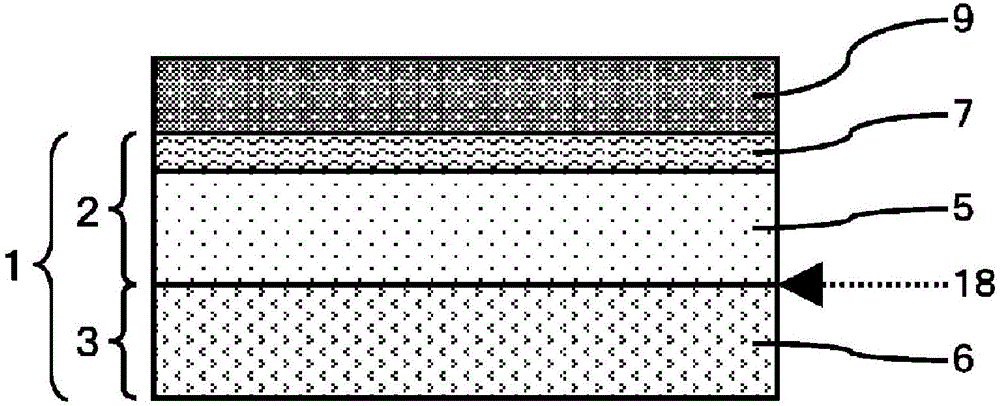

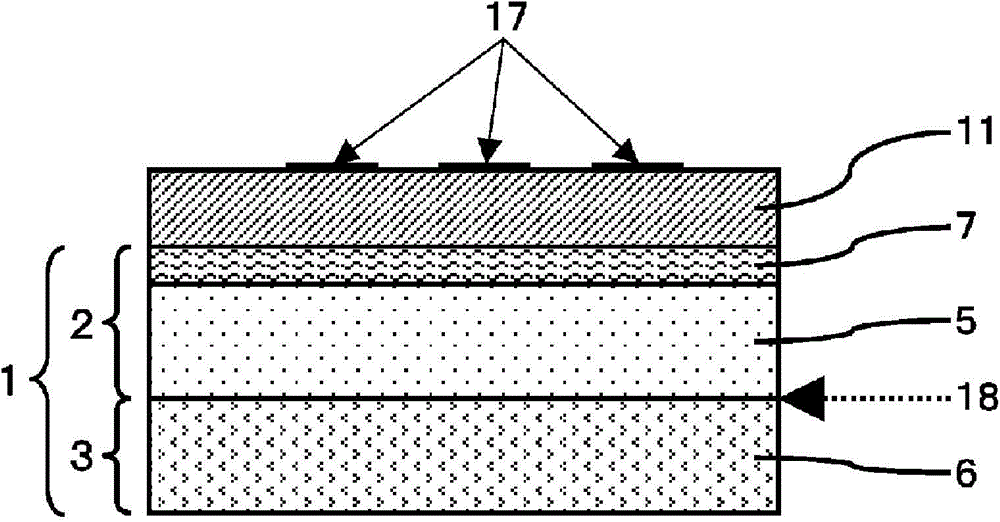

InactiveUS6917021B2Improve the anchoring effectAvoid it happening againLiquid surface applicatorsSemiconductor/solid-state device manufacturingBoron carbideGraphite

There is disclosed a heating apparatus with electrostatic attraction function 1, comprising at least a supporting base 2, an electrode for electrostatic attraction 4 and a heating layer 5 that are formed on the supporting base, and an insulating layer 6 that is formed on the electrode for electrostatic attraction and the heating layer, wherein the electrode for electrostatic attraction and / or the heating layer are / is composed of pyrolytic graphite containing boron and / or boron carbide of 0.001-30% by weight in terms of boron concentration, and the insulating layer has an electric resistivity of 106-1015 Ωcm. There is provided a heating apparatus with electrostatic attraction function, which has a high thermal shock resistance, no problem of delamination, a proper resistance value, and a sufficient electrostatic attraction force even in a medium and high temperature range of 500-800° C., which causes no breakage of devices due to leakage current, and which can be used stably during rapid rise and rapid drop in temperature.

Owner:SHIN ETSU CHEM IND CO LTD

Needled/melt-blown/spunbond composite filter material and preparation method thereof

ActiveCN110772889ASmall filter resistanceDelay the rise of filter resistanceDispersed particle filtrationMembrane filtersComposite filterFilter material

The invention belongs to the technical field of air filter materials, and discloses a needled / melt-blown / spunbond composite filter material and a preparation method thereof. The preparation method comprises the steps that modified polypropylene master-batches are mixed with polypropylene slices, and then mixed granules are obtained; the mixed granules are made into a polypropylene fiber net, and needling reinforcement is conducted to obtain a dust-facing layer needled material; a fine filter layer melt-blown material is prepared from the mixed granules; polypropylene slices are made into a polypropylene fiber net, and hot-rolling reinforcement is conducted to obtain a supporting layer spunbond material; and the dust-facing layer needled material, the fine filter layer melt-blown material and the supporting layer spunbond material are placed on an electret condensing device to be subjected to electret condensing simultaneously, and online compositing is conducted through electrostatic attraction to obtain the needled / melt-blown / spunbond composite filter material. The composite filter material prepared by the preparation method can reduce filtration resistance and delay rising of thefiltration resistance in the loading filtration process to intercept small-particle-size particles, and the filtration efficiency and stability are higher.

Owner:NANTONG UNIVERSITY

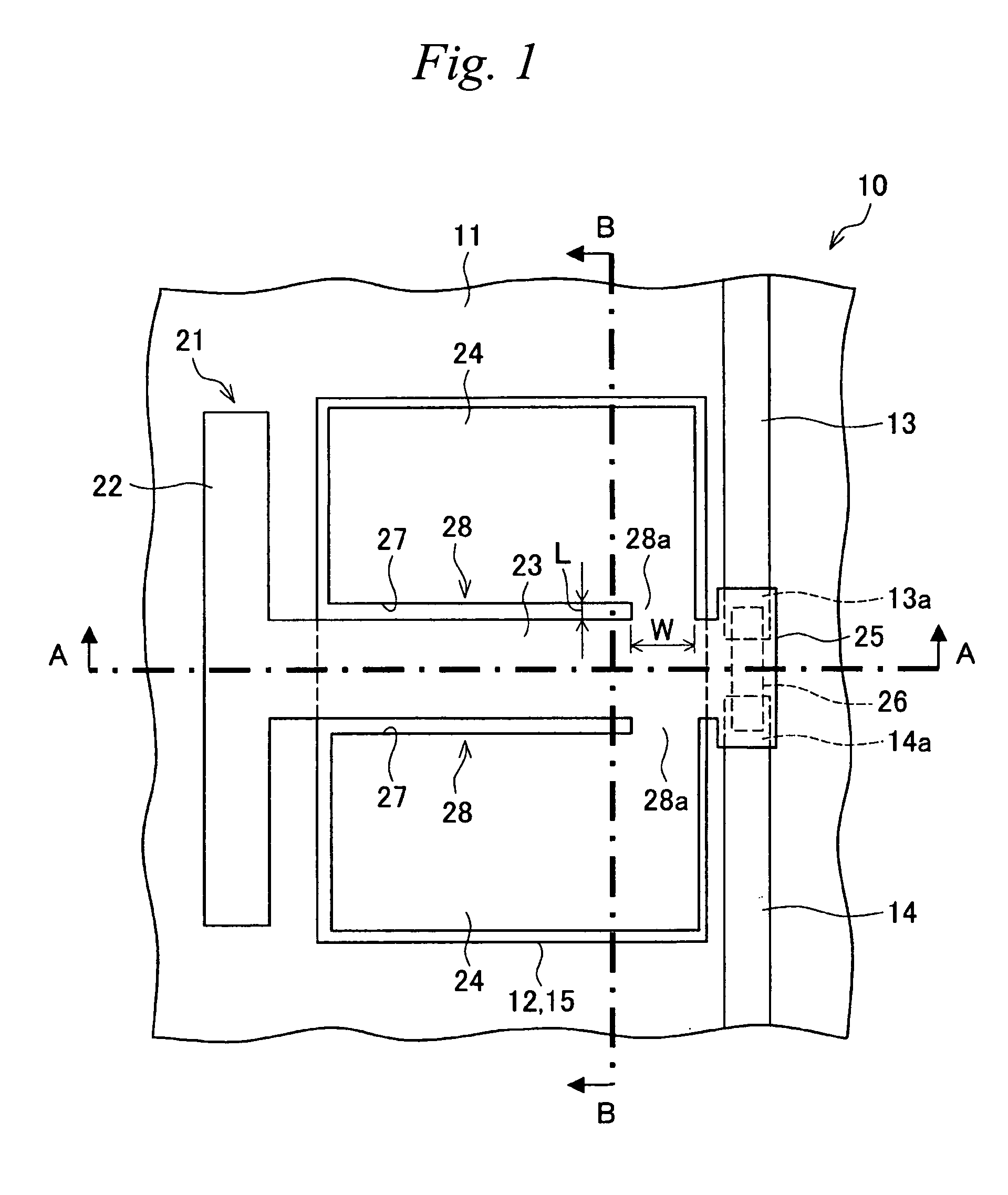

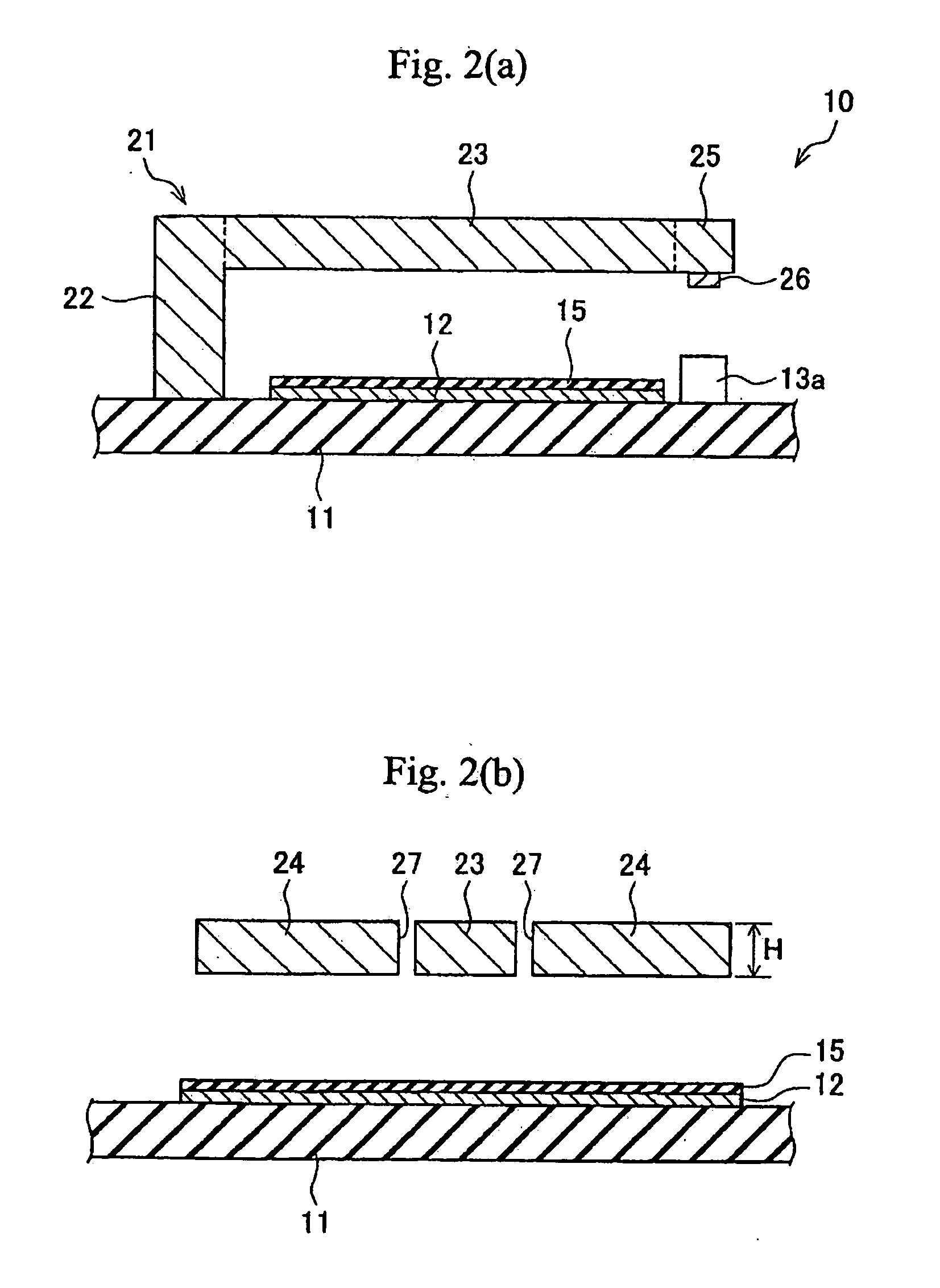

Micro electromechanical switch and method of manufacturing the same

InactiveUS20060208837A1Increase contact forceMaintaining restorative forceElectrostatic/electro-adhesion relaysMan-operated mechanismEngineeringActuator

A micro electromechanical relay opens and closes an electrical circuit by contact / separation between a fixed contact disposed on a base and a movable contact disposed on an actuator by driving of a movable electrode by electrostatic attraction by application of voltage between a fixed electrode disposed on the base and a movable electrode of the actuator. The actuator comprises a supporting portion disposed on the base, a beam portion extending in a cantilevered manner from the supporting portion, and a movable electrode and a movable contact elastically supported by the beam portion. The beam portion elastically supports, in order from the supporting portion end, the movable electrode and the movable contact. A slit is formed from the side of the supporting portion in the portion of the actuator connecting the beam portion and the movable electrode.

