Method for treating biological filler from waste hollow fiber ultrafiltration membrane or microfiltration membrane as matrix

A technology of biological fillers and ultrafiltration membranes, which is applied in the treatment of granular microbial carriers, biological water/sewage treatment, chemical instruments and methods, etc. Reduce environmental hazards and reduce the effect of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The discarded hollow fiber membranes in this example come from the membrane bioreactor of the municipal sewage treatment plant, and its material is polyvinylidene fluoride. The hollow fiber membranes have been in operation for about three years. At this time, the flux of the hollow fiber membranes is very serious. Already lower than the flow rate involved in the membrane bioreactor, a thick layer of microbial or pollutant deposits has been deposited on the membrane surface.

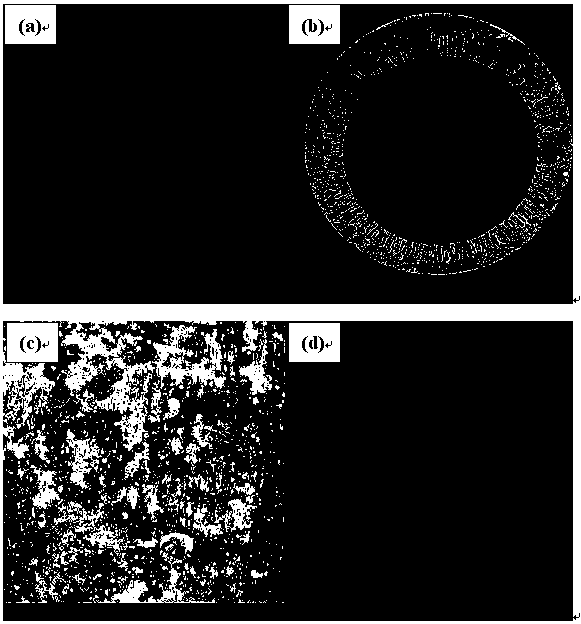

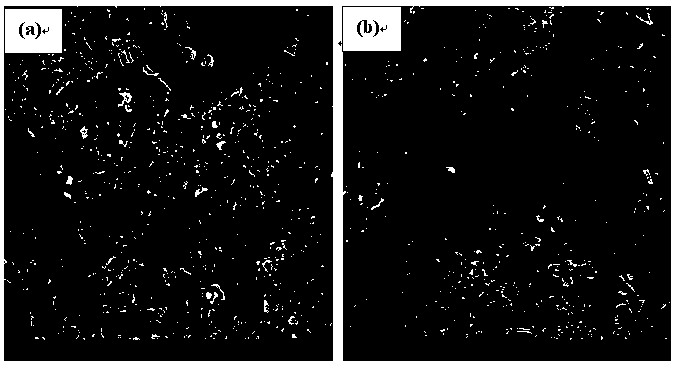

[0038] Clean the discarded hollow fiber membrane under the action of 100 KHz ultrasound for 1 hour to remove the microorganisms that are relatively easy to fall off the surface, then dry the membrane in an oven at 80-90°C, and cut it into 15 cm long In the short section, hollow fiber membrane fillers were prepared by preparing traditional biological fillers. In order to test the effect of film formation, the traditional fillers and the prepared waste hollow fiber membrane fillers were placed in two ...

Embodiment 2

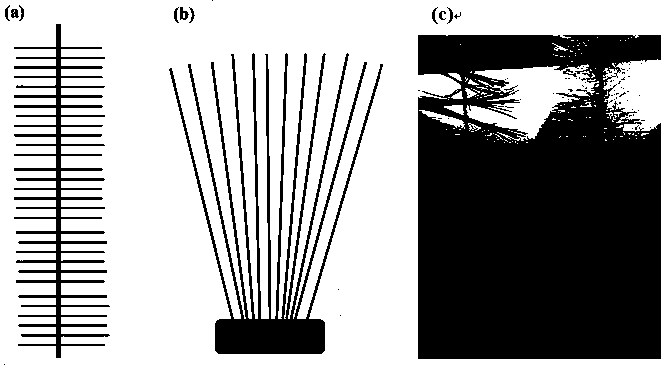

[0040] The discarded hollow fiber membranes in this example come from MBR membranes used in the treatment of printing and dyeing wastewater. The material of the membranes is polyvinylidene fluoride. After analysis, the main pollutants on the surface of the hollow fiber membranes are not only some microorganisms, but also many dyes. related organic matter, and there may be a small amount of toxic and harmful substances in printing and dyeing wastewater. First, use 1% sodium hypochlorite solution to clean the membrane module again. The cleaning and soaking time is 10 hours to remove the pollutants on the surface of the membrane, and then soak in water for 1 hour, and then the entire membrane material is sterilized by high temperature. The environment for disinfection is 121 ℃, and the time is 30 minutes. It mainly uses high temperature to digest some toxic and harmful substances. Then one end of the hollow fiber membrane filler is fixed, and the other end is spread out to form a...

Embodiment 3

[0042] The waste hollow fiber membranes in this example are taken from the membrane filaments in the waterworks, and the material is polyvinyl chloride, because the relative pollution degree of the membrane filaments is relatively low, but in order to further improve the membrane-hanging performance of the membrane filaments, the surface of the membrane filaments is hydrophilic modification. The specific process is as follows:

[0043] (1) Fully wet and soak the membrane filaments of the discarded hollow fiber membranes first, generally using tap water for 2-4 hours;

[0044] (2) Surface hydroxylation modification. Put the membrane filament in step (1) into 10% hydrogen peroxide solution for 20 minutes, then take it out and put it into 3% polyvinyl alcohol solution, so that the polyvinyl alcohol can fully cross-link on the membrane surface , and the reaction time is 10 min. Now the film surface has formed a macromolecular hydrophilic layer, and the contact angle of the film...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com