Patents

Literature

250results about "Refrigerators/freezers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

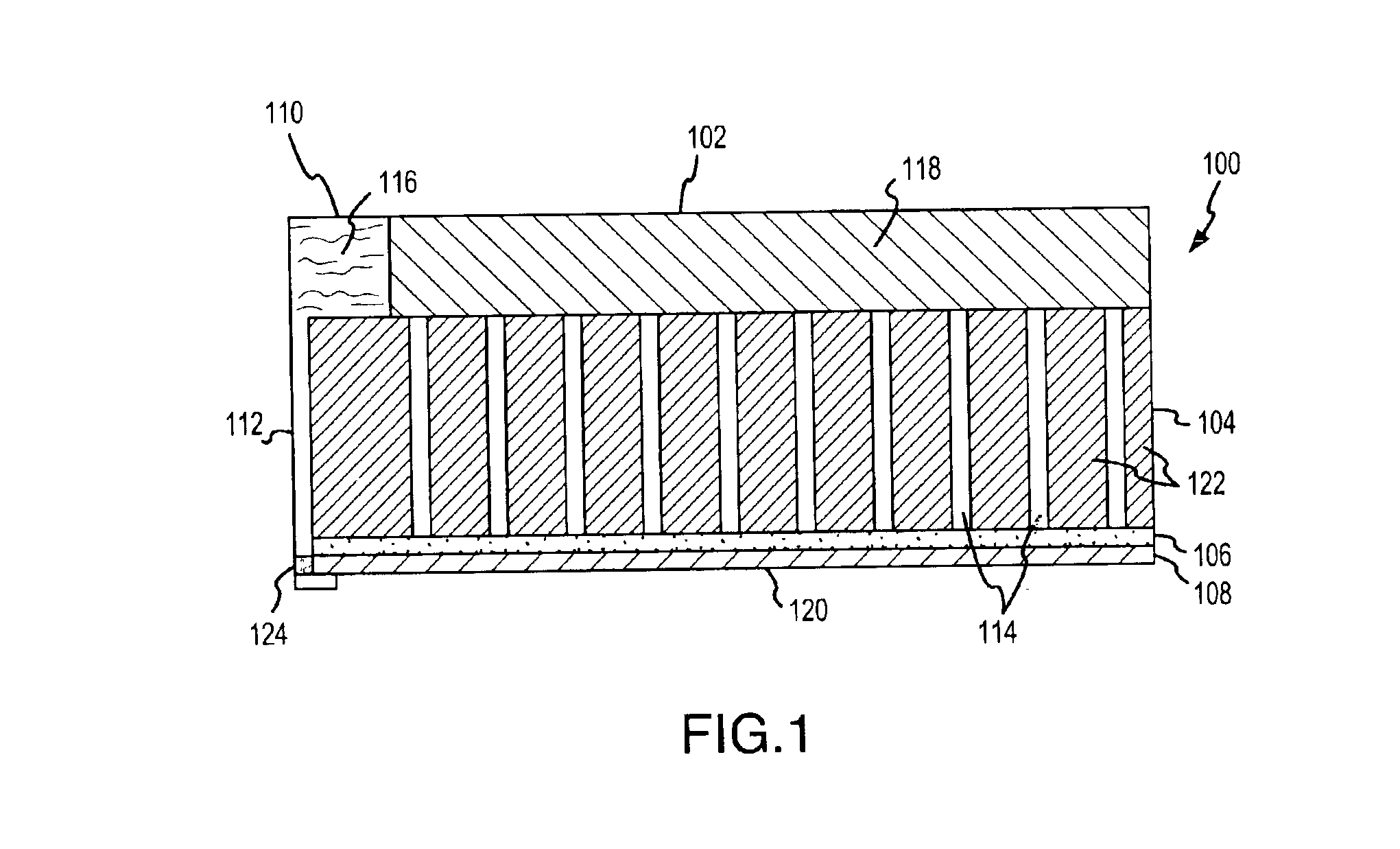

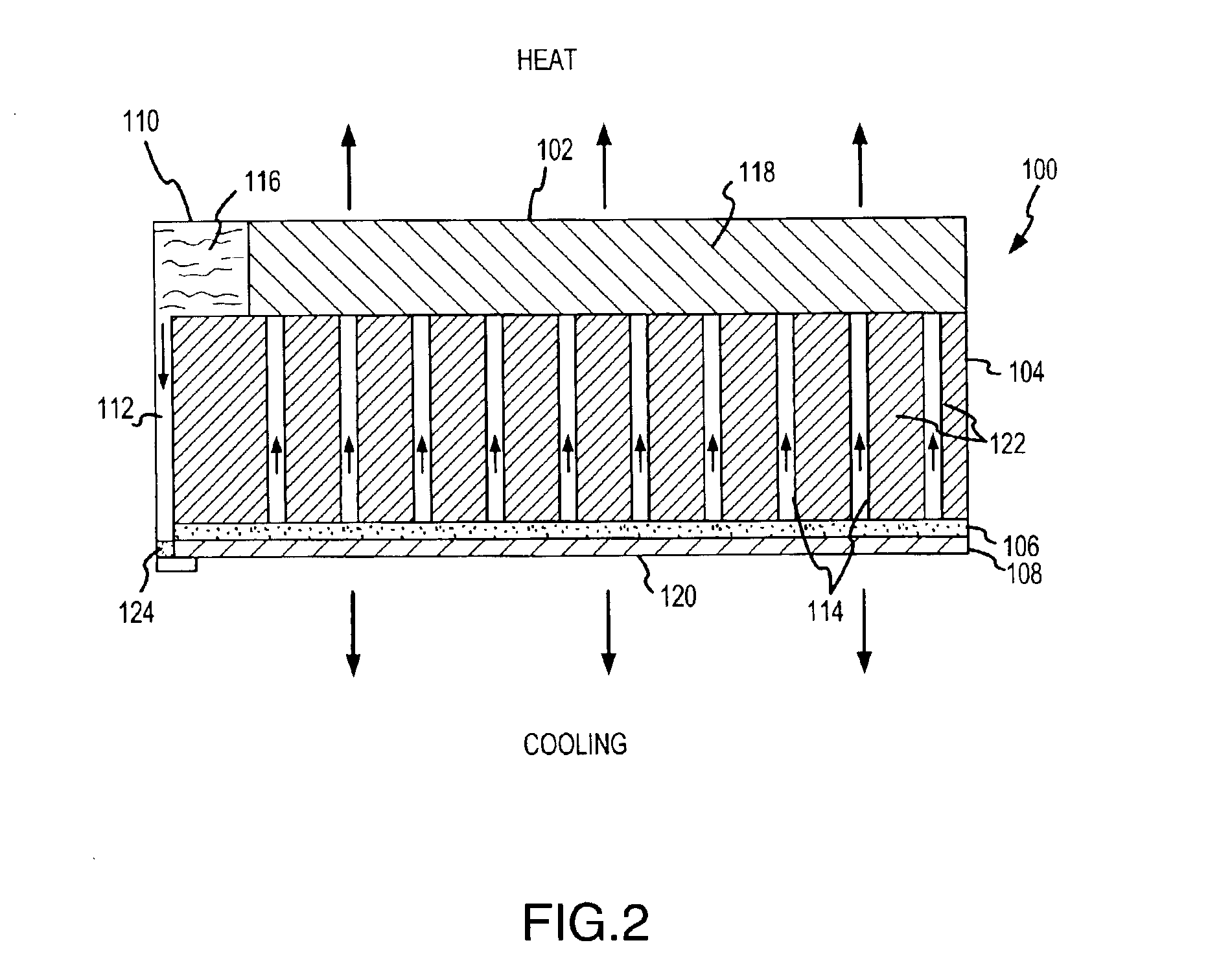

Vacuum insulation panel with smooth surface method for making and applications of same

InactiveUS20090179541A1Reduce roughnessUniform appearanceLighting and heating apparatusHollow inflatable ballsEngineeringRefrigeration

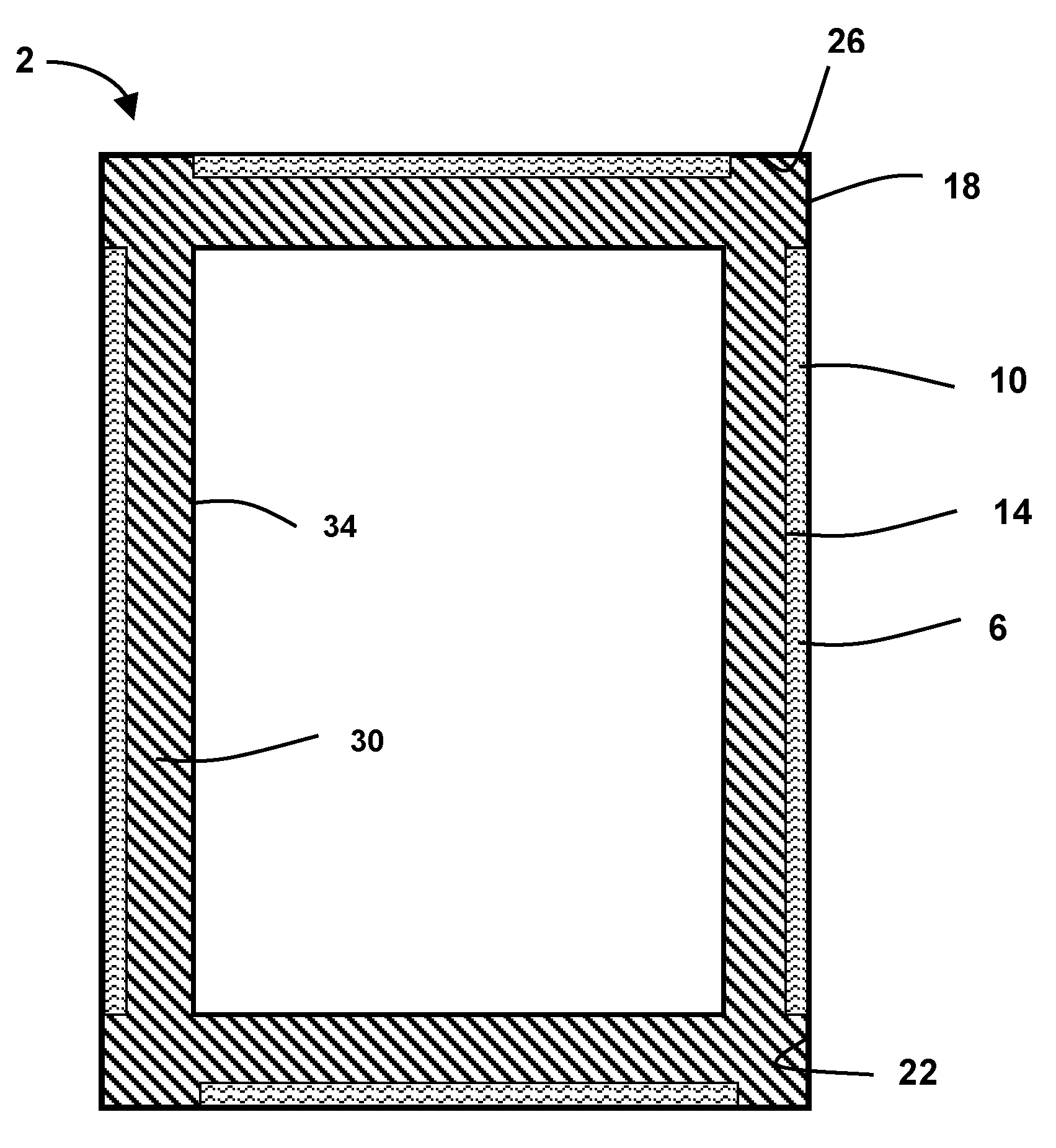

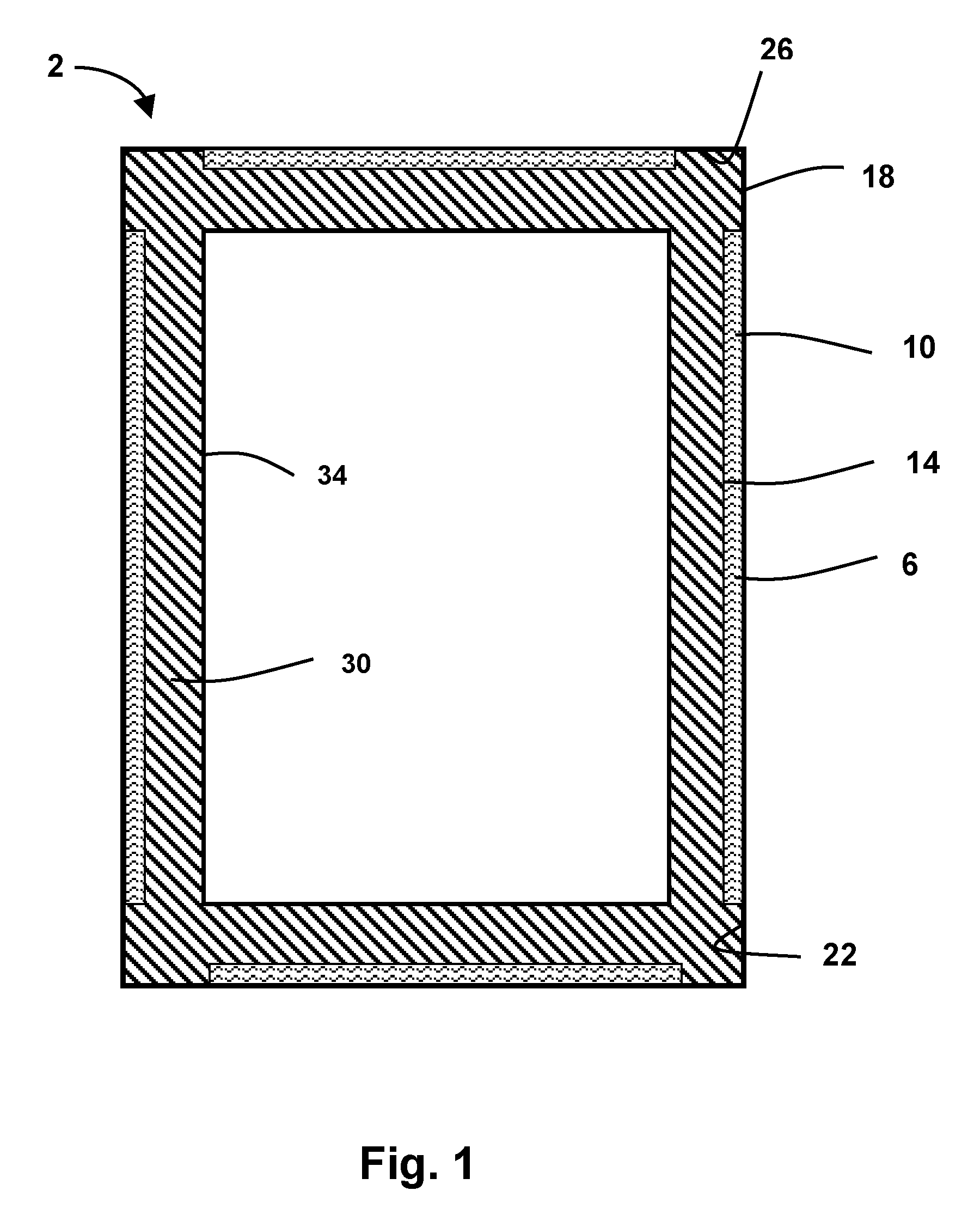

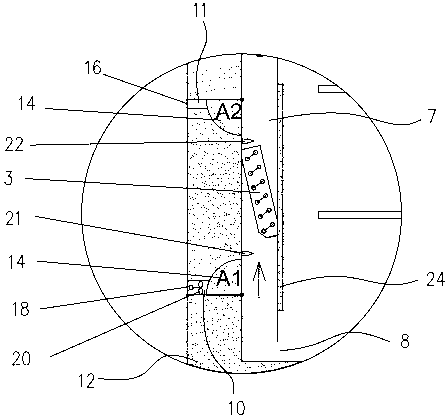

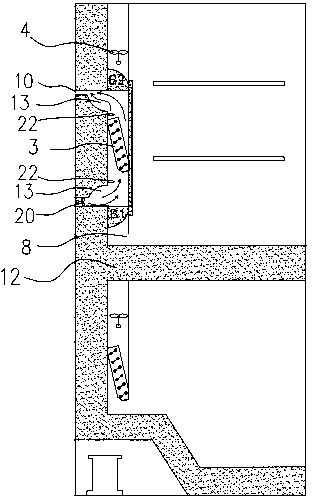

Vacuum insulation panels and methods for making vacuum insulation panels. The panels include first and second spaced-apart sidewalls, where at least one of the sidewalls has a very smooth surface. The panels are particularly useful as insulation in applications where a smooth and aesthetically acceptable surface is required, such as in a refrigeration appliance. A method for making a vacuum insulation panel can include placing an insulative core material and a liner within a barrier envelope defining an enclosure, evacuating the enclosure, and sealing the envelope to form the vacuum insulation panel.

