Sludge dewatering device

A sludge dewatering and sludge technology, which is applied in dewatering/drying/concentrating sludge treatment, combustion methods, lighting and heating equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

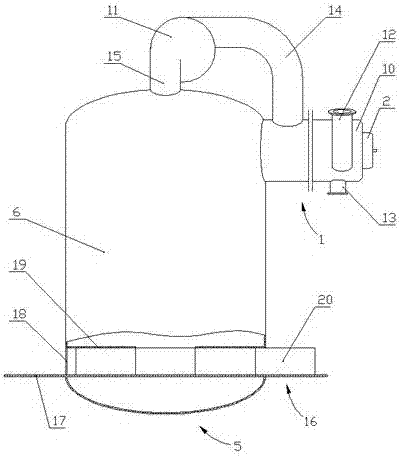

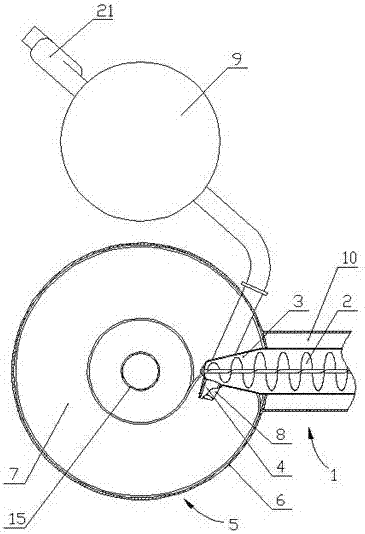

[0020] like Figure 1-2 As shown, this embodiment is a sludge dewatering device, including a conveying mechanism 1, and the conveying mechanism 1 includes an auger 2. The diameter of the end of the auger 2 is gradually reduced to form an extruding part 3, and the end of the extruding part 3 is arranged There are sludge nozzles4.

[0021] The conveying mechanism 1 is connected with a sludge rolling mechanism 5. The sludge rolling mechanism 5 includes a cylindrical shell 6. The extruding part 3 extends into the inside of the shell 6. The projection of the axis of the sludge nozzle 4 is located on the projection of the shell 6. on the eccentric chord; the inside of the housing 6 is provided with a spiral slideway 7, and the top of the spiral slideway 7 is located below the sludge nozzle 4 and close to the sludge nozzle 4.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com