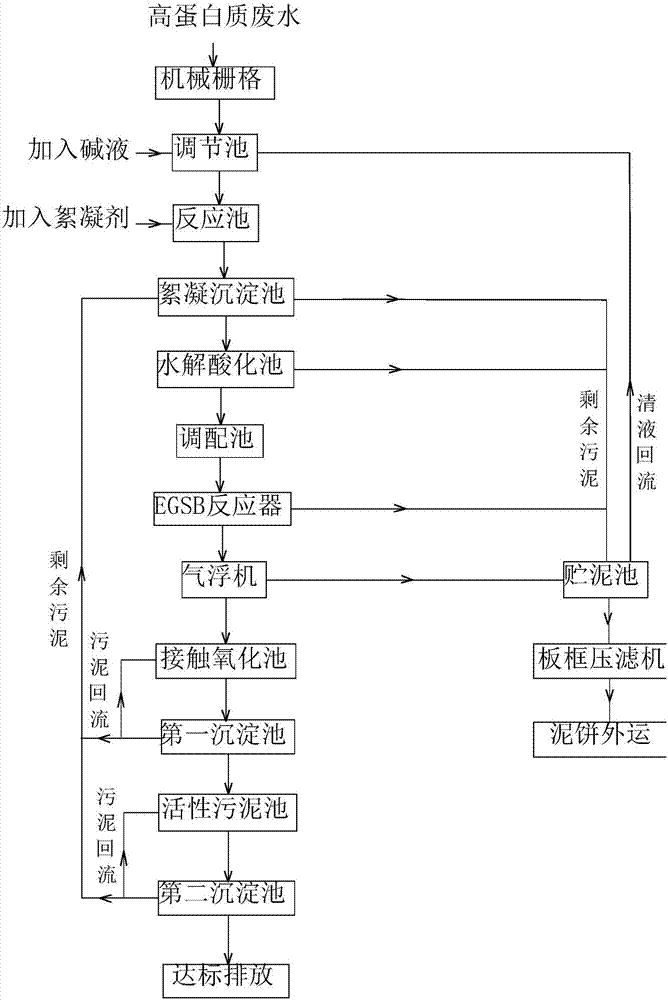

High-protein wastewater treatment process

A wastewater treatment and high-protein technology, applied in the field of high-protein wastewater treatment process, can solve the problems of high operating cost and poor treatment effect of high-protein wastewater, and achieve the effects of low operating cost, prominent substantive features, and convenient management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