Owner:NANOPORE INC

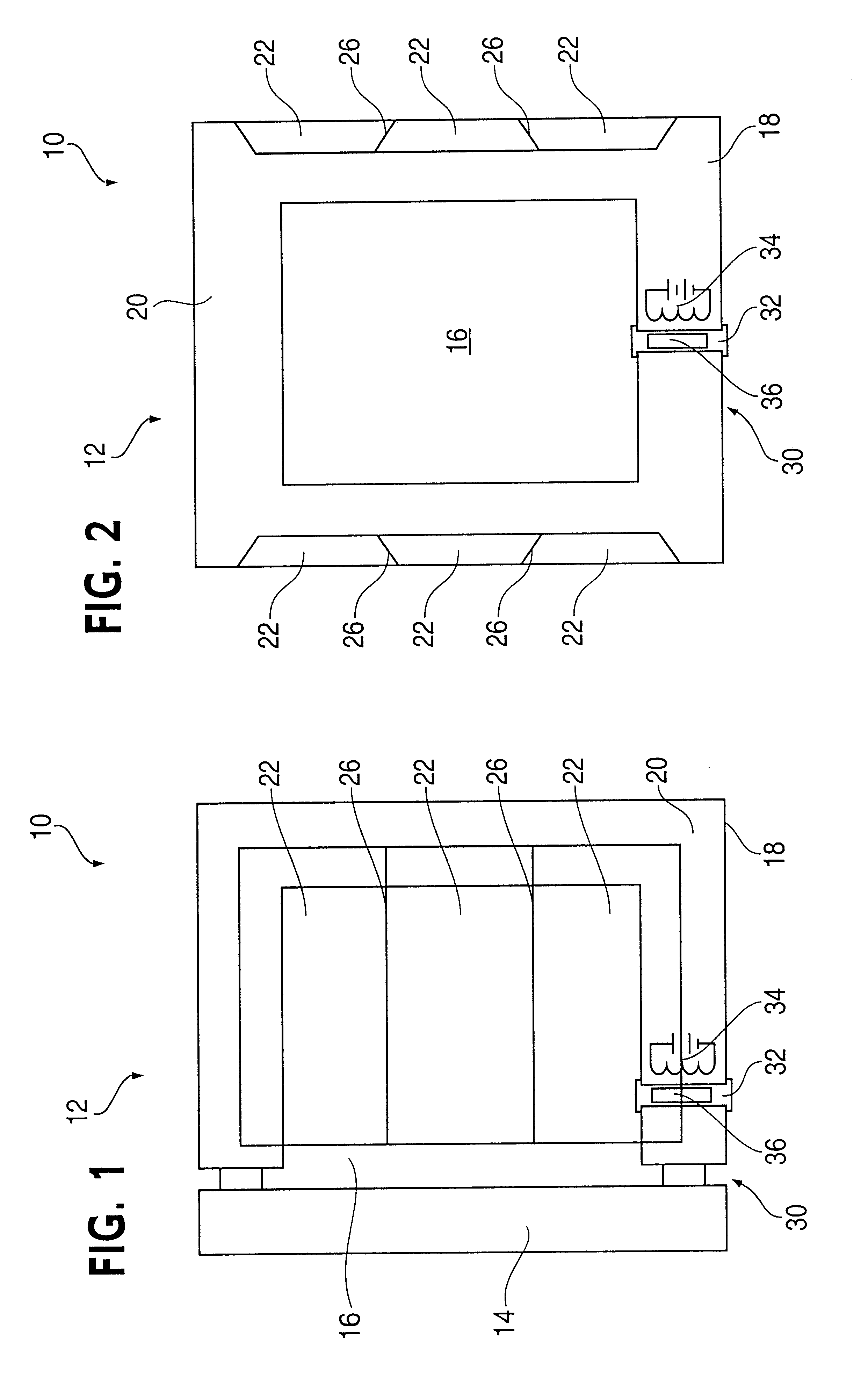

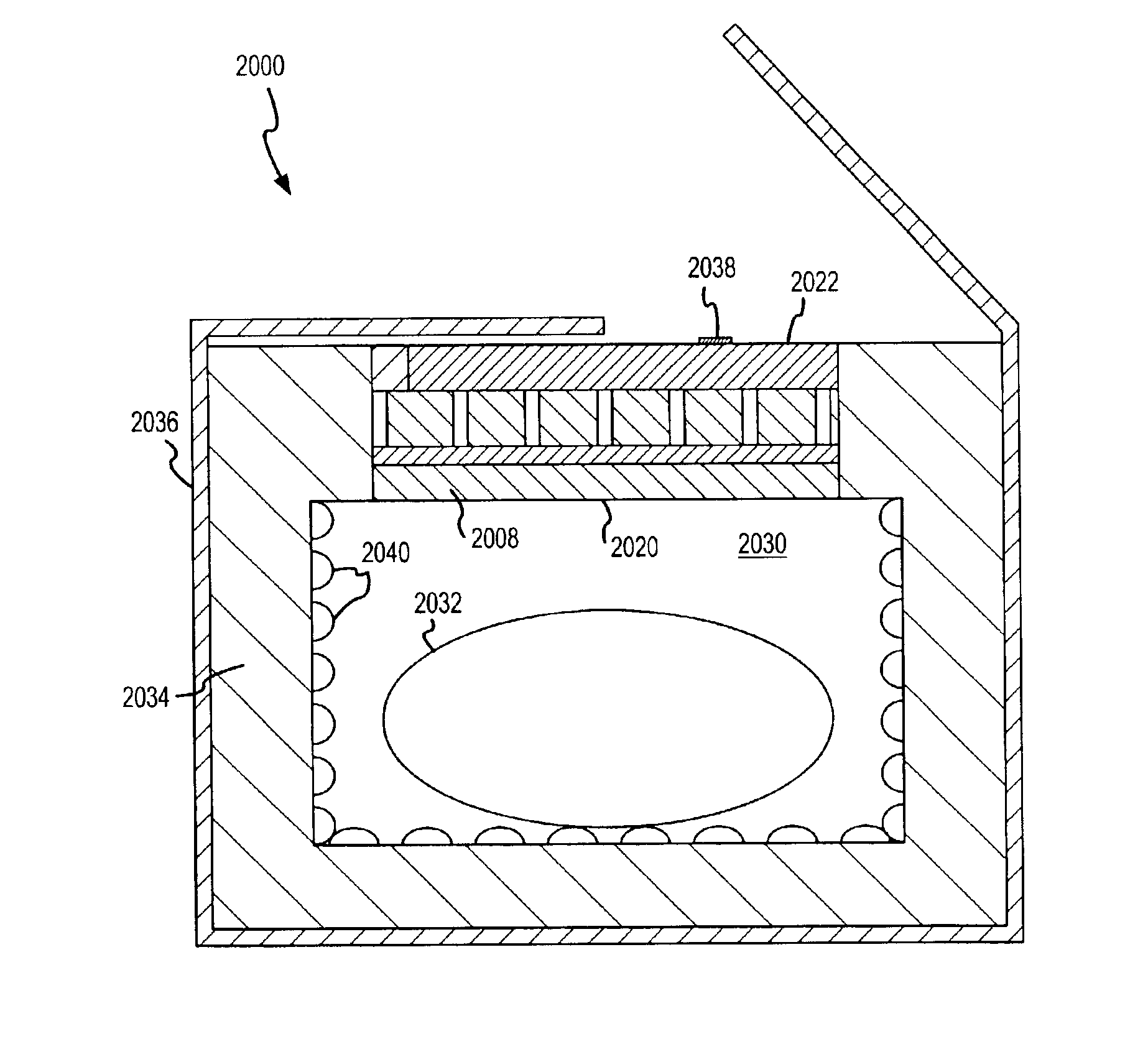

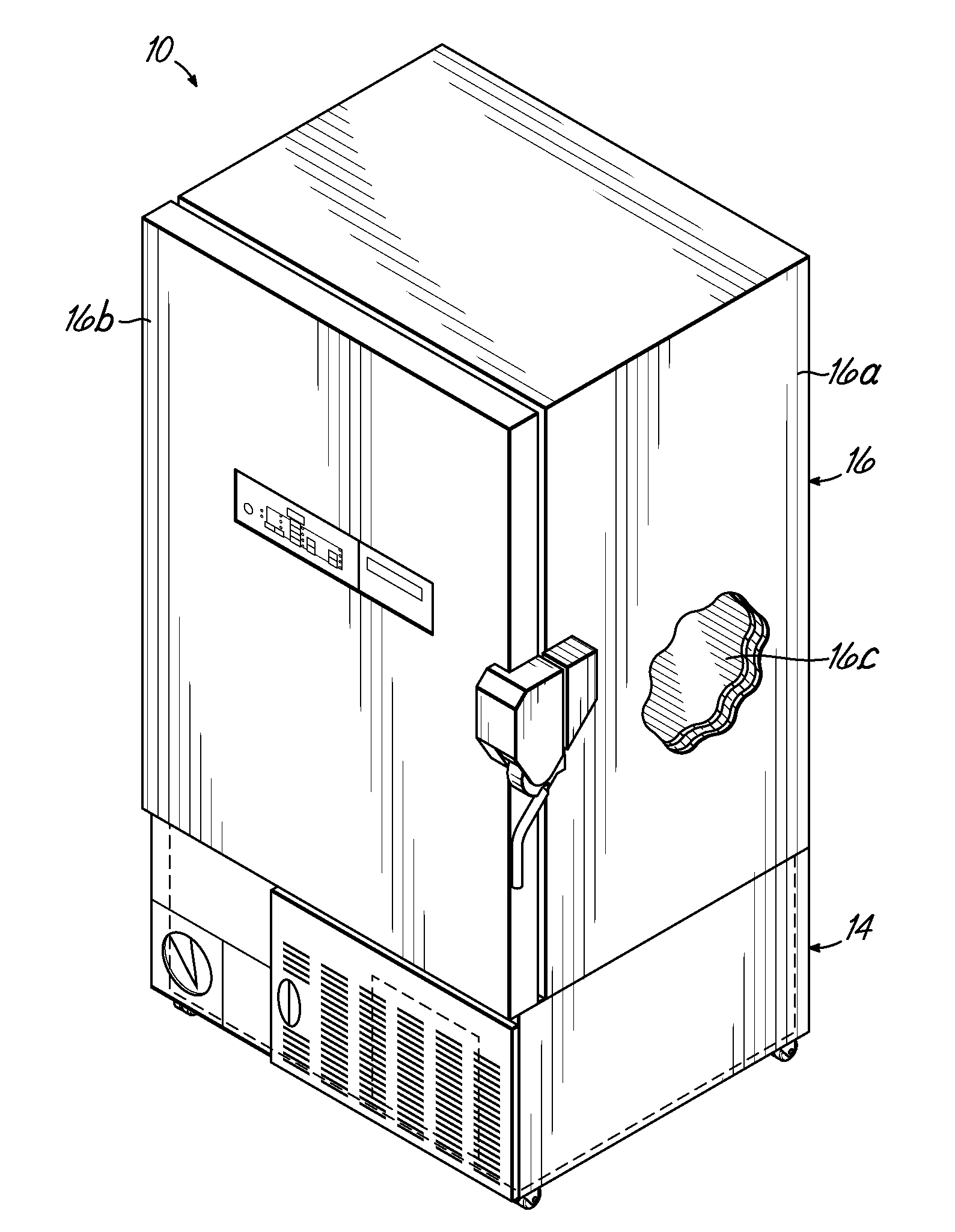

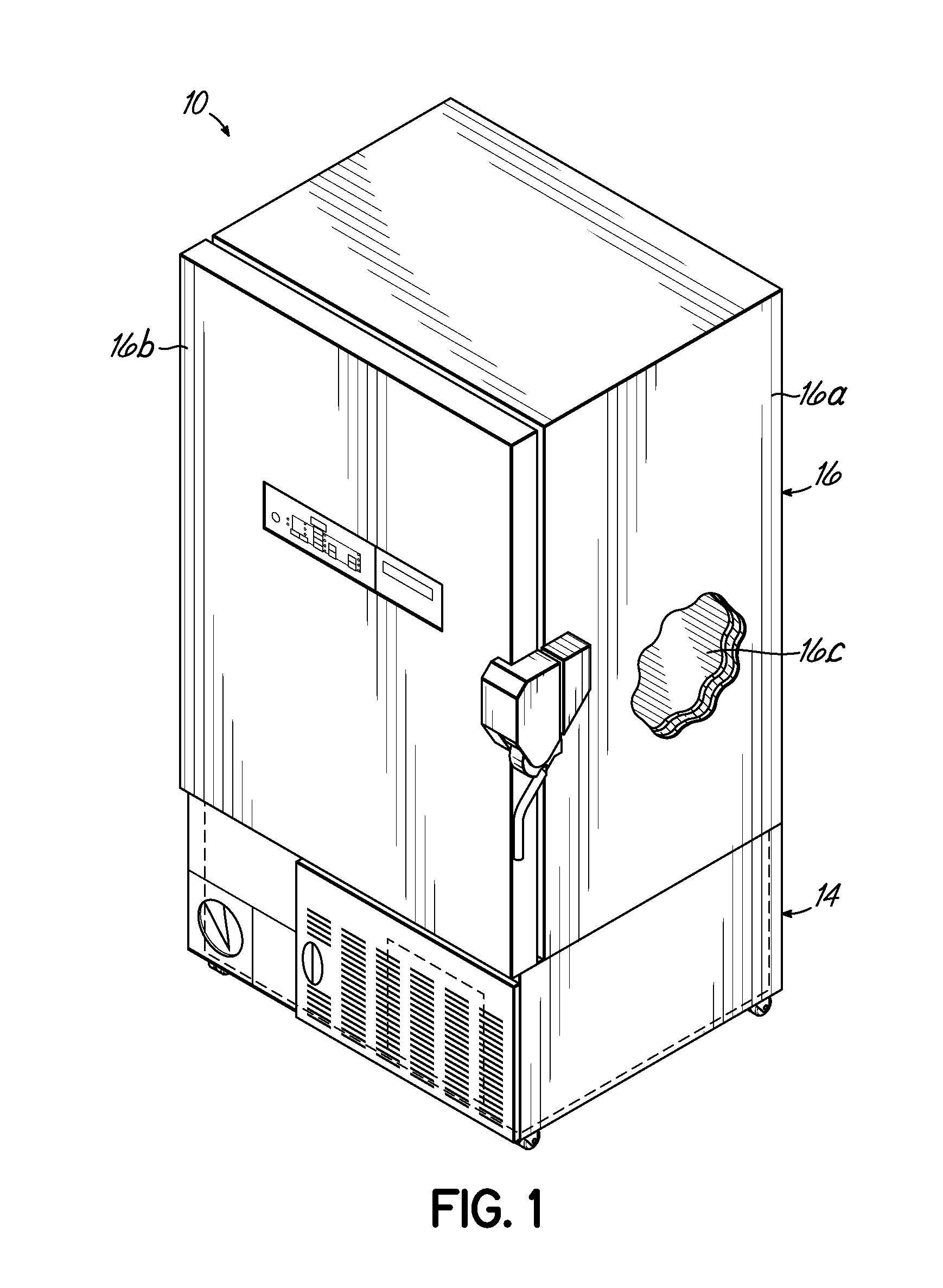

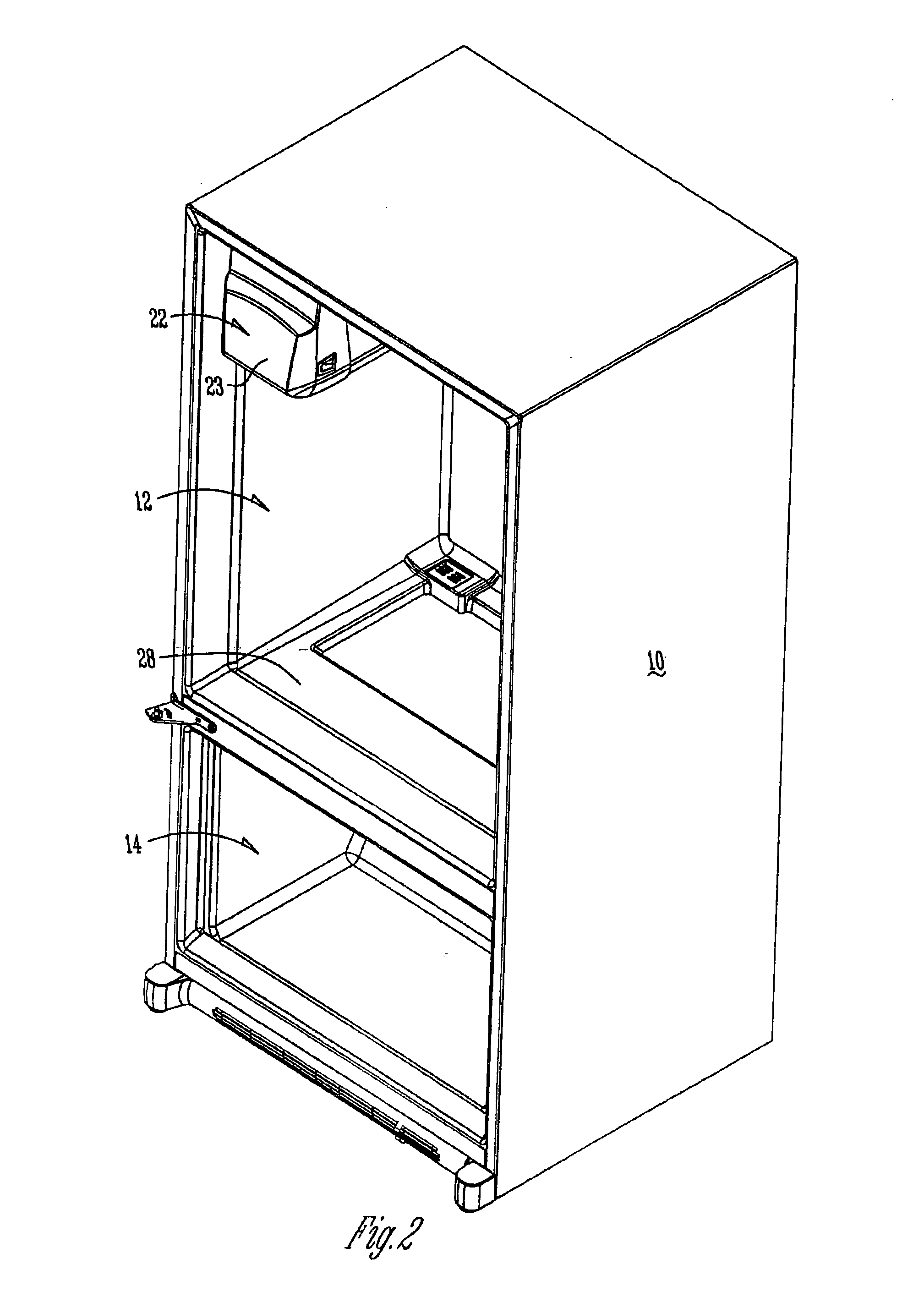

Ultra-low temperature freezer cabinet utilizing vacuum insulated panels

InactiveUS6397620B1Lighting and heating apparatusDomestic refrigeratorsUltra Low Temperature FreezerEngineering

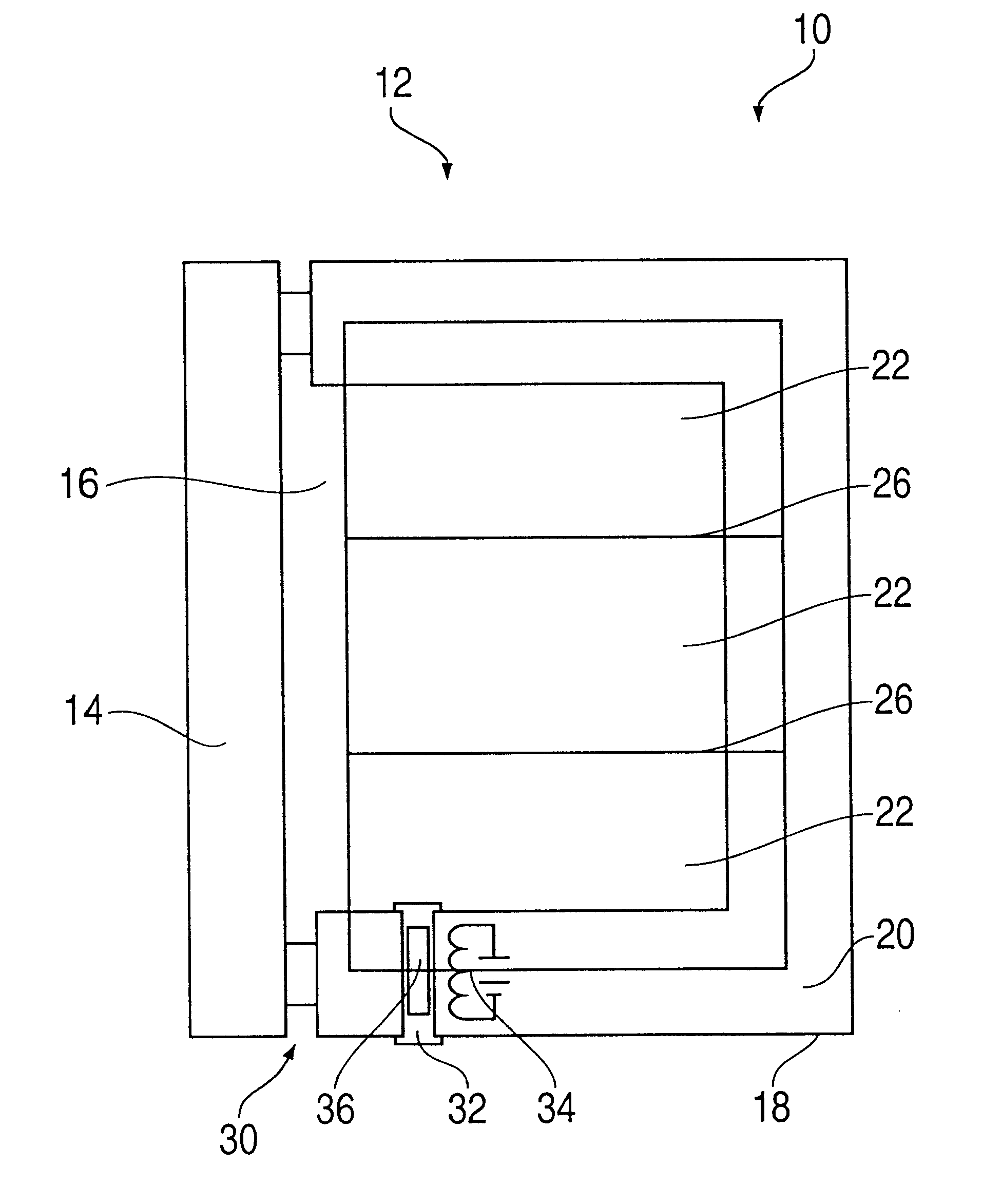

An ultra-low temperature refrigeration system (10) comprising a housing (12) and a door (14) which together define an interior storage compartment (16). The system (10) uses multiple layers (20,22) of varying insulative materials to insulate the housing (12), including conventional foam (20) and vacuum insulation panels (22), to balance cost, size, and capacity considerations. The vacuum insulation panels (22) are provided with beveled edges (26) or otherwise positively interfacing edges so as to overlap adjacent panels and present a more reliably insulative seam. The system (10) further includes a self-defrosting pressure equalization port (30) for automatically equalizing interior and exterior pressures.

Owner:SPX CORP +1

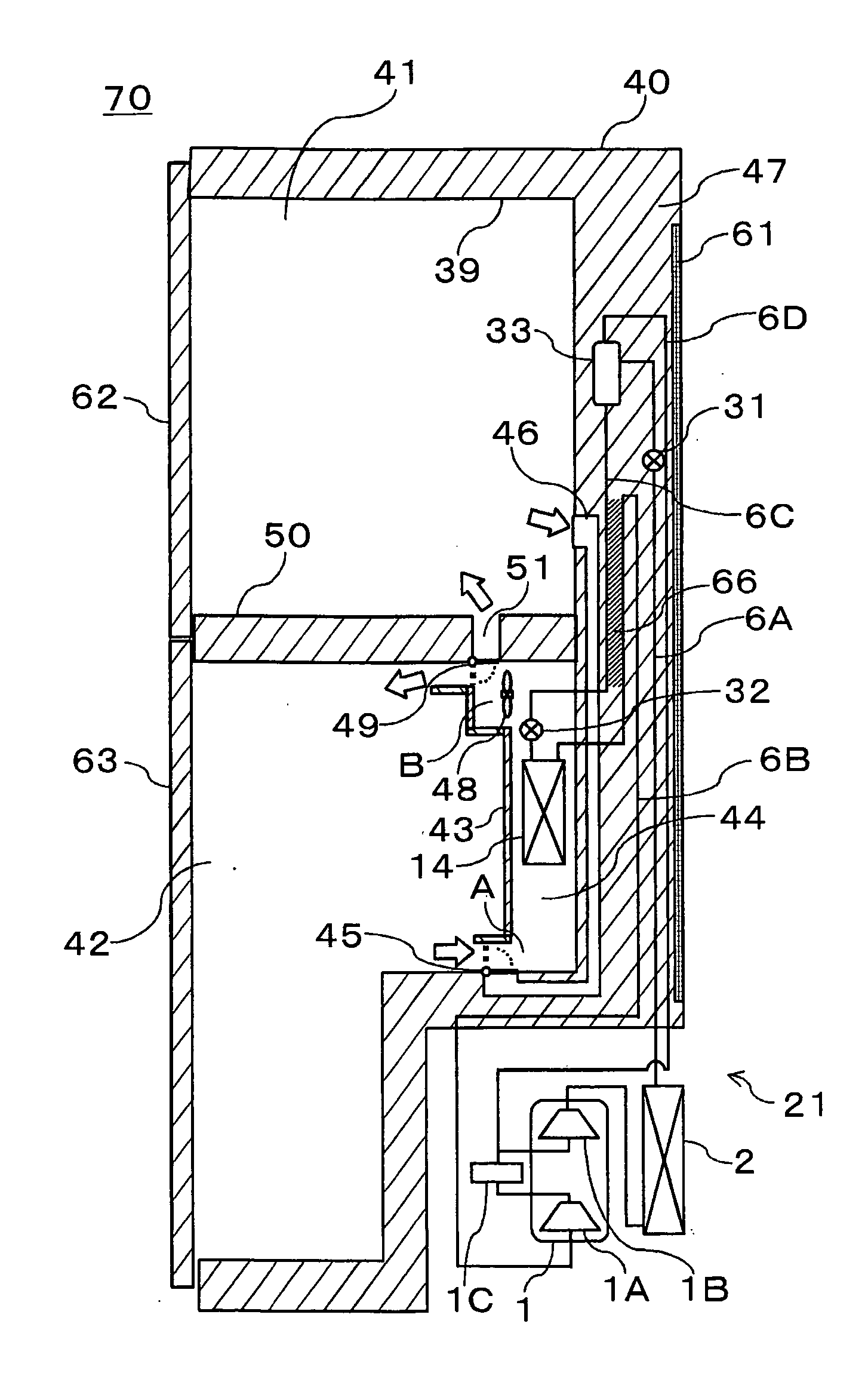

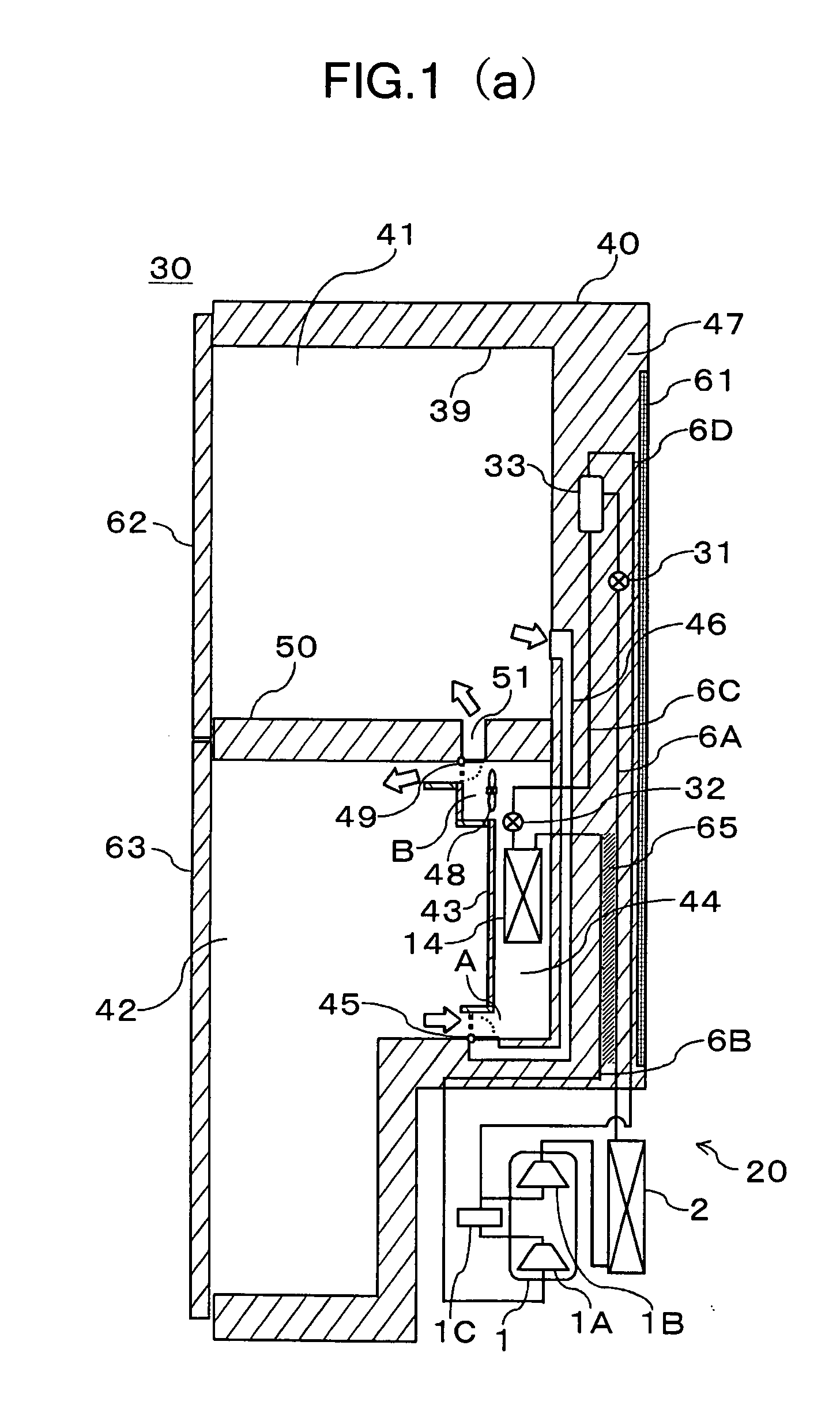

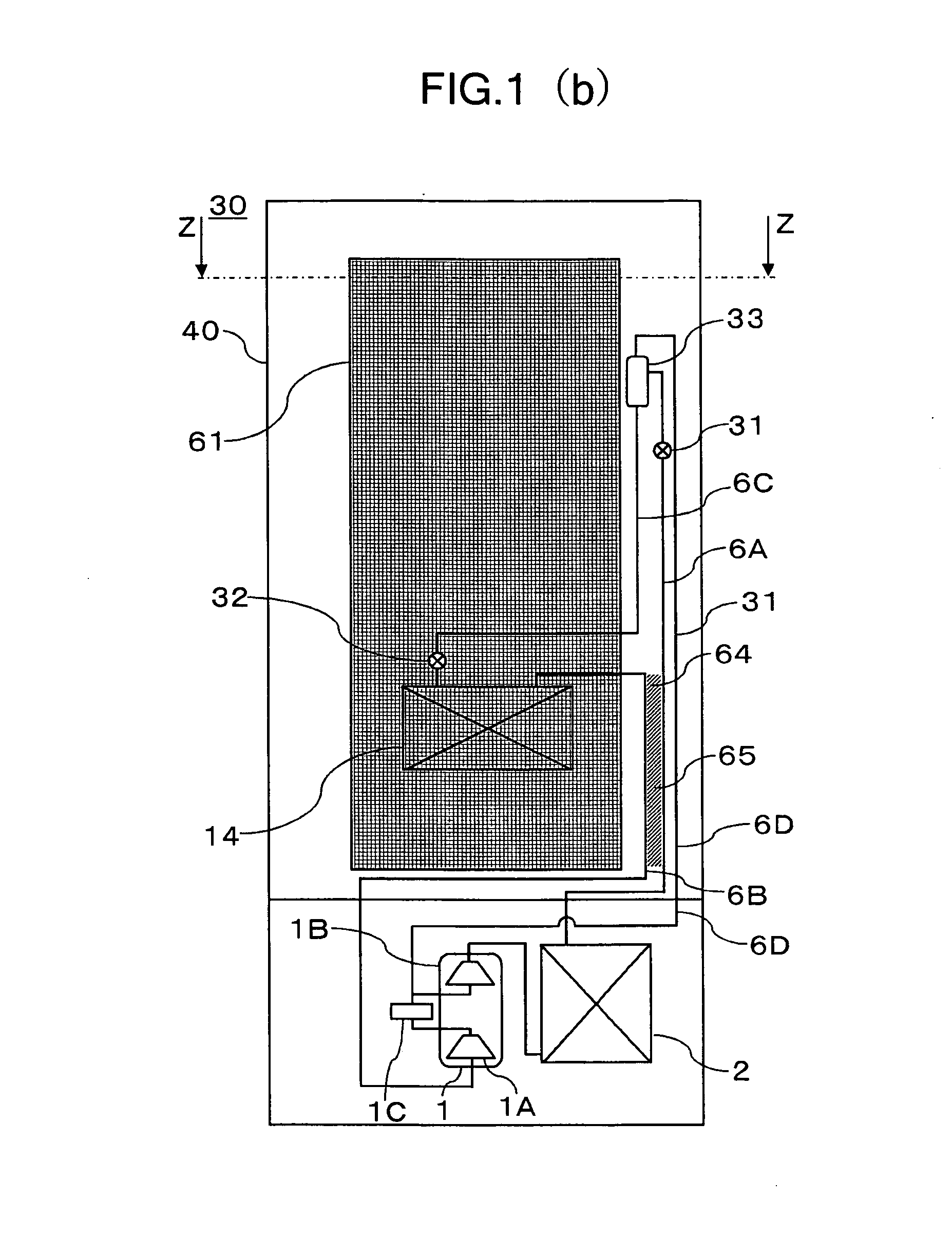

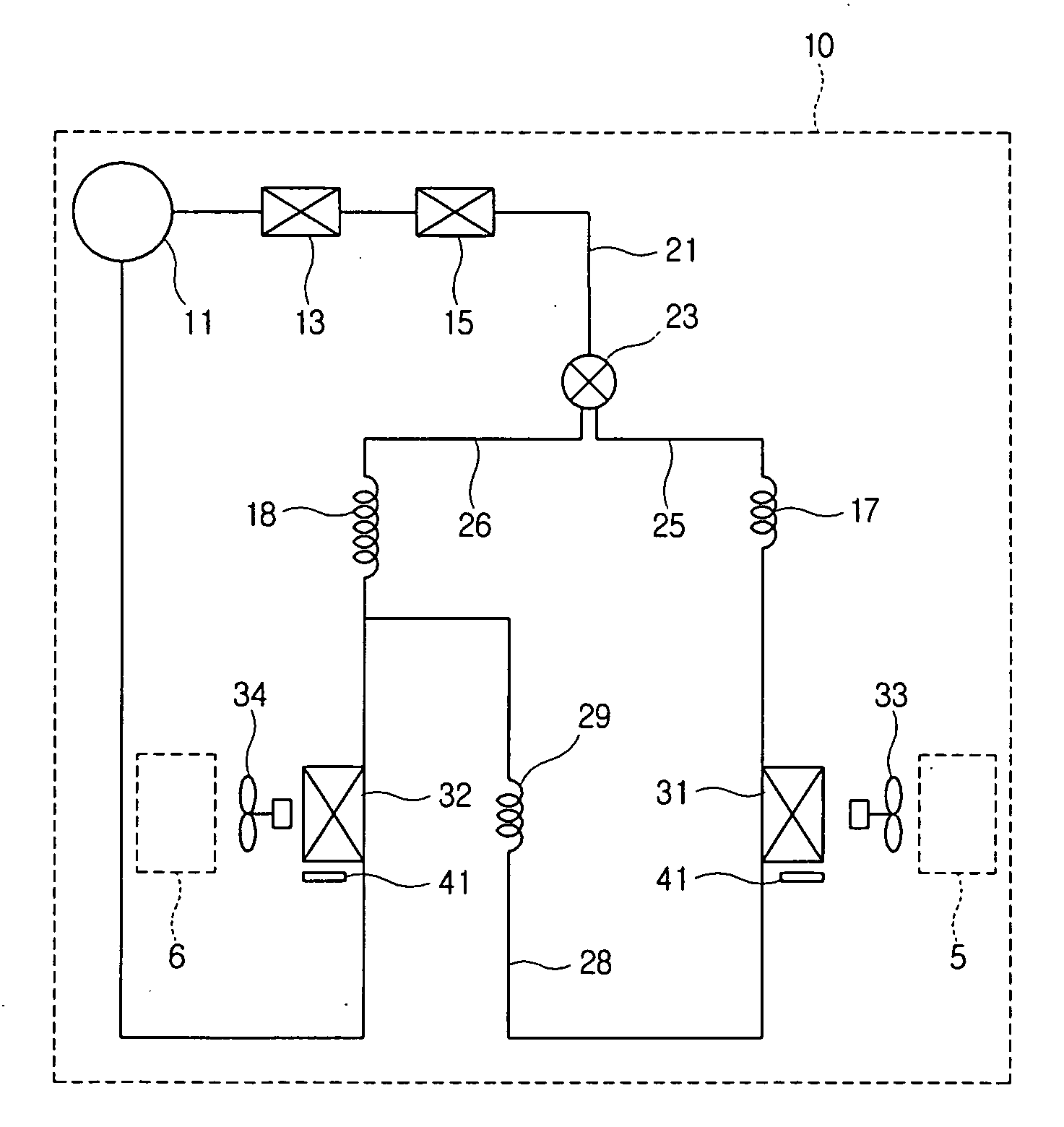

Refrigerator

InactiveUS20060266075A1Improve cooling effectLow thermal conductivityCompression machines with non-reversible cycleDomestic refrigeratorsVapor–liquid separatorLiquid state

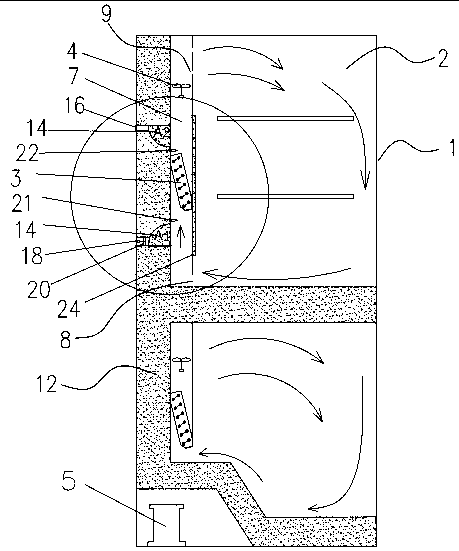

It is an object of the present invention to provide a refrigerator which is able to improve the efficiency of the refrigerating cycle while avoiding causing the structure of the refrigerator to be complicated, and avoiding a cost increase. Refrigerator 30 includes a refrigerating cycle device 20 having a compressor 1, a radiator 2 connected to a discharge side of the compressor 1, a first expansion valve 31 connected to an exit side of the radiator 2, a gas-liquid separator 33 for separating a refrigerant, which is in a mixed gas-liquid state by being decompressed by the first expansion valve 31, into a gas refrigerant and a liquid refrigerant, a heat absorber 14 into which the liquid refrigerant discharged from the gas-liquid separator 33 flows, and a refrigerant pipe 6D for delivering the gas refrigerant discharged from the gas-liquid separator 33 into the middle pressure portion of the compressor 1; an outer case 40; an inner case 39; and a heat insulating material. The gas-liquid separator 33 is arranged in the heat insulating material 47.

