Device for purifying air by eliminating smoke and dust and the technique thereof

A technology for flue gas purification and dust removal equipment, which is applied in the direction of chemical instruments and methods, separation methods, lighting and heating equipment, etc. It can solve the problems that affect the sufficient atomization of washing water, affect the effect of flue gas purification and dust removal, and achieve improved dust removal effect, lengthening effect, lengthening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

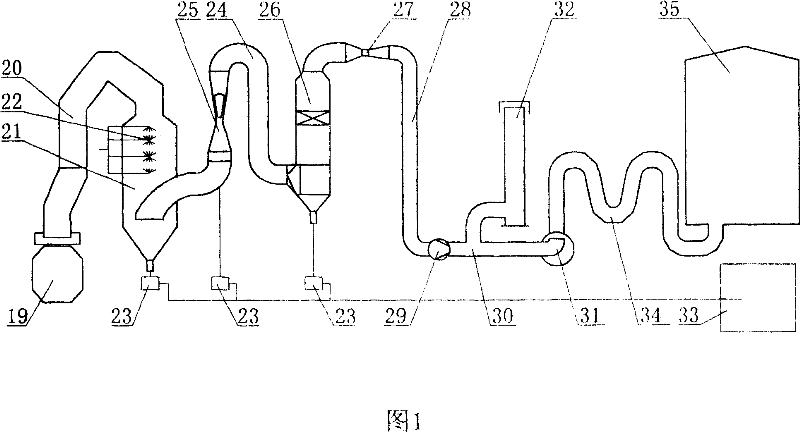

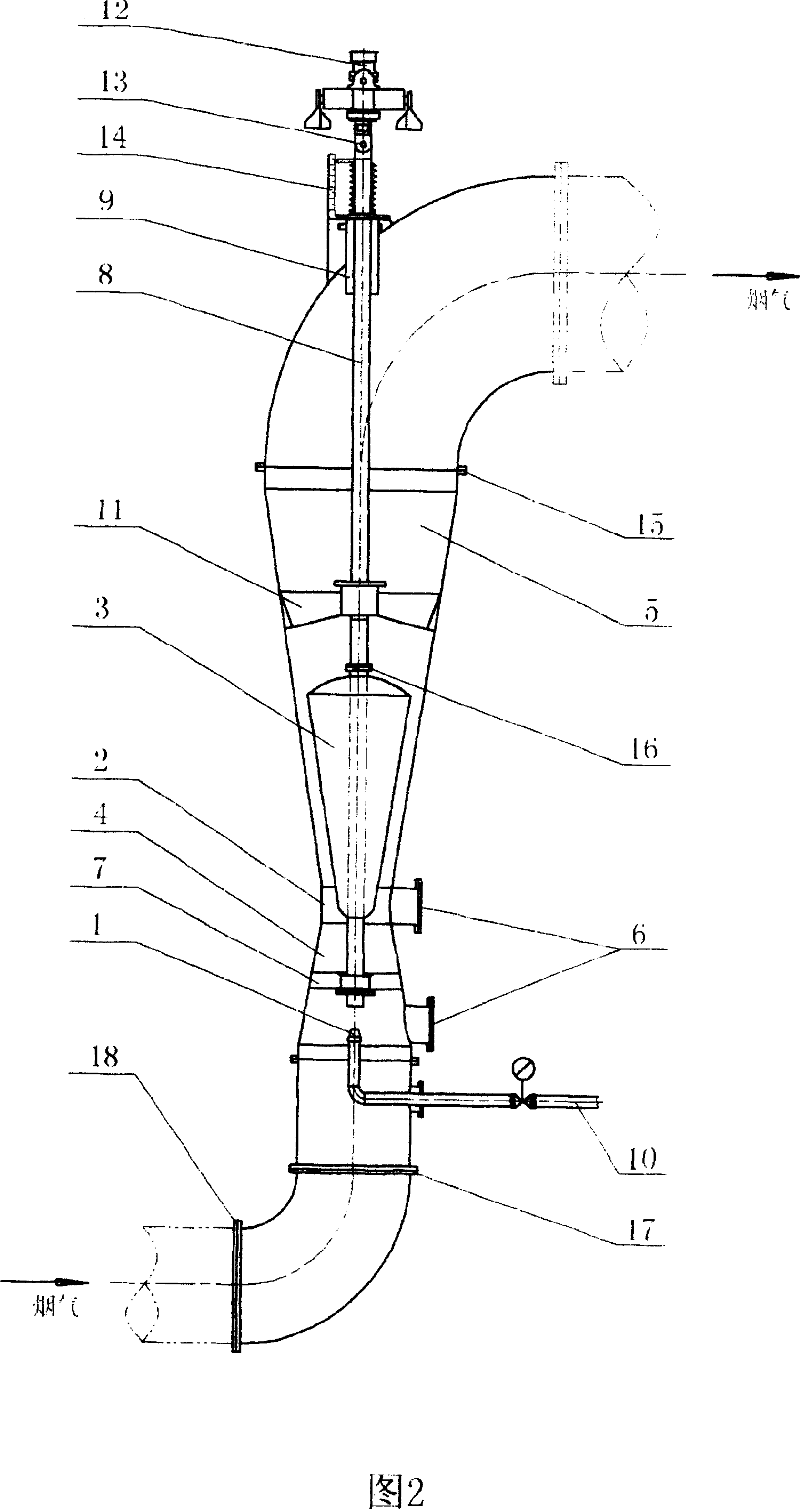

[0012] Fig. 1 is a simplified process flow diagram of a flue gas purification and dedusting equipment and its process method embodiment of the present invention, as shown in Fig. 1, the flue gas produced by the converter 19 steelmaking enters the cooling scrubber through the gasification cooling flue 20 21. There are 5 layers of spraying devices inside the cooling and washing tower 21. The spraying device is composed of a spray gun, a spray head and a water pipe. 1. Under the condition of low water consumption, a large amount of gas is atomized, and at the same time, due to the evaporative cooling scrubber, the resistance is reduced to below 0.5kpa, and the resistance of the entire purification system can be redistributed, ensuring the pressure loss required for Erwen dust removal. After cooling The preliminarily purified flue gas treated by the scrubber 21 directly enters the bottom of the annular venturi tube 25, and the atomizing spray gun with one nozzle is placed in the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com