Owner:ORMON CORP

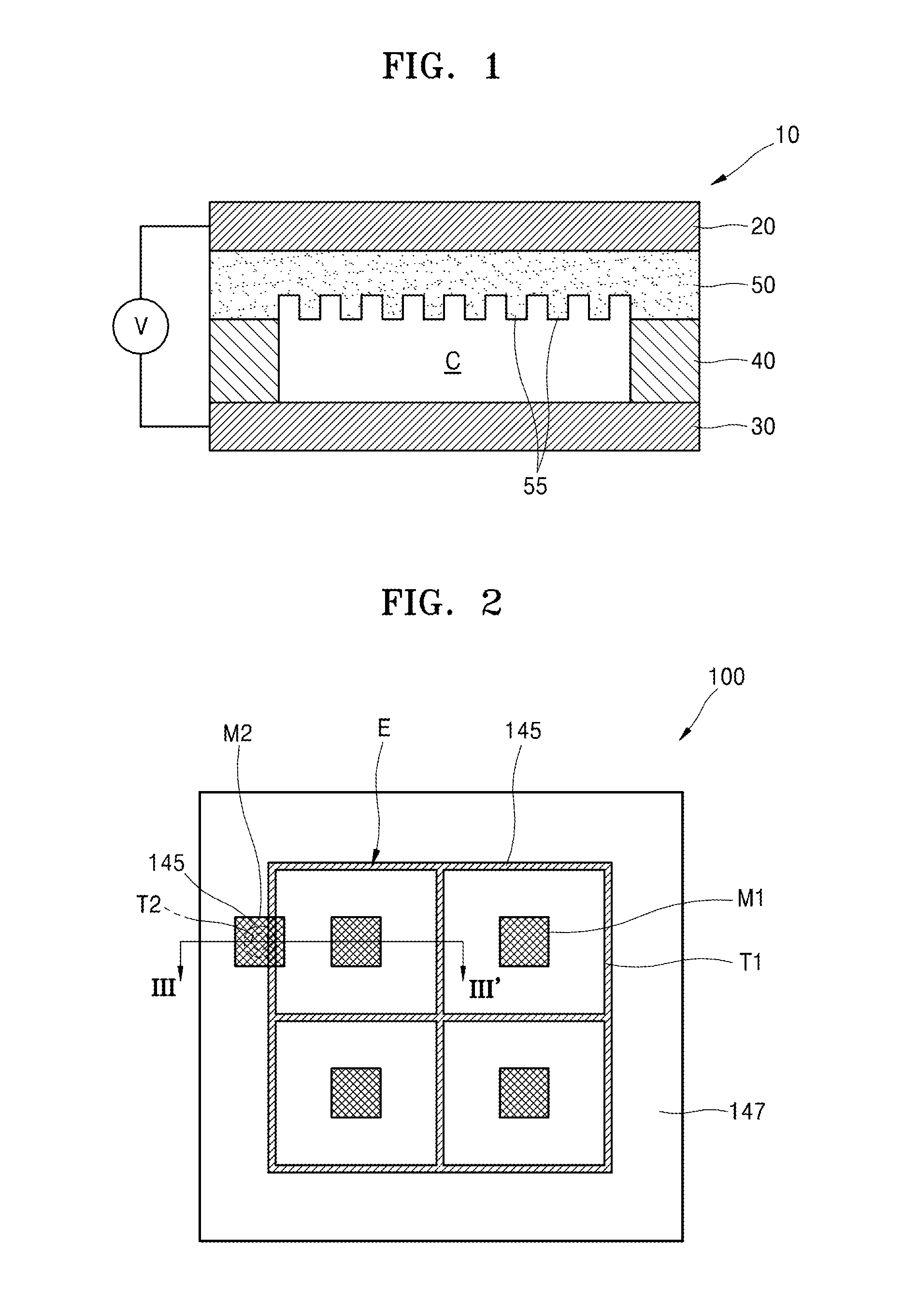

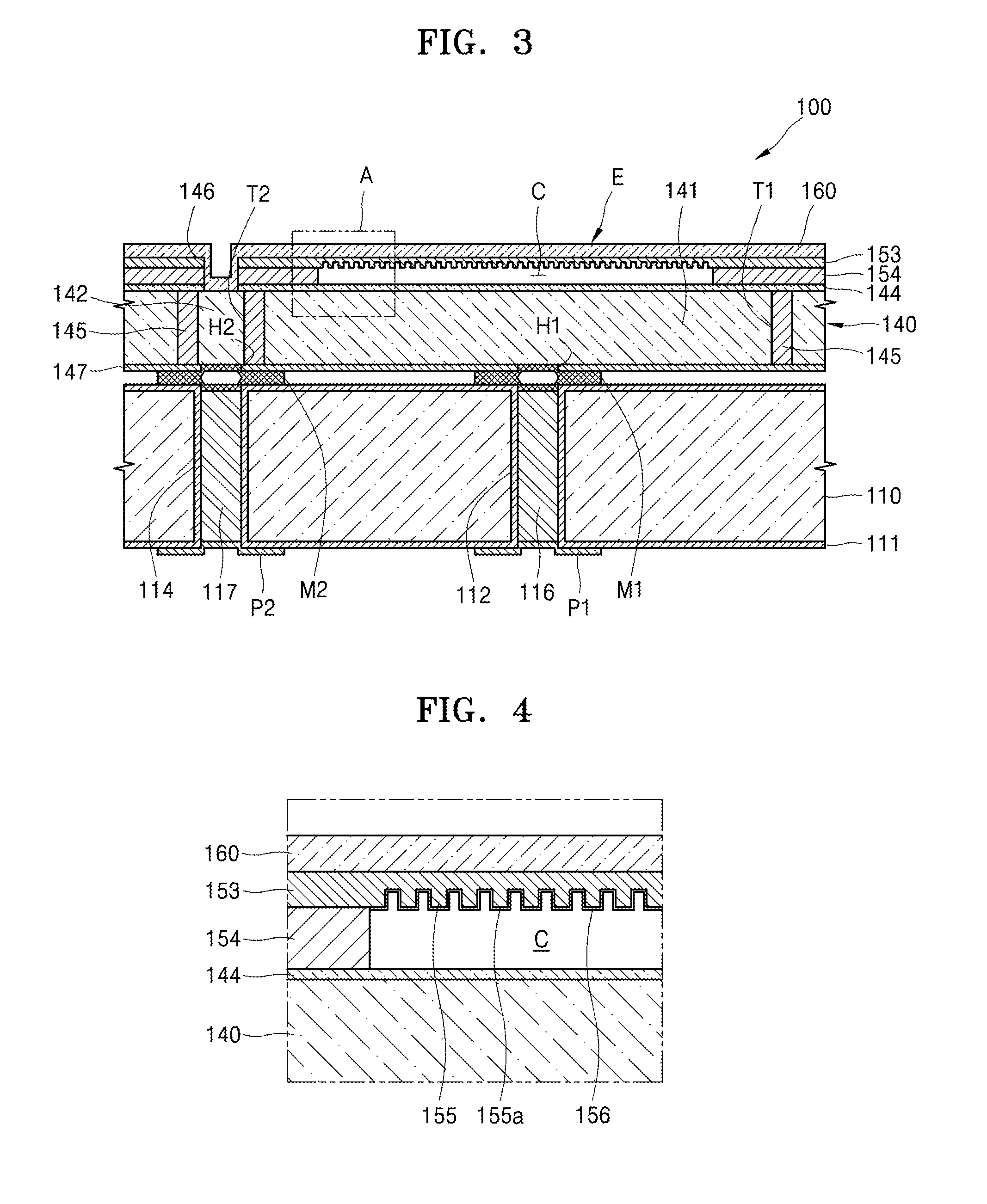

Capacitive micromachined ultrasonic transducer having nanopillar structure and method of fabricating the same

InactiveUS20160045935A1Increase electrostatic attractionDecorative surface effectsSolid-state devicesMembrane configurationCapacitive micromachined ultrasonic transducers

Example embodiments relate to a capacitive micromachined ultrasonic transducer (CMUT) having a nanopillar structure and a method of fabricating the same. The CMUT may include a conductive device substrate, a support defining a plurality of cavities corresponding to elements on the device substrate, a membrane on the support to form the plurality of cavities, an upper electrode on the membrane, and a plurality of nanopillars on at least one of the membrane and the device substrate exposed to the plurality of cavities.