Owner:SANYO ELECTRIC CO LTD

Temperature controlled shipping containers

InactiveUS6968711B2Improve cooling effectImprove thermal conductivityContainer filling methodsDomestic refrigeratorsTemperature controlSufficient time

Novel sorption cooling devices capable of providing cooling over an extended period of time are disclosed. The sorption cooling devices are particularly useful for temperature-controlled shipping containers that are required to maintain a temperature below ambient for a time sufficient to complete delivery of the container and its contents. The shipping containers can be utilized to cost-effectively transport temperature-sensitive products.

Owner:PELICAN NANOCOOL HLDG LLC

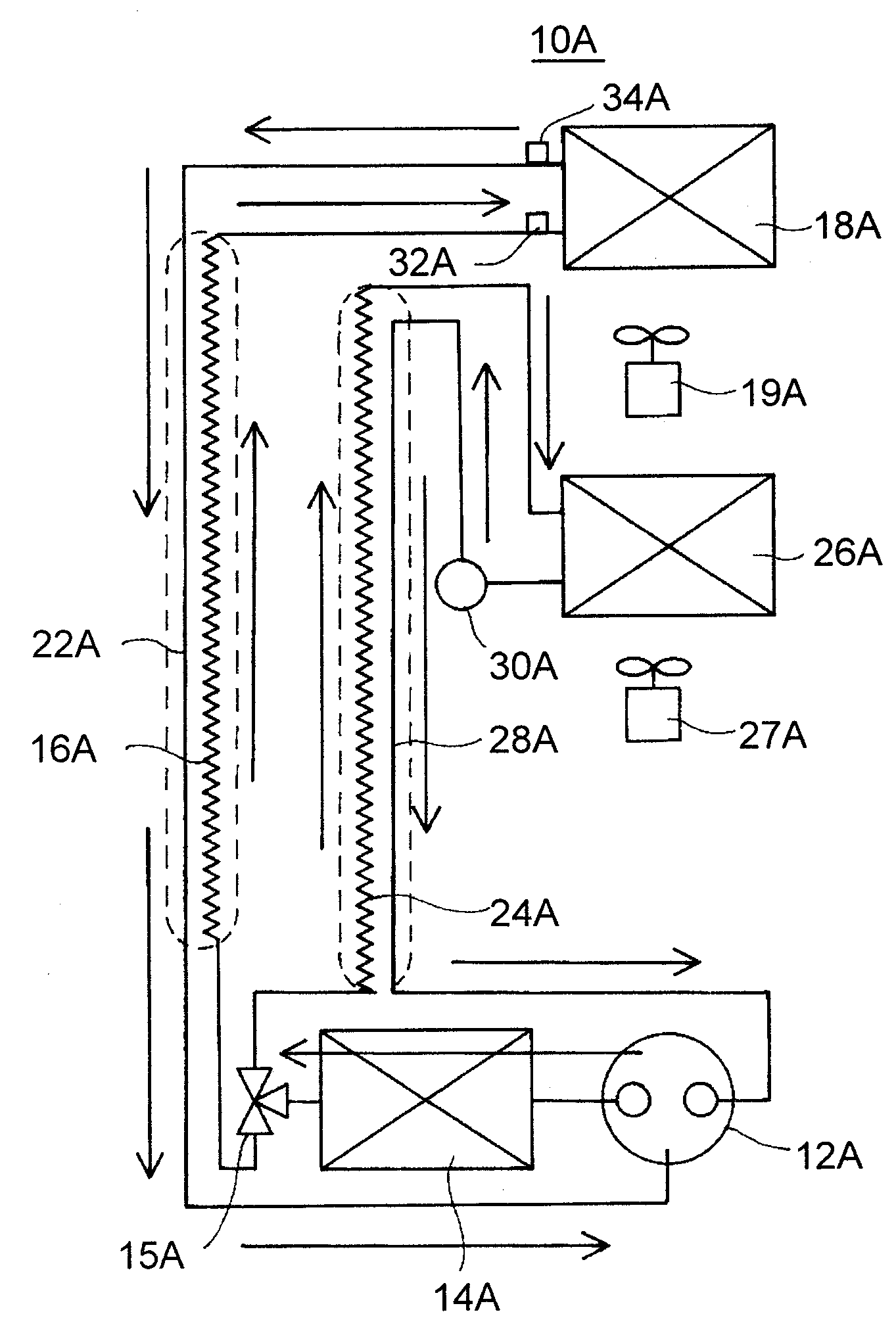

Refrigerator

InactiveUS20080190125A1Easy to controlReduce cooling efficiencyCompression machines with non-reversible cycleDomestic refrigeratorsEngineeringTemperature difference

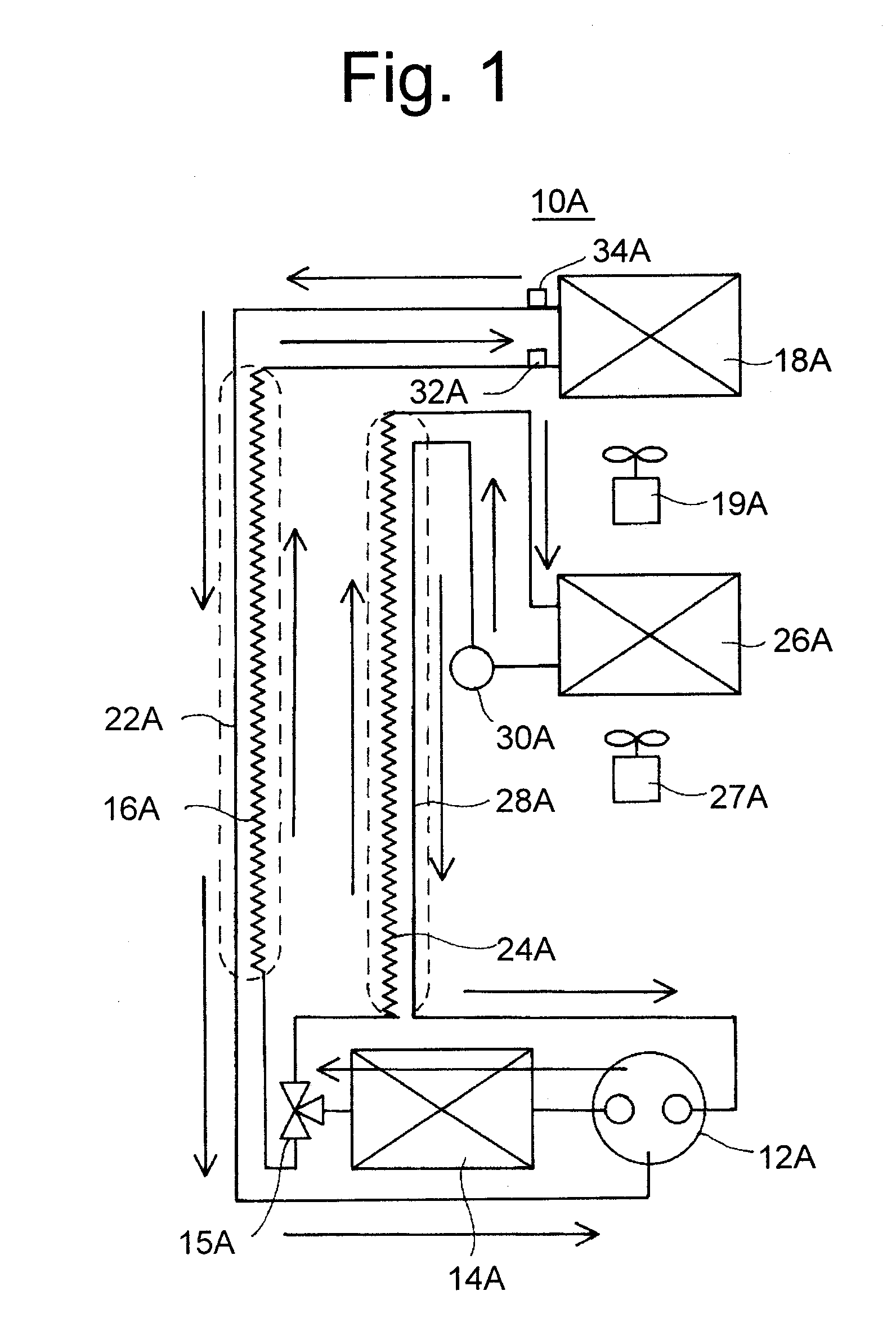

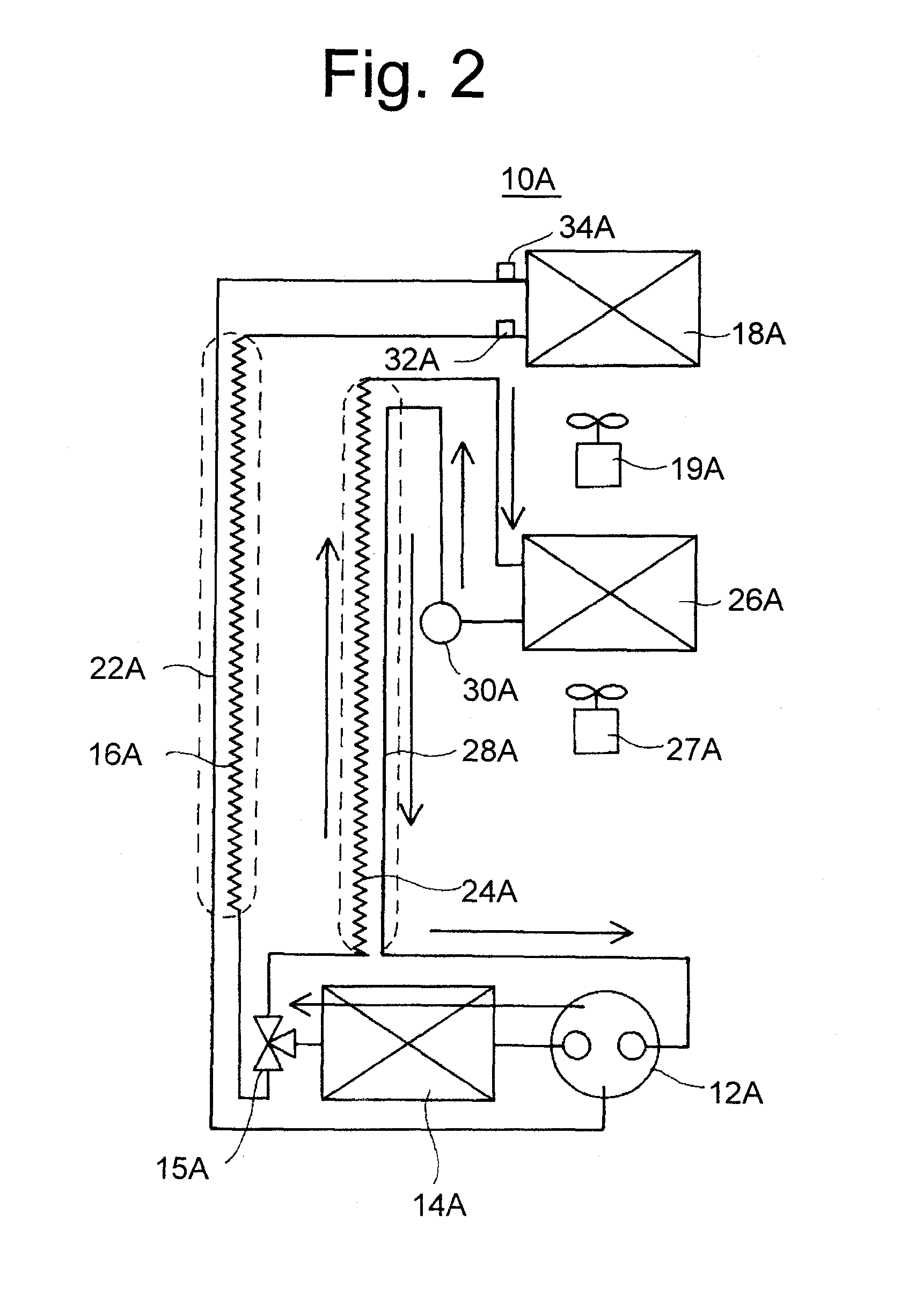

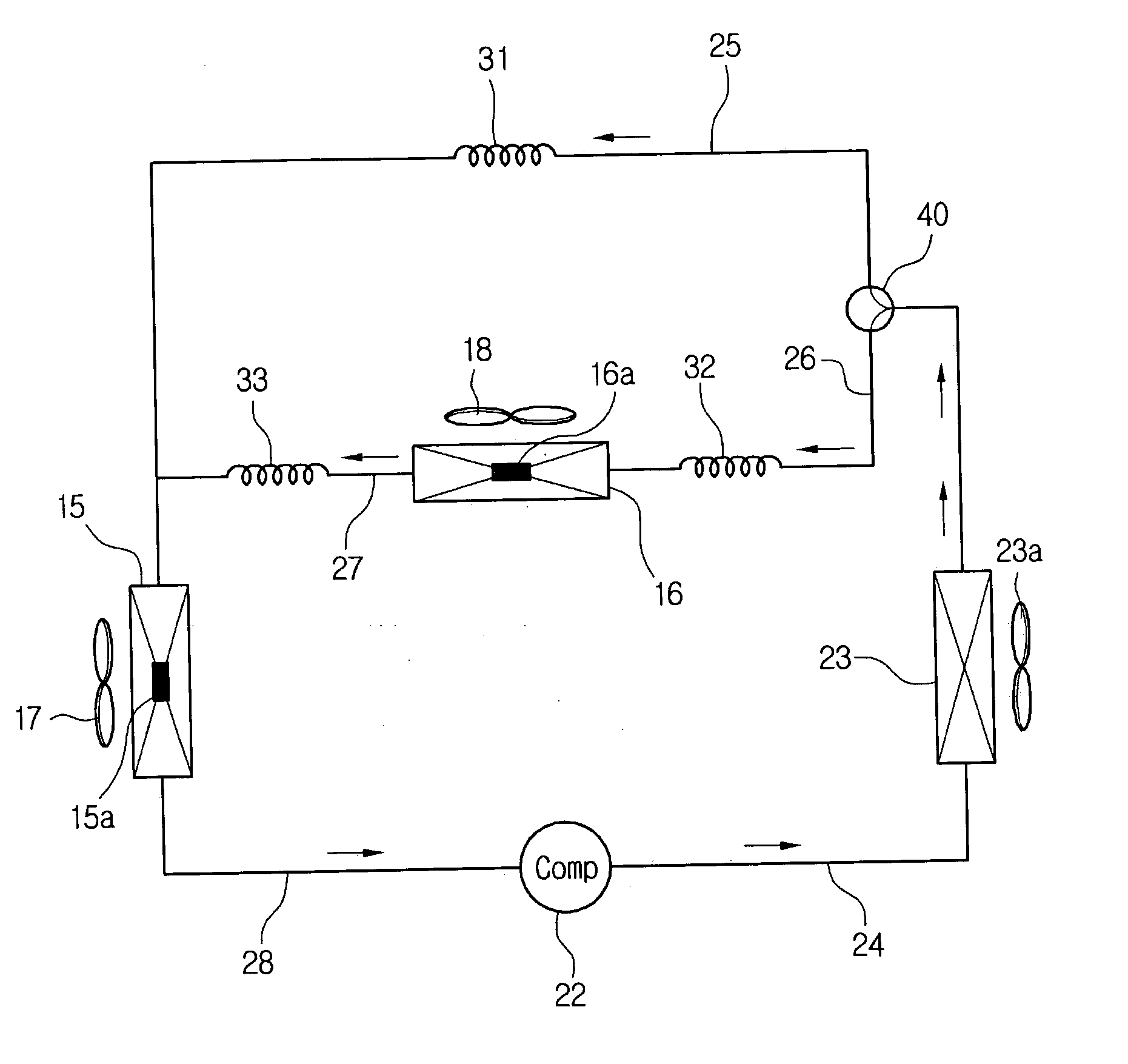

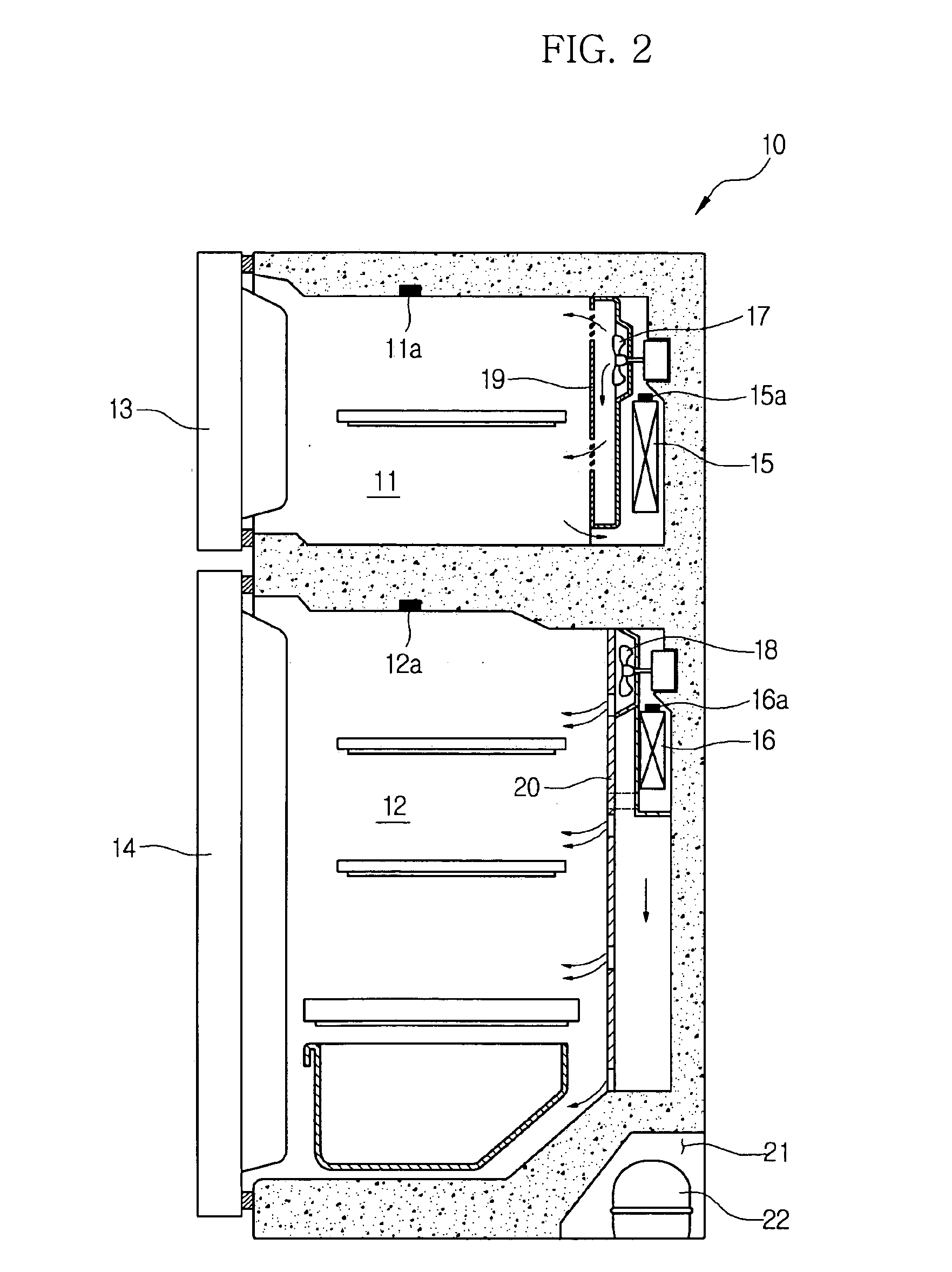

A high-pressure side discharge port of a two-stage compressor (12A) and a condenser (14A) are connected, condenser (14A) and a PMV (15A) are connected, a refrigerating side exit of PMV (15A) is connected to a medium pressure side suction port of two-stage compressor (12A) via an R capillary tube (16A) and an F evaporator (18A), connected to an F evaporator (26A) via an F capillary tube (24A), F evaporator (26A) is connected to a low-pressure side suction port of two-stage compressor (12A) via a low-pressure suction pipe (28A), PMV (15A) can switch a simultaneous cooling mode and a freezing mode, and in the simultaneous cooling mode, a refrigerant flow rate toward R evaporator (18A) is adjusted by PMV (15A), and thereby a temperature difference control is performed so as to make a difference between an entrance temperature and an exit temperature of R evaporator (18A) equal to a preset temperature difference (for example, 4° C.).A controller (22), on the basis of the detection condition of a temperature sensor (23) for a freezing chamber and a temperature sensor (24) for a refrigerating chamber, controls a freezing cycle device (10). Here, controller (22) controls an opening of a regulating valve (12) so as to make a superheat amount which is a difference between an exit temperature and an entrance temperature of a refrigerating evaporator (5) equal to a target superheat amount, and thereby adjusts a refrigerant flow rate to refrigerating evaporator (5) in a limited state.In this case, when a power is turned on, the entrance temperature and the exit temperature of refrigerating evaporator (5) are the same, so that controller (22), when the power is turned on, calibrates detected temperatures of an entrance temperature sensor (27) and an exit temperature sensor (26) so as to coincide with each other, and thereby can execute surely the subsequent limiting adjustment of regulating valve (12) on the basis of the superheat amount.Further, in this case, when a refrigerant supply to refrigerating evaporator (5) is stopped and the temperature of refrigerating evaporator (5) rises suddenly, controller 22 increases an opening of a valve opening (42) to refrigerating evaporator (5) of regulating valve (12) to a predetermined return value, so that the refrigerant supply amount to refrigerating evaporator (5) is increased at a stretch, and thus the refrigerating evaporator can be cooled quickly.A refrigerator having a two-stage compressor (12A) for cooling efficiently both a refrigerating chamber (2A) and a freezing chamber (5A) will be provided.When limiting and adjusting a refrigerant flow rate to one evaporator according to an opening of a valve body so as to make a superheat amount of one evaporator appropriate on the basis of the superheat amount which is a difference between an exit temperature and an entrance temperature of one evaporator, a refrigerator for detecting accurately the entrance temperature and the exit temperature of one evaporator will be provided.When limiting and adjusting a refrigerant flow rate to one evaporator according to an opening of a valve body, a refrigerator for causing no delay in a refrigerant supply to one evaporator will be provided.