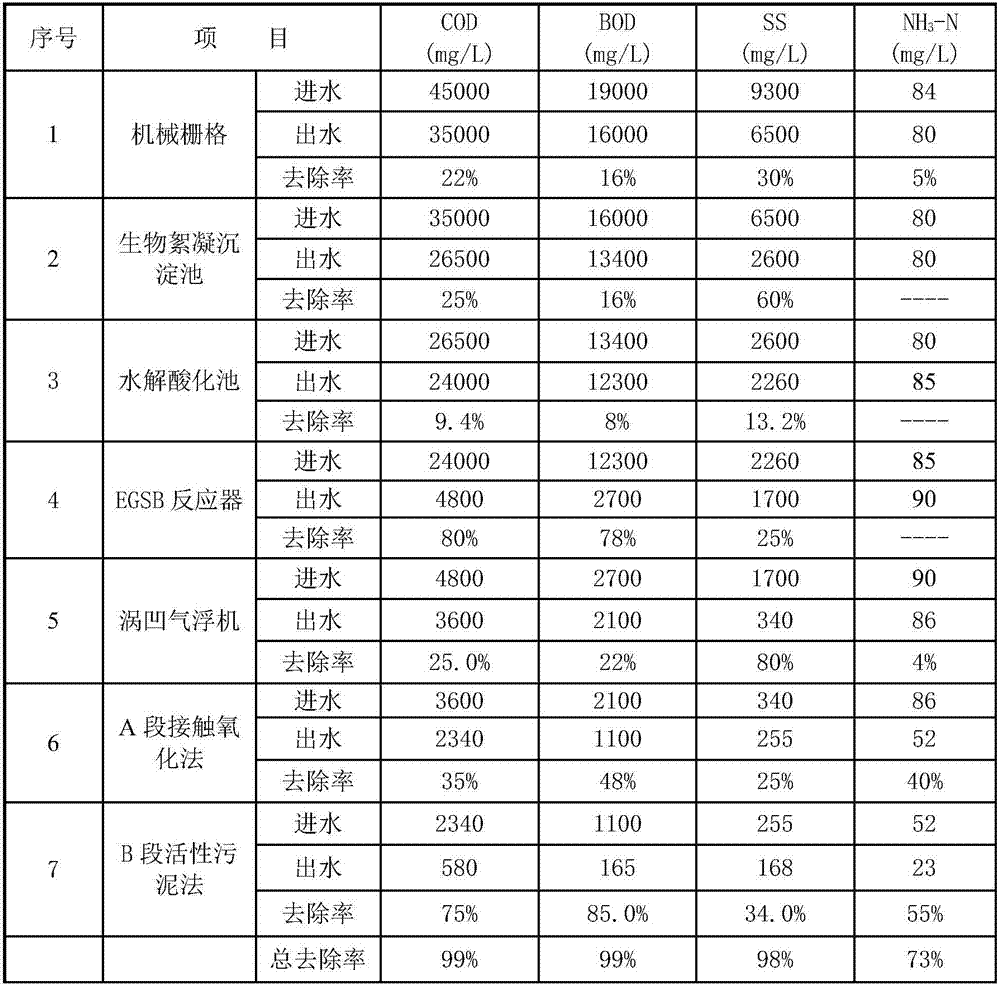

Embodiment 1

[0042] A high-protein wastewater treatment process includes the following steps:

[0043] Step (1) Waste water passes through a mechanical grid to remove floating objects with a diameter of more than 3mm, and then enter the next process;

[0044] Step (2) The wastewater enters the regulating tank, add lye to the regulating tank, and stir with a submersible mixer, and stop adding lye when the PH value in the regulating tank is 7 measured by the PH controller, and the wastewater stays in the regulating tank for 12 hours. Adjust the water quality and quantity, and then enter the next process;

[0045] Step (3) Add biological flocculant and common flocculant in the reaction tank at a ratio of 20:1, and the total amount of biological flocculant and common flocculant added is 1 / 20 of the water volume of the regulating pool, and the wastewater from the regulating pool is raised to The reaction tank, staying in the reaction tank for 0.5h, after being fully mixed with the flocculant, flows i...

Embodiment 2

[0060] A high-protein wastewater treatment process includes the following steps:

[0061] Step (1) Waste water passes through a mechanical grid to remove floating objects with a diameter of more than 3mm, and then enter the next process;

[0062] Step (2) The wastewater enters the regulating tank, add lye to the regulating tank, and stir with a submersible mixer. When the PH value in the regulating tank is measured by the PH controller, stop adding lye, and the wastewater stays in the regulating tank for 12 hours. Adjust the water quality and quantity, and then enter the next process;

[0063] Step (3) Add biological flocculant and common flocculant in the reaction tank at a ratio of 20:1, and the total amount of biological flocculant and common flocculant added is 1 / 20 of the water volume of the regulating pool, and the wastewater from the regulating pool is raised to The reaction tank, stay in the reaction tank for 0.5h, after fully mixing with the flocculant, flow into the floccu...