Owner:SAMSUNG ELECTRONICS CO LTD

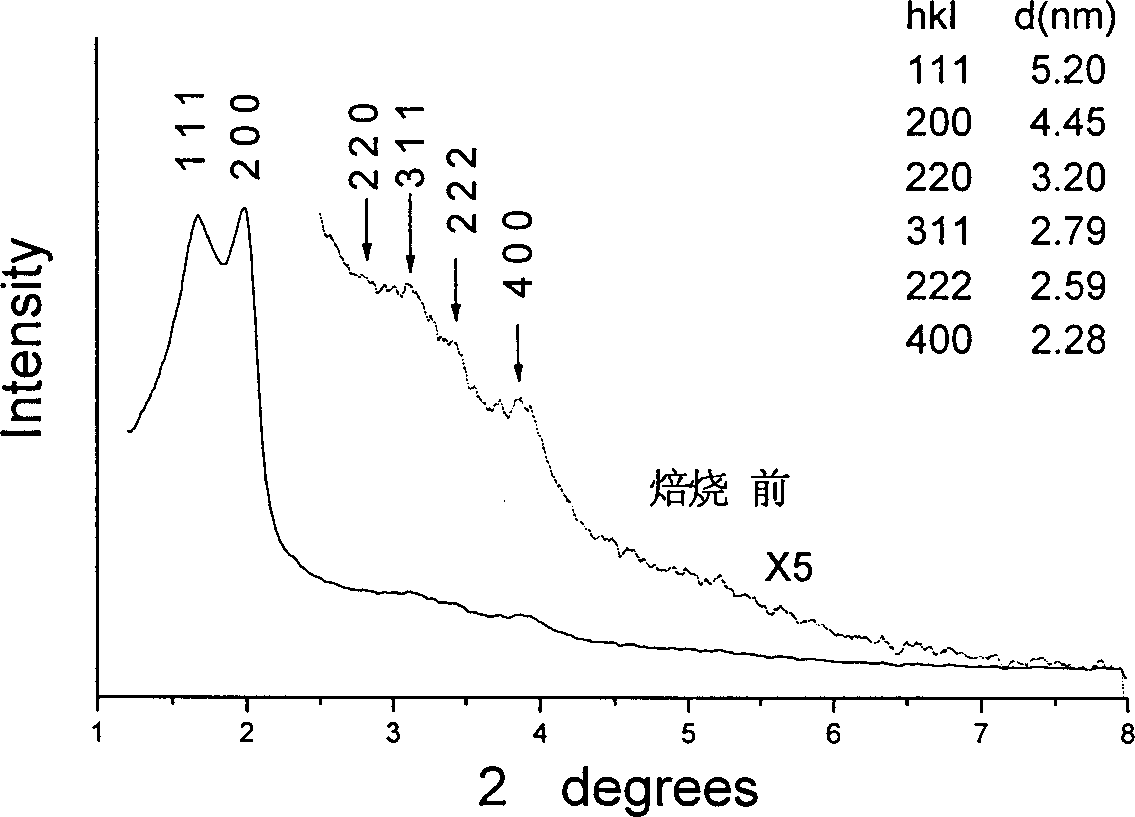

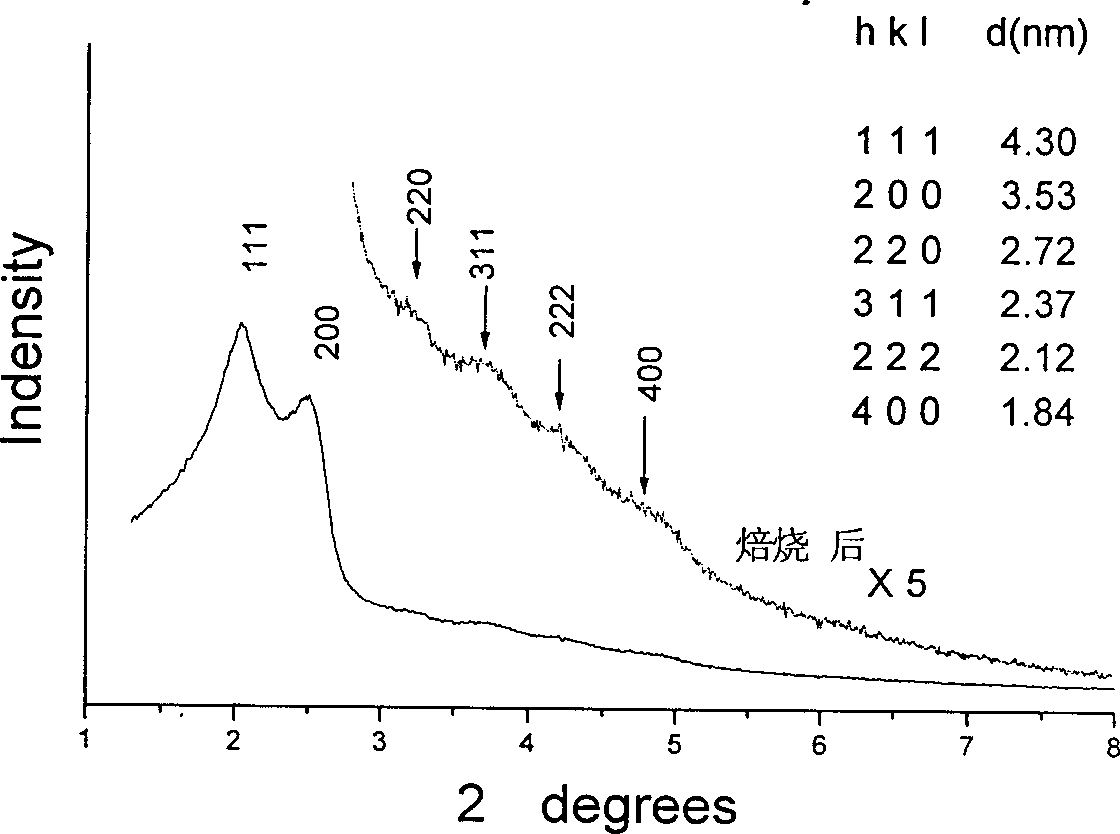

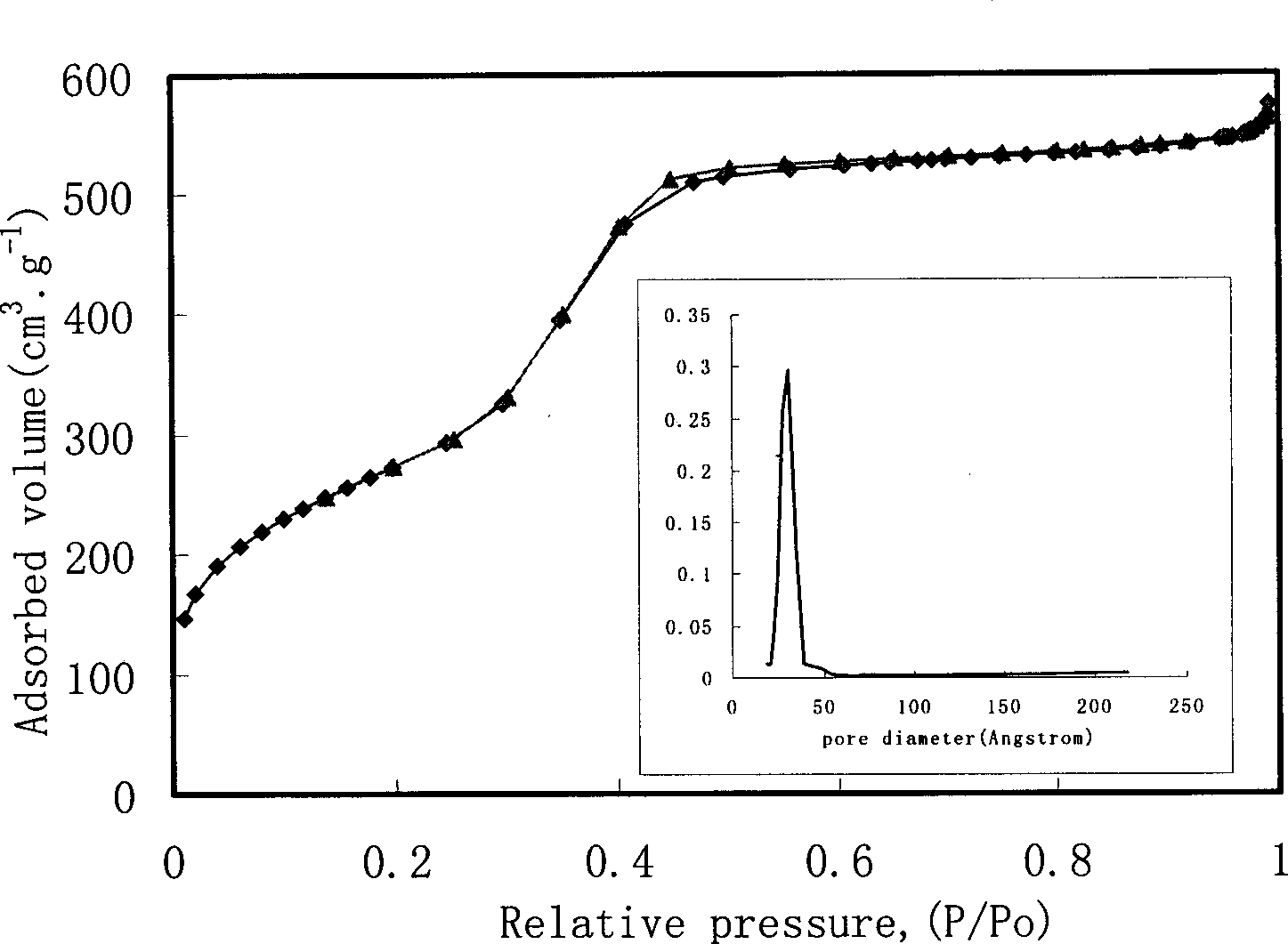

Process for synthesizing mesoporous SiO2 melecular sieve with cubic structure

InactiveCN1342607AEnhance the interface forceIncrease electrostatic attractionCrystalline aluminosilicate zeolitesCrystallographyMolecular sieve

A mesoporous SiO2 as molecular sieve with novel cubic structure is synthesized in alkaline condition by using tri-quaterrary ammonium salt cationic surfactant as structure guide agent. It has 3-D cubic structure (its space group is Fd3m), great specific surface area (about 1000 sq.m / g) and uniform pore diameter.

Owner:FUDAN UNIV

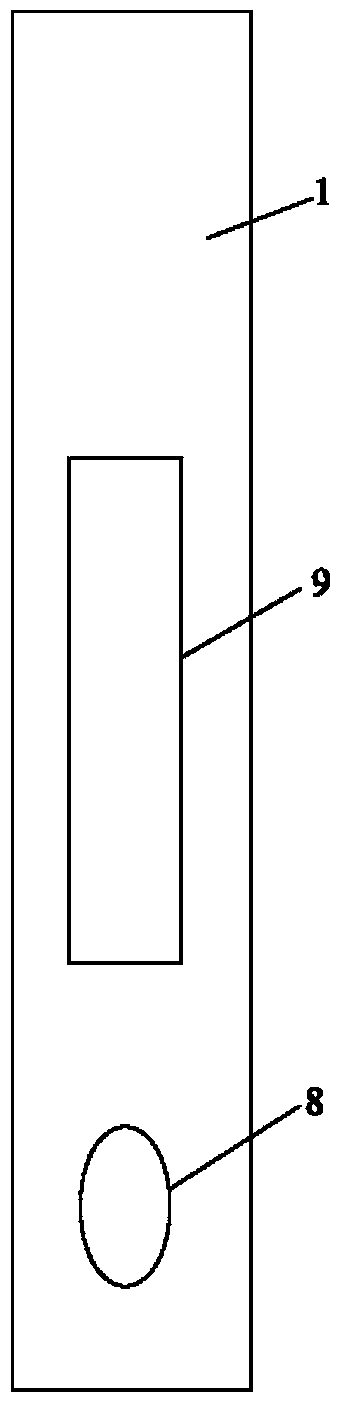

Colloidal gold immunochromatography quick test card for pyrethriods pesticides, and preparation method and using method of quick test card

The invention relates to a colloidal gold immunochromatography quick test card for pyrethriods pesticides, and a preparation method and a using method of the quick test card. The quick test card comprises a card shell and a test strip in the card shell, wherein the test strip comprises a bottom plate, and a sample pad, a gold-labeled pad, a reaction film and a water absorption pad which are stuck onto the bottom plate and sequentially connected with one another; the gold-labeled pad is enveloped by a pyrethriods pesticide gold-labeled wide-spectrum antibody; a detection line of the reaction film is enveloped by a pyrethriods pesticide antibody; a control line of the reaction film is enveloped by a goat anti-rabbit second antibody; the pyrethriods pesticide gold-labeled wide-spectrum antibody is enveloped by nanoscale chloroauric acid colloidal particles. After the colloidal gold immunochromatography quick test card is used, at least nine pyrethriods pesticides can be detected at the same time, and the limit of detection reaches up to 0.01mg / kg; the colloidal gold immunochromatography quick test card can be stably stored for more than 1.5 years at room temperature, and is high in specificity and sensitivity, good in stability, simple, convenient and accurate in operation and short in detection time, thus being widely used for rapidly detecting pyrethriods residues in agricultural products, water environment and soil.

Owner:SHANGHAI ACAD OF AGRI SCI

Manufacturing method for arranging white mud on Nixing pottery green body in filling manner

InactiveCN106079053AIncrease electrostatic attractionReduce sheddingDecorative surface effectsCeramic shaping apparatusCelluloseCarving

The invention discloses a manufacturing method for arranging white mud on a Nixing pottery green body in a filling manner. The manufacturing method includes the processes of blank preparation, green body forming, drawing, carving, mud filling, drying and firing. In the mud filling process, a layer of aluminum oxide powder and a layer of carboxymethyl propyl cellulose are evenly spread in a carved groove, and then the white mud is arranged in the carved groove in the filling manner; the white mud is obtained by mixing east mud and west mud according to the weight ratio of 7-8 to 2-3, and then the Nixing pottery green body is formed according to a manufacturing process of the blank; and in the drying process, the green body with the mud arranged in the filling manner is treated for 1 min to 5 min under the condition of 10 MPa to 15 MPa, and natural air drying is conducted. According to the manufacturing method, the electrostatic attraction of the white mud and the green body can be enhanced greatly by adding aluminum oxide particles, the molecular long chain of the carboxymethyl propyl cellulose has the involvement and crosslinking functions so that the white mud and the blank can be tightly bonded together, and the green body further has certain water retention uniformity so that water removal can be more even, and cracking and falling off are avoided.

Owner:钦州市永和坭兴陶艺有限公司

Method for preventing filler of Nixing pottery from disengaging and cracking

InactiveCN106083127AIncrease electrostatic attractionReduce sheddingClaywaresMaterials scienceCarving

The invention discloses a method for preventing filler of Nixing pottery from disengaging and cracking. The method comprises the steps of blank preparing, blank forming, drawing, carving, filler filling, drying and firing; for the filler filling step, a carved groove is evenly scattered with a layer of alumina powder, and then the carved groove is filled with filling pug; for the drying step, the blank filled with the pug is treated for 1 min to 5 min under the condition of 10 Mpa to 15 Mpa, and then natural air-drying is conducted. Compared with the prior art, according to the method for preventing the filler of the Nixing pottery from disengaging and cracking, alumina particles are added into the carved groove, the electrostatic attraction between the filled pug and a blank body can be greatly increased, and disengaging and cracking of the filled pug in the firing process can be greatly reduced.