Owner:TOSHIBA HA PROD +2

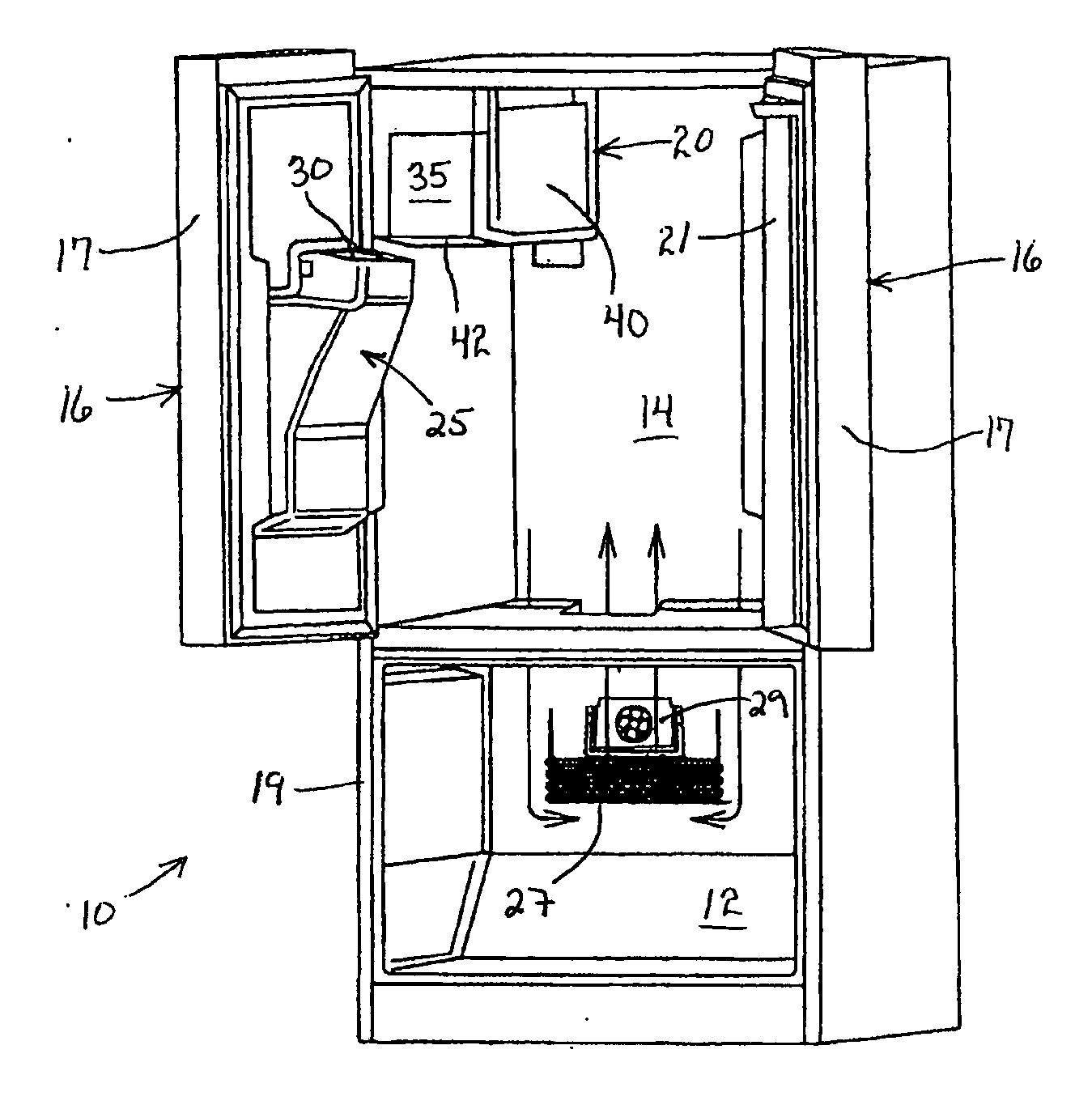

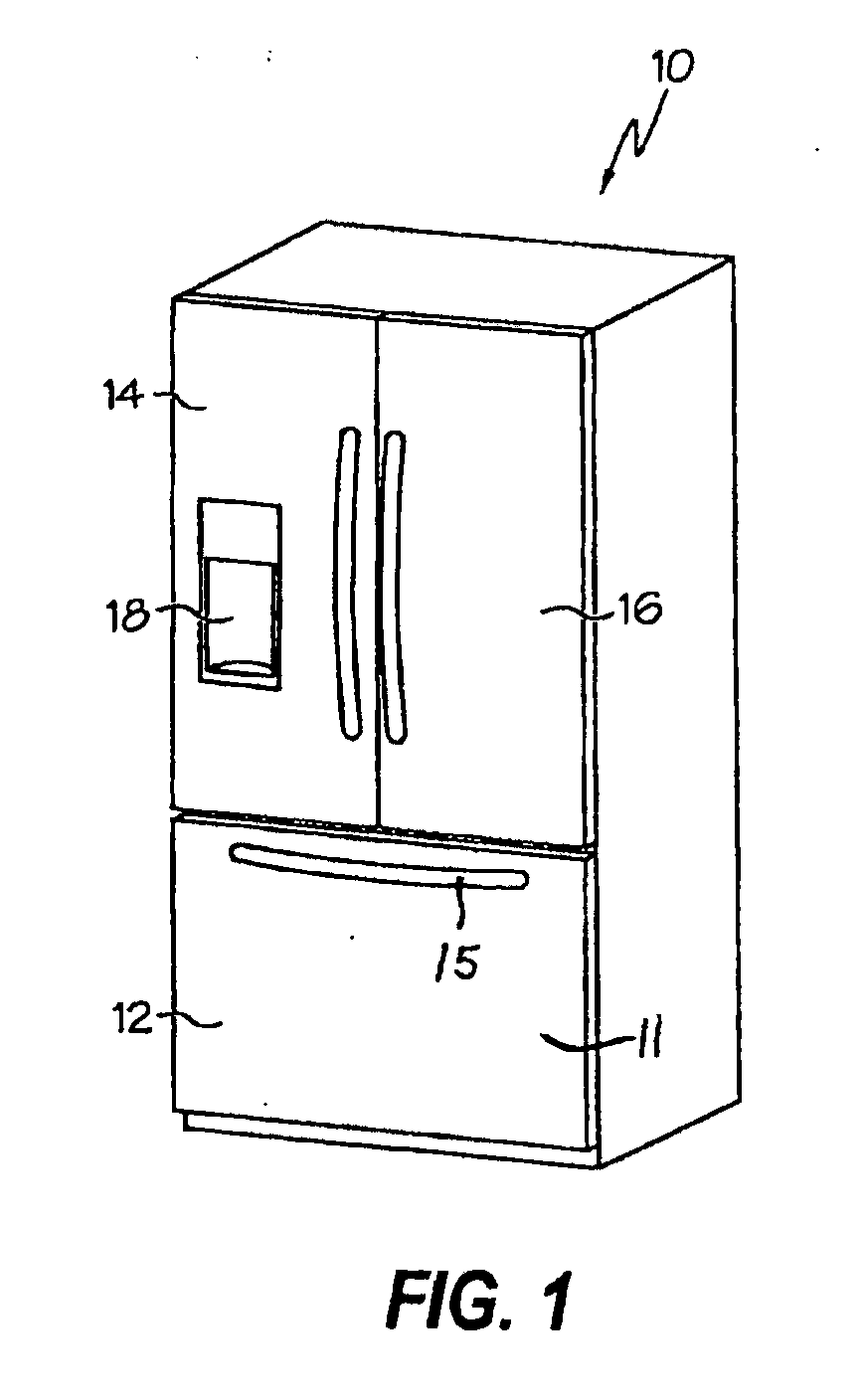

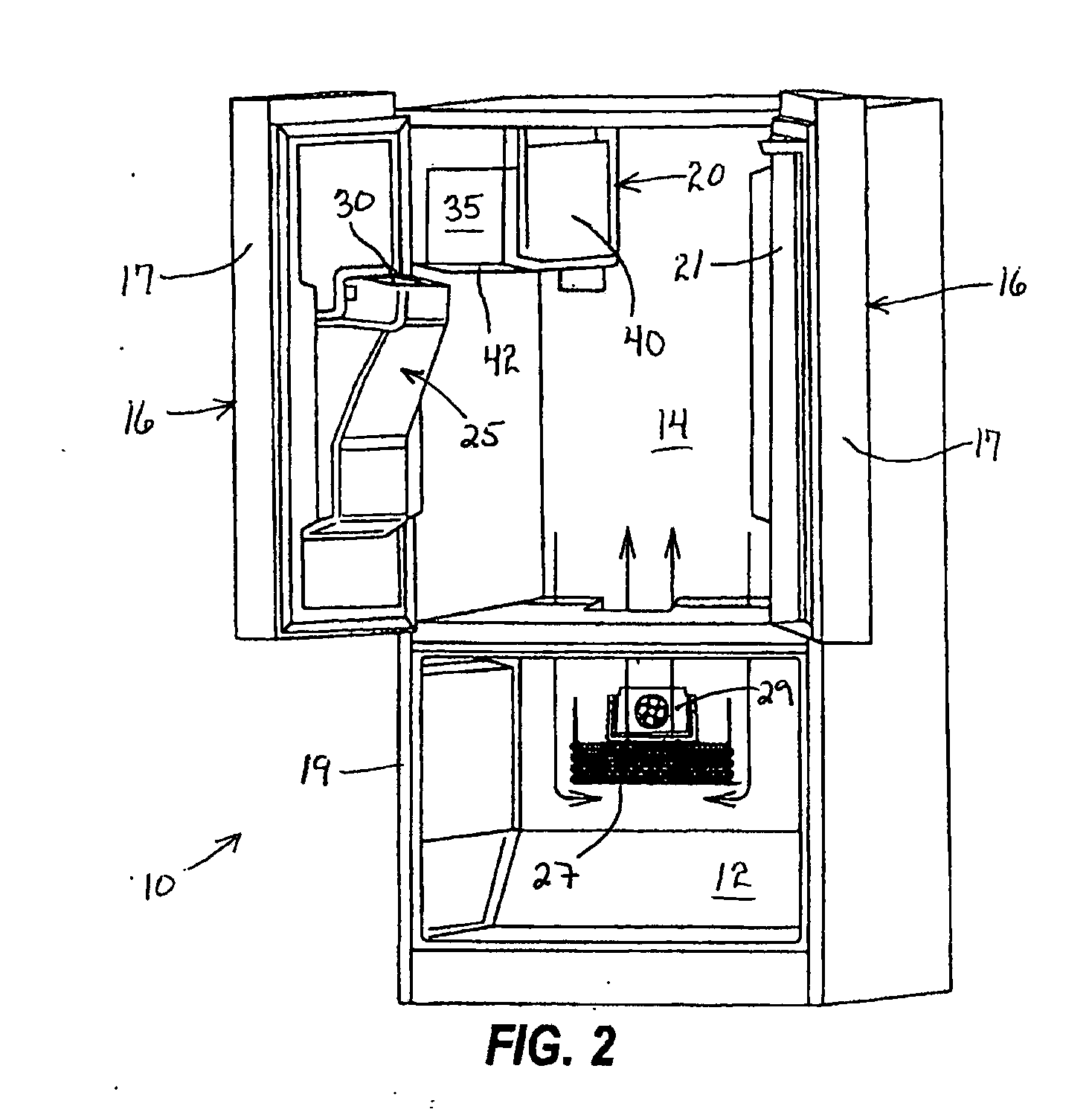

Refrigerator ice compartment with intermediate temperature

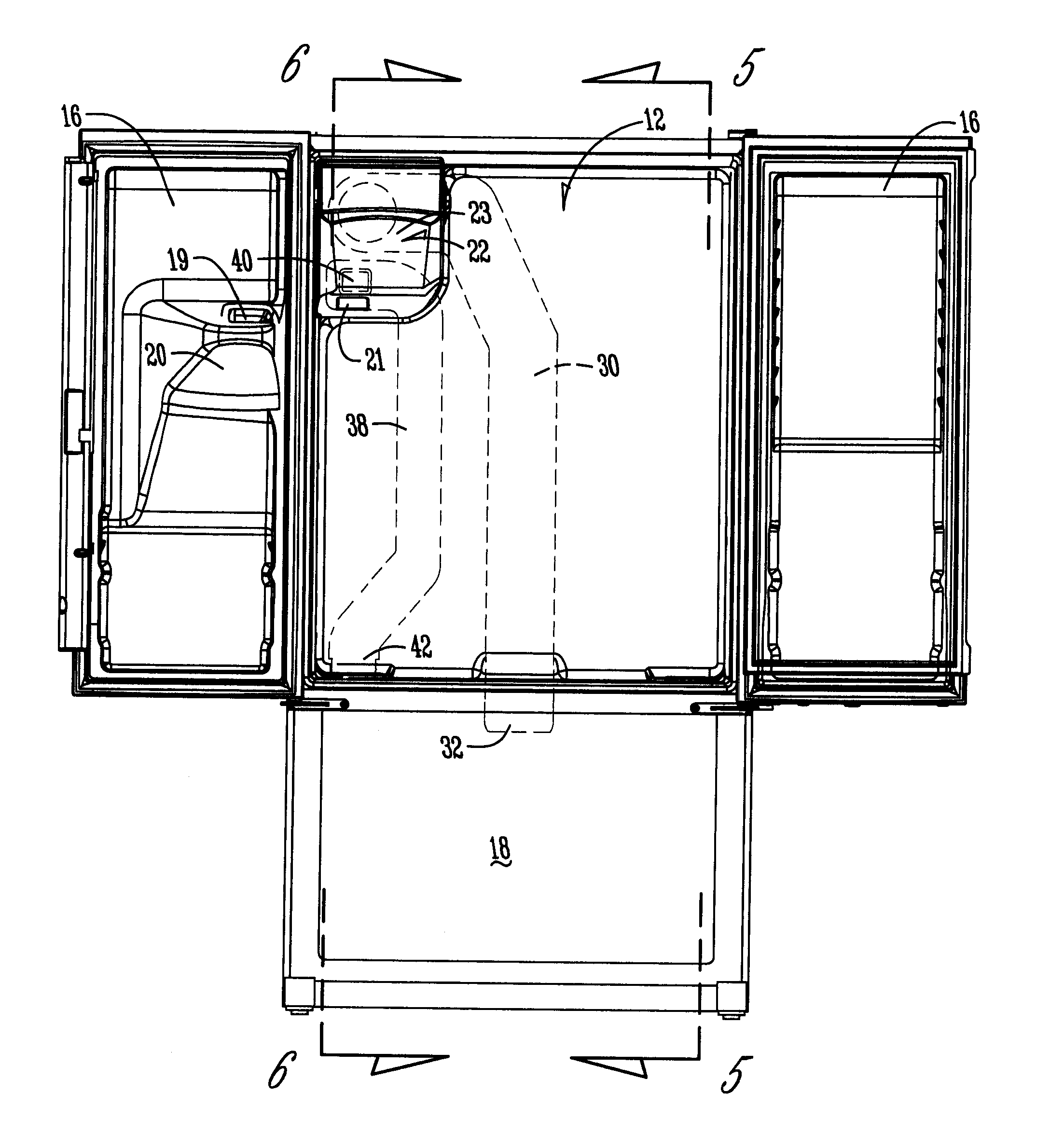

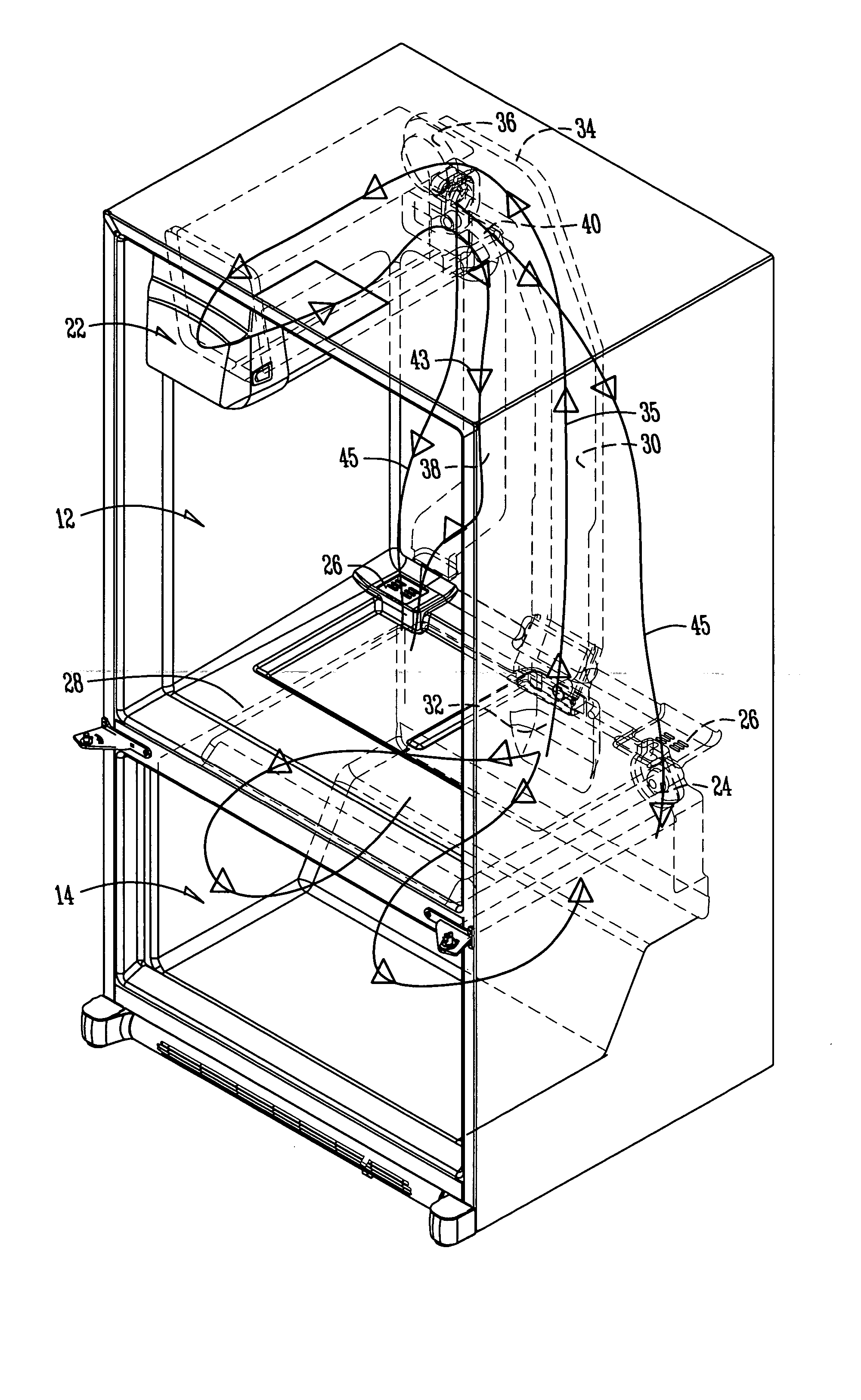

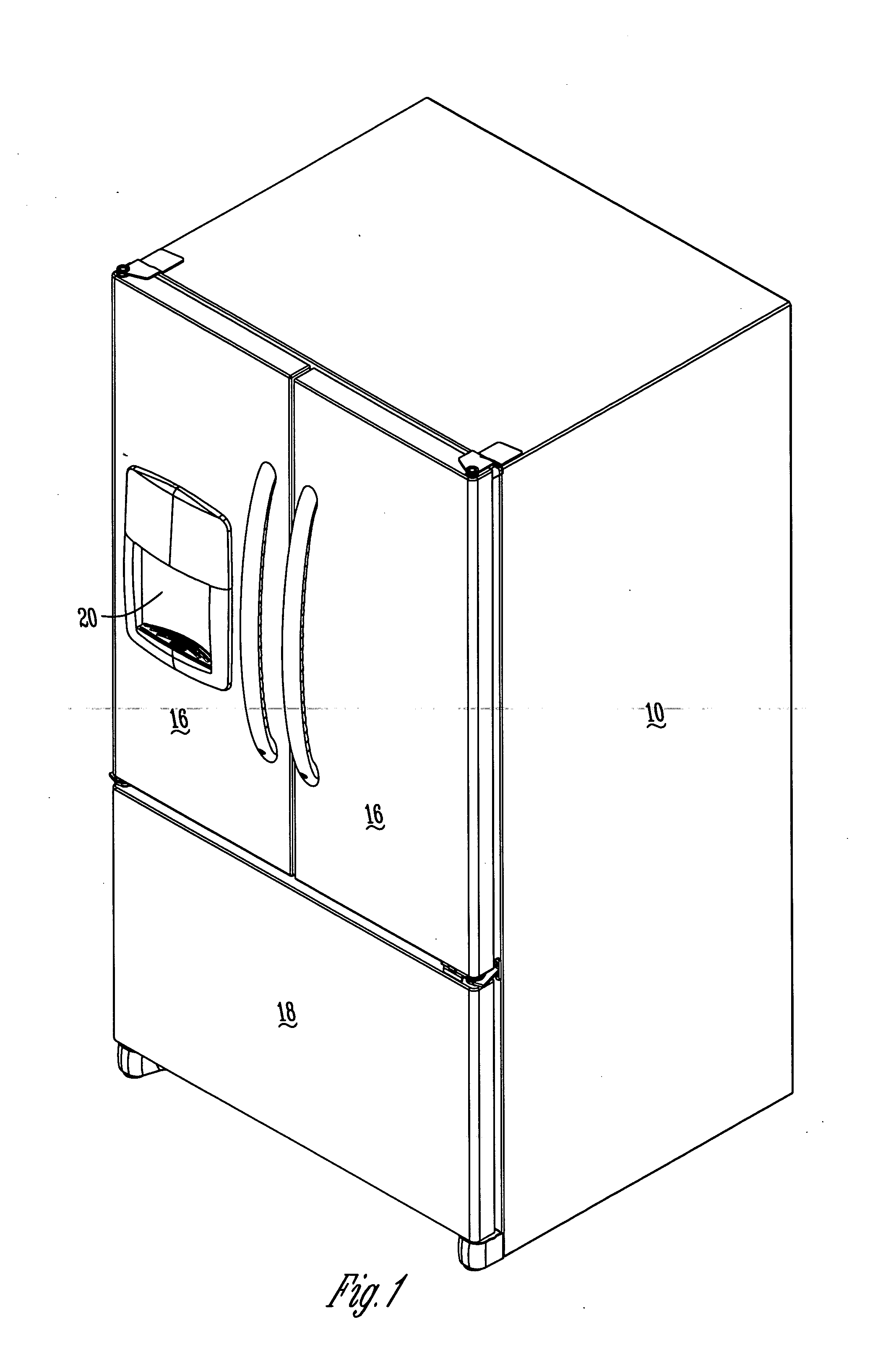

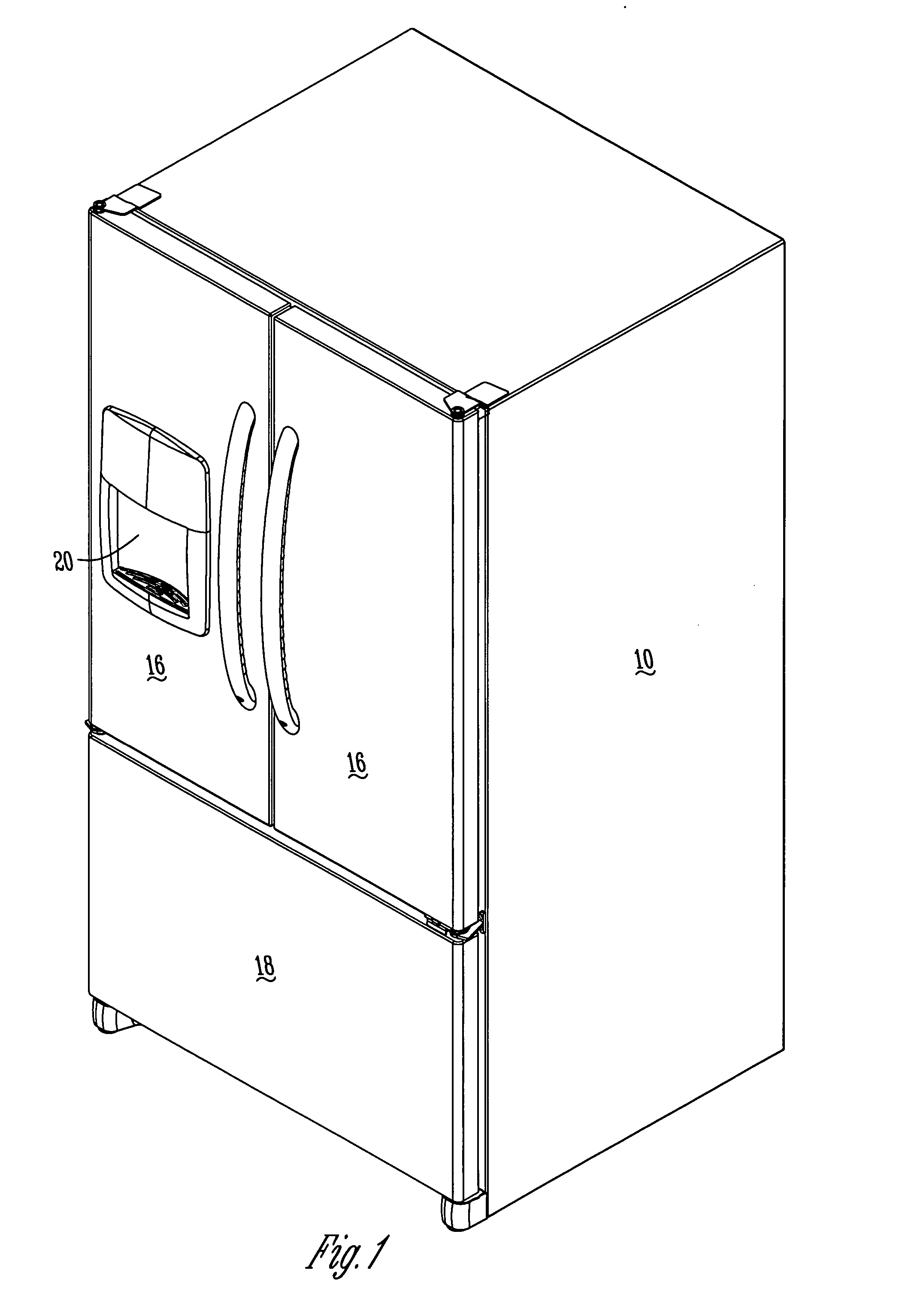

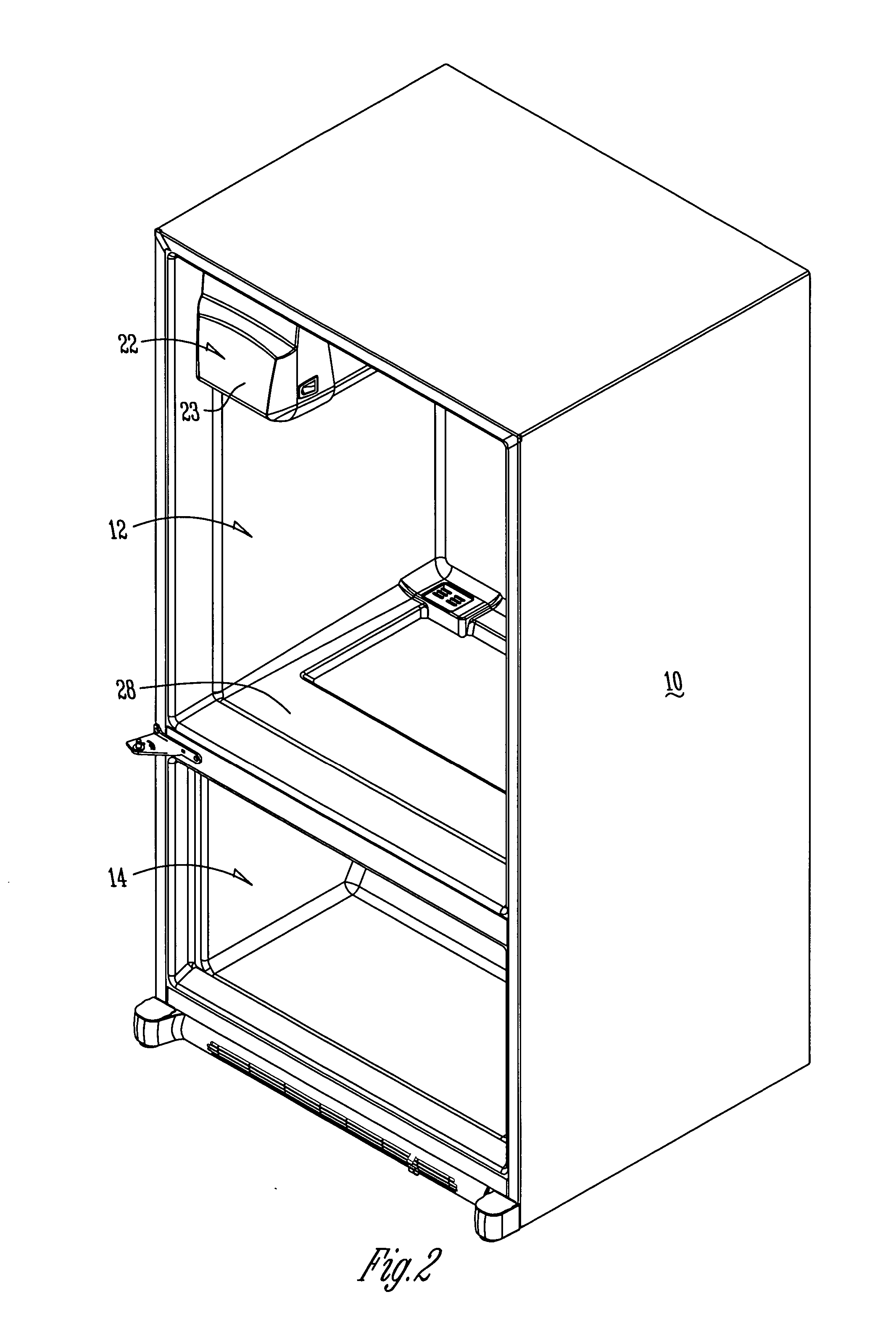

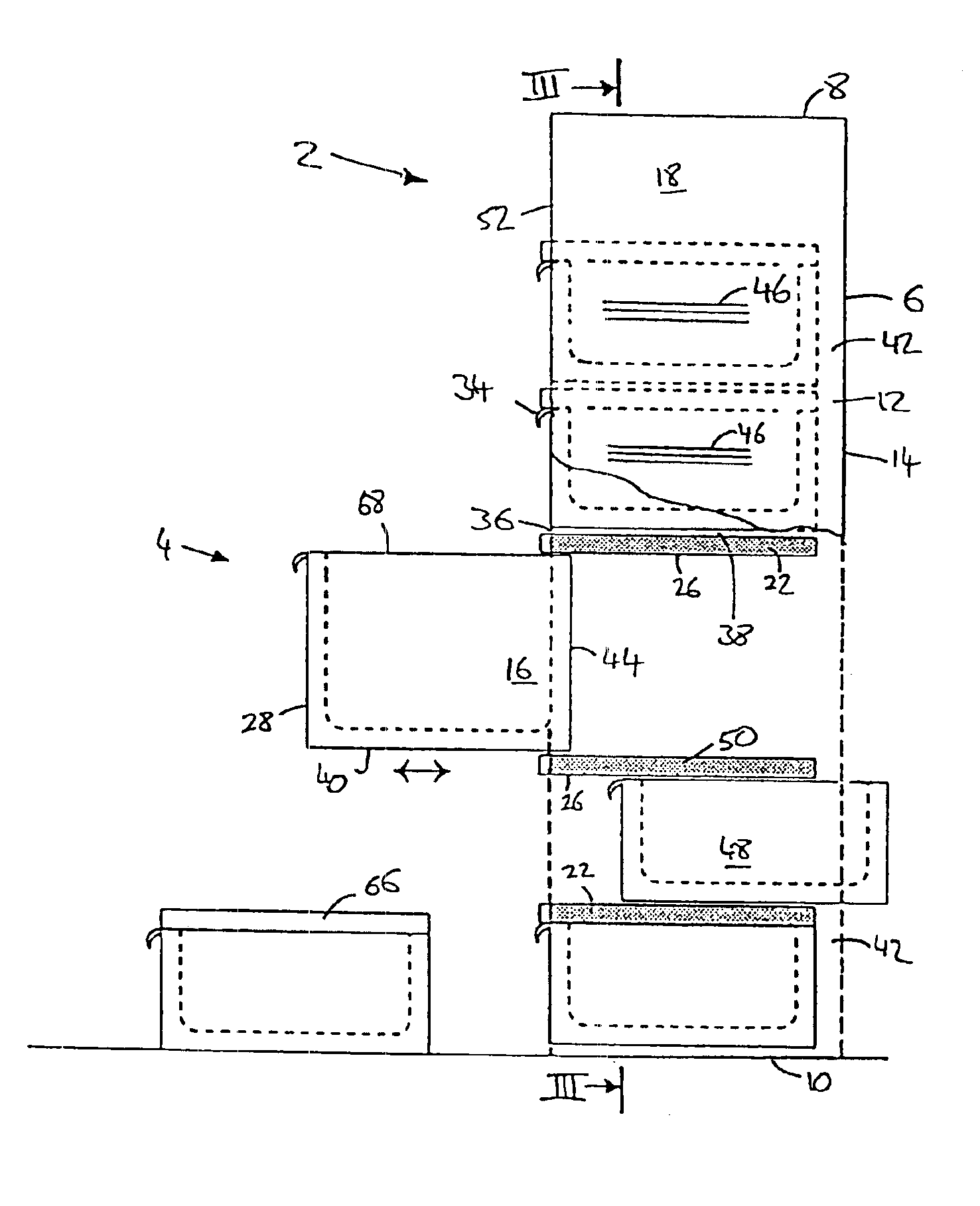

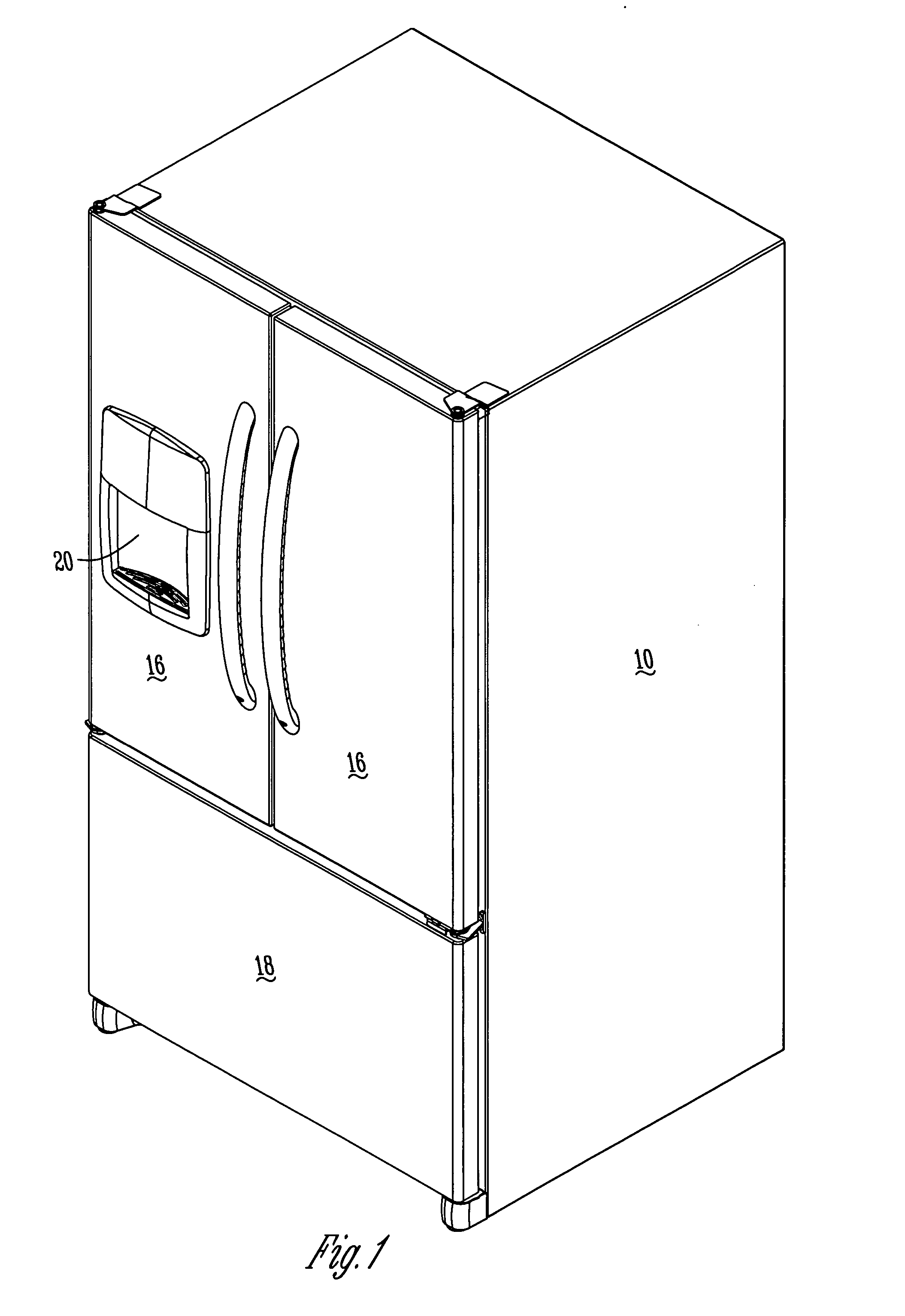

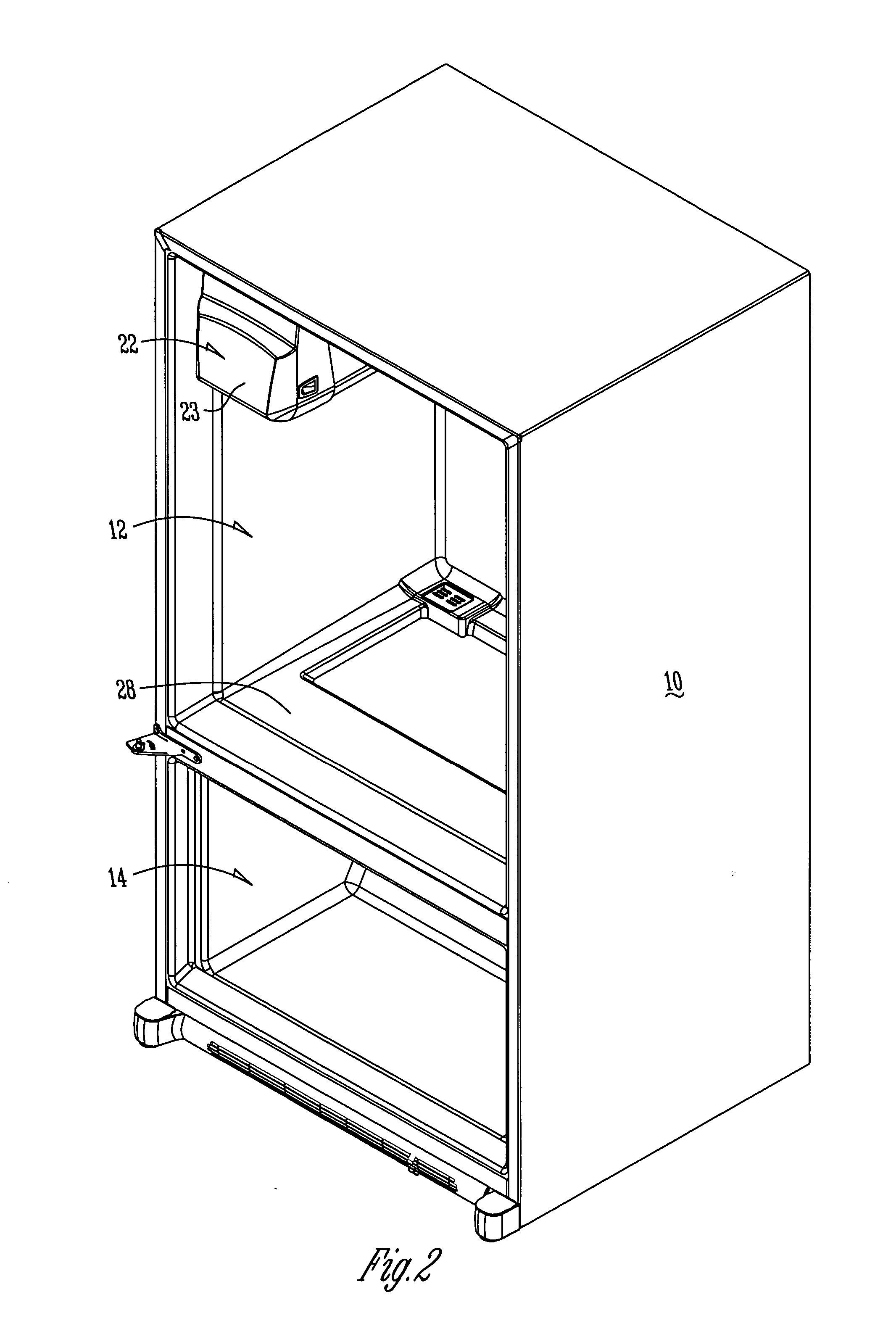

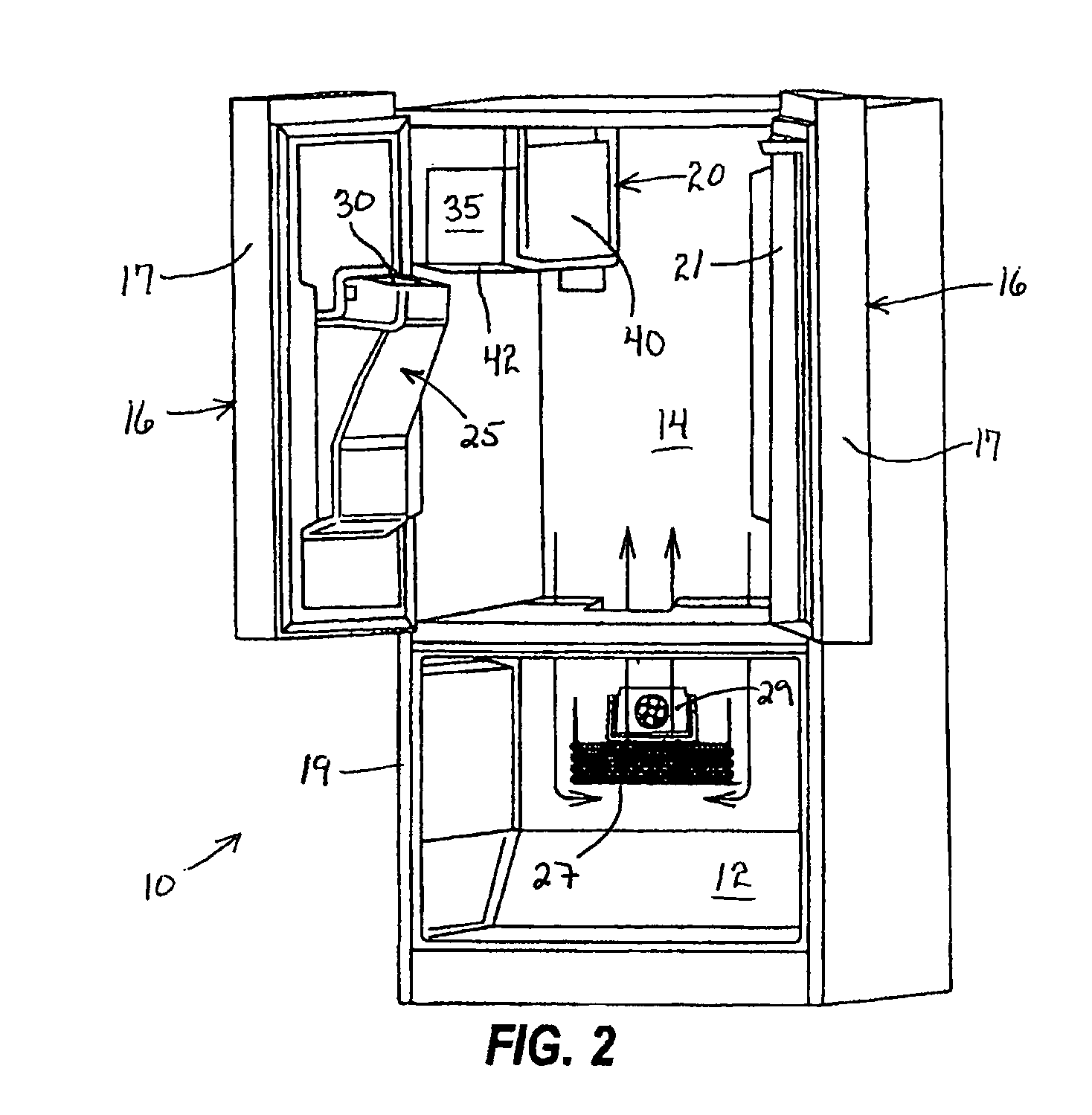

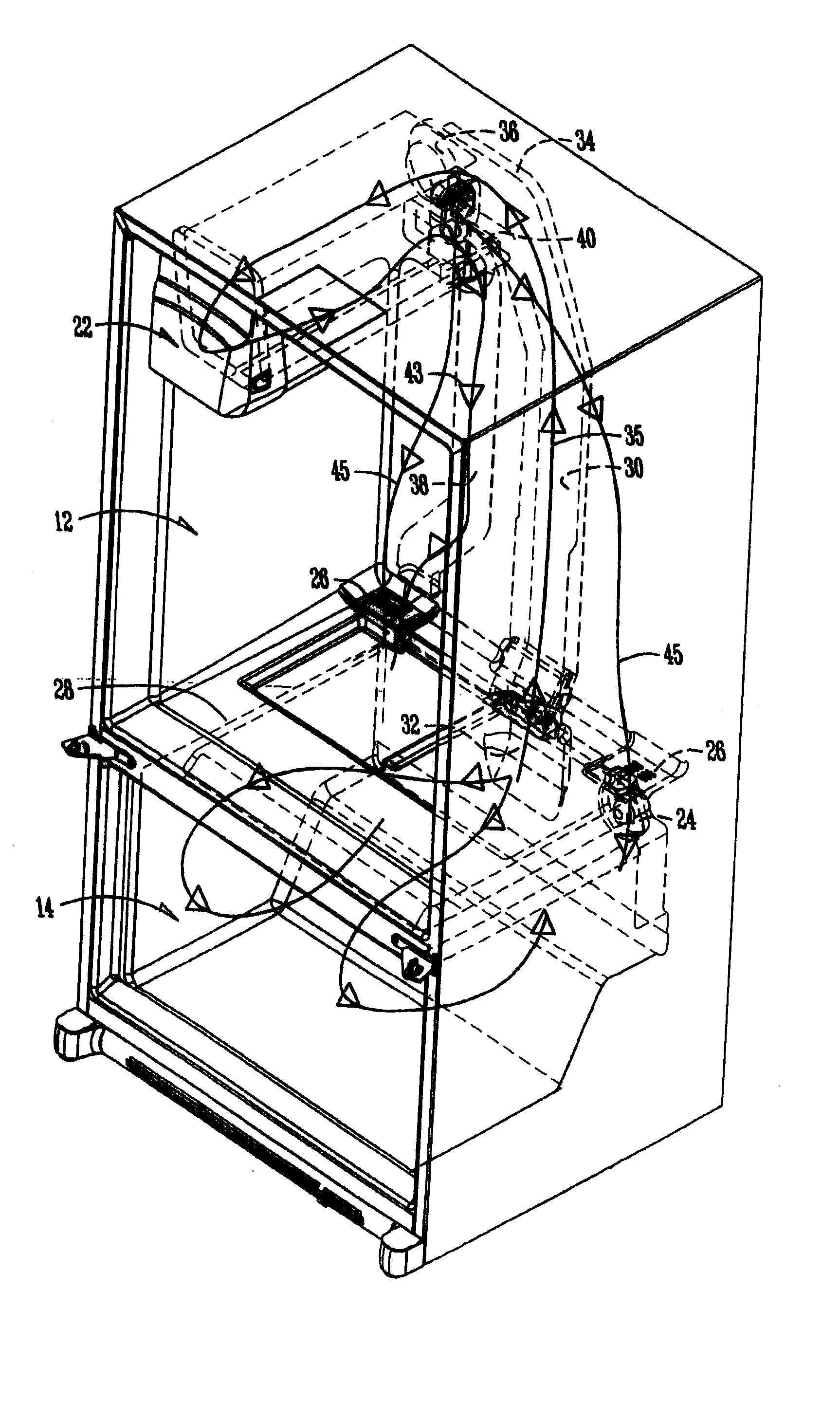

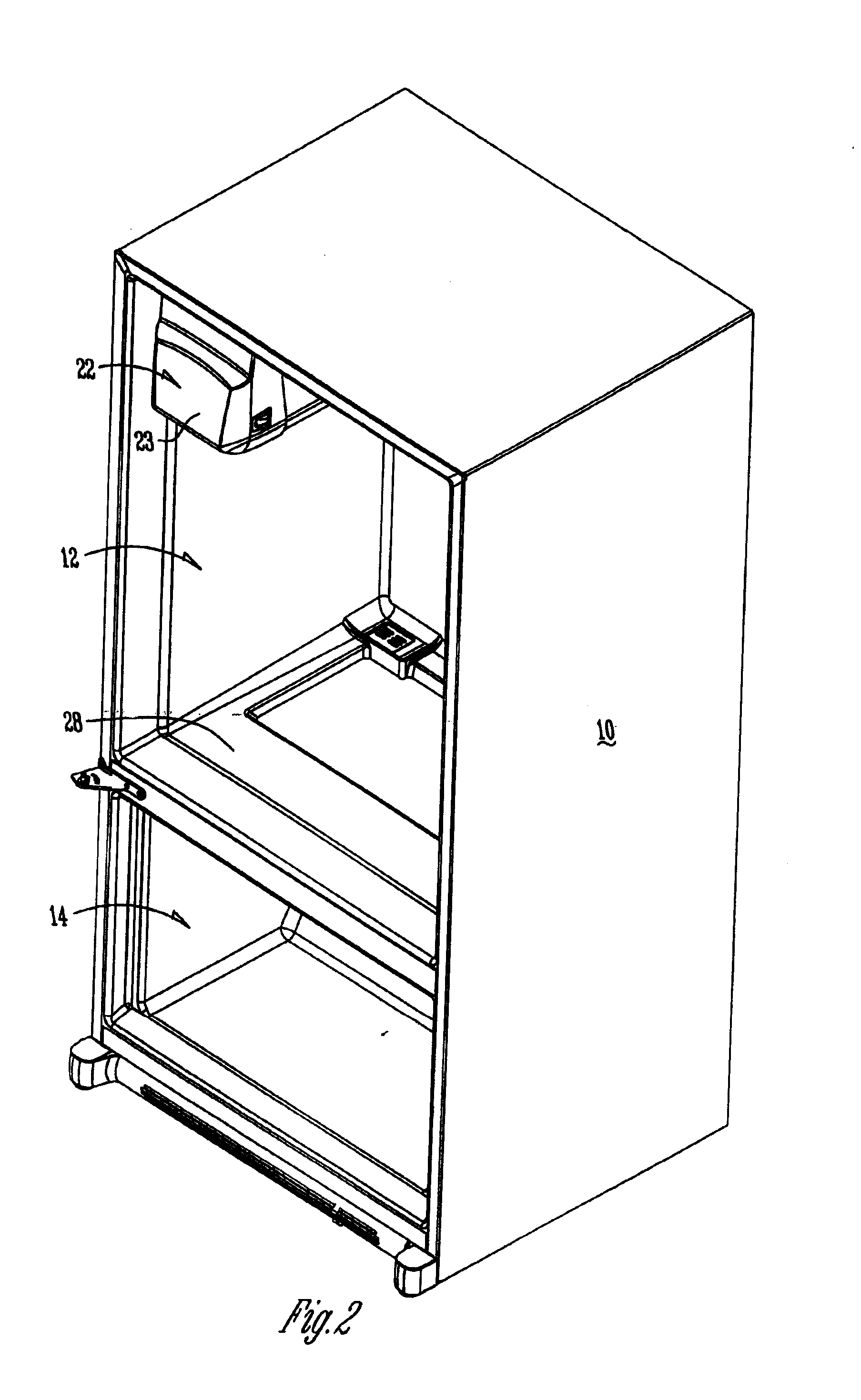

An insulated icemaking compartment is provided in the fresh food compartment of a bottom mount refrigerator. The icemaking compartment may be integrally formed with the liner of the fresh food compartment, or alternatively, may be modular for installation anywhere in the fresh food compartment. A removable bin assembly with a front cover normally seals the icemaking compartment to maintain the temperature in the compartment. A cold air duct formed in the rear wall of the refrigerator supplies cold air from the freezer compartment to the icemaking compartment. A return air duct directs a portion of the air from the icemaking compartment back to the freezer compartment. An air vent in the icemaking compartment directs another portion of air into the fresh food compartment. A control system provides for controlling refrigerator functions in a manner that promotes energy efficiency. The temperature of the ice compartment is between the temperatures of the fresh food and freezer compartments.