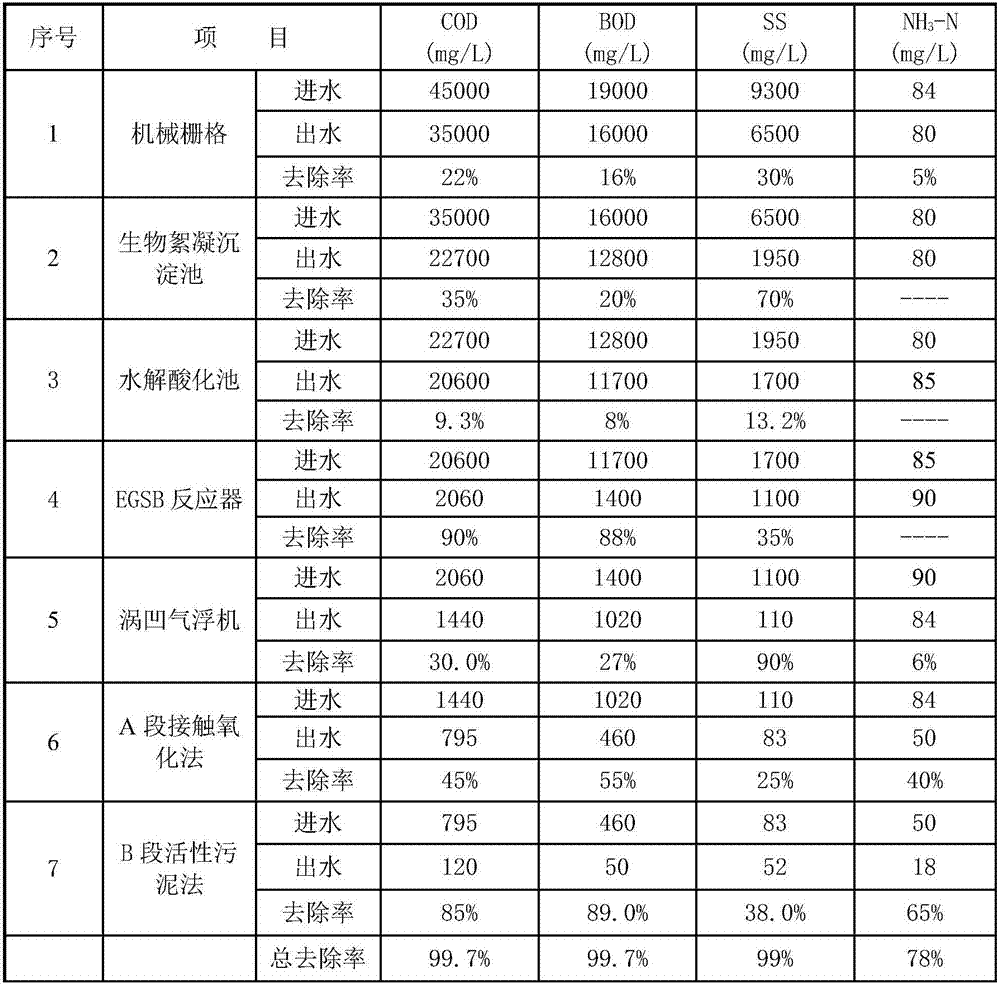

Embodiment 3

[0078] A high-protein wastewater treatment process includes the following steps:

[0079] Step (1) Waste water passes through a mechanical grid to remove floating objects with a diameter of more than 3mm, and then enter the next process;

[0080] Step (2) The wastewater enters the regulating tank, add lye to the regulating tank, and stir with a submersible mixer, and stop adding lye when the PH value in the regulating tank is 9 measured by the PH controller, and the wastewater stays in the regulating tank for 12 hours. Adjust the water quality and quantity, and then enter the next process;

[0081] Step (3) Add biological flocculant and common flocculant in the reaction tank at a ratio of 20:1, and the total amount of biological flocculant and common flocculant added is 1 / 20 of the water volume of the regulating pool, and the wastewater from the regulating pool is raised to The reaction tank stays in the reaction tank for 0.5h, after being fully mixed with the flocculant, enters the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com