Owner:钦州市永和坭兴陶艺有限公司

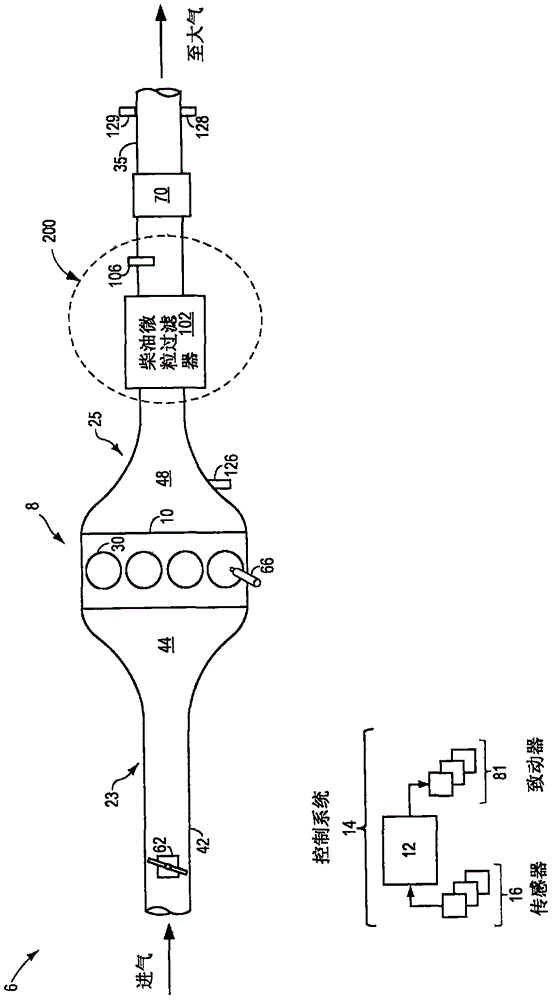

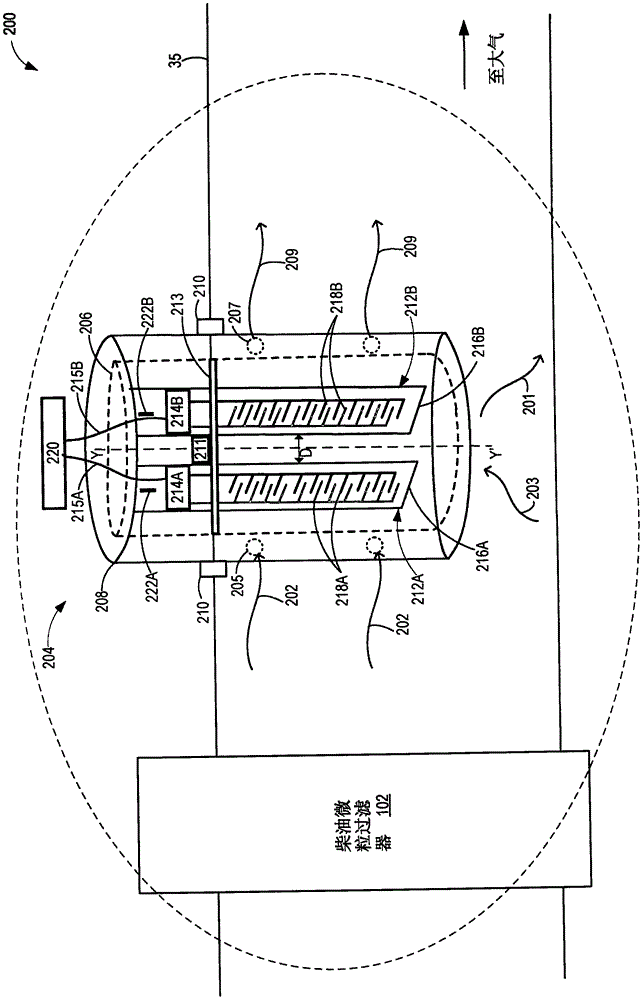

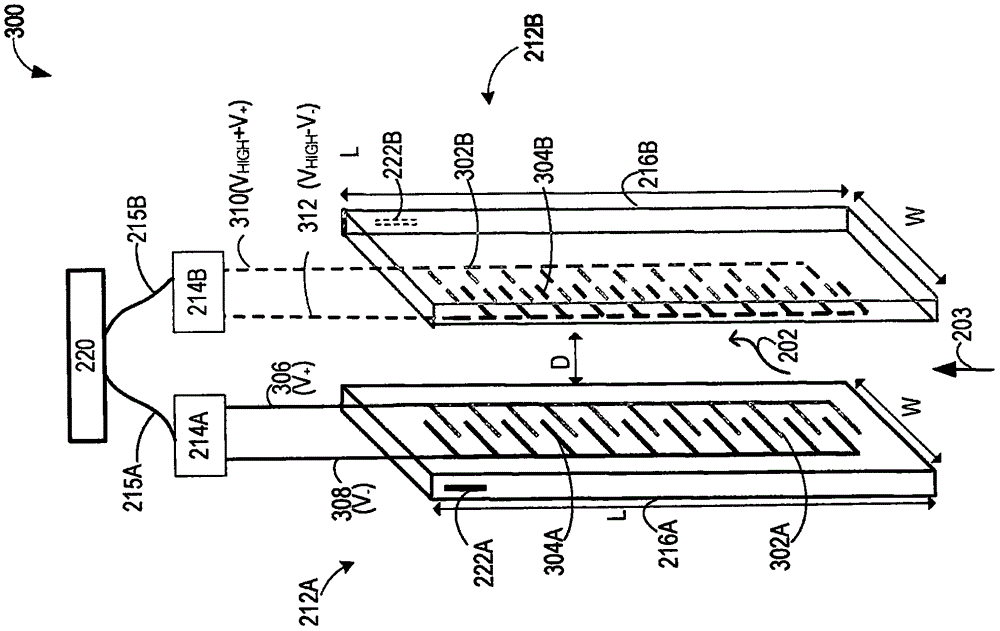

Method and system for exhaust particulate matter sensing

PendingCN105842295AHigh sensitivityIncreased efficiency of regeneration operationsExhaust apparatusSilencing apparatusParticulatesEngineering

The invention relates to a method and system for exhaust particulate matter sensing. Methods are described for increasing the sensitivity of particulate matter detection in an exhaust system of a vehicle. An example particulate matter sensor assembly comprises a pair of planar interdigitated electrode structures held at a voltage bias with respect to each other. An alternate embodiment may comprise a planar interdigitated electrode pair, and a conducting plate assembly again held at a voltage bias with respect to the planar interdigitated electrode pair. The bias may overlay an additional electric field drive, which improves the capture of soot particles on the sensor assembly surface thereby increasing sensitivity of particulate matter sensors.

Owner:FORD GLOBAL TECH LLC

Dyeing method based on cotton fabric active dye cationic modifier

InactiveCN107740295AIncrease electrostatic attractionImprove dye uptakeDyeing processChemical industrySodium carbonate

The invention belongs to the technical field of dye chemical industry and discloses a dyeing method based on a cotton fabric active dye cationic modifier. The dyeing method comprises the following steps: (1) carrying dyeing treatment by adding cotton fiber into a glutamate aqueous solution or a phenylalanine salt aqueous solution, carrying out temperature-increasing treatment, taking the cotton fiber out, washing the cotton fiber to obtain modified cotton fiber; (2) carrying out dyeing treatment by dyeing the modified cotton fiber according to a conventional process, wherein the content of reactive dye in a dyeing solution is 1-2wt%, the content of sodium carbonate is 5-10g / L, the content of sodium chloride is 23-30g / L, and dyeing for 40-60 minutes under the dyeing condition at the temperature of 50-70 DEG C; and (3) carrying out aftertreatment of the dyed cotton fiber according to the conventional process to obtain the dyed cotton fiber. The method is capable of not changing all the properties of the cotton fabric after carrying out aftertreatment, even obtaining excellent dyeing effect, effectively reducing the consumption of salt and alkali, achieving low-temperature dyeing, achieving environment-friendly dyeing and reducing the cost.