Owner:WHIRLPOOL CORP

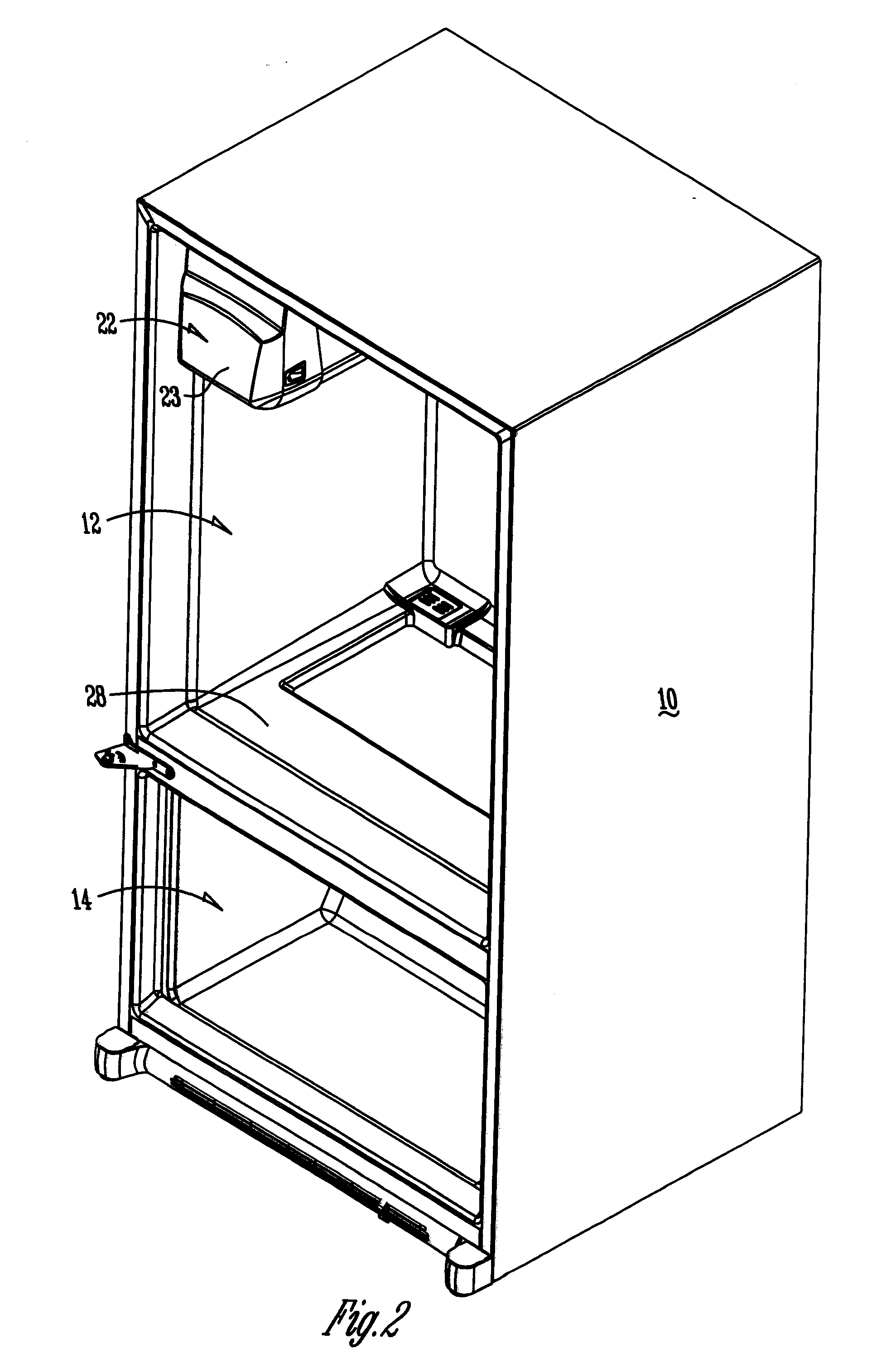

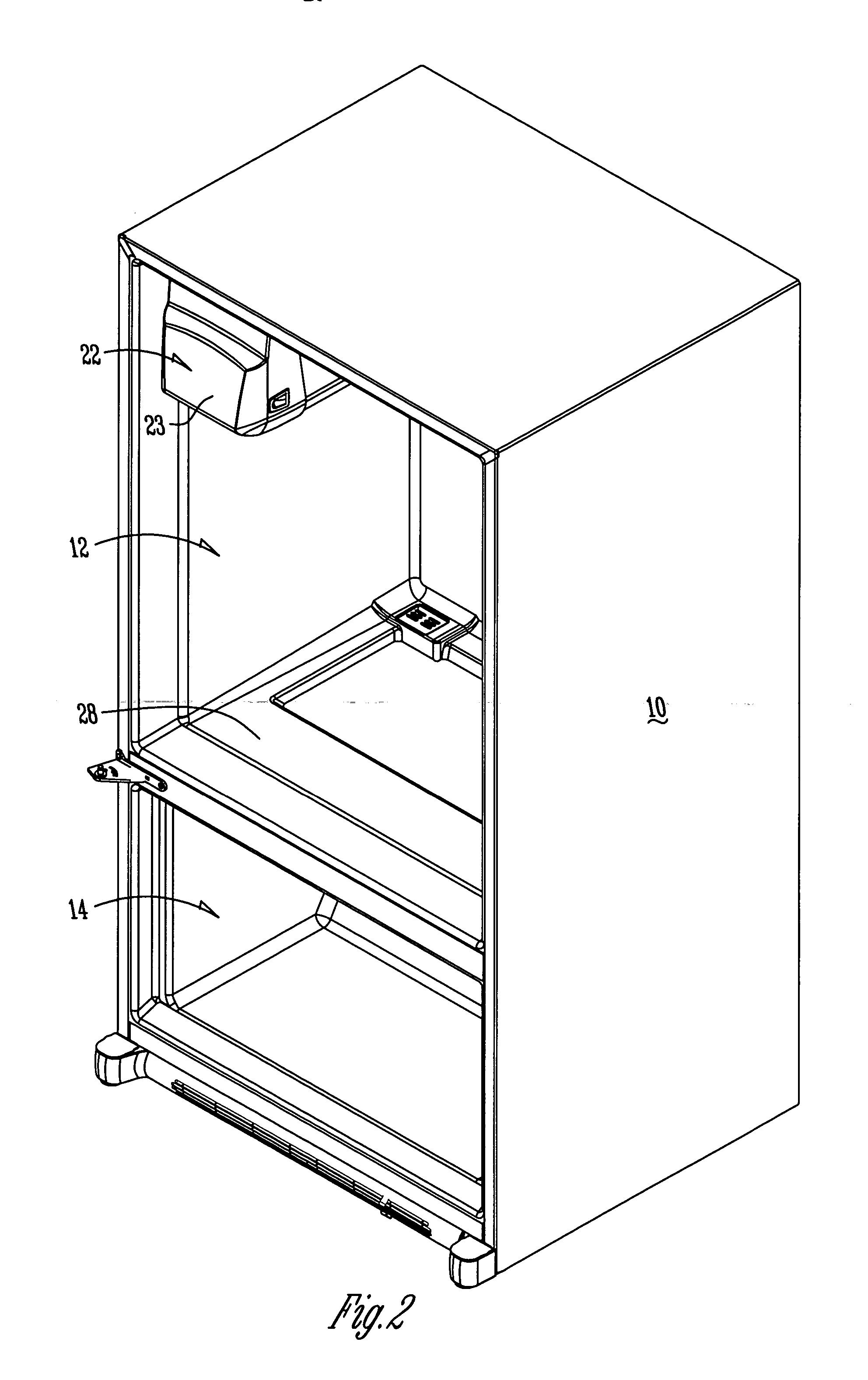

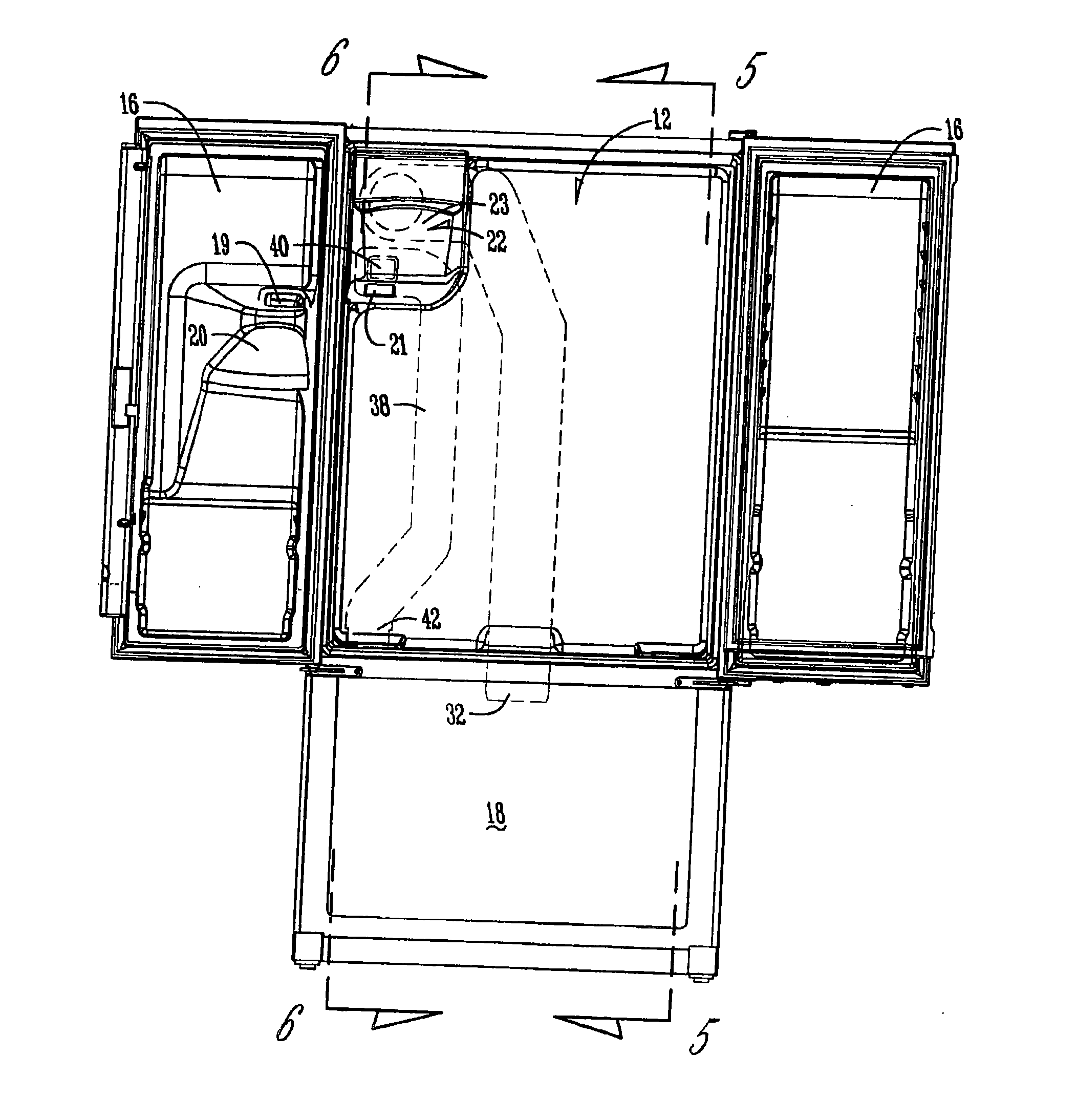

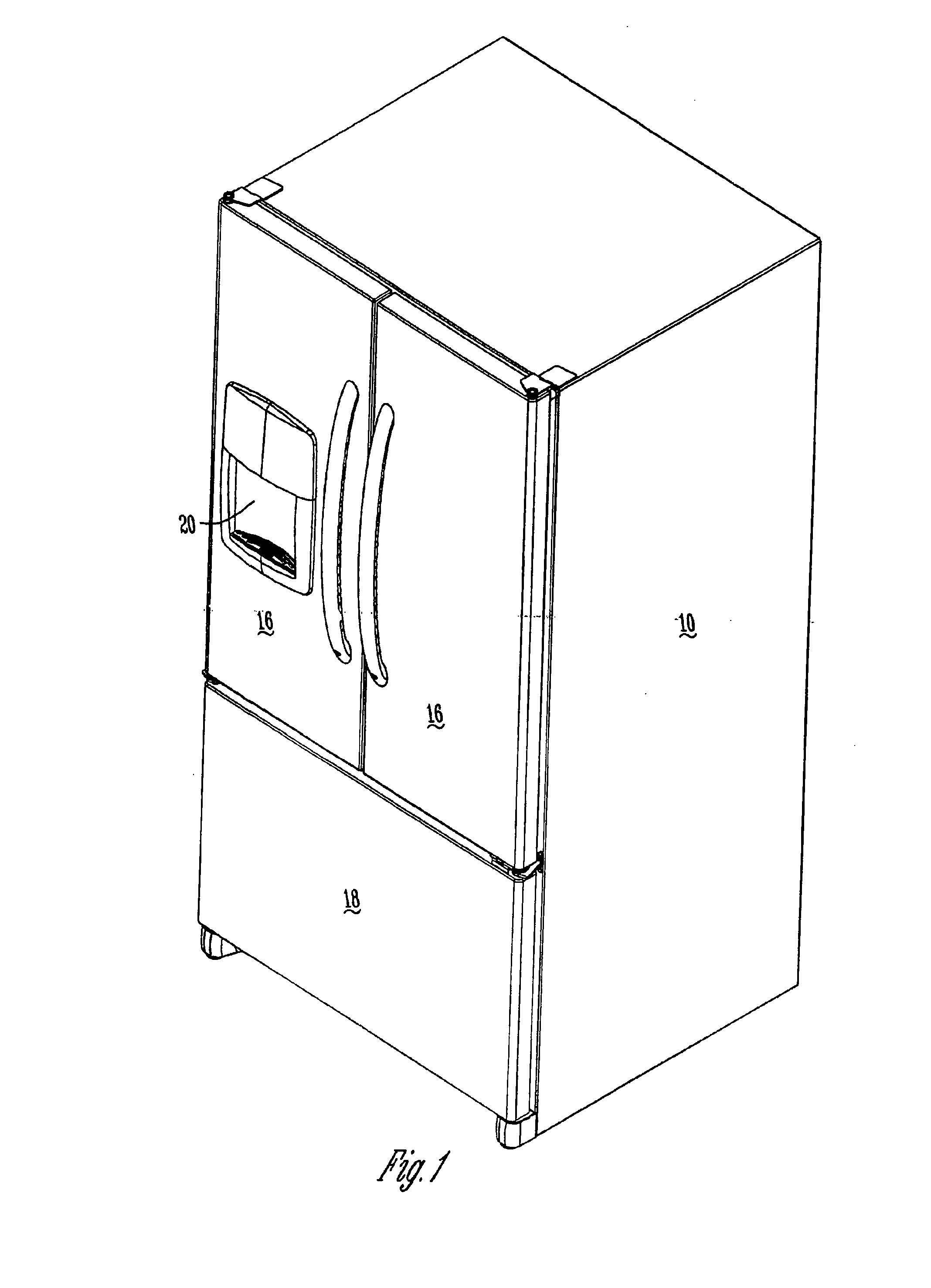

Insulated ice compartment for bottom mount refrigerator

An insulated icemaking compartment is provided in the fresh food compartment of a bottom mount refrigerator. The icemaking compartment may be integrally formed with the liner of the fresh food compartment, or alternatively, may be modular for installation anywhere in the fresh food compartment. A removable bin assembly with a front cover normally seals the icemaking compartment to maintain the temperature in the compartment. A cold air duct formed in the rear wall of the refrigerator supplies cold air from the freezer compartment to the icemaking compartment. A return air duct directs a portion of the air from the icemaking compartment back to the freezer compartment. An air vent in the icemaking compartment directs another portion of air into the fresh food compartment. A control system provides for controlling refrigerator functions in a manner that promotes energy efficiency.

Owner:WHIRLPOOL CORP

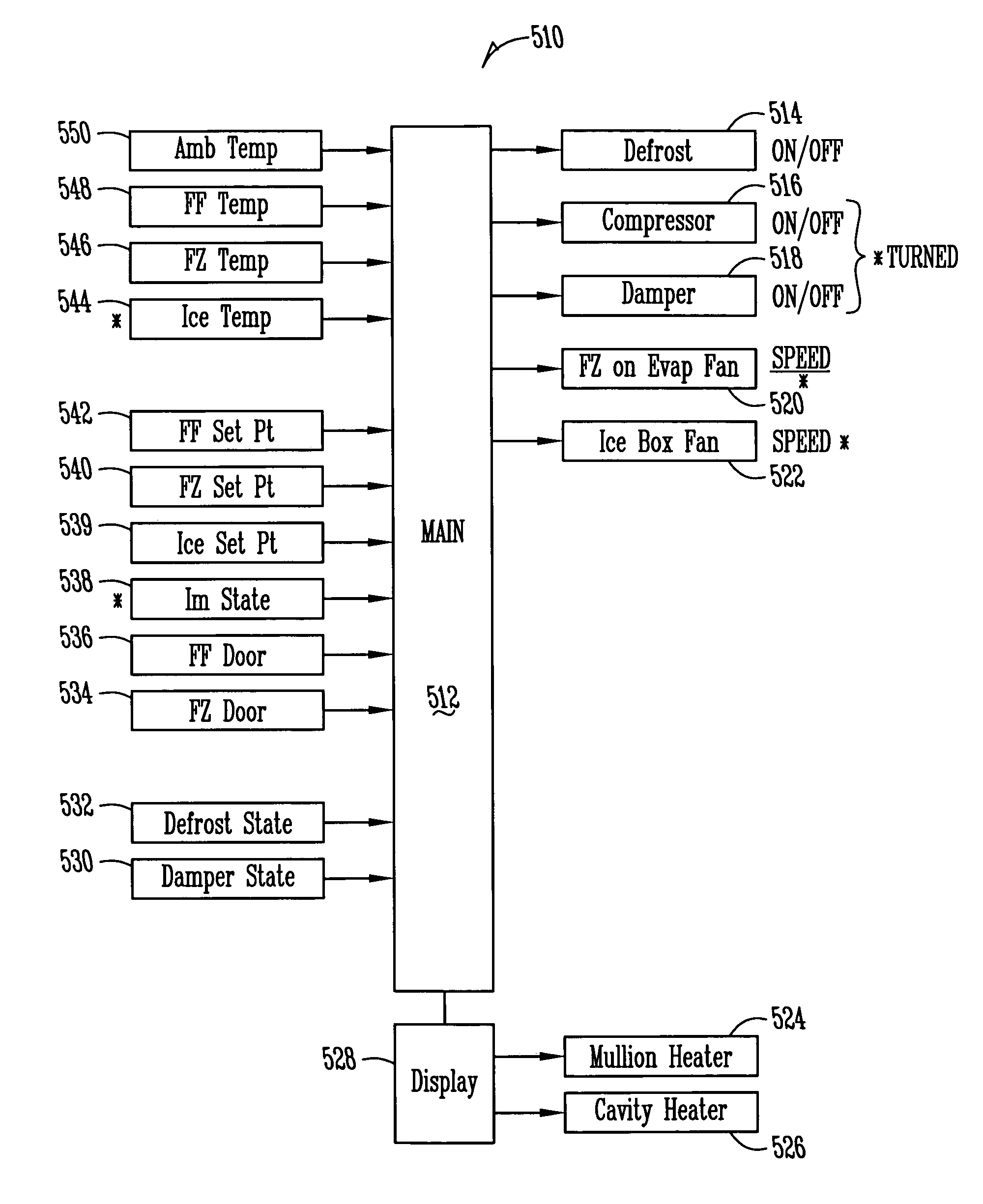

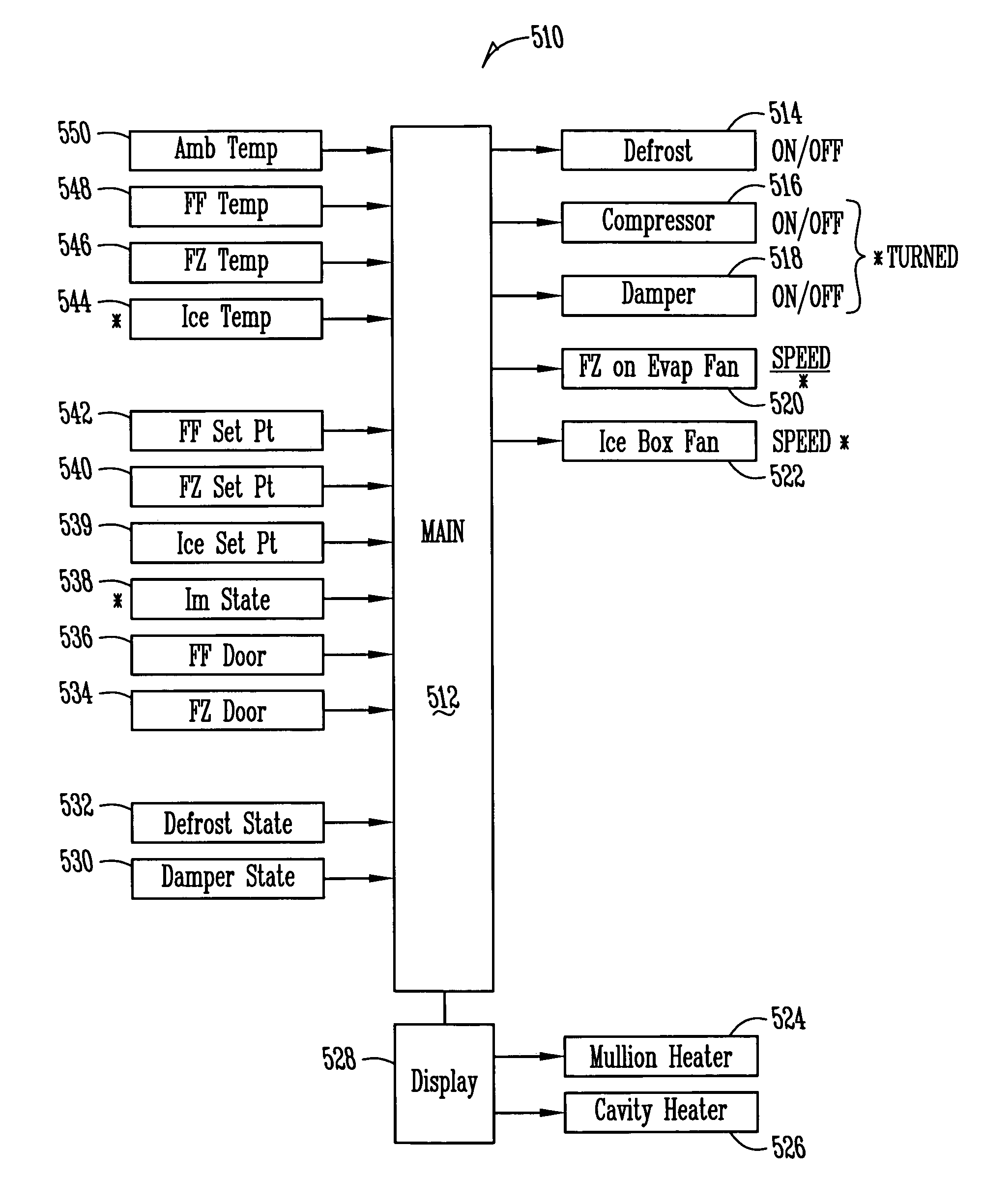

Electronic control system for insulated ice compartment for bottom mount refrigerator

A refrigerator includes a refrigerator cabinet, a fresh food compartment disposed within the cabinet, a freezer compartment disposed within the cabinet, an ice compartment disposed within the cabinet, and an electronic control system associated with the refrigerator and adapted to monitor and control the fresh food compartment, the freezer compartment and the ice compartment. The control system provides for energy efficient control and operation through various means, including by monitoring state of an ice maker associated with the ice compartment and controlling temperature within compartments of the refrigerator based on the ice maker state. The control system can also use correlations in determining appropriate temperatures for different compartments within the refrigerator.

Owner:WHIRLPOOL CORP

Cold-storage appliance

InactiveUS6915657B1Least riskEasy to cleanLighting and heating apparatusDomestic refrigeratorsEngineeringAmbient air

A cold-storage appliance comprises an open-topped insulating container defining an external surface, an insulating lid adapted to close the open top of the container, a cooling means adapted to cool the interior but not the exterior of the container, and a structure supporting the container, the lid and the cooling means. In accordance with the invention, the container is mounted to the structure for movement relative to the structure and the lid to open the container and afford access to its interior or to close the container, and at least a majority of the external surface of the container is exposed to ambient air when the container is closed by the lid.

Owner:APPLIED DESIGN & ENG

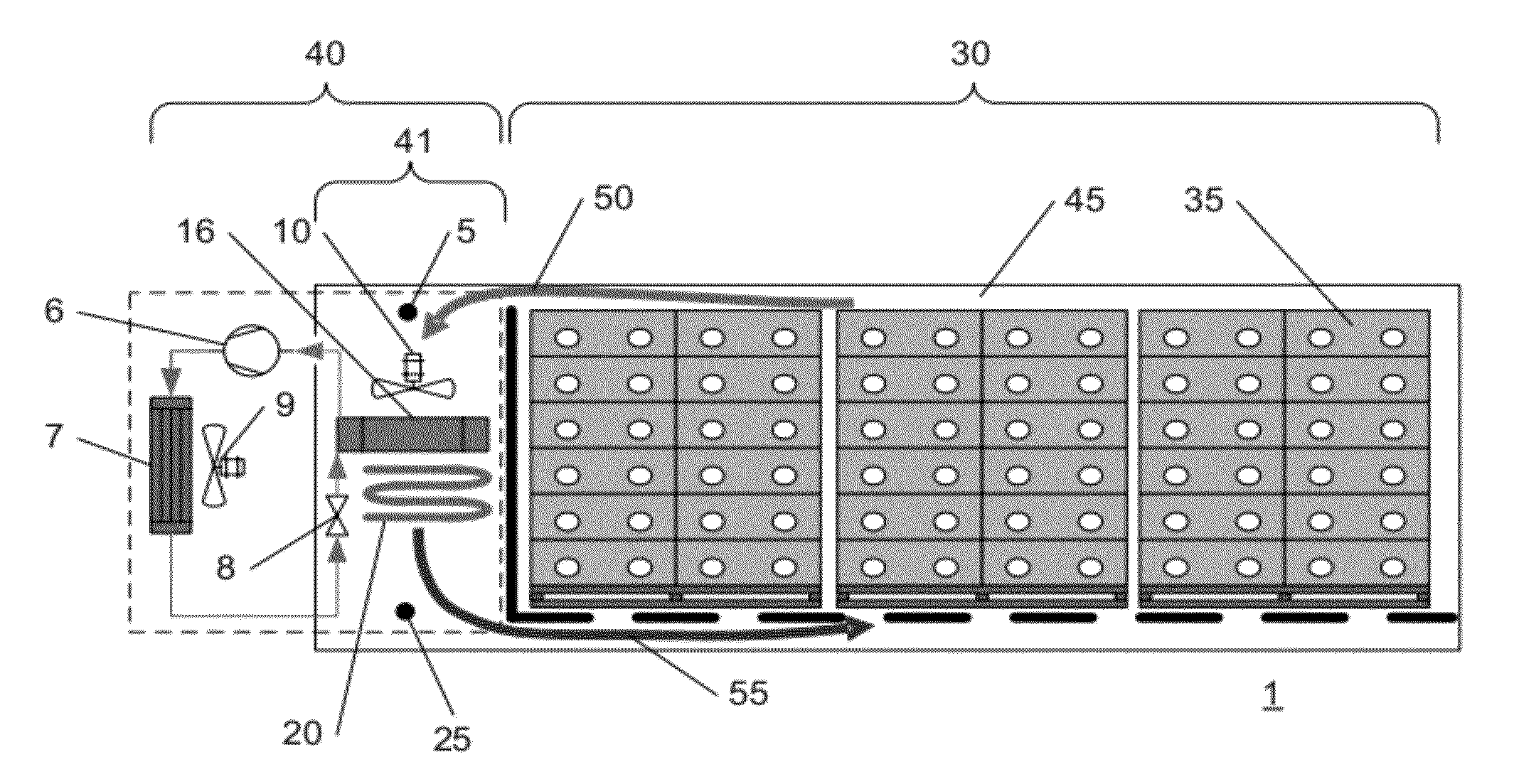

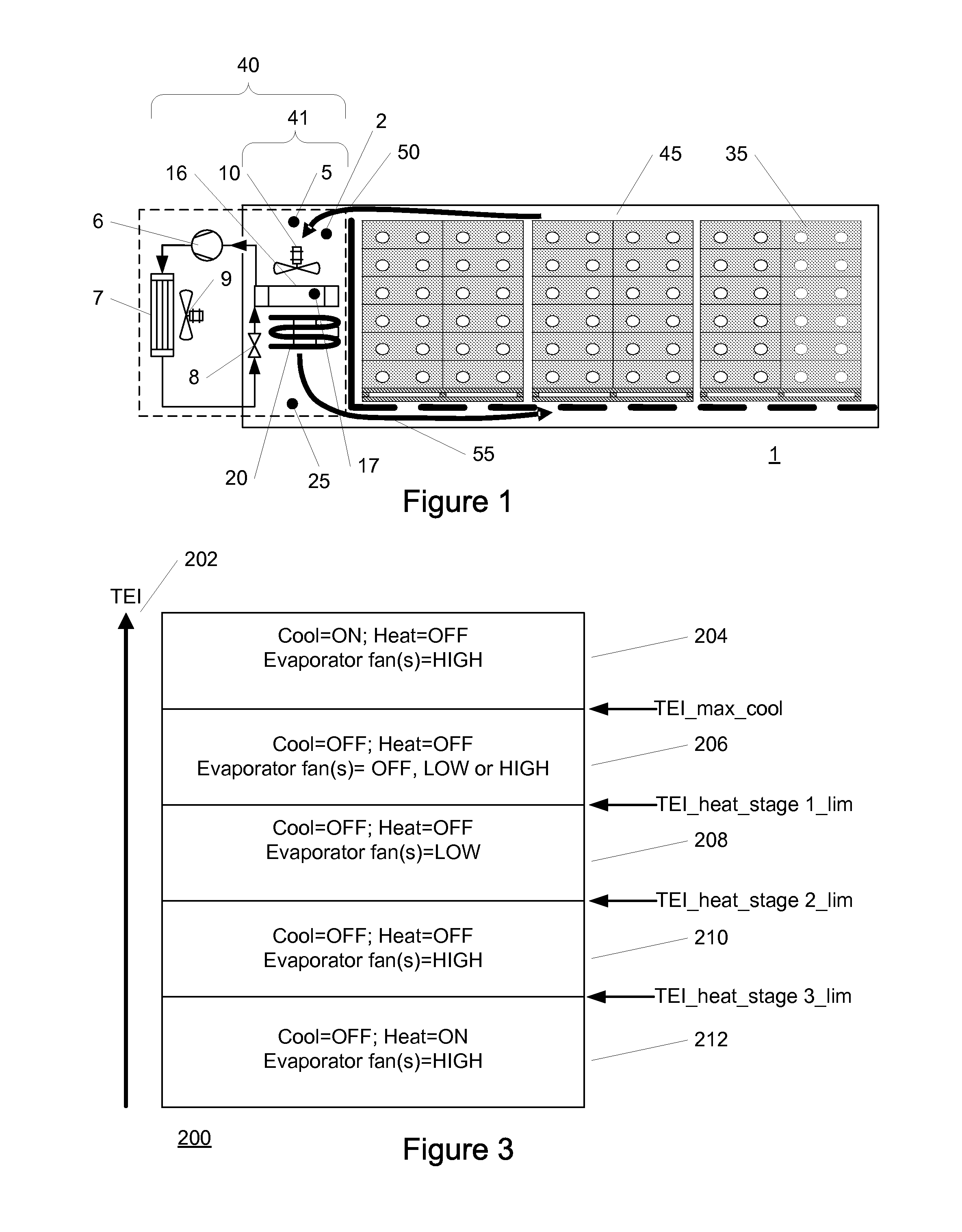

Internal air circulation control in a refrigerated transport container

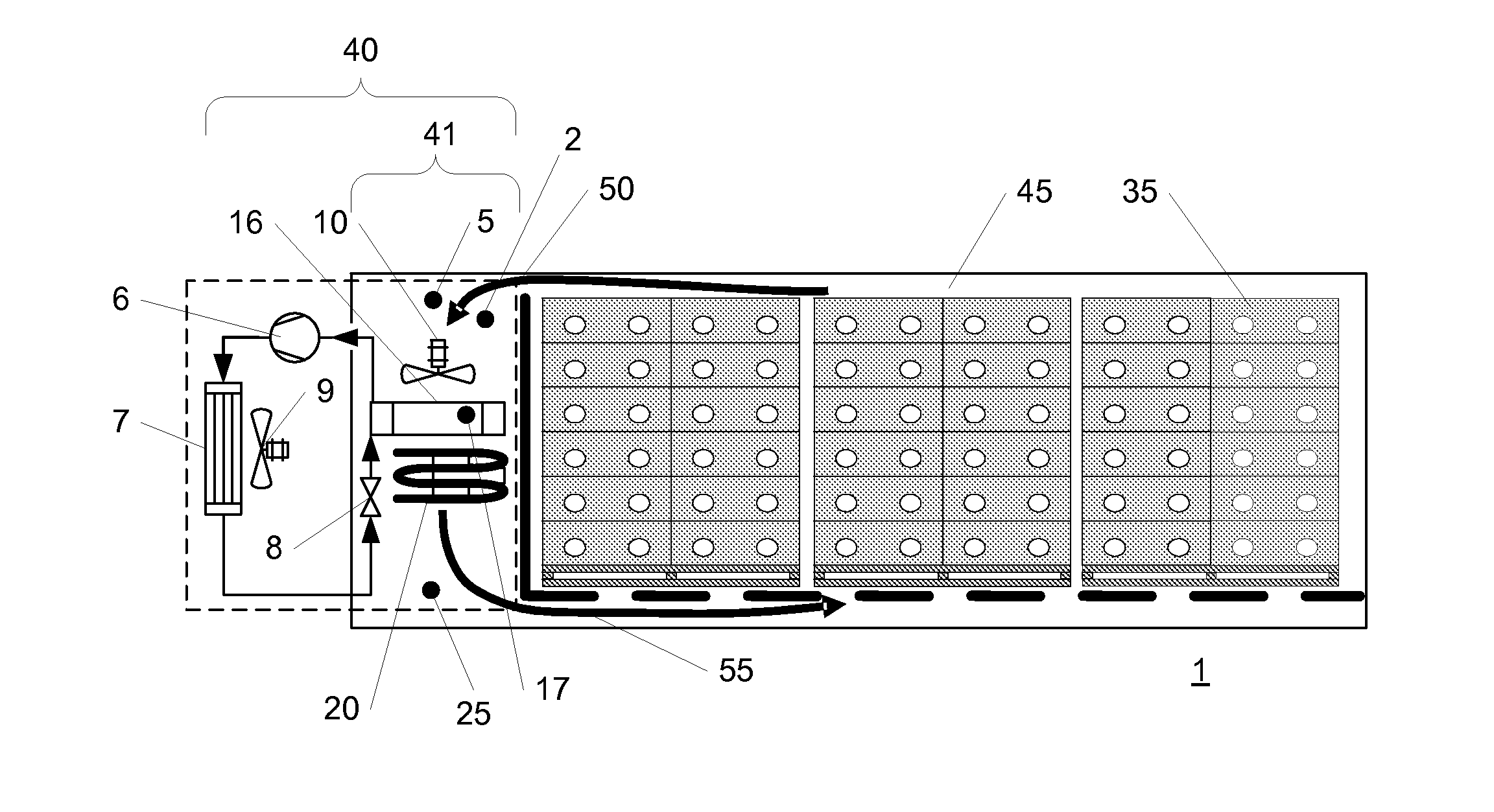

InactiveUS20120318007A1Minimizing temperature distributionSave energyDomestic refrigeratorsEfficient regulation technologiesAir cycleProcess engineering

Disclosed is a system for and a method of controlling internal air circulation within a refrigerated transport container (1), the refrigerated transport container (1) comprising a cooling unit (40), and a control unit, where the cooling unit (40) comprises at least a compressor (6) and an evaporator (16) comprising one or more evaporator fans (10) wherein the method comprises the step of: controlling the operation of the one or more evaporator fans (10) based on one or more predetermined heat load related indicators during periods where the compressor (6) is inactive wherein the one or more evaporator fans (10) are controlled to increase internal air circulation when the one or more predetermined heat load related indicators indicate a heat load increase and wherein the one or more evaporator fans (10) are controlled to decrease internal air circulation when the one or more predetermined heat load related indicators indicate a heat load reduction.

