Refrigeration device

A refrigeration device and cooling capacity technology, which is applied to household refrigeration devices, cooling fluid circulation devices, refrigerators, etc., and can solve problems such as energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

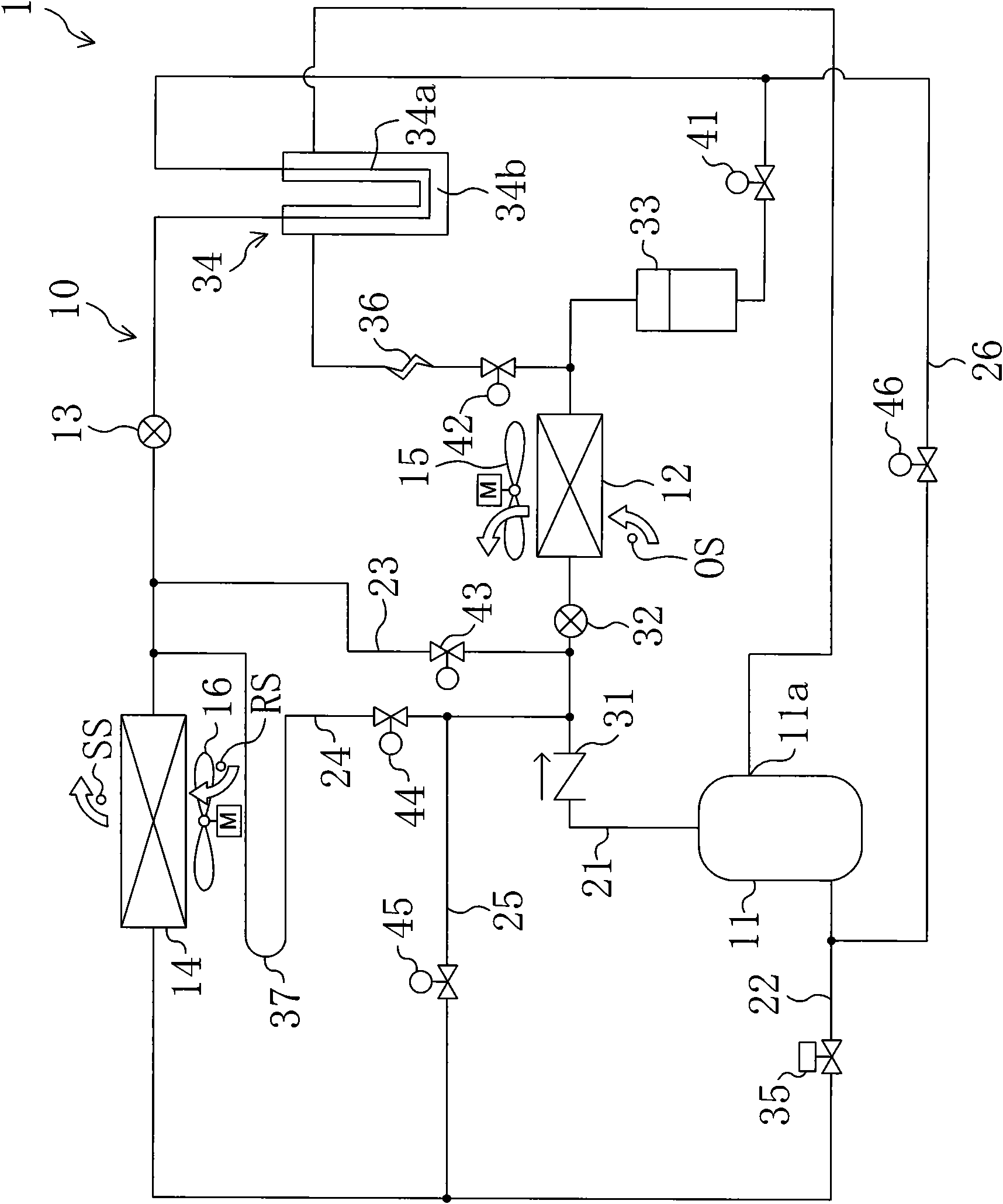

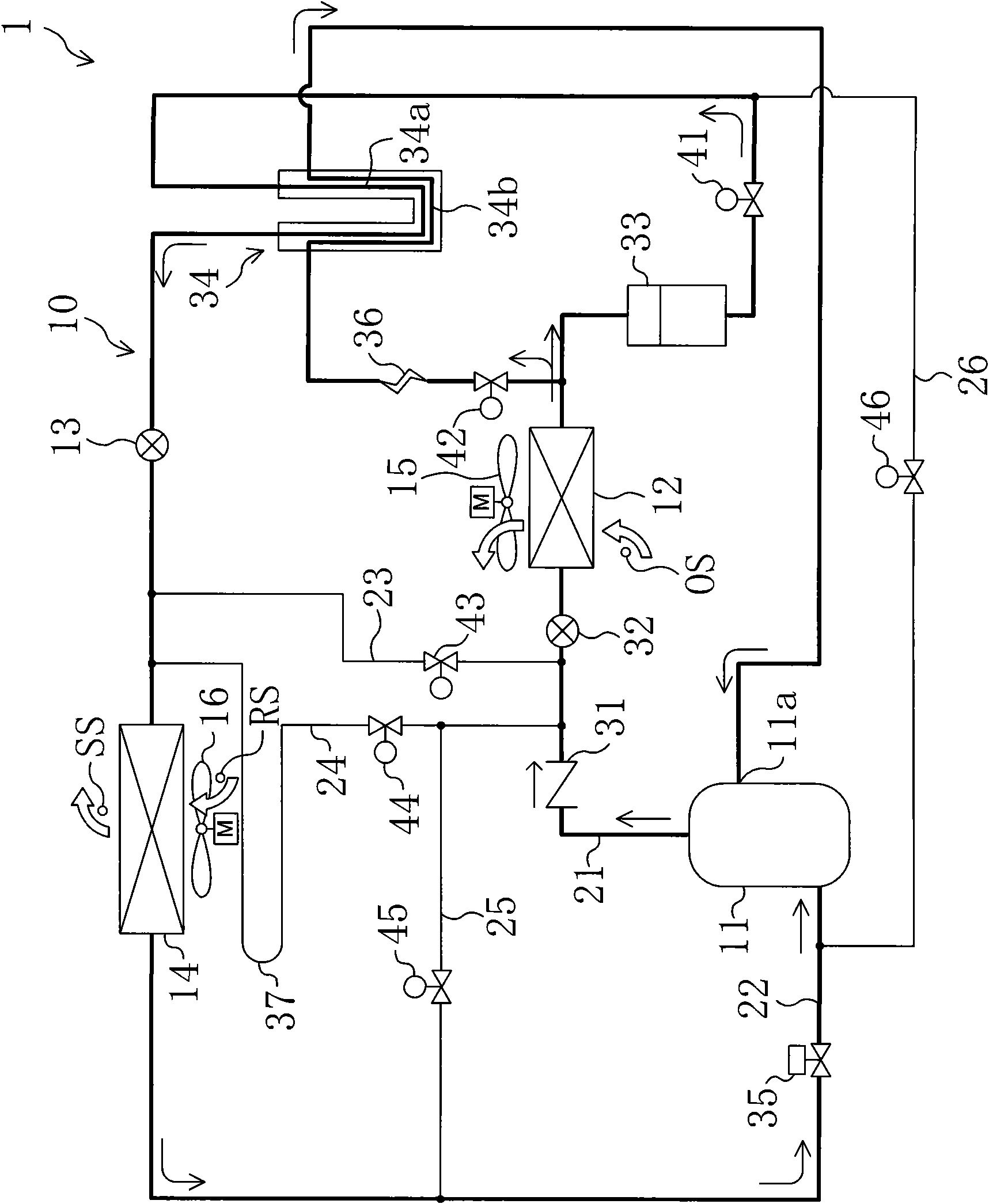

A first embodiment of the present invention will be described. Such as figure 1 As shown, the refrigeration apparatus 1 of this embodiment is an apparatus which cools the interior of the container used for sea transportation etc. FIG. This refrigerating apparatus 1 includes a refrigerant circuit 10 , an external fan 15 , and an internal fan 16 , and the refrigerant circuit 10 circulates a refrigerant to perform a vapor compression refrigeration cycle.

[0049] In the refrigerant circuit 10, a compressor 11, a condenser 12, an expansion valve 13, and an evaporator 14 are provided as main components.

[0050] The compressor 11 is constituted by a fixed capacity type scroll compressor in which the rotation speed of a compressor motor is constant.

[0051] The condenser 12 is arranged outside the refrigerator, and constitutes a so-called air-cooled condenser. The outdoor fan 15 is provided near the condenser 12 . The outside fan 15 sends outside air (outside air) to the condens...

