Long-acting electret PP non-woven fabric and preparation method thereof

A technology of non-woven fabrics and electret, which is applied in the direction of non-woven fabrics, textiles, papermaking, rayon manufacturing, etc. It can solve the problems of short static charge storage time, cannot be used repeatedly, and is not very effective, and achieves the extension of static electricity decay cycle , prolong the service life and improve the adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

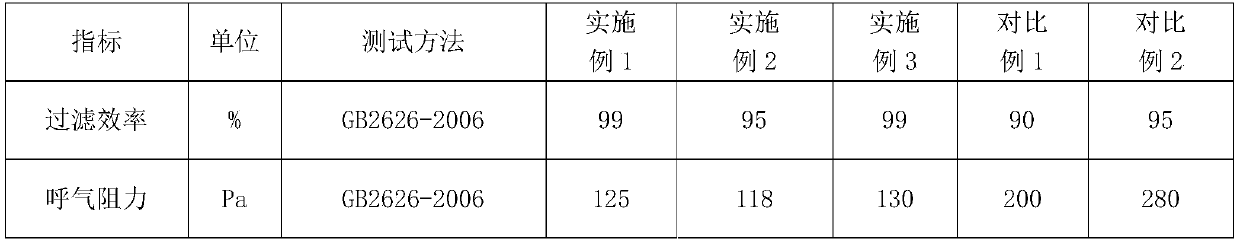

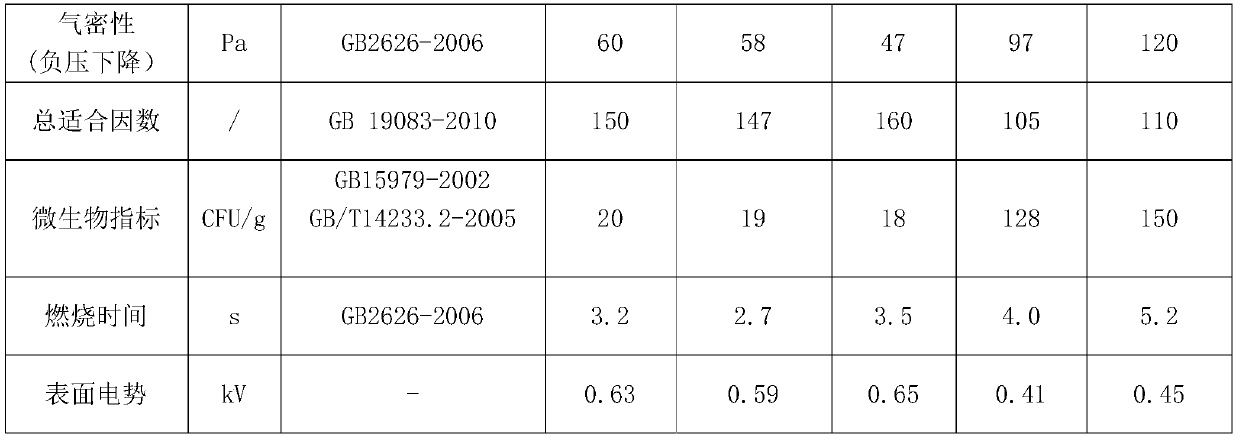

Examples

Embodiment 1

[0032] In this example, a long-lasting electret PP nonwoven fabric is mainly prepared from the following components in parts by weight: 35 parts of electret masterbatch, 40 parts of melt-blown grade PP, 12 parts of surface-treated silica, 4 parts of polyvinylidene fluoride, 5 parts of polytetrafluoroethylene, 3 parts of PFA, and additives.

[0033] A kind of long-acting electret PP nonwoven fabric preparation method of the present embodiment comprises the following steps:

[0034] Step 1, 35 parts of electret masterbatch, 40 parts of melt-blown grade PP, 12 parts of surface-treated silica, 4 parts of polyvinylidene fluoride, 5 parts of polytetrafluoroethylene, and 3 parts of PFA are mixed;

[0035] Step 2, then add 0.2 parts of antioxidant 1010, 0.1 part of nylon PA6, 0.1 part of BASF light stabilizer 234, 0.1 part of pentaerythritol stearate, 0.1 part of sorbitol PP nucleating agent, 0.2 part of phthalate Dibutyl formate, 0.1 part of butyl rubber, and 0.1 part of azodicarbonam...

Embodiment 2

[0038] In this example, a long-lasting electret PP nonwoven fabric is mainly prepared from the following components in parts by weight: 30 parts of electret masterbatch, 36 parts of melt-blown grade PP, 17 parts of surface-treated silica, 5 parts of polyvinylidene fluoride, 7 parts of polytetrafluoroethylene, 4 parts of PFA, and additives.

[0039] A kind of long-acting electret PP nonwoven fabric preparation method of the present embodiment comprises the following steps:

[0040] Step 1, 30 parts of electret masterbatch, 36 parts of melt-blown grade PP, 17 parts of surface-treated silica, 5 parts of polyvinylidene fluoride, 7 parts of polytetrafluoroethylene, and 4 parts of PFA are mixed;

[0041] Step 2, then add 0.2 parts of antioxidant 1010, 0.1 part of nylon PA6, 0.1 part of BASF light stabilizer 234, 0.1 part of pentaerythritol stearate, 0.1 part of sorbitol PP nucleating agent, 0.2 part of phthalate Dibutyl formate, 0.1 part of butyl rubber, and 0.1 part of azodicarbon...

Embodiment 3

[0044] In this example, a long-lasting electret PP nonwoven fabric is mainly prepared from the following components in parts by weight: 33 parts of electret masterbatch, 44 parts of melt-blown grade PP, 8 parts of surface-treated silica, 3 parts of polyvinylidene fluoride, 6 parts of polytetrafluoroethylene, 5 parts of PFA, and additives.

[0045] A kind of long-acting electret PP nonwoven fabric preparation method of the present embodiment comprises the following steps:

[0046] Step 1, 33 parts of electret masterbatch, 44 parts of melt-blown grade PP, 8 parts of surface-treated silica, 3 parts of polyvinylidene fluoride, 6 parts of polytetrafluoroethylene, and 5 parts of PFA are mixed;

[0047] Step 2, then add 0.2 parts of antioxidant 1010, 0.1 part of nylon PA6, 0.1 part of BASF light stabilizer 234, 0.1 part of pentaerythritol stearate, 0.1 part of sorbitol PP nucleating agent, 0.2 part of phthalate Dibutyl formate, 0.1 part of butyl rubber, and 0.1 part of azodicarbonam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| Vicat softening point | aaaaa | aaaaa |

| thermal stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com