Owner:MAERSK LINE AS

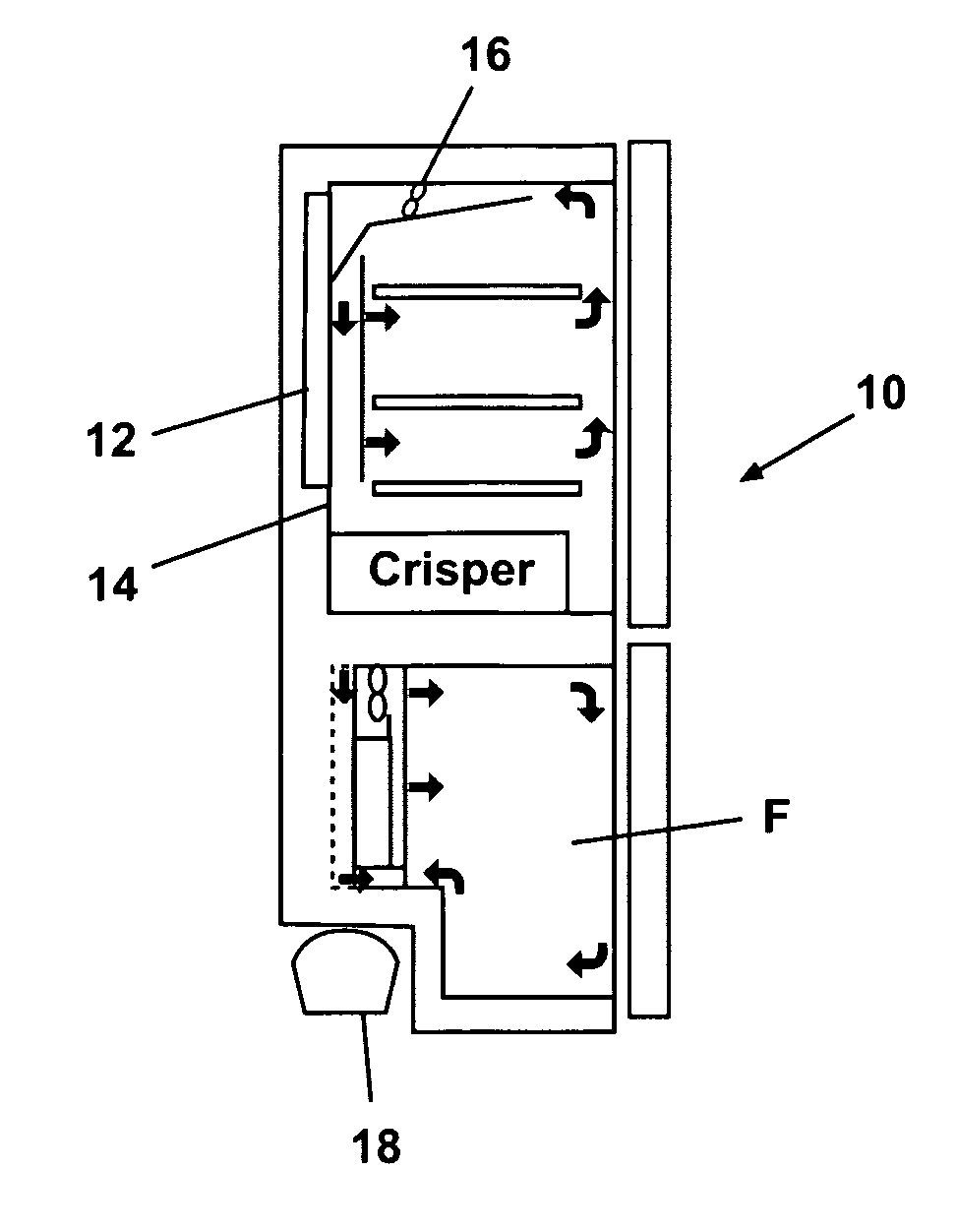

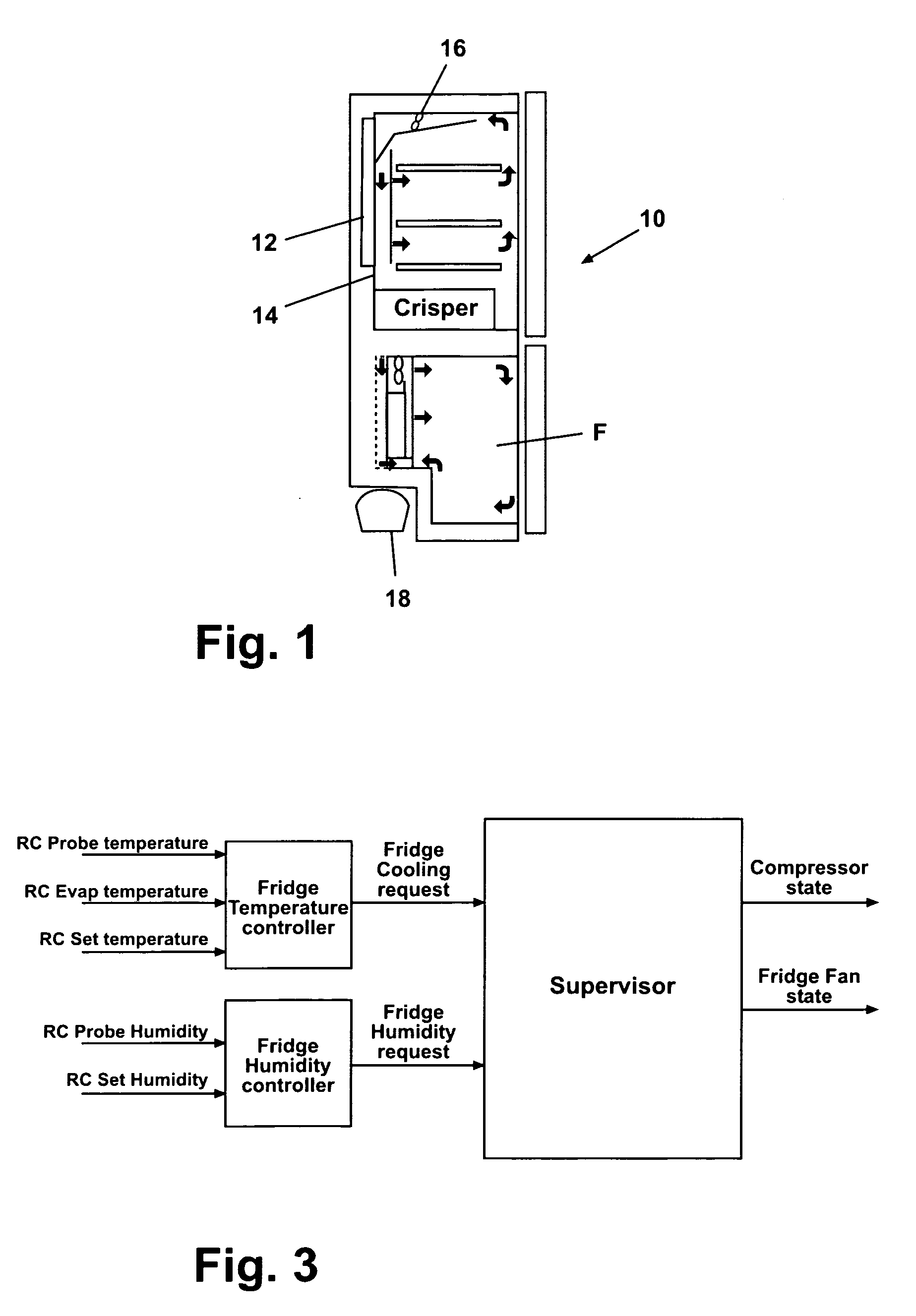

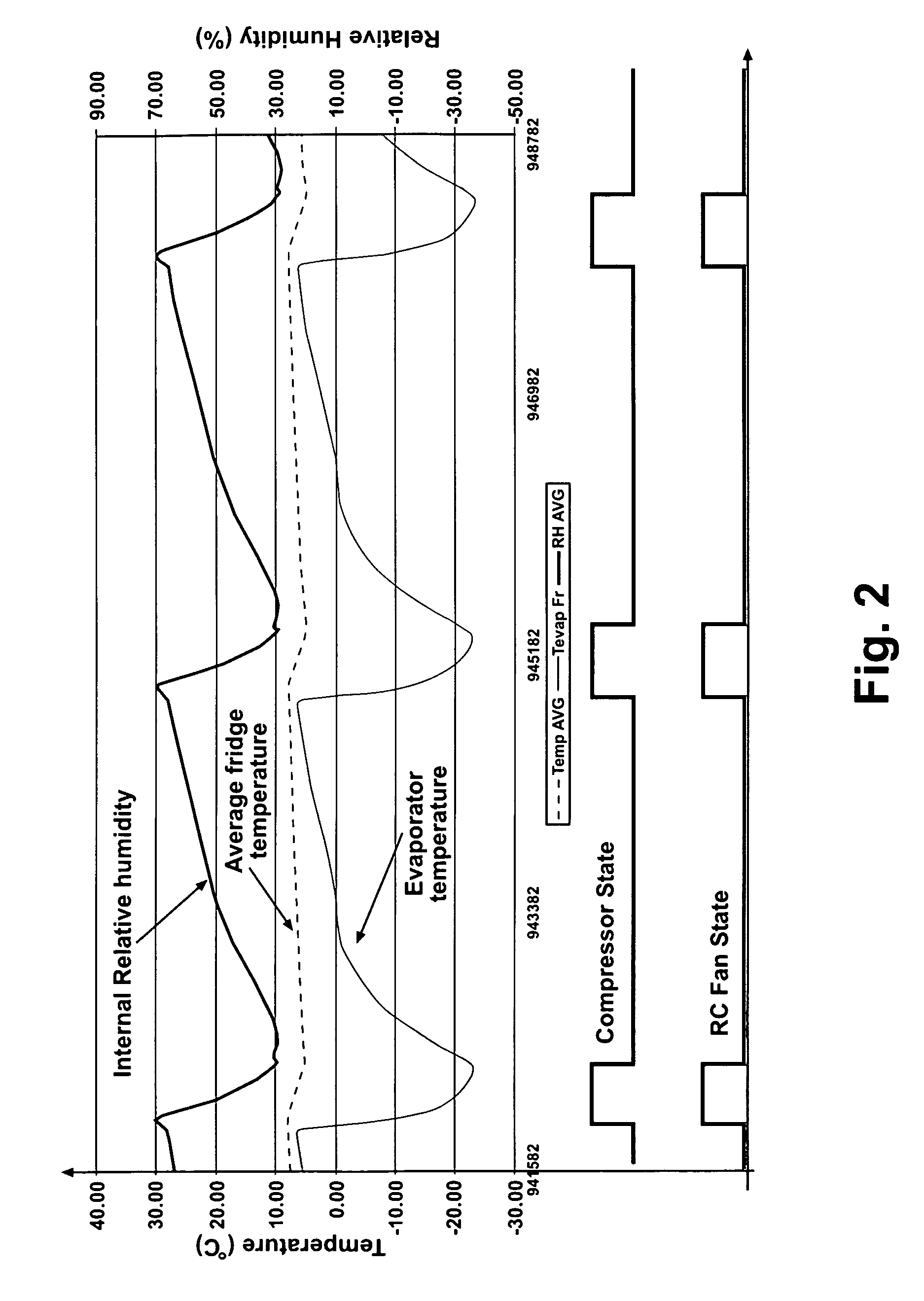

Method for controlling humidity in a domestic refrigerator, and refrigerator adapted to carry out such method

A method for controlling the humidity inside a refrigerator, having at least a cavity and a refrigeration circuit including an evaporator and a compressor, comprising the step of measuring the relative humidity level inside the cavity, measuring the temperature of the evaporator and feeding the above measured values to a control algorithm capable of driving the refrigeration circuit in order to maintain substantially constant the average level of relative humidity and corresponding to a set value.

Owner:WHIRLPOOL CORP

Insulated ice compartment for bottom mount refrigerator

ActiveUS20060260333A1Good conditionIce productionDomestic refrigeratorsTemperature controlElectronic control system

A refrigerator includes a refrigerator cabinet, a fresh food compartment disposed within the cabinet, a freezer compartment disposed within the cabinet, an ice compartment disposed within the cabinet, and an electronic control system associated with the refrigerator and adapted to monitor and control the fresh food compartment, the freezer compartment and the ice compartment. The control system provides for energy efficient control and operation through various means, including by monitoring state of an ice maker associated with the ice compartment and controlling temperature within compartments of the refrigerator based on the ice maker state. The control system can also use correlations in determining appropriate temperatures for different compartments within the refrigerator.

Owner:WHIRLPOOL CORP

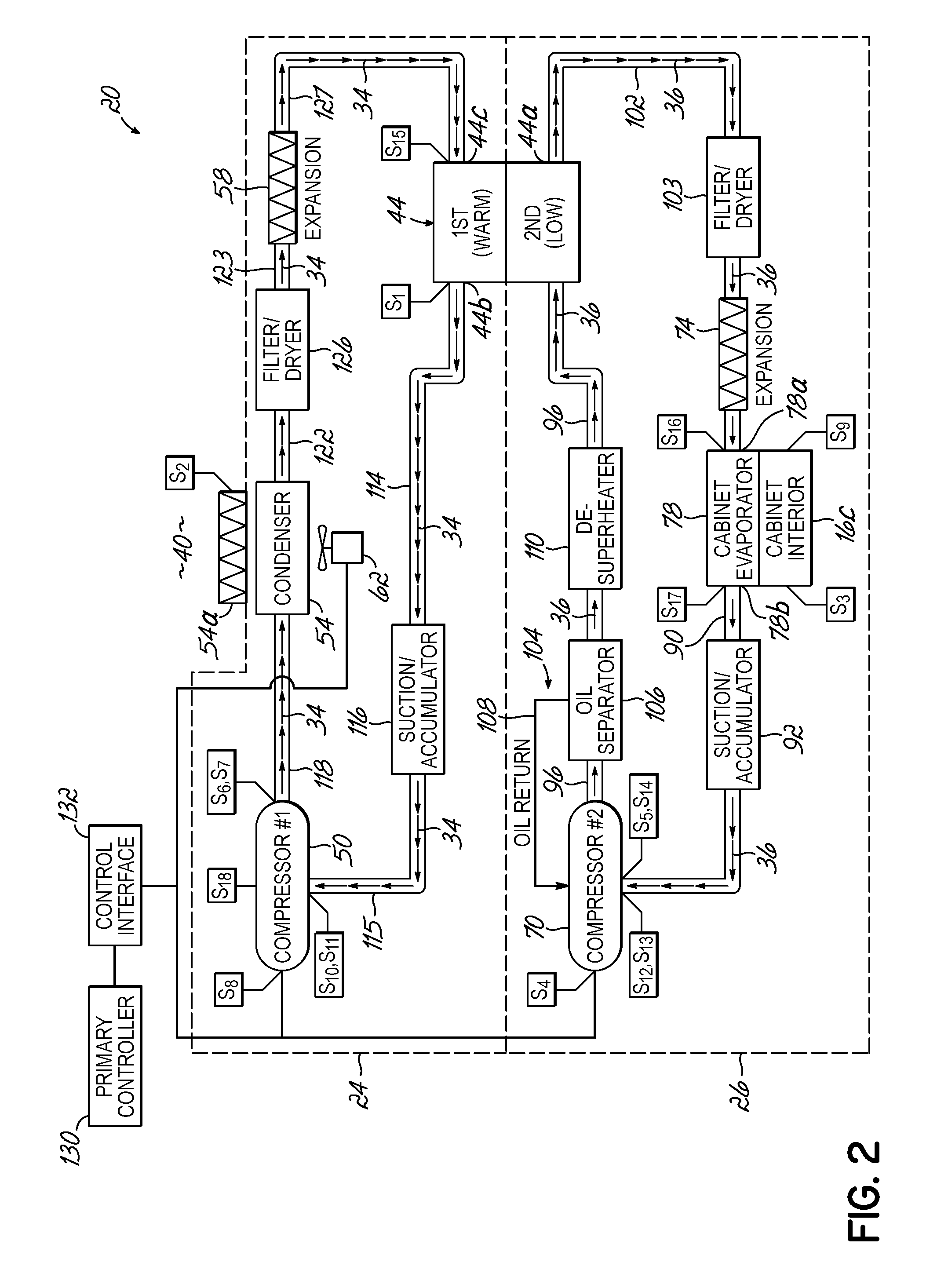

Refrigeration system having a variable speed compressor

ActiveUS20110072836A1Uniform temperature distributionImprove life expectancyCompression machines with non-reversible cycleEvaporators/condensersEngineeringRefrigeration

A two-stage cascade refrigeration system is provided having a first refrigeration stage and a second refrigeration stage. The first refrigeration stage defines a first fluid circuit for circulating a first refrigerant, and has a first compressor, a condenser, and a first expansion device that is in fluid communication with the first fluid circuit. The second refrigeration stage defines a second fluid circuit for circulating a second refrigerant, with the second refrigeration stage having a second compressor, a second expansion device, and an evaporator that is in fluid communication with the second fluid circuit. A heat exchanger is in fluid communication with the first and second fluid circuits to exchange heat between the first and second refrigerants. At least one of the first or second compressors is a variable speed compressor.

