Stainless steel polishing wax and preparation method thereof

A polishing wax and stainless steel technology, which is applied in the field of metal surface treatment, can solve the problems of affecting the health of polishing workers, shortening the service life of polishing wax, floating dust in the polishing room, etc., and achieves the effect of smooth polishing surface, improved gloss, and not easy to burn

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

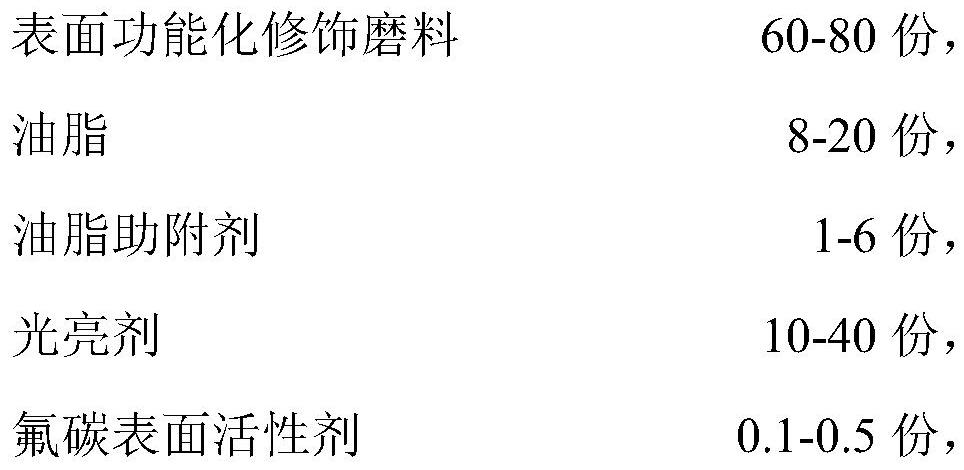

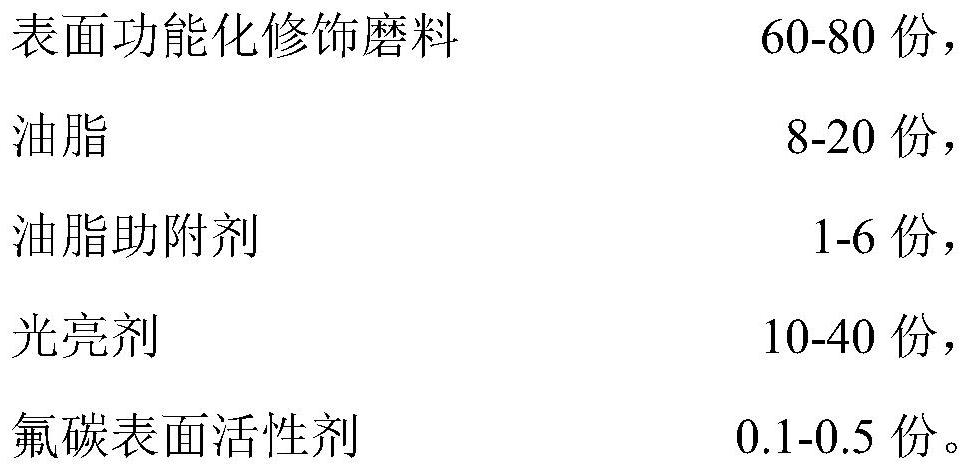

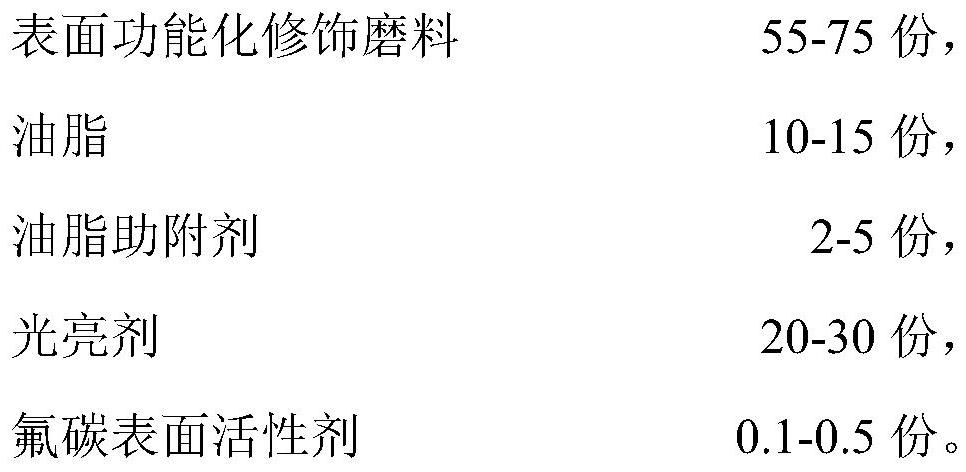

Method used

Image

Examples

Embodiment 1

[0046] The preparation method of the surface functionalized modified abrasive of the present embodiment is as follows:

[0047] Soak alumina with D50 particle size between 0.2-0.3 μm in 10% sodium hydroxide solution for 20min, then wash and dry, and then soak in 80°C containing 1% polydiallyl dimethyl ammonium chloride. In the ethanol solution for 10 min, the surface functionalized modified abrasive of Example 1 was obtained, and it was naturally air-dried.

Embodiment 2

[0049] The preparation method of the surface functionalized modified abrasive of the present embodiment is as follows:

[0050] Alumina and zirconia with a D50 particle size of 0.2-0.3μm were soaked in 8% sodium hydroxide solution for 25 minutes, then washed and dried, and then soaked in 75°C containing 1.5% polydiallyl dimethyl In ethanol solution of ammonium chloride for 12min, surface functionalized alumina and surface functionalized modified zirconia were obtained, respectively, dried naturally, and then surface functionalized alumina and surface functionalized modified zirconia were in a mass ratio of 10:3 Mixing was carried out to obtain the surface functionalized modified abrasive of Example 2.

Embodiment 3

[0052] The preparation method of the surface functionalized modified abrasive of the present embodiment is as follows:

[0053] The mixture of alumina and zirconia with a D50 particle size of 0.2-0.3 μm (mass ratio 11:1) was soaked in 15% sodium hydroxide solution for 15 minutes, then washed and dried, and then soaked at 85 ° C containing 0.9% In the ethanol solution of polydiallyl dimethyl ammonium chloride for 18 min, the surface functionalized modified abrasive of Example 3 was obtained, and it was naturally air-dried.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com