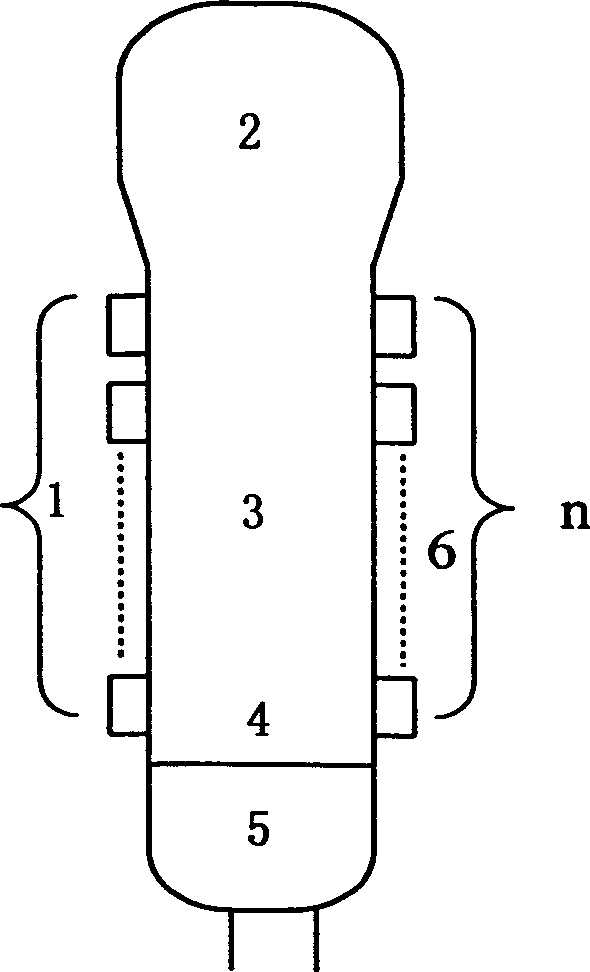

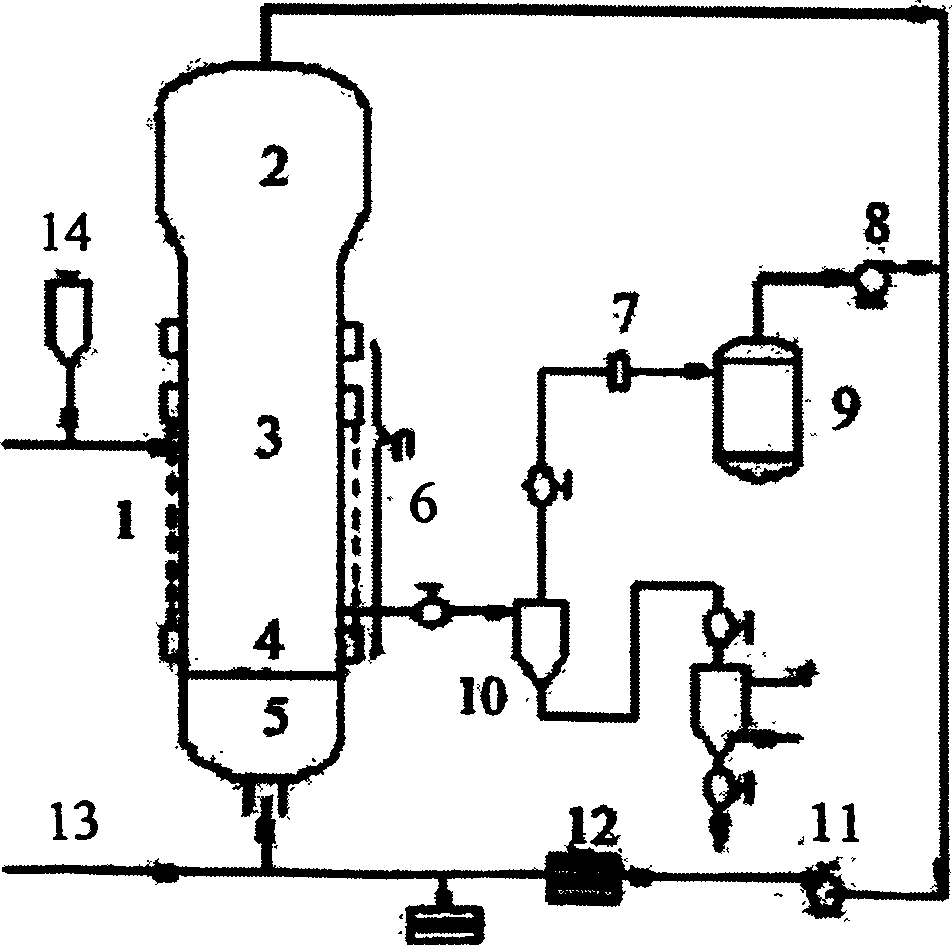

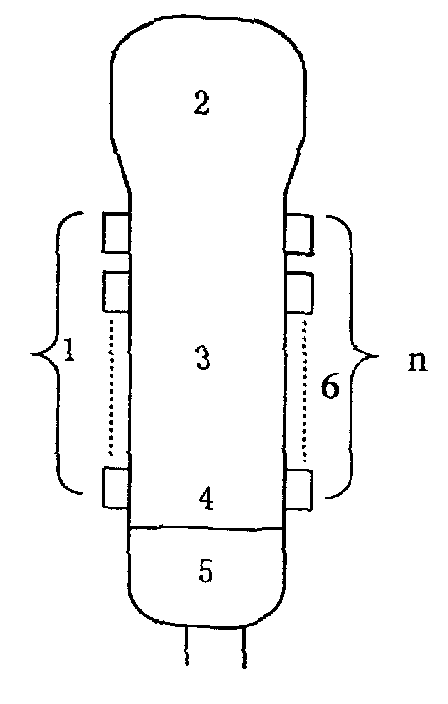

Condensation and cooling combined gas-phase fluidized-bed polymerization method and apparatus

A technology of gas-phase fluidized bed and polymerization method, which is applied in the field of gas-phase ethylene polymerization fluidized bed reactor to achieve high yield, and can solve the problems of hindering the fluidization of resin powder, uneven temperature distribution, and inconvenient maintenance of equipment, etc. problems, to achieve the effect of improving the heat removal capacity, increasing the expansion margin, and reducing the degassing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0023] Under the conditions of conventional high-activity Z-N catalyst, the polymerization of ethylene and butene is carried out, the polymerization pressure is 2.069MPa, the polymerization temperature is 88°C, the space-time yield of the reactor is 100kgPE / hr·m3, and the linear low-density polyethylene resin is produced. Suppose the target production intensity of the reactor is 200% of the design value, STY=200kg / m3hr. It is found that under the condition of a certain amount of heat dissipation (i.e. 200% load), the amount of condensate (hexane and isopentane) required for the production of conventional condensation is 0.075 and 0.060, respectively, and the required condensate is produced by composite technology. The amount of liquid (hexane and isopentane) is 0.047 and 0.018 respectively, and the concentration of isopentane (or normal hexane) in the recycle gas can be reduced by 50%. It can be seen that the required condensate (hexane and isopentane) is produced by composite ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com