Owner:THERMO FISHER SCI ASHEVILLE

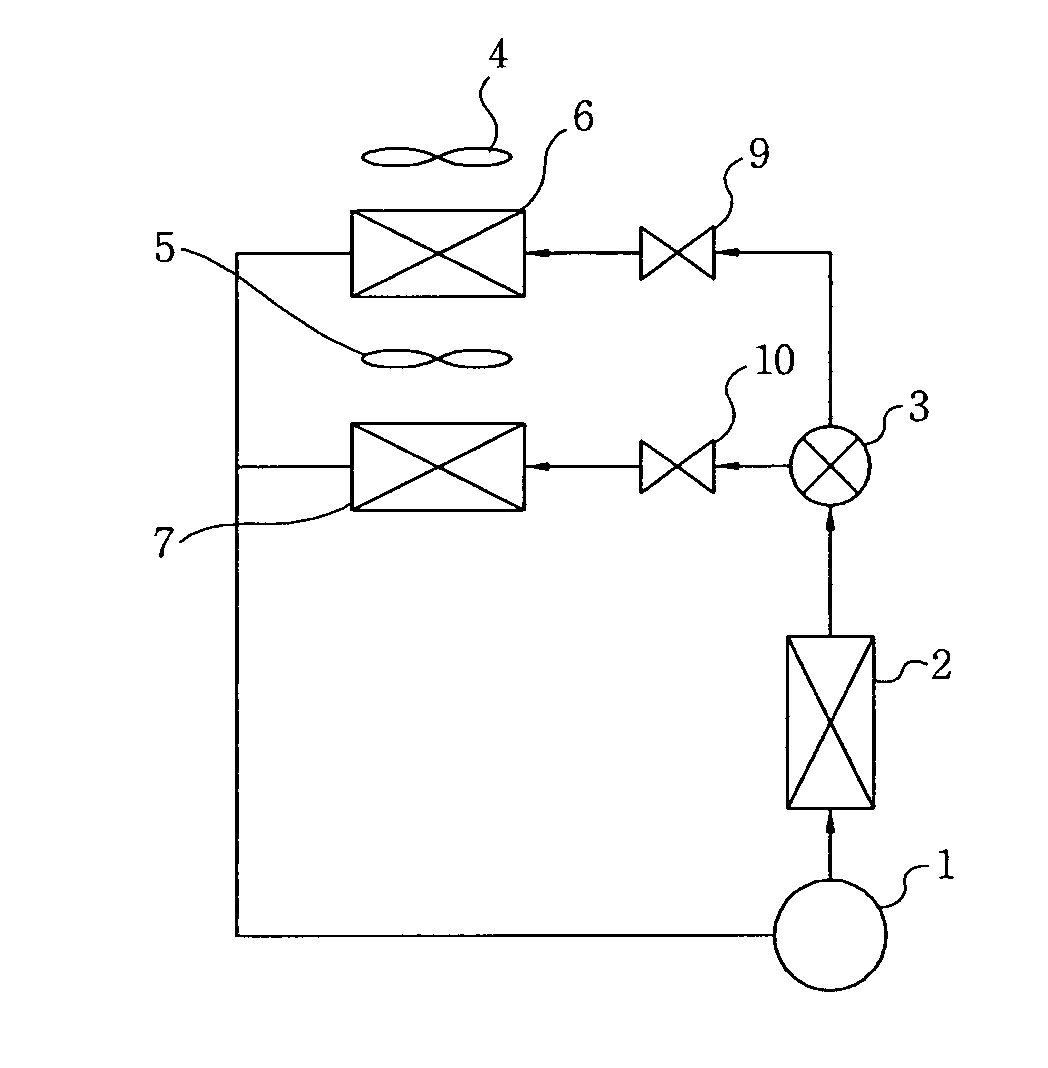

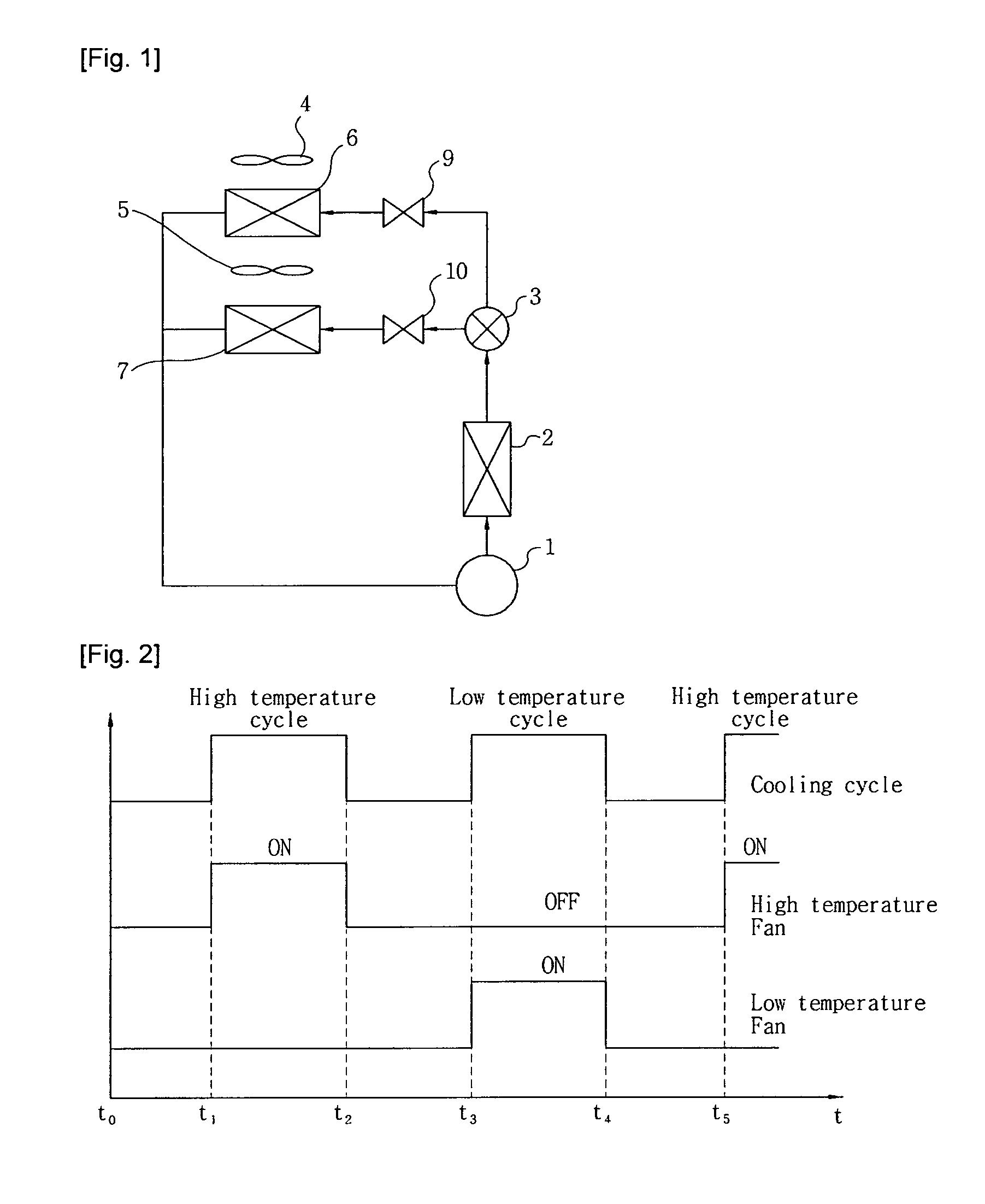

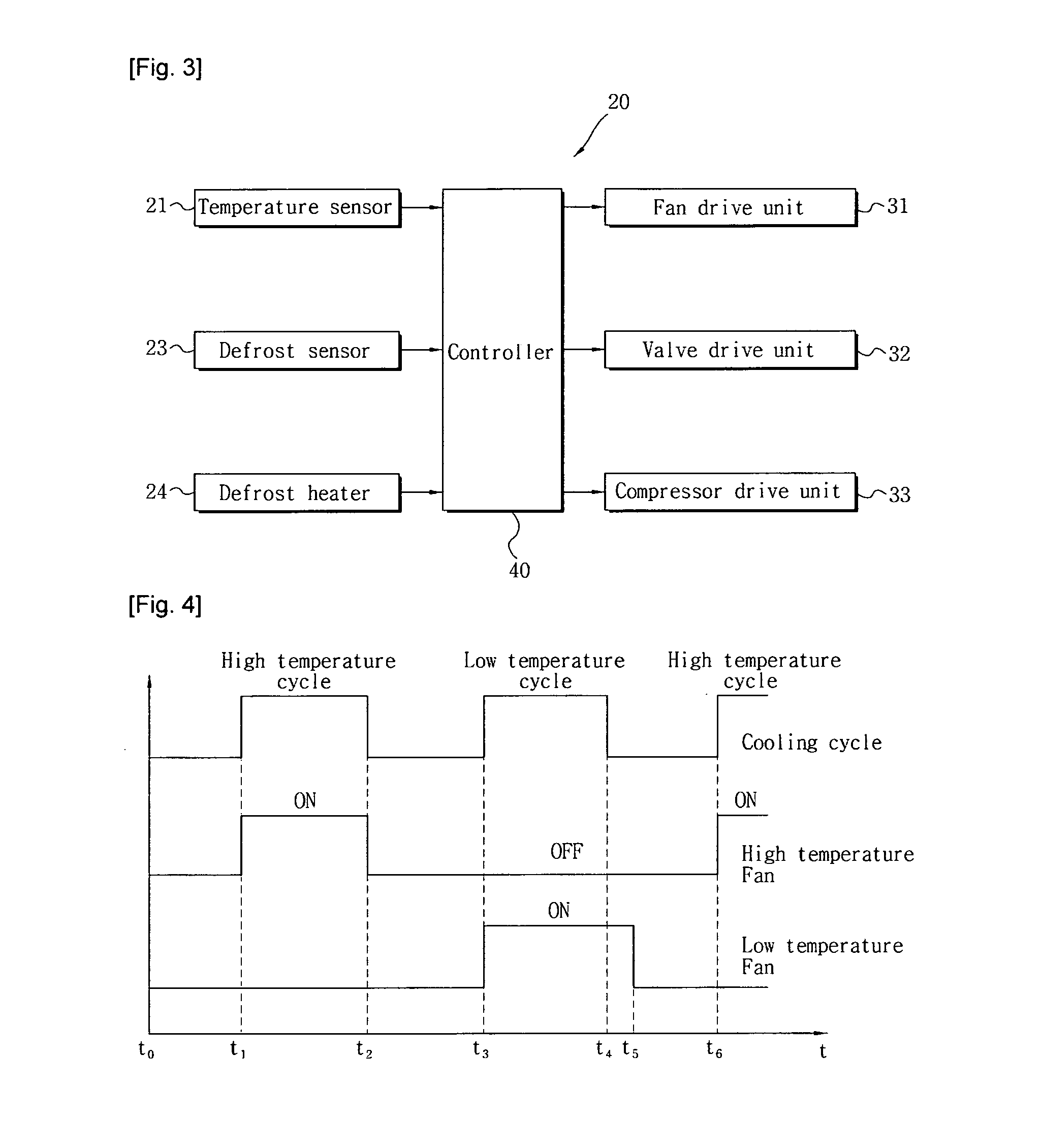

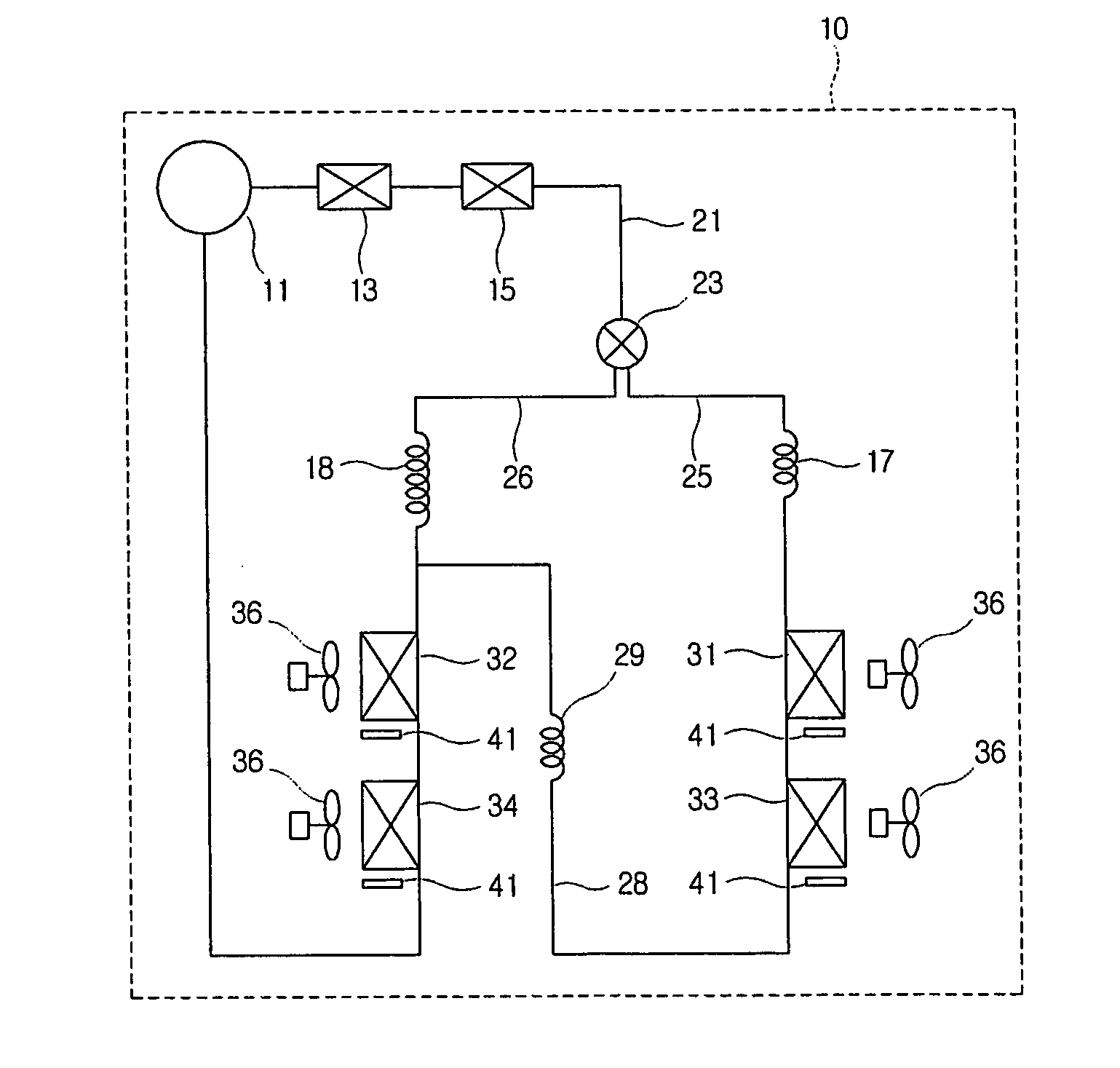

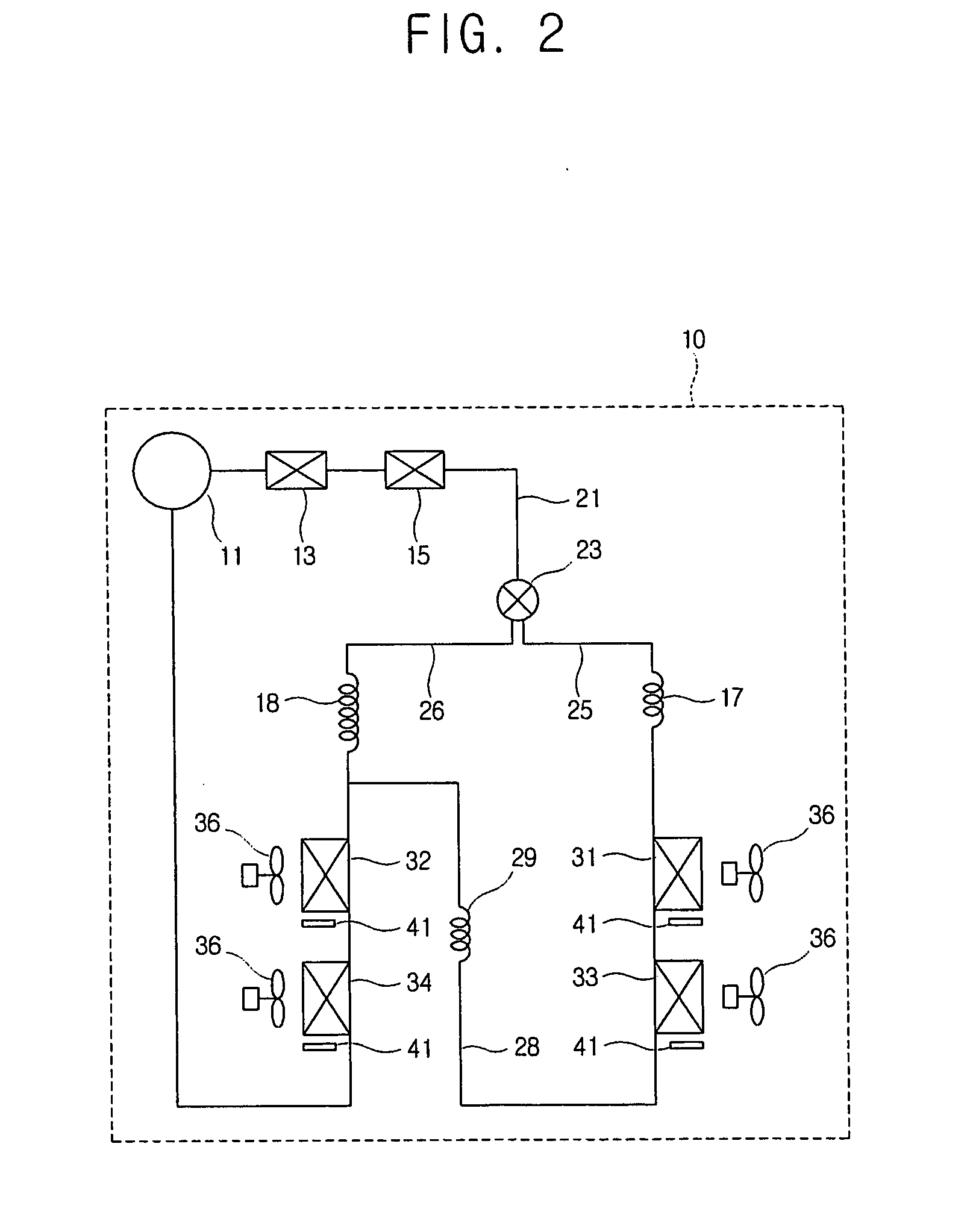

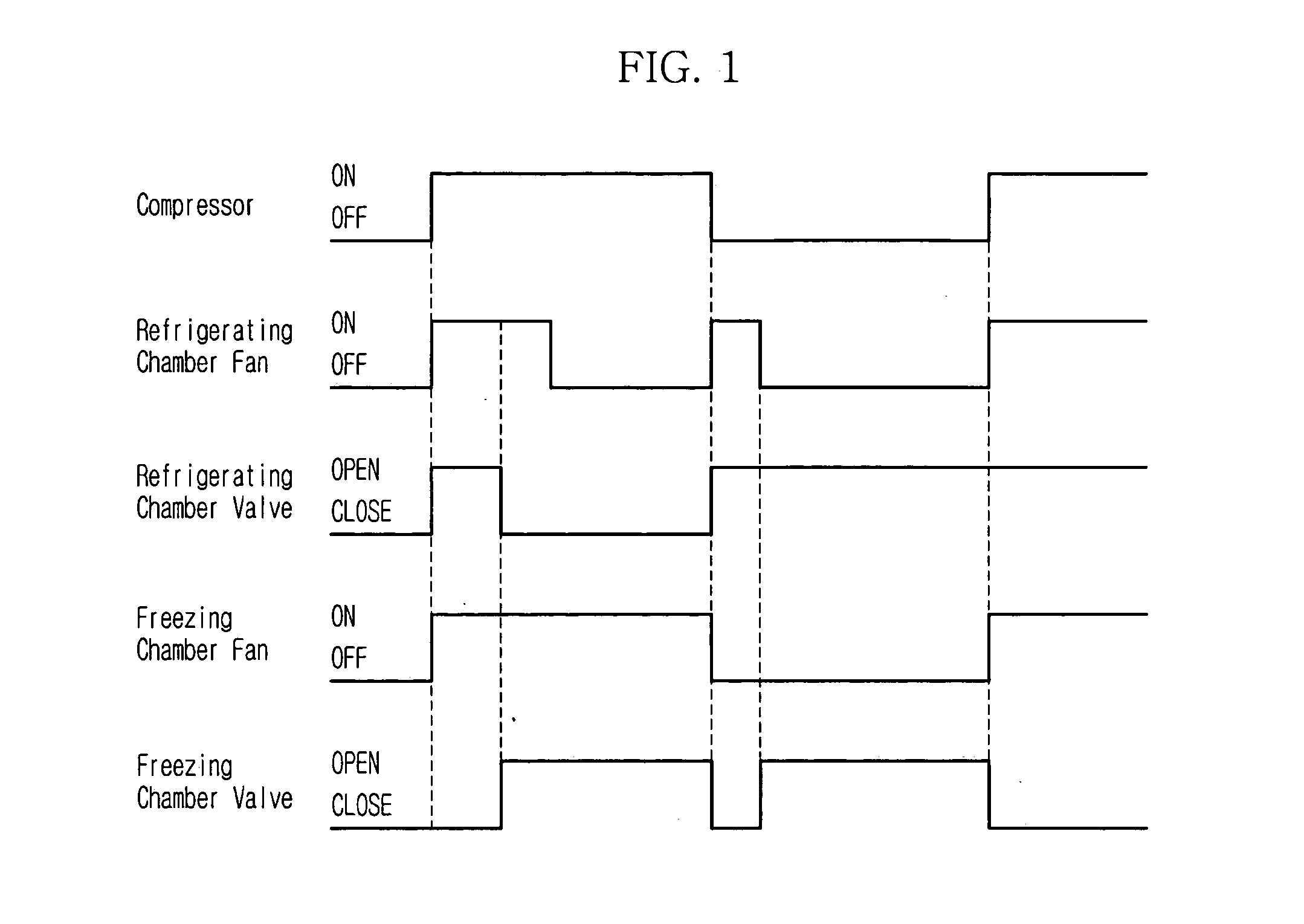

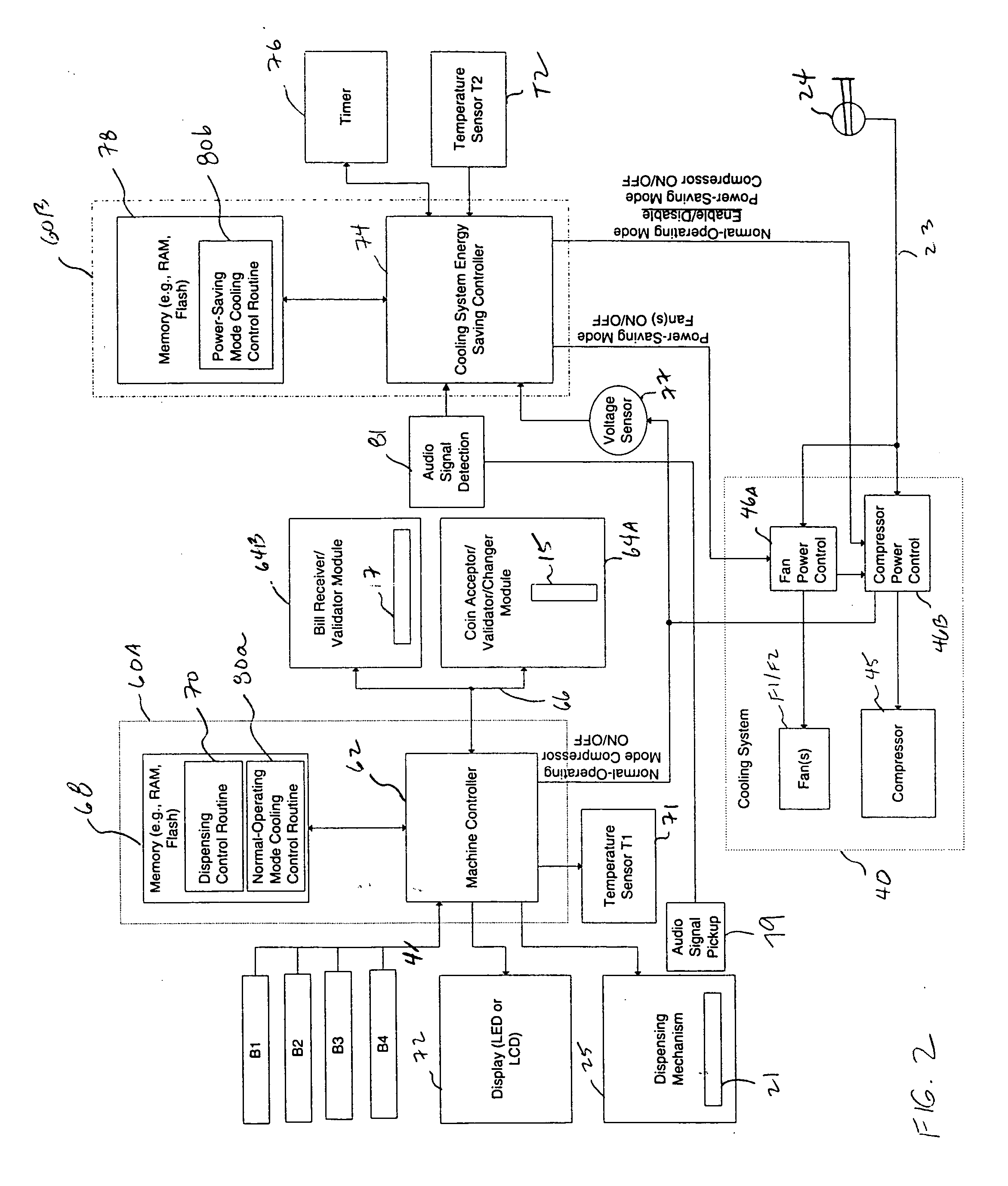

Control method of refrigerator

ActiveUS20110041525A1Promote circulationIncrease temperatureDomestic refrigeratorsCompression machines with several evaporatorsEngineeringRefrigerant

The present invention relates to a control method of a refrigerator which operates a cooling cycle including two storage compartments, a compressor, a condenser, a valve, fans, and evaporators for cooling the respective storage compartments, with one of the fans (5) corresponding to the storage compartment for storing items at relatively low temperatures being activated for a set amount of time even after the compressor is deactivated at the completion of cooling of the storage compartment for storing items at relatively low temperatures. In a refrigerator comprising a first storage compartment for storing an item, a second storage compartment for storing an item at a lower temperature than the first storage compartment, a cooling cycle including a compressor, a condenser for condensing a refrigerant from the compressor, a valve for directing the refrigerant from the condenser to first and second evaporators, with the first and second evaporators evaporating supplied refrigerants to cool the first and second storage compartments, respectively, and first and second (5) fans for circulating cool air from the first and second evaporators, respectively, and a controller for controlling the first and second (5) fans, the valve and the compressor, a control method of the refrigerator comprising: a first step of the controller activating the compressor if cooling of the second storage compartment is required and activating the second fan (5); and a second step of the controller deactivating the operation of the compressor, if the cooling of the second storage compartment is completed, and deactivating the operation of the second fan (5) after the operation of the compressor is deactivated.

Owner:LG ELECTRONICS INC

Refrigerator and control method thereof

InactiveUS20070033962A1Improve cooling efficiencyEvaporators/condensersDomestic refrigeratorsEngineeringRefrigerant

A refrigerator comprising a main body which is formed with three or more storage compartments and a cooling unit having a plurality of evaporators corresponding to the respective storage compartments, the cooling unit comprising a refrigerant supply pipe to supply a refrigerant to the plurality of evaporators; a plurality of refrigerant branch pipes which are branched from the refrigerant supply pipe to mount the evaporators thereto, and to at least one of which the plurality of evaporators are connected in series; and a refrigerant connection pipe to connect an outlet of one of the plurality of refrigerant branch pipes and an inlet of the other one of the plurality of refrigerant branch pipes.

Owner:SAMSUNG ELECTRONICS CO LTD

Refrigerating device and control method thereof

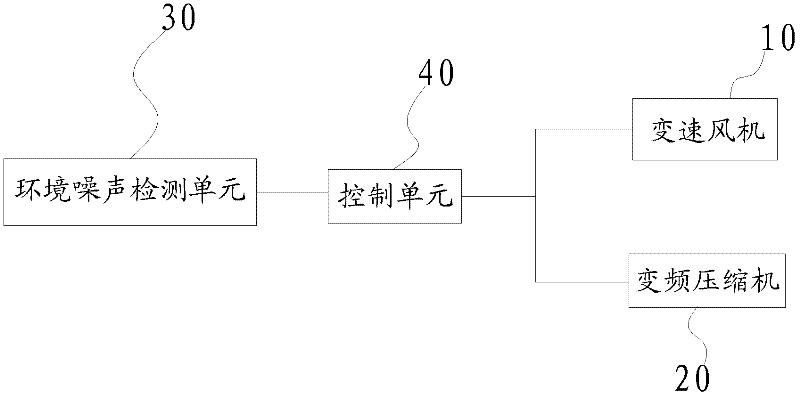

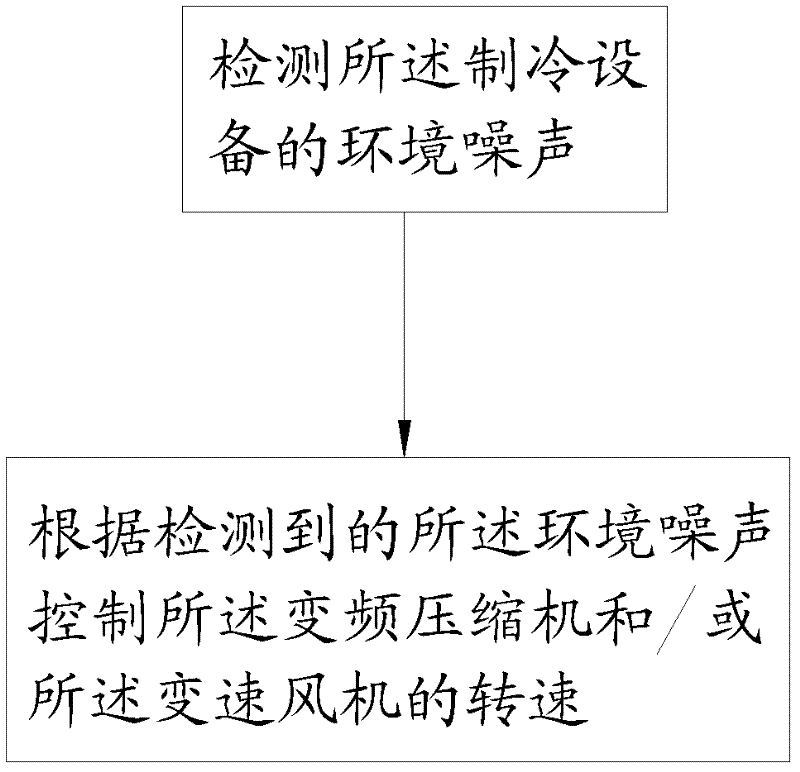

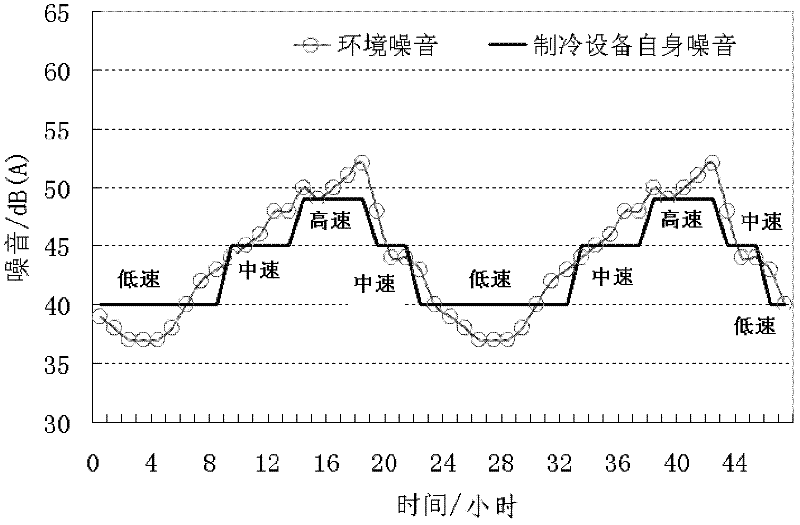

InactiveCN102506535AImprove the perception of noiseLighting and heating apparatusDomestic refrigeratorsEnvironmental noiseFrequency conversion

The invention discloses a refrigerating device and a control method thereof. The refrigerating device comprises a speed-changing fan, a frequency-conversion compressor, an environmental noise detecting unit and a control unit, wherein the environmental noise detecting unit is used for detecting the environmental noise of the refrigerating device, and the control unit is connected with the environmental noise detecting unit, the speed-changing fan and the frequency-conversion compressor, so as to control the rotating speed of the speed-changing fan and / or the frequency-conversion compressor according to the magnitude of the environmental noise detected by the environmental noise detecting unit. The refrigerating device has the beneficial effect that the rotating speed of the speed-changing fan and / or the frequency-conversion compressor can be controlled according to the magnitude of the environmental noise of the refrigerating device, so that the noise generated by the refrigerating device corresponds to the environmental noise, and a user hardly can sense the noise of the refrigerating device, thereby increasing the quality of the refrigerating device.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD +1

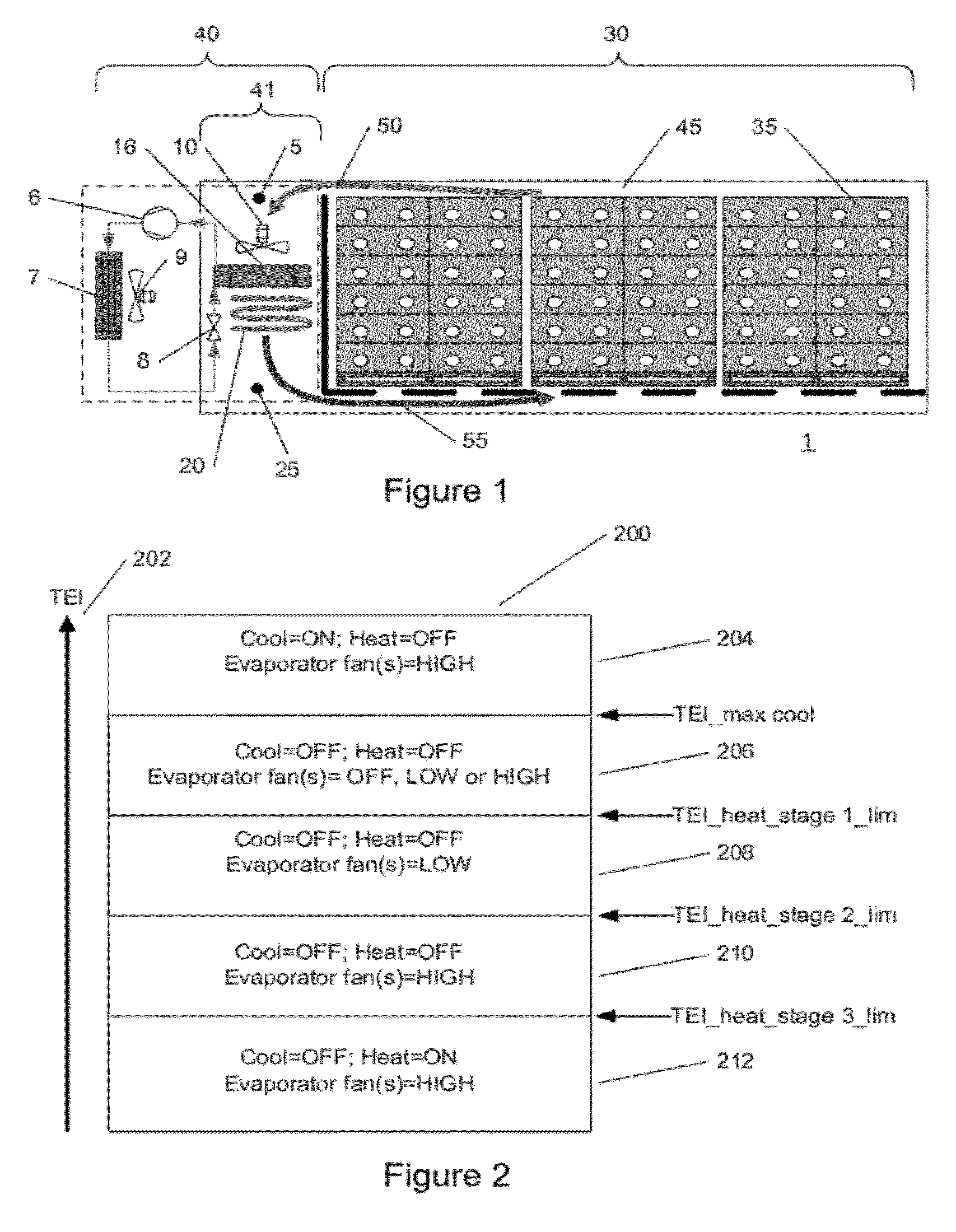

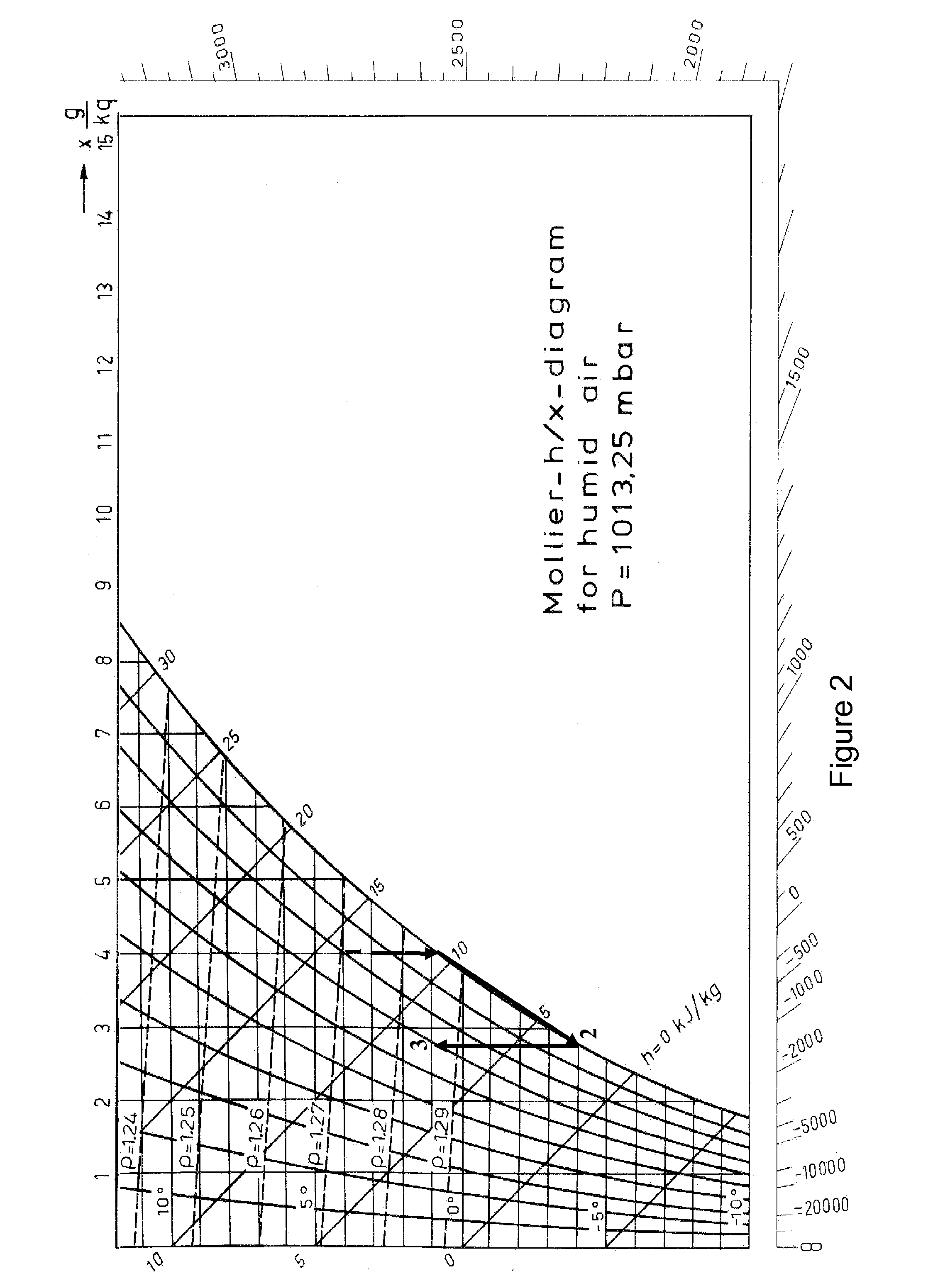

Humidity control in a refrigerated transport container with an intermittently operated compressor

InactiveUS20130014522A1Precise temperature controlIncrease speedDomestic refrigeratorsEfficient regulation technologiesControl systemWater vapor

