Additive for rock-fill concrete production

A technology of rockfill concrete and admixtures, applied in the field of concrete admixtures, can solve the problems of high water reduction rate, poor adaptability, reduced adsorption, etc., and achieve the effect of reducing dosage, good performance and reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1, a kind of admixture synthesis method for rockfill concrete production, its steps are:

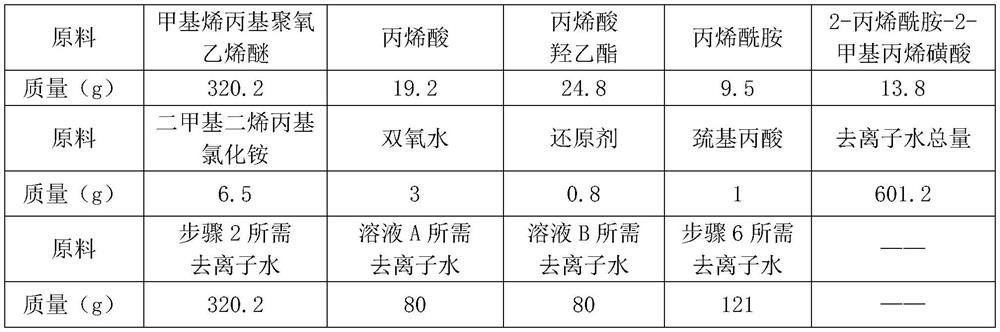

[0028] 1.1.1 Raw materials, the specific materials and quality are shown in Table 1 below:

[0029] Table 1 Example 1 raw material

[0030]

[0031] 1.1.2 Preparation

[0032] (1) Prepare raw materials

[0033] ①Weigh the raw materials;

[0034] ②Preparation of solution A: Add acrylic acid, hydroxyethyl acrylate, acrylamide, 2-acrylamide-2-methacrylic acid, dimethyldiallyl ammonium chloride to the mixing kettle, and then add deionized water ;

[0035] ③ Prepare solution B: add deionized water to the mixing kettle, then add reducing agent and mercaptopropionic acid;

[0036] (2) methallyl polyoxyethylene ether and deionized water are added to the reactor and kept stirring, and the water bath temperature is 50 °C;

[0037] (3) add hydrogen peroxide to the reactor, stir 5min;

[0038] (4) Keep the temperature of the water bath at 50°C, add solution A for 2.5 hour...

Embodiment 2

[0041] Embodiment 2, a kind of admixture synthesis method for rockfill concrete production, its steps are:

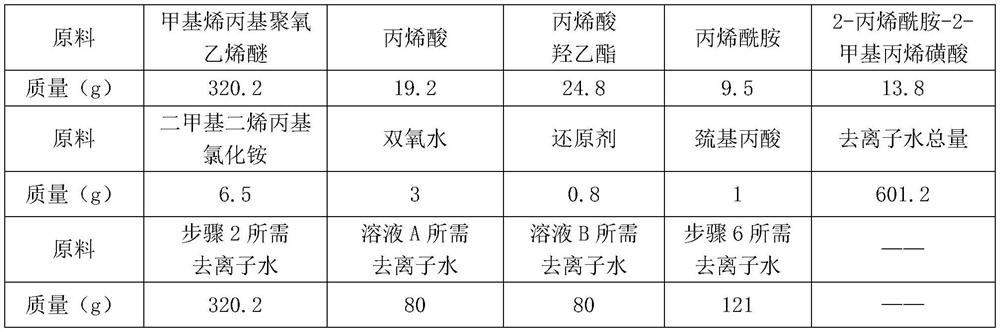

[0042] 1.2.1 Raw materials, the specific materials and quality are shown in Table 2 below:

[0043] Table 2 Example 2 raw materials

[0044]

[0045] 1.2.2 Preparation

[0046] (1) Prepare raw materials

[0047] ①Weigh the raw materials;

[0048] ②Preparation of solution A: Add acrylic acid, hydroxyethyl acrylate, acrylamide, 2-acrylamide-2-methacrylic acid, dimethyldiallyl ammonium chloride to the mixing kettle, and then add deionized water ;

[0049] ③ Prepare solution B: add deionized water to the mixing kettle, then add reducing agent and mercaptopropionic acid;

[0050] (2) methallyl polyoxyethylene ether and deionized water are added to the reactor and kept stirring, and the water bath temperature is 60 °C;

[0051] (3) add hydrogen peroxide to the reactor, stir 3min;

[0052] (4) Keep the temperature of the water bath at 60°C, add solution A for 2 hours...

Embodiment 3

[0055] Embodiment 3, a kind of admixture synthesis method for rockfill concrete production, its steps are:

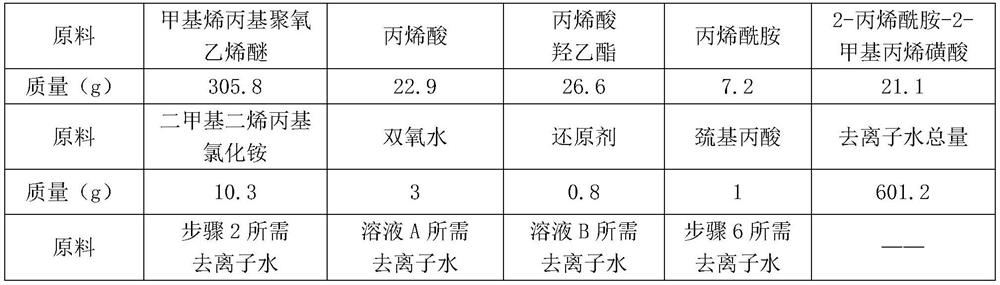

[0056] 1.3.1 Raw materials, the specific materials and quality are shown in Table 3 below:

[0057] Table 3 Example 3 raw materials

[0058]

[0059]

[0060] 1.3.2 Preparation

[0061] (1) Prepare raw materials

[0062] ①Weigh the raw materials;

[0063] ②Preparation of solution A: Add acrylic acid, hydroxyethyl acrylate, acrylamide, 2-acrylamide-2-methacrylic acid, dimethyldiallyl ammonium chloride to the mixing kettle, and then add deionized water ;

[0064] ③ Prepare solution B: add deionized water to the mixing kettle, then add reducing agent and mercaptopropionic acid;

[0065] (2) methallyl polyoxyethylene ether and deionized water are added to the reactor and kept stirring, and the water bath temperature is 60 °C;

[0066] (3) add hydrogen peroxide to the reactor, stir 3min;

[0067](4) Keep the temperature of the water bath at 60°C, add solution A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com