Owner:ZHAOQING UNIV

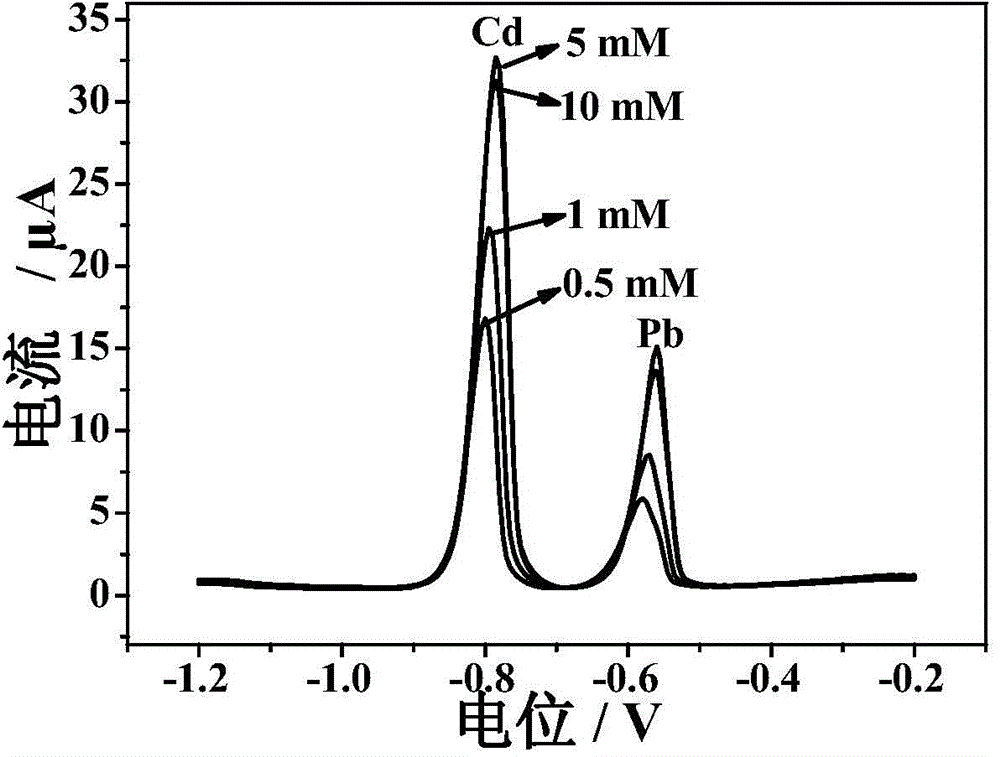

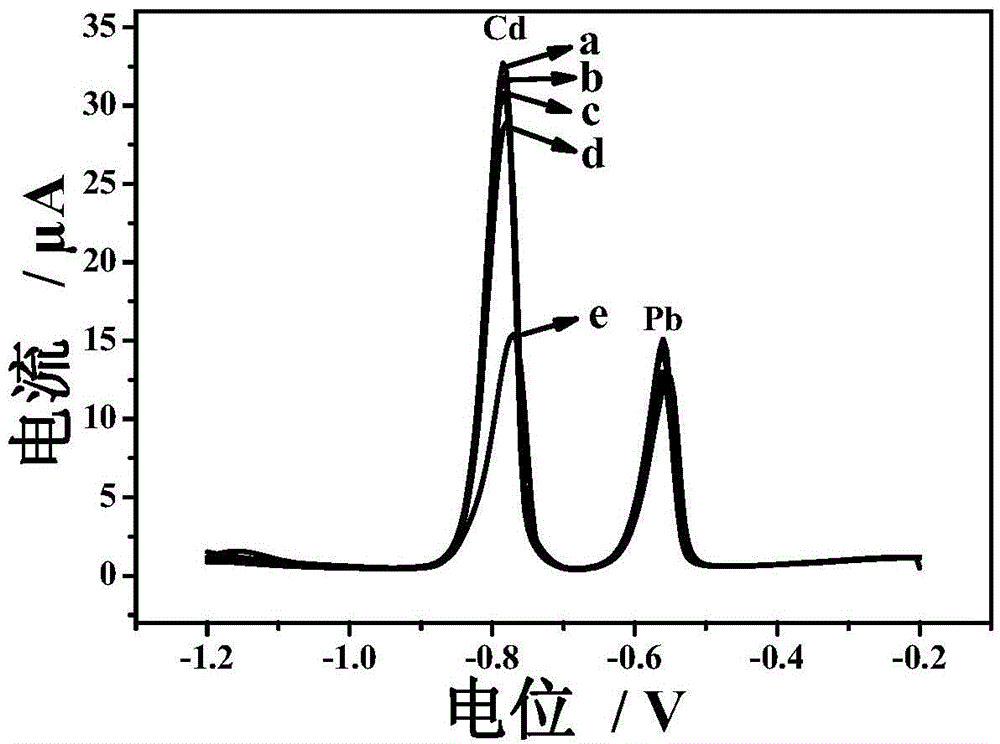

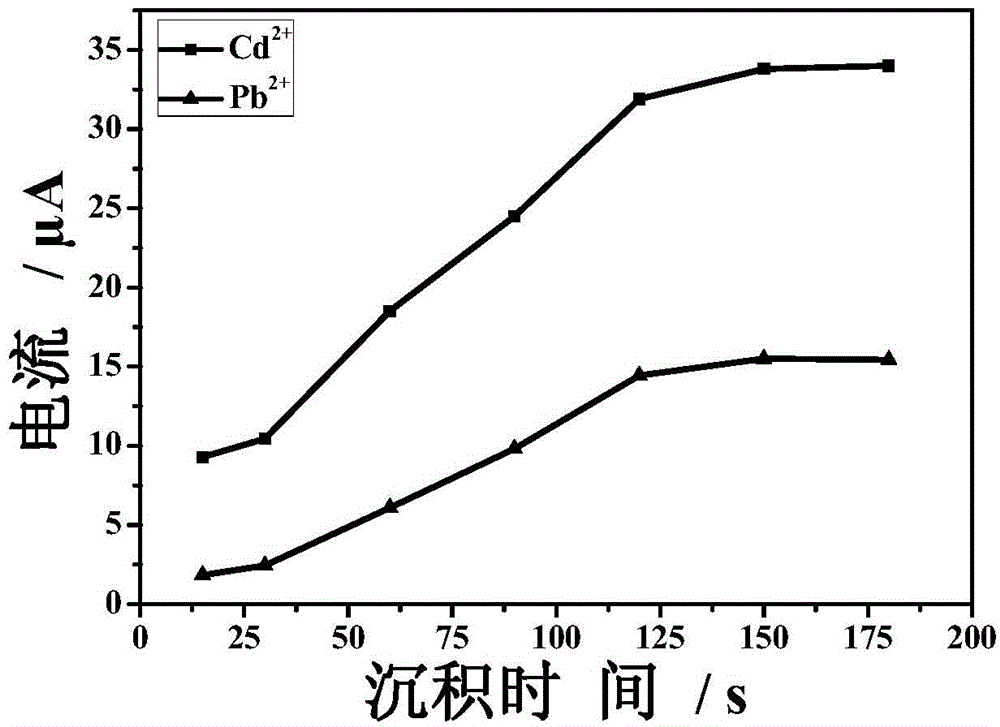

Method for simultaneously detecting cadmium and lead ions by employing sulfhydrylated peroxidized poly(m-phenylenediamine) modified bismuth membrane electrode

ActiveCN104535640AEasy to operateEasy to detectMaterial electrochemical variablesConductive polymerPhysical chemistry

The invention relates to a method for simultaneously detecting cadmium and lead ions by employing a sulfhydrylated peroxidized poly(m-phenylenediamine) modified bismuth membrane electrode. The method comprises the following steps: preparing a sulfhydrylated poly(m-phenylenediamine) modified electrode by employing a one-step process, preparing a peroxidized sulfhydrylated poly(m-phenylenediamine) modified electrode, and simultaneously detecting cadmium and lead ions. The beneficial effects comprise that by using the one-step process for preparing the sulfhydrylated poly(m-phenylenediamine) modified electrode, operation is simple, time is saved and labor is saved; and the bismuth membrane deposited on the surface of a peroxidized conductive polymer is relatively uniform and smooth, also the electrostatic attraction between the bismuth membrane and heavy metals is improved, and thus the heavy metal detection capability is improved.

Owner:CHANGZHOU UNIV

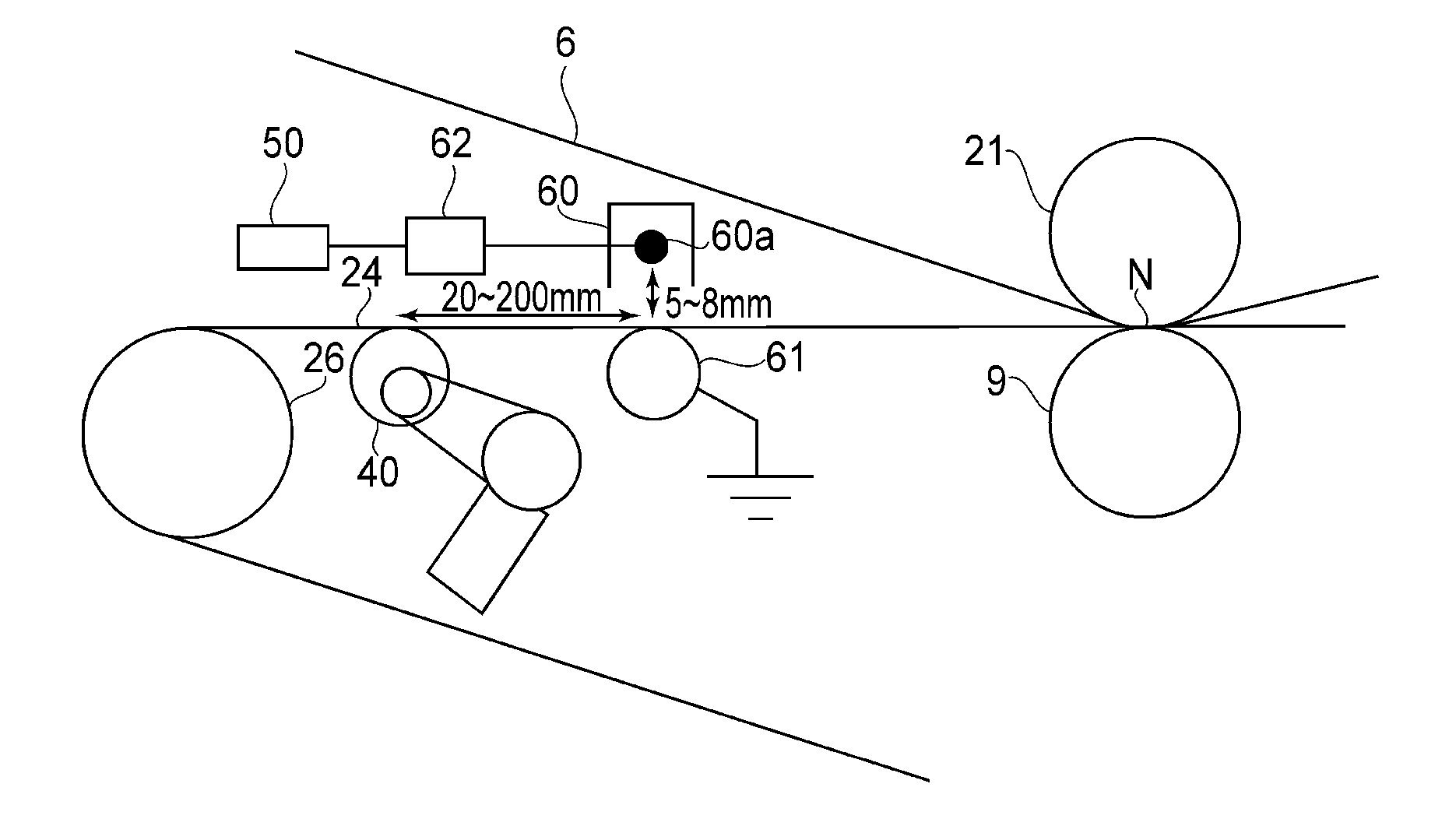

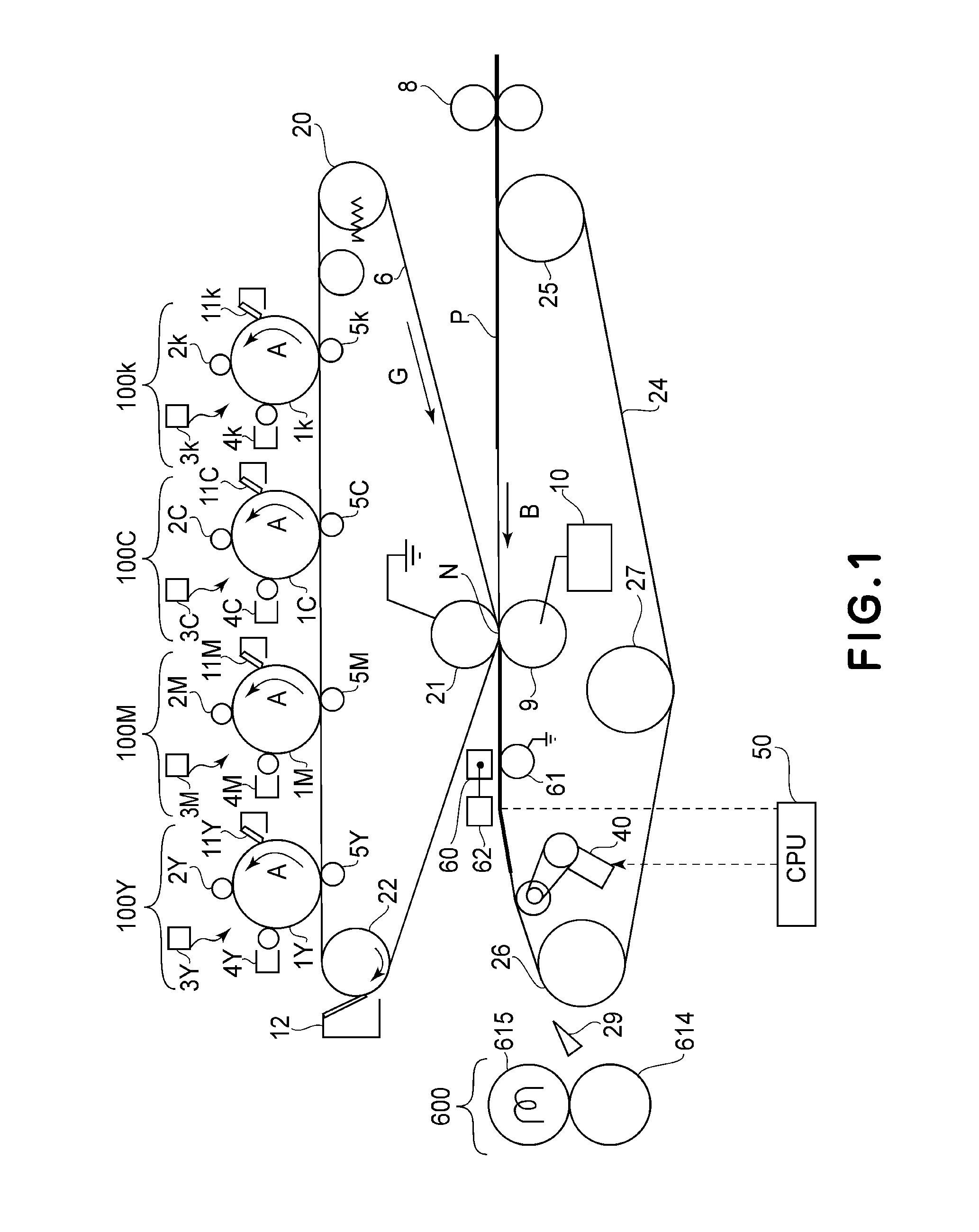

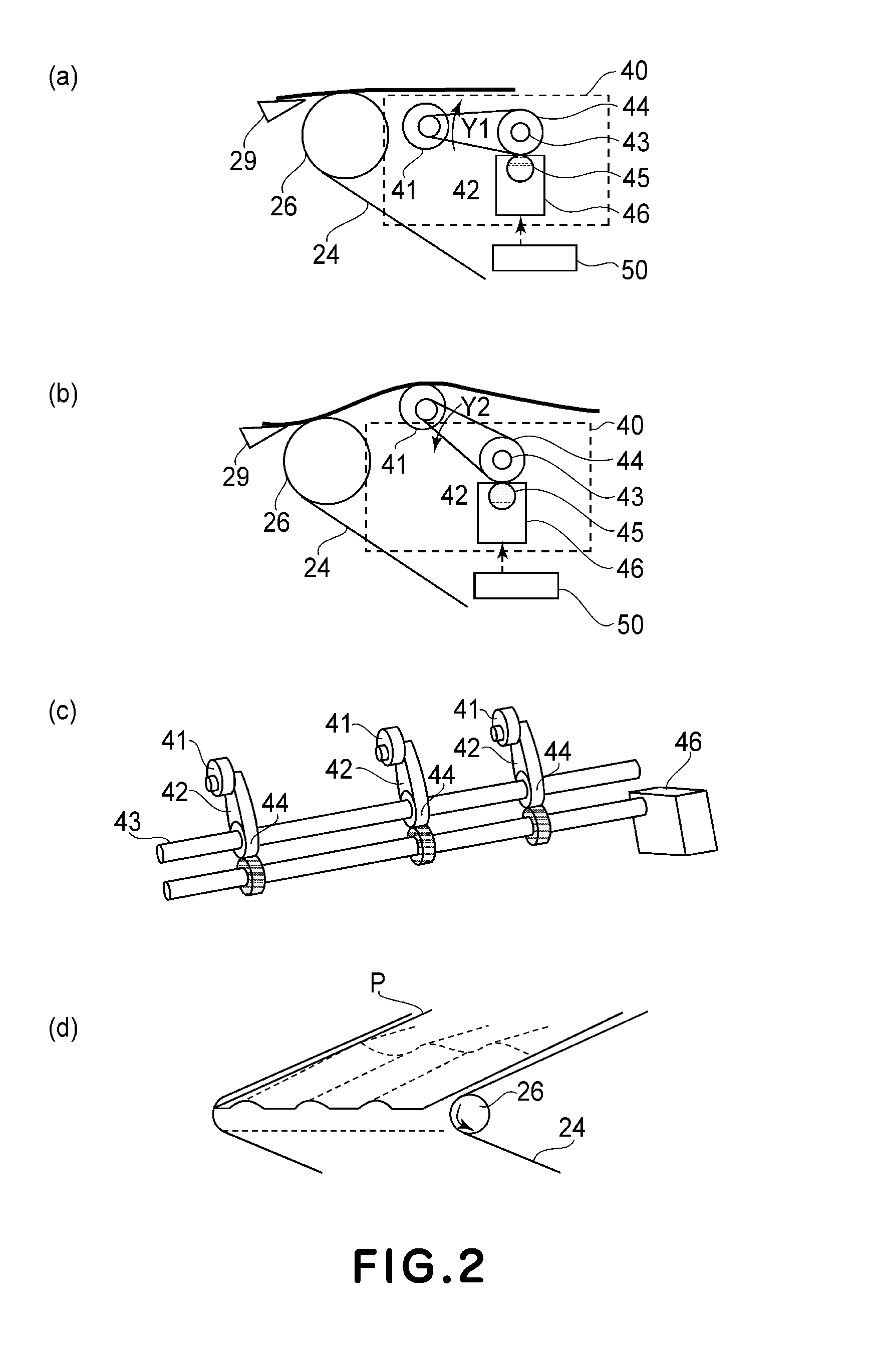

Image forming apparatus

InactiveUS20120099907A1Improve propertiesImproved separation propertiesElectrographic process apparatusImage formationVoltage

