Integral process for washing and filtering terephthalic acid and water recovery

A technology of terephthalic acid and washing water, applied in the separation/purification of carboxylic acid compounds, organic chemistry, etc., can solve the problems of long process flow, many redundant operations, increased load of centrifuges, etc., to improve the quality of washing , High operability, the effect of reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

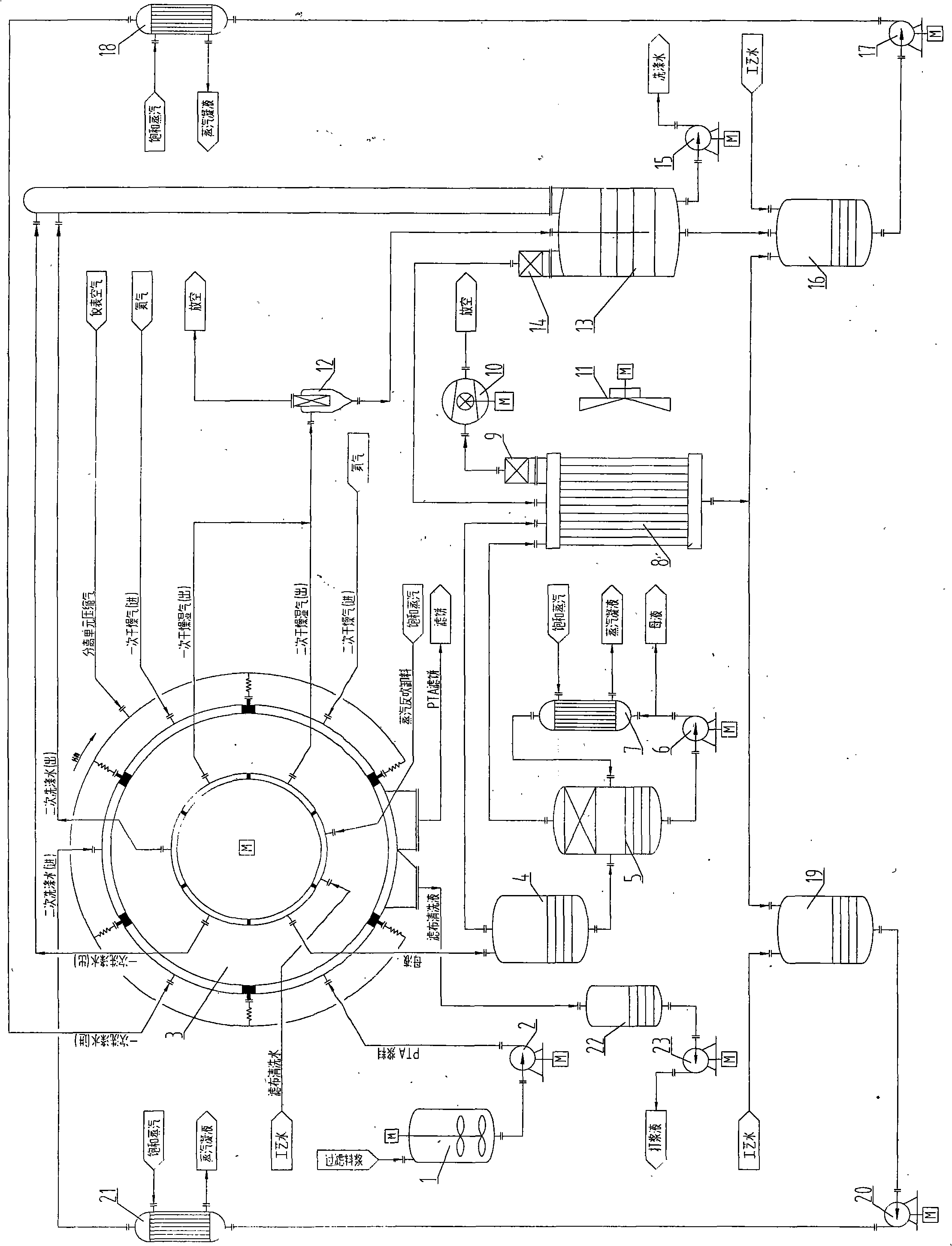

[0025] Attached below figure 1 The process flow of the "filtration and washing" process of terephthalic acid (PTA) suspension and the process of "water recovery after filtration and washing" are as follows:

[0026] A terephthalic acid (PTA) washing filtration and water recovery integrated process, its step is carried out in two steps:

[0027] ① "Filtration and washing" of PTA suspension

[0028] The PTA suspension from the PTA slurry tank 1 with a temperature of 100-150°C and a pressure of 0.3-0.5MPa(G) is pressurized by the PTA slurry pump 2 and enters the filter unit of the pressure filter 3. The pressure filter 3 uses frequency conversion The way of speed regulation is to do centripetal rotation. The annular area between the drum and the shell is sealed by packing, and is divided into different airtight cavities by spacers, and 0.4-0.6MPa(G) nitrogen gas is introduced into the airtight cavities to make the pressure filter 3 in a pressurized state . The filtrate tube o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com