no. 2 approach

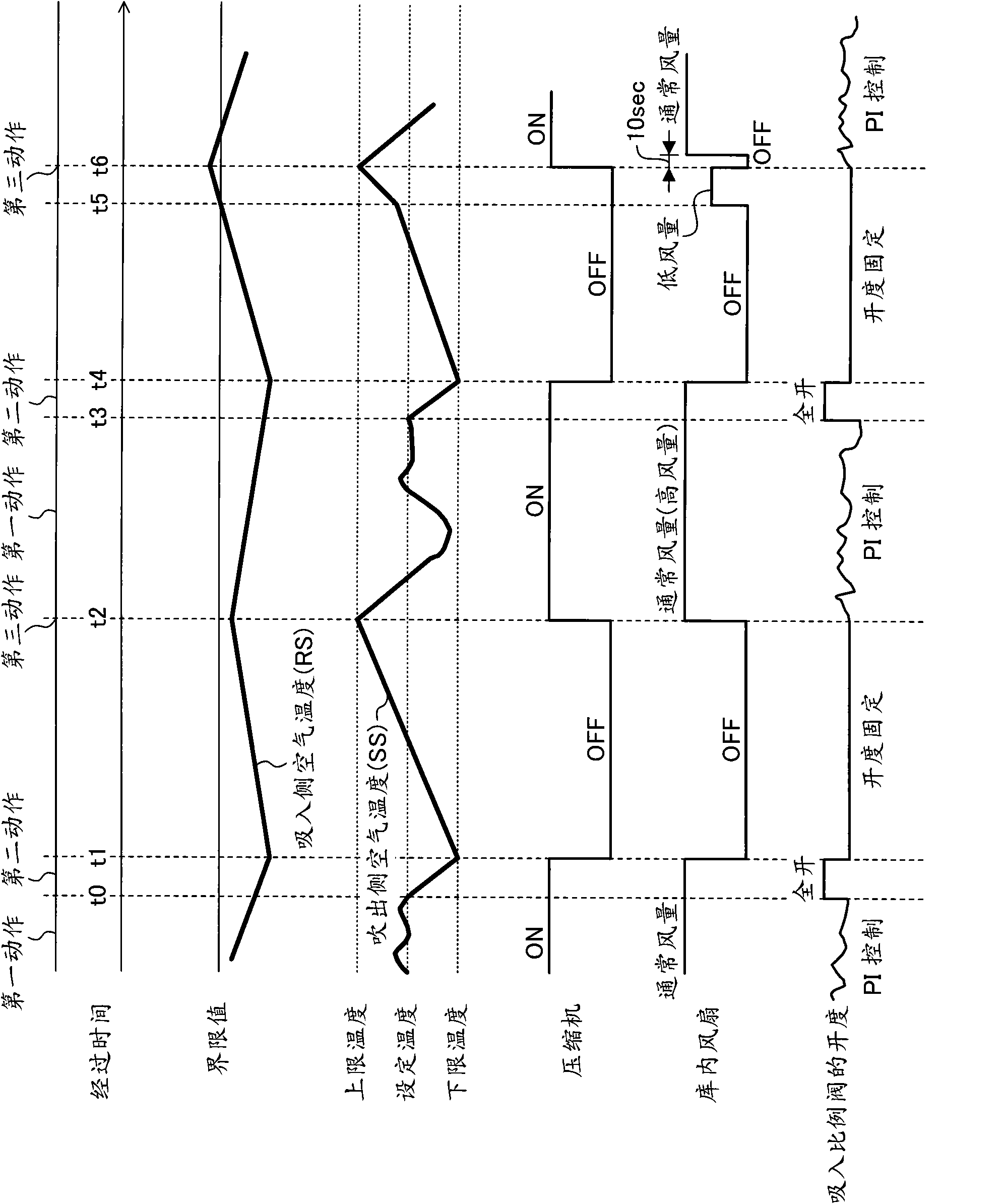

A second embodiment of the present invention will be described. Such as Figure 8 As shown, in the refrigerating apparatus 1 of the present embodiment, different lower limit temperatures of the outlet-side air temperature are set for the normal operation mode and the energy-saving operation mode in the first embodiment. In addition, points different from the first embodiment described above will be described here.

[0106] Specifically, in the normal operation mode of the present embodiment, the lower limit value of the target range of the outlet air temperature is set as the first lower limit temperature. On the other hand, in the energy-saving operation mode, the lower limit value of the target range of the outlet air temperature is set to a second lower limit temperature lower than the first lower limit temperature. That is, in the present embodiment, the lower limit value of the target range of the outlet air temperature in the energy-saving operation mode is made lower t...

no. 3 approach

A third embodiment of the present invention will be described. Although not shown, in the refrigeration system 1 of this embodiment, in the energy-saving operation mode of the first embodiment described above, the set temperature of the outlet air temperature is lowered every time a predetermined operation time elapses. In addition, at this time, the upper limit temperature and the lower limit temperature of the target range of the outlet air temperature do not change. In addition, points different from the first embodiment described above will be described here.

[0110] Specifically, the set temperature of the outlet-side air temperature is maintained at the initial value until a predetermined time (for example, one hour) elapses from the start of operation in the energy-saving operation mode. Then, when a predetermined time elapses from the start of the operation, the controller lowers the set temperature of the outlet air temperature by a certain amount (for example, 0.1° ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com