An image forming apparatus includes an image bearing member; a stretched rotatable belt member; a transfer member for forming a toner image onto a recording material carried on the belt member; a separation roller, for stretching the belt member; a push-up device for pushing up a belt surface of the belt member; a pre-separation charging device, for electrically charging the recording material with a voltage of an opposite polarity to a normal charge polarity of a toner; and an execution portion for executing an operation in which the recording material charged by the voltage to the pre-separation charging means is separated from the belt member by pushing up the belt member by the push-up device.

Owner:CANON KK

Electrostatically fixable sheets and display object including same

InactiveCN105517798ACapable of electrostatic adsorptionEasy to peelStampsSignboardsEngineeringPressure sensitive

Double-faced adhesive sheets are provided with each of which a printed matter having no pressure-sensitive adhesiveness, e.g., an advertising leaflet, can be applied to and displayed on an adherend without requiring the use of a pressure-sensitive adhesive or the like. When the printed matter is applied to the adherend, air bubbles are less apt to remain. One of the double-faced adhesive sheets is an electrostatically fixable sheet which comprises: a support layer (A) comprising a thermoplastic resin film that has undergone a charging treatment; and a protective layer (B) which comprises a dielectric film and has been laminated to at least one surface of the support layer (A) by electrostatic attraction. Another is an electrostatically fixable sheet which comprises: a support layer (A) comprising a thermoplastic resin film; and a protective layer (B) which comprises a dielectric film that has undergone a charging treatment and which has been laminated to at least one surface of the support layer (A) by electrostatic attraction.

Owner:YUPO CORP

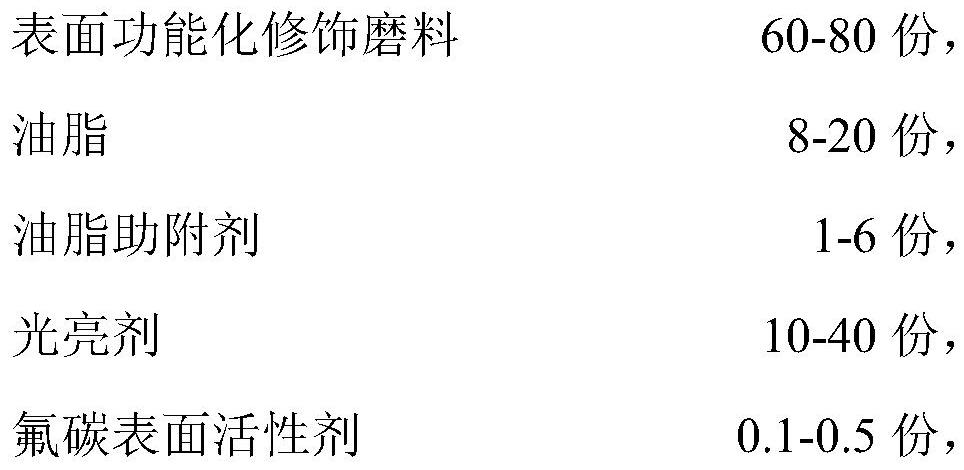

Stainless steel polishing wax and preparation method thereof

ActiveCN112500800AEasy to cutImprove the lubrication effectPolishing compositions with abrasivesPolishingActive agent

At present, in the polishing process of some polishing paste, molten polishing paste is easily gathered at the edge of the outer edge of a polishing wheel due to centrifugal force, when a workpiece makes contact with the polishing wheel, part of the polishing paste directly splashes out, and a large amount of polishing paste which does not act is scraped off by the workpiece to form thick wax scale. The invention provides stainless steel polishing wax capable of obviously improving the durability of the polishing wax, which comprises the following components in parts by weight: 60-80 parts ofsurface functional modified abrasive, 8-20 parts of grease, 1-6 parts of grease adhesion promoter, 10-40 parts of brightener and 0.1-0.5 part of fluorocarbon surfactant. Through the synergistic effectof the abrasive, the grease adhesion promoter, the grease, the brightener and the fluorocarbon surfactant, the polishing wax can not easily fall off from the surface of the polishing cloth wheel while maintaining excellent cutting, lubricating and brightening effects, and the durability of the polishing wax is obviously improved.

Owner:GUANGDONG REDSUNSTAR IND

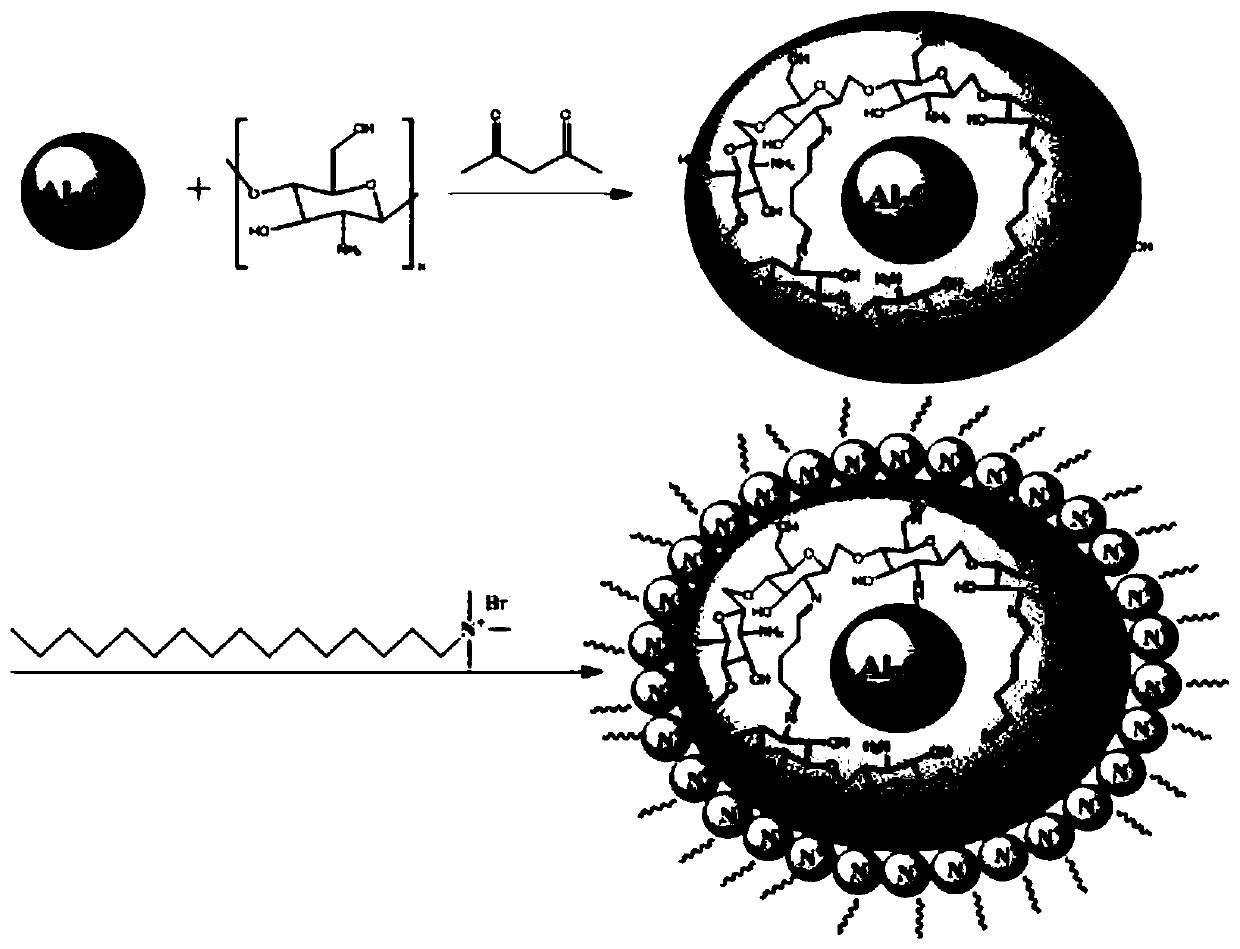

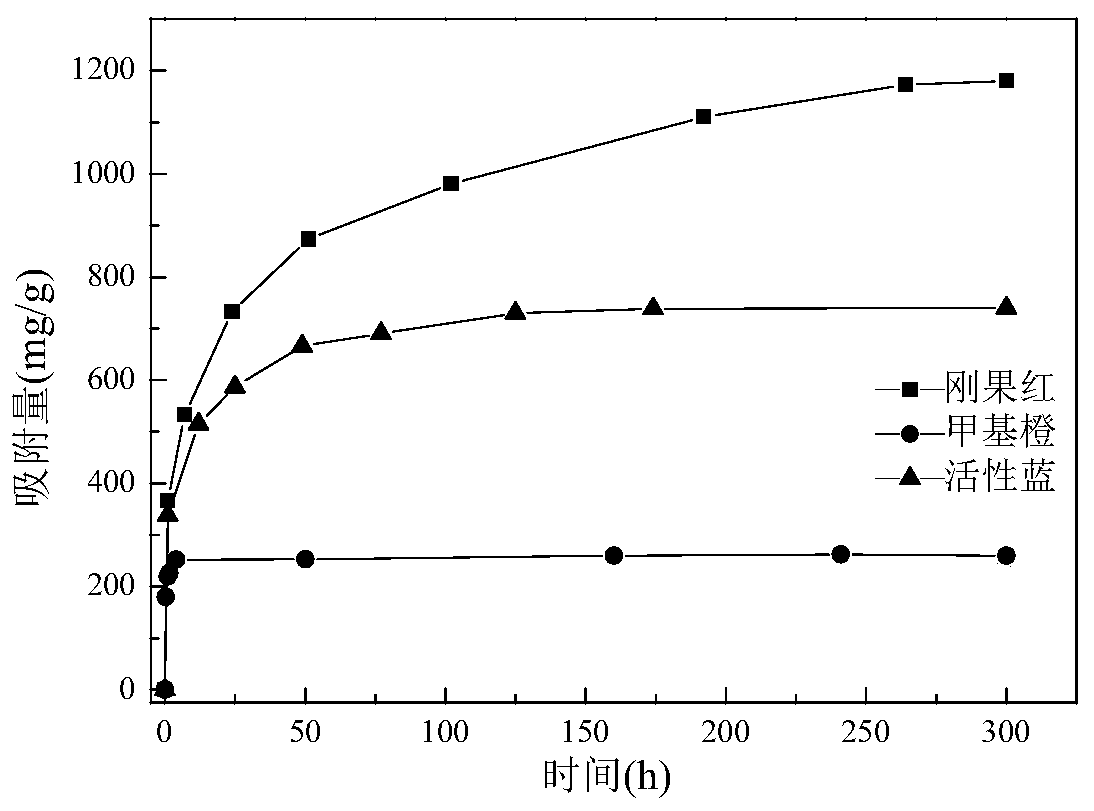

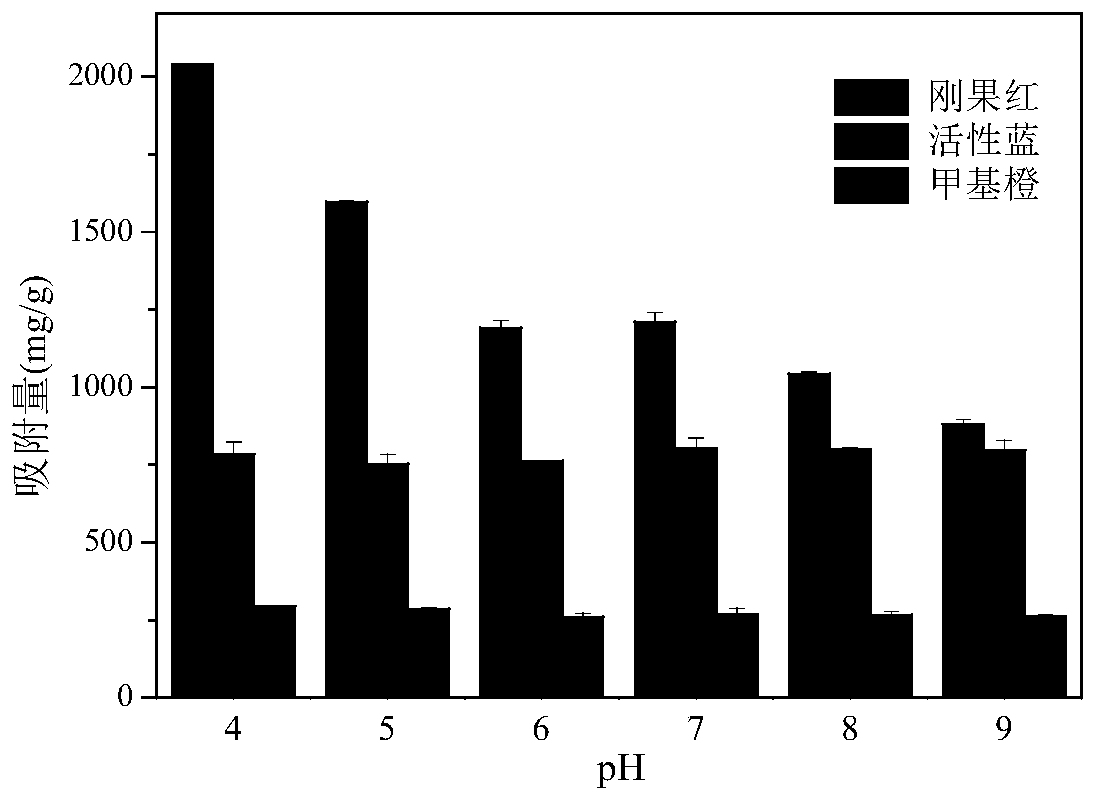

Modified composite adsorbent as well as preparation method and application thereof

InactiveCN110665469AImprove efficiencyImprove adsorption capacityOther chemical processesWater contaminantsActive agentAqueous solution

The invention belongs to the field of water treatment, and discloses a modified composite adsorbent as well as a preparation method and application thereof. The preparation method of the modified composite adsorbent comprises the following steps: adding an aluminum salt aqueous solution into an alkaline solution under stirring until the pH value of an obtained solution is 6.5-7.5, heating an obtained suspension in a sealed manner, filtering, washing, drying and heating to obtain aluminum oxide; adding aluminum oxide in an acetic acid solution of chitosan, adding glutaraldehyde to form a colloid, drying, grinding, washing, drying, adding an obtained chitosan composite aluminum oxide into deionized water, adding a cationic surfactant, stirring, filtering, washing with ethanol and deionizedwater, and drying to obtain a finished product. The preparation method of the modified composite adsorbent is simple, and the adsorbent has the advantages of strong adsorption capacity, high adsorption efficiency on ionic dyes, easiness in separation from a reaction solution, no secondary pollution to the environment and the like, can effectively adsorb the ionic dyes in printing and dyeing wastewater, and is suitable for treating the printing and dyeing wastewater containing the ionic dyes.

Owner:GUANGDONG UNIV OF TECH

Preparation method of quick-drying dust-proof oil paint pigment

InactiveCN108359300AImprove adsorption capacityIncrease electrostatic attractionArtist's paintsAcrylic resinResin-Based Composite

The invention discloses a preparation method of a quick-drying dust-proof oil paint pigment, and belongs to the technical field of oil paint pigment preparation. A double-electric-layer structure is formed in modified zeolite powder in the air drying process, and the adsorption capacity of the modified zeolite powder for the resin is enhanced due to existence of the double-electric-layer structure. A pre-mixed solution is used as a mixed monomer of acrylic resin and then is doped with additives, and a composite resin emulsion is obtained by grafting reaction; after the oil paint pigment is aired, hydrophobic substances in the resin emulsion micelle can be aggregated and arranged on the surface of oil paint; essential oil can be slowly released from diatomite after being absorbed by diatomite, emulsification of the oil paint is promoted, hydrophobicity of the essential oil also contributes to volatilization of water in the oil paint pigment, wettability of the oil paint can be improvedby added bovine bile, fluidity of the pigment is enhanced, surface tension of water is reduced, water is prevented from gathering into water droplets, so that surface drying time of the oil paint pigment is shorted during air drying, the purpose of quick drying is achieved, and the application prospect is broad.

Owner:谢新昇

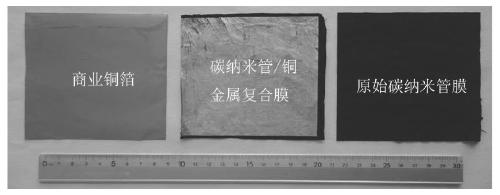

Preparing method of flexible carbon nanotube/metal composite film applied to electromagnetic shielding field

InactiveCN109881229AReduce weightIncrease electrostatic attractionCarbon nanotubesElectricityComposite film

The invention relates to a preparing method of a flexible carbon nanotube / metal composite film applied to the electromagnetic shielding field, and relates to a method for improving the existing nanotube film electromagnetic shielding effectiveness by growing metal particles on the carbon nanotube film surface. The preparing method sequentially comprises the following steps that firstly, the surface morphology of the carbon nanotube film is constructed; secondly, electrodeposition liquid is prepared; thirdly, a cathode deposition component is assembled; and fourthly, the metal particles are grown on the surface of the carbon nanotube film. The carbon nanotube film obtained by the method has high conductivity, excellent flexibility and light weight, and the adopted method and equipment are simple, cost is low, pollution is avoided, repeated use can be achieved, and the electrodeposition process can achieve the characteristics of industrialization and the like.

Owner:JIANGXI UNIV OF SCI & TECH

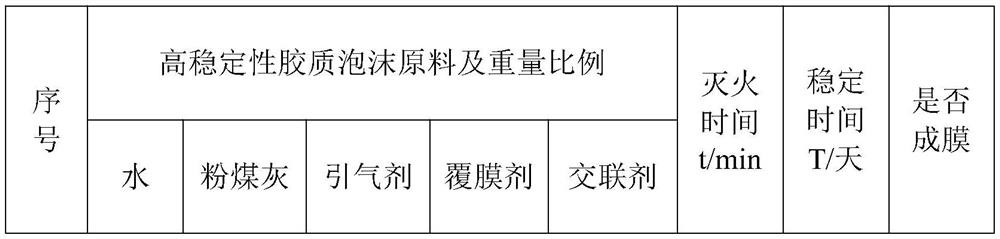

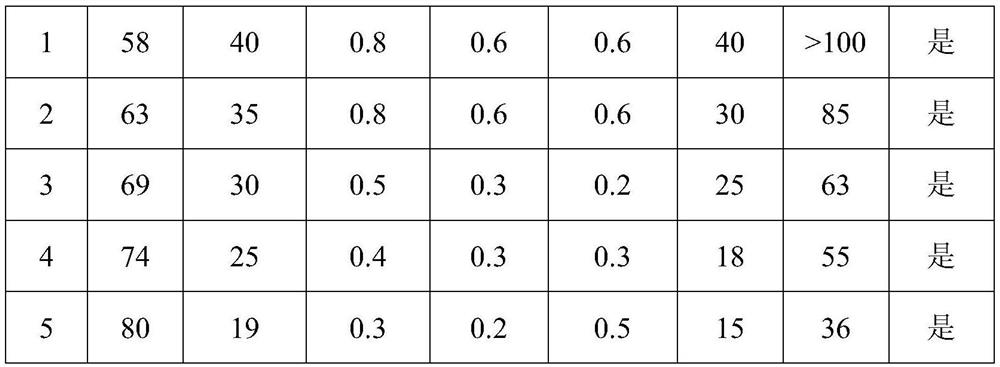

High-stability colloidal foam for inhibiting oxidation self-heating of loose coal body and preparation method thereof

ActiveCN113213821AImprove stabilityImprove water retentionDust removalFire preventionCross linkerThermal stability

The invention discloses high-stability colloidal foam for inhibiting oxidation self-heating of a loose coal body and a preparation method of the high-stability colloidal foam. The high-stability colloidal foam is prepared from the following raw materials in percentage by weight: 58-80% of water, 19-40% of fly ash, 0.4-0.8% of an air entraining agent, 0.2-0.6% of a film coating agent and 0.2-0.6% of a cross-linking agent. The preparation method of the high-stability colloidal foam comprises the following steps: firstly, weighing the fly ash and the film coating agent in proportion, adding the fly ash and the film coating agent into water, and fully stirring to obtain a uniform fly ash suspension; adding the air entraining agent into the fly ash suspension in proportion, quickly stirring for 5-10 minutes, and preparing fly ash foam through an air entraining foaming expansion process; and finally, adding the cross-linking agent in proportion, and stirring for 3-5 minutes to obtain the high-stability colloidal foam. The high-stability colloidal foam disclosed by the invention is good in heat-resistant stability and excellent in flame retardant property, can keep moisture for a long time and wet a coal body, has a good wrapping and bonding effect on loose coal bodies such as residual coal in a mine goaf, fire coal in a coal field fire area and the like, and can form a layer of coating film on the surface of the coal body to isolate oxygen for a long time.

Owner:CHINA UNIV OF MINING & TECH +1

Urea-free ink-jet printing pretreatment solution suitable for wool fabric and pretreatment method

InactiveCN111501382AEmission reductionGood hygroscopicityDyeing processTextile printerPolymer science

The invention relates to a urea-free ink-jet printing pretreatment solution suitable for a wool fabric and a pretreatment method. The pretreatment solution comprises the following components of, in percentage by mass, 0.5% - 3% of a polymer, 0.5% - 2% of a quaternary ammonium salt type cationic surfactant, 0.1% - 4% of a pH adjusting agent, and the balance water. The pretreatment solution is applied to the surface of the wool fabric through a padding or coating method to obtain a pretreated fabric with the solution carrying rate of 60% - 100%. The ink-jet printed wool fabric prepared by the ink-jet printing pretreatment is high in apparent color yield, good in definition and brighter in color.

Owner:TIANJIN POLYTECHNIC UNIV

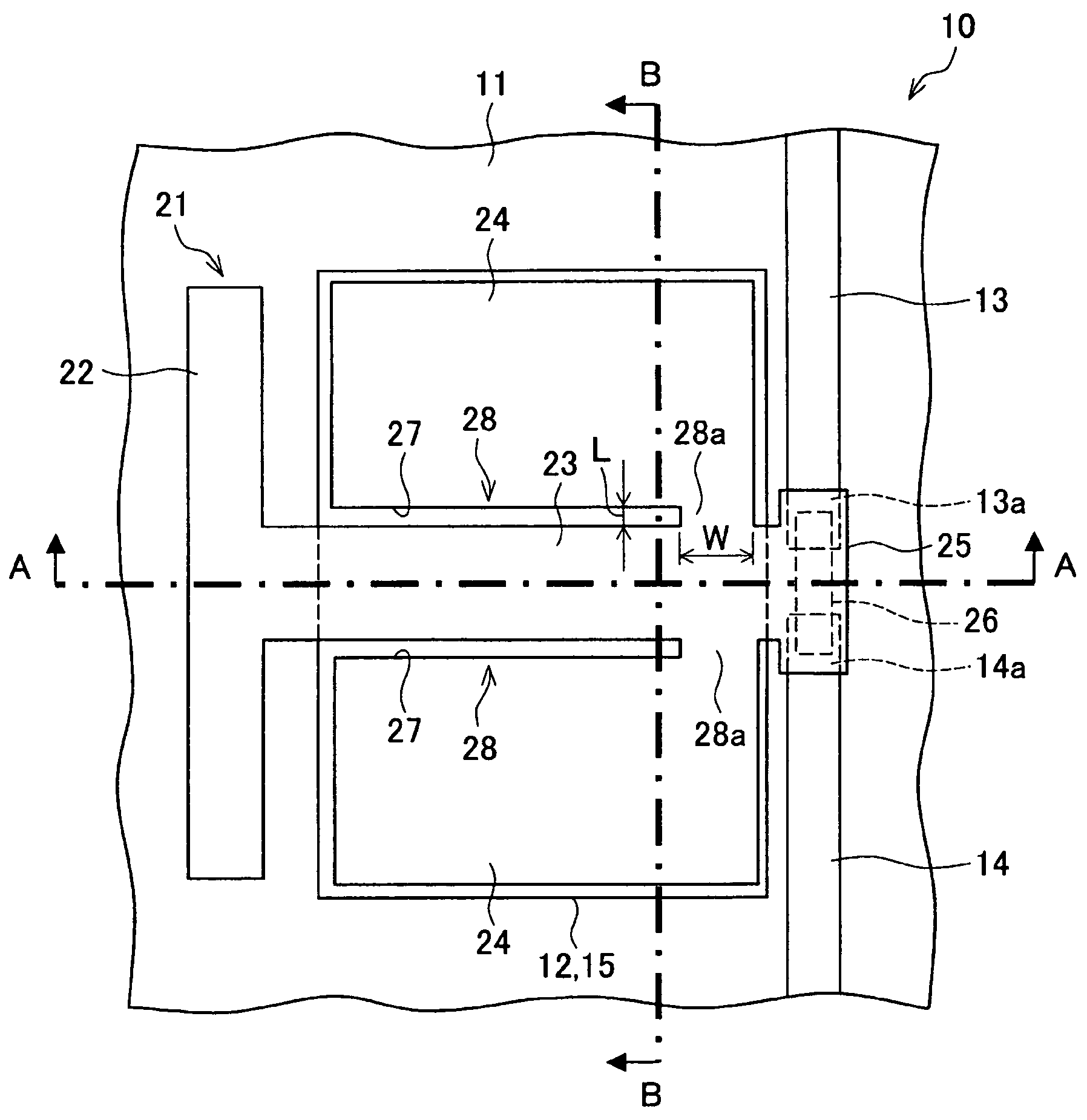

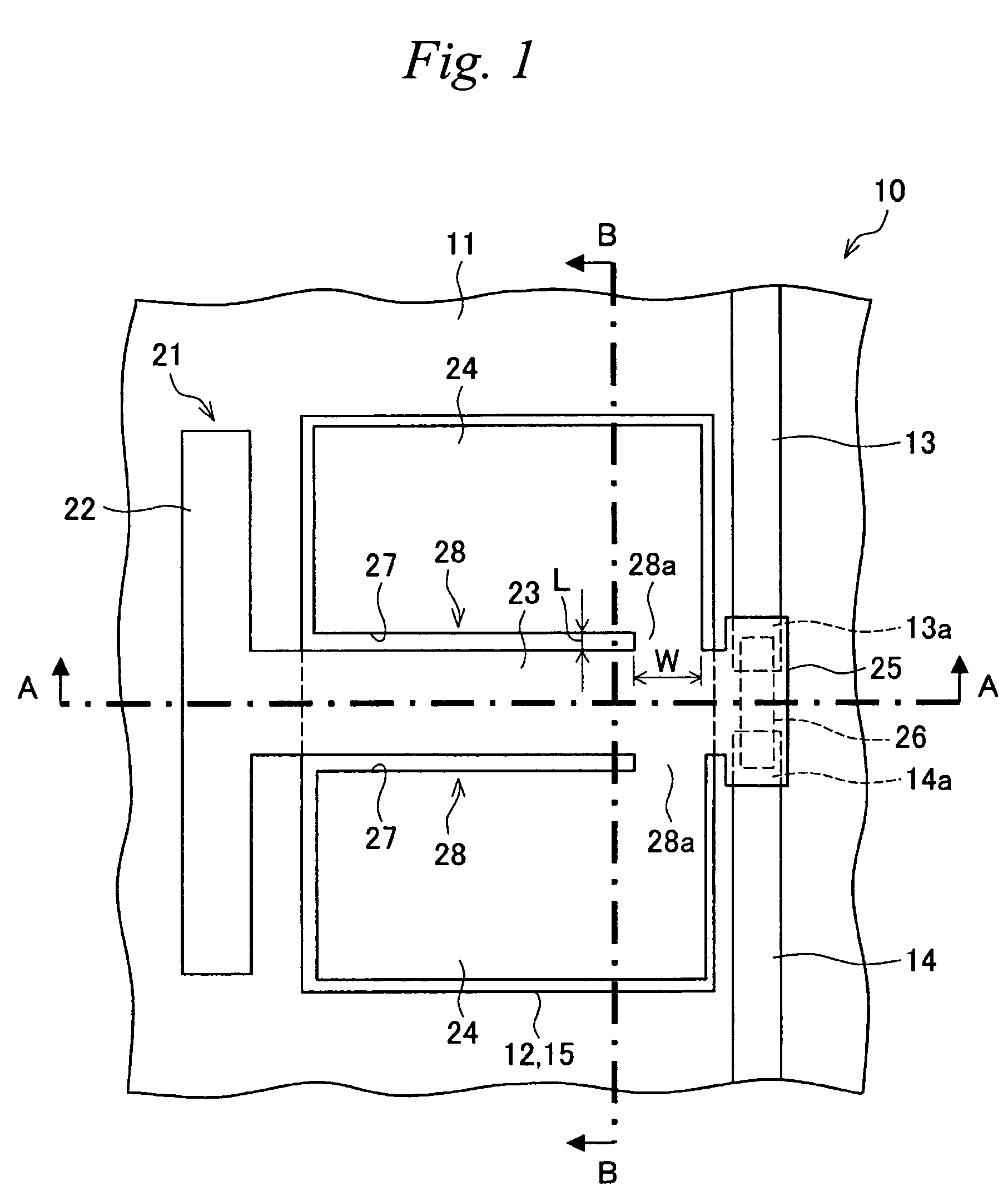

Plasma processing apparatus and method therefor

ActiveUS9620336B2Improve performanceLess influence on the plasma process performanceElectric discharge tubesDecorative surface effectsWaferingMechanical engineering

A dry etching apparatus plasma processes a wafer held by a carrier having a frame and an holding sheet. A electrode unit of a stage includes an electrostatic chuck. Adjacent to an upper surface of the electrostatic chuck, a first electrostatic attraction electrode and a second electrostatic attraction electrode are incorporated. The first electrostatic attraction electrode is of unipolar type and electrostatically attracts the wafer via the holding sheet. The second electrostatic electrode is of bipolar type and electrostatically attracts the frame via the holding sheet as well as a holding sheet between the wafer and the frame. Both of plasma processing performance and electrostatic attraction performance are improved.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

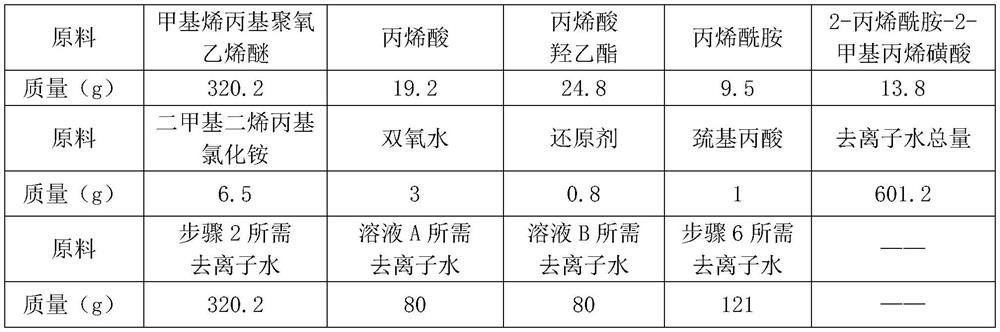

Additive for rock-fill concrete production

PendingCN114539485AIncreased steric hindranceIncrease electrostatic attractionSolid waste managementMeth-Propanoic acid

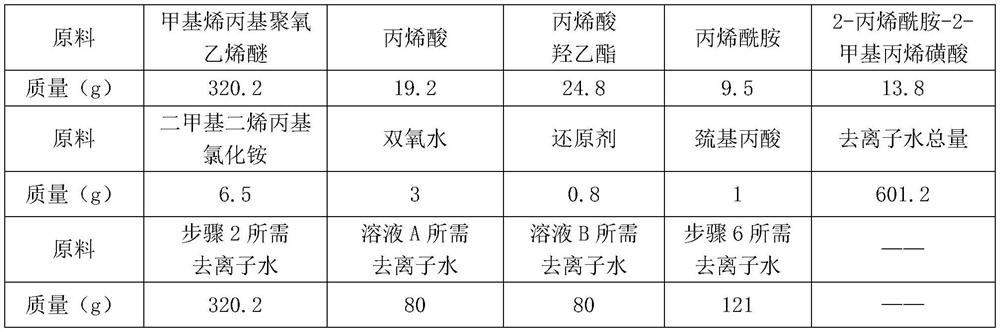

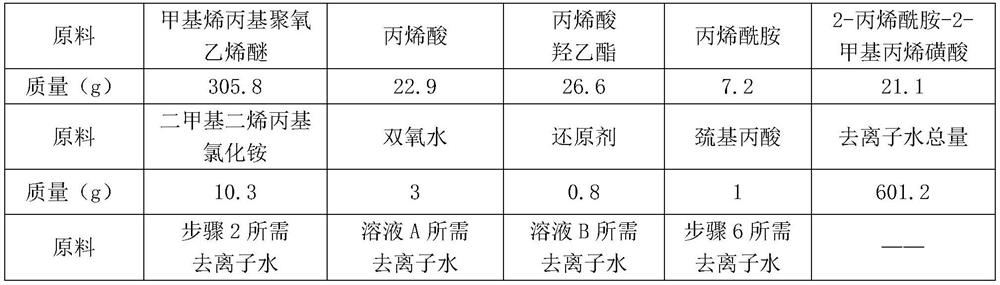

The invention relates to the field of concrete admixtures, in particular to a synthetic method of an admixture for rockfill concrete production. The admixture for rock-fill concrete production is prepared from the following components in parts by weight: 300-380 parts of methyl allyl polyoxyethylene ether; 3-47 parts of acrylic acid; 1.0 to 55 parts of hydroxyethyl acrylate; 1.0 to 15 parts of acrylamide; 5 to 40 parts of 2-acrylamide-2-methallyl sulfonic acid; 5 to 20 parts of dimethyl diallyl ammonium chloride; 1-8 parts of hydrogen peroxide; 0.2 to 2.0 parts of a reducing agent; 0.5 to 2.6 parts of mercaptopropionic acid; and 400 to 641.6 parts of deionized water. The admixture for rockfill concrete production is excellent in performance, the use amount of a cementing material can be reduced, the problem that an existing admixture is poor in adaptability to rockfill concrete and gravel is solved, the admixture has good water reducing performance and plasticity maintaining performance, the use amount of the water reducing agent can be reduced during compounding, and a mixture is good in performance, free of bleeding and free of bottom grabbing; the water reducing agent has certain water reducing property, the use amount of the water reducing agent is reduced when the water reducing agent is compounded, and the use effect is good; the consumption is small and the cost is saved; and the method is environment-friendly.

Owner:北京华石纳固科技有限公司

Nixing pottery filling technology

InactiveCN106082980AIncrease electrostatic attractionReduce sheddingClaywaresEngravingMaterials science

The invention discloses a Nixing pottery filling technology. The Nixing pottery filling technology comprises blank preparation, blank molding, painting, engraving, pottery filling, drying and sintering. The pottery filling process comprises uniformly scattering a layer of iron oxide powder in an engraved groove and filling the engraved groove with filling pottery. The drying process comprises treating the blank filled with the pottery under pressure of 10-15Mpa for 1-5min and carrying out natural air drying. Compared with the prior art, iron oxide particles are added into the engraved groove so that electrostatic attraction between the filling pottery and the blank main body is greatly improved and filling pottery falling and cracking are greatly reduced in sintering.

Owner:钦州市永和坭兴陶艺有限公司

Micro electromechanical switch and method of manufacturing the same

InactiveUS7463126B2Increase displacementReduce distanceElectrostatic/electro-adhesion relaysMan-operated mechanismEngineeringActuator

A micro electromechanical relay opens and closes an electrical circuit by contact / separation between a fixed contact disposed on a base and a movable contact disposed on an actuator by driving of a movable electrode by electrostatic attraction by application of voltage between a fixed electrode disposed on the base and a movable electrode of the actuator. The actuator comprises a supporting portion disposed on the base, a beam portion extending in a cantilevered manner from the supporting portion, and a movable electrode and a movable contact elastically supported by the beam portion. The beam portion elastically supports, in order from the supporting portion end, the movable electrode and the movable contact. A slit is formed from the side of the supporting portion in the portion of the actuator connecting the beam portion and the movable electrode.

Owner:ORMON CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com