Method and system for exhaust particulate matter sensing

A particulate matter and sensor technology, applied in exhaust devices, measuring devices, instruments, etc., can solve problems such as prolonging processing time, data output and diagnosis, electric field attenuation, and reducing sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

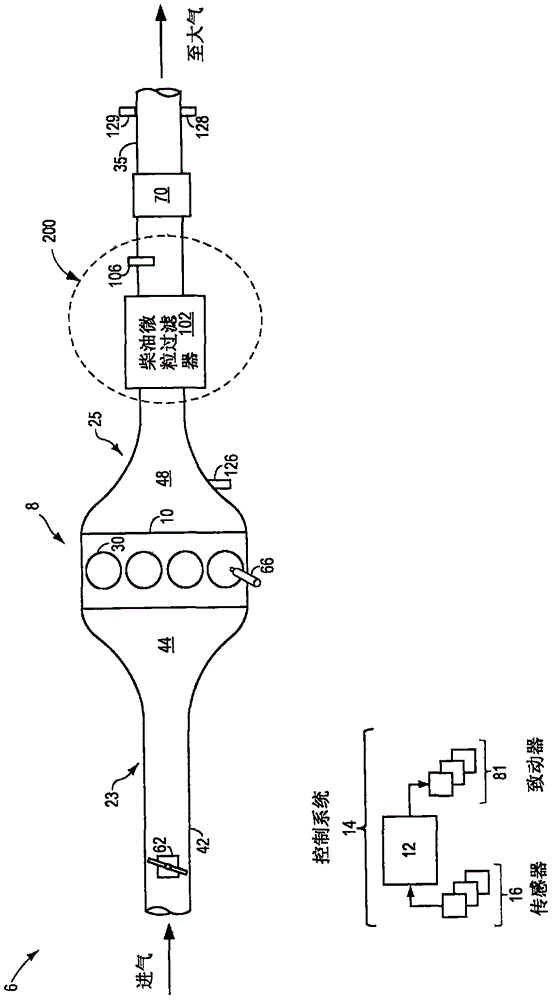

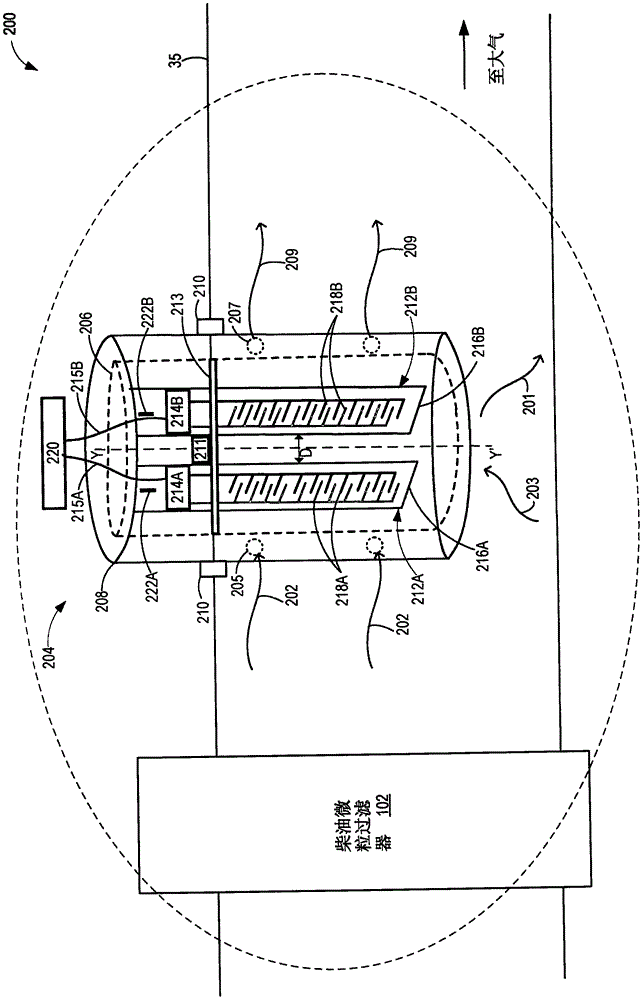

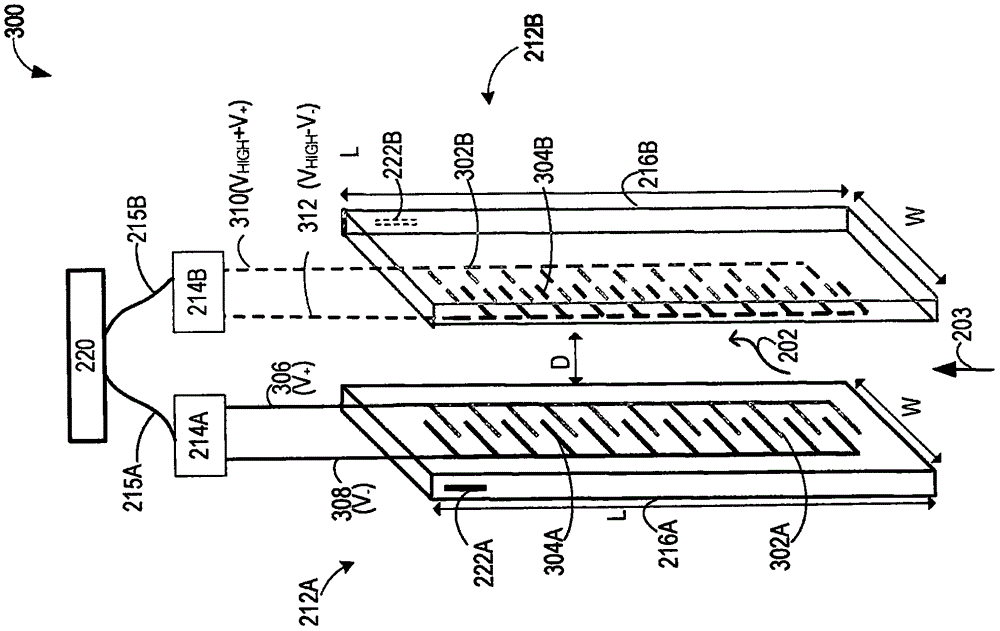

[0019] The following description relates to systems and methods for measuring the amount of particulate matter stored on an engine exhaust particulate filter, such as in figure 1 in the vehicle system. Configured with gaps ( figure 2 to Fig. 3) A particulate matter (PM) sensor with a pair of spaced electrodes may be located downstream or upstream of the diesel particulate filter. The electrodes can be operated with a voltage bias relative to each other to increase the electrostatic force exerted on the exhaust soot particles, thereby improving soot buildup on the sensor ( Figure 4 to Figure 5 ). The controller can be configured to execute control programs such as Figure 6 The program regenerates the particulate filter based on the output of the pressure sensor and performs diagnostics on the particulate filter based on the output of the PM sensor ( Figure 9 ). Additionally, the controller can intermittently clean the PM sensor ( Figure 7 ) to enable continued PM mon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com