Washing machine with function of automatic release of additives and method

An automatic feeding and additive technology, applied in the field of washing machines, can solve the problems of inability to guarantee the sealing, increase the manufacturing cost, affect the use effect of detergents, etc., so as to avoid poor washing effect, avoid clogging of the metering device, and improve the convenience of feeding. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

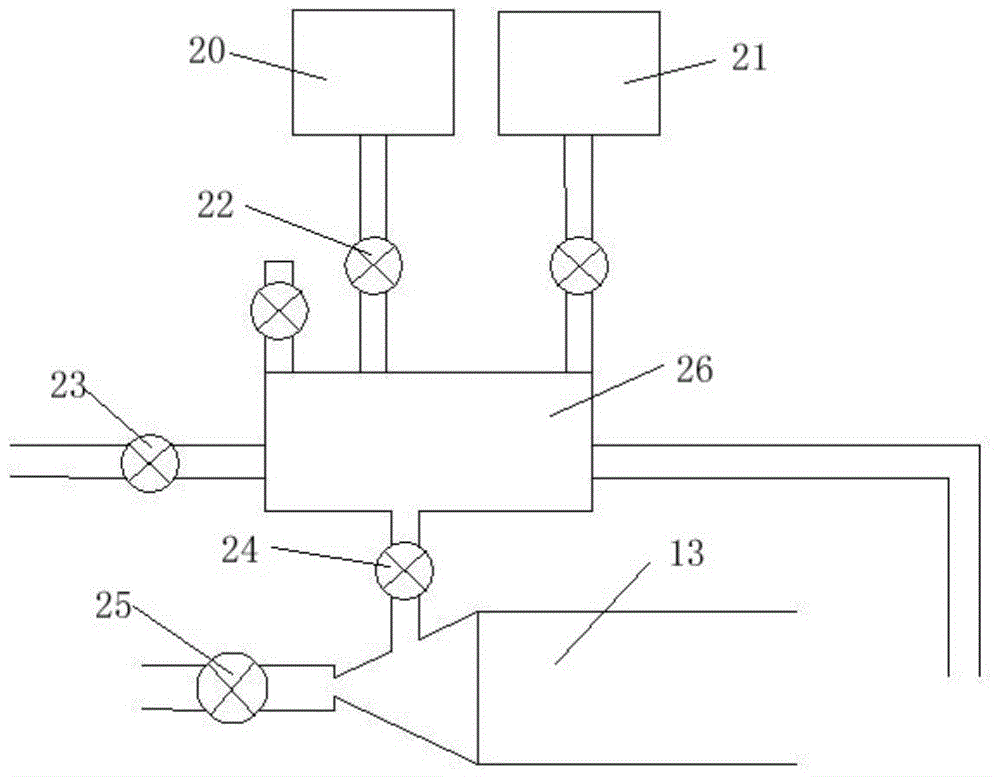

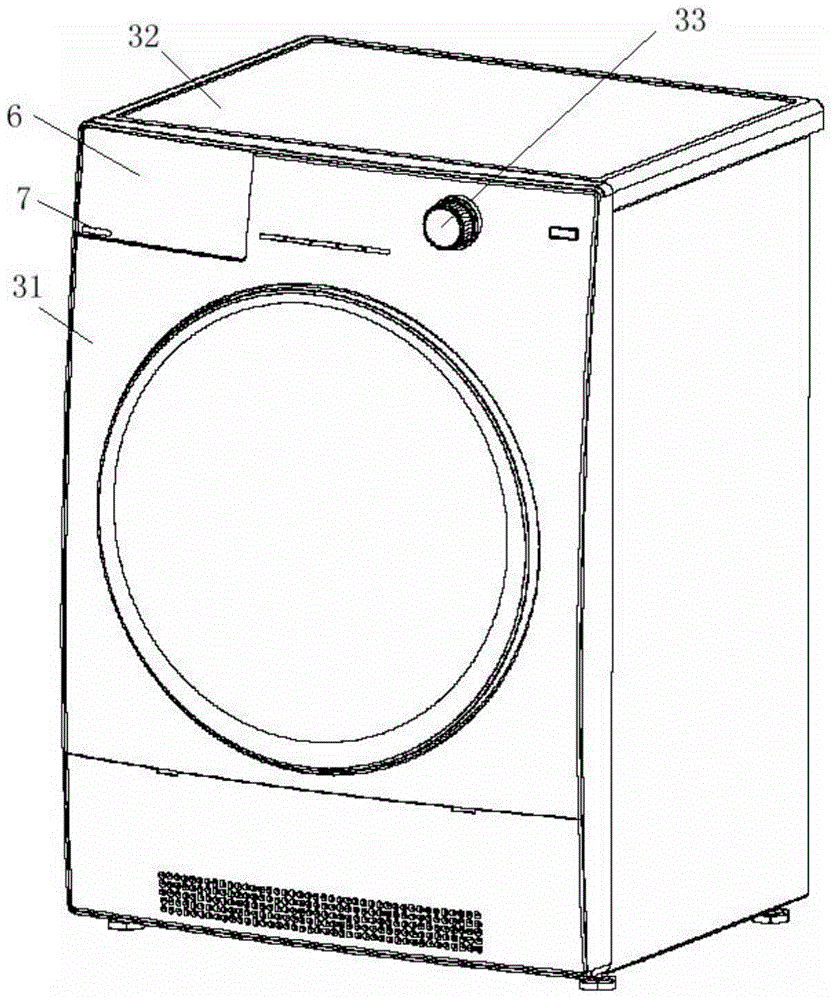

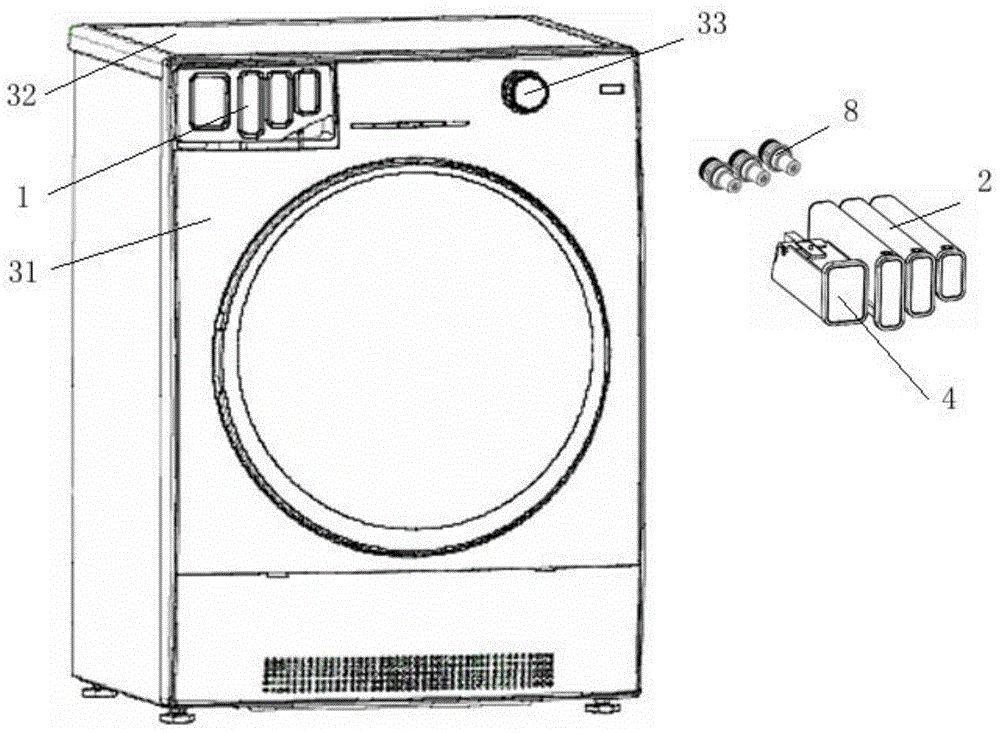

[0035] Such as figure 2 , image 3As shown, a washing machine for automatically injecting additives according to the present invention includes an additive automatic injecting device and an additive storage box 2 for containing liquid additives. The additive storage box is an independently sealed ink cartridge structure, and the washing machine shell At least one opening 1 is provided on the top, and the additive containing boxes 2 are arranged in the opening 1 in a one-to-one push-pull manner, and are connected / disconnected with the automatic additive injection device.

[0036] Preferably, the additive holding box 2 is a regular cylindrical chamber, and is provided with a liquid outlet 3. The additive holding box 2 is of a push-and-open type, and the liquid outlet 3 is provided with a pressure opening and closing valve. Flick the switch, when the additive holding box 2 is fully pushed into the opening, the pressure opening and closing valve opens, the liquid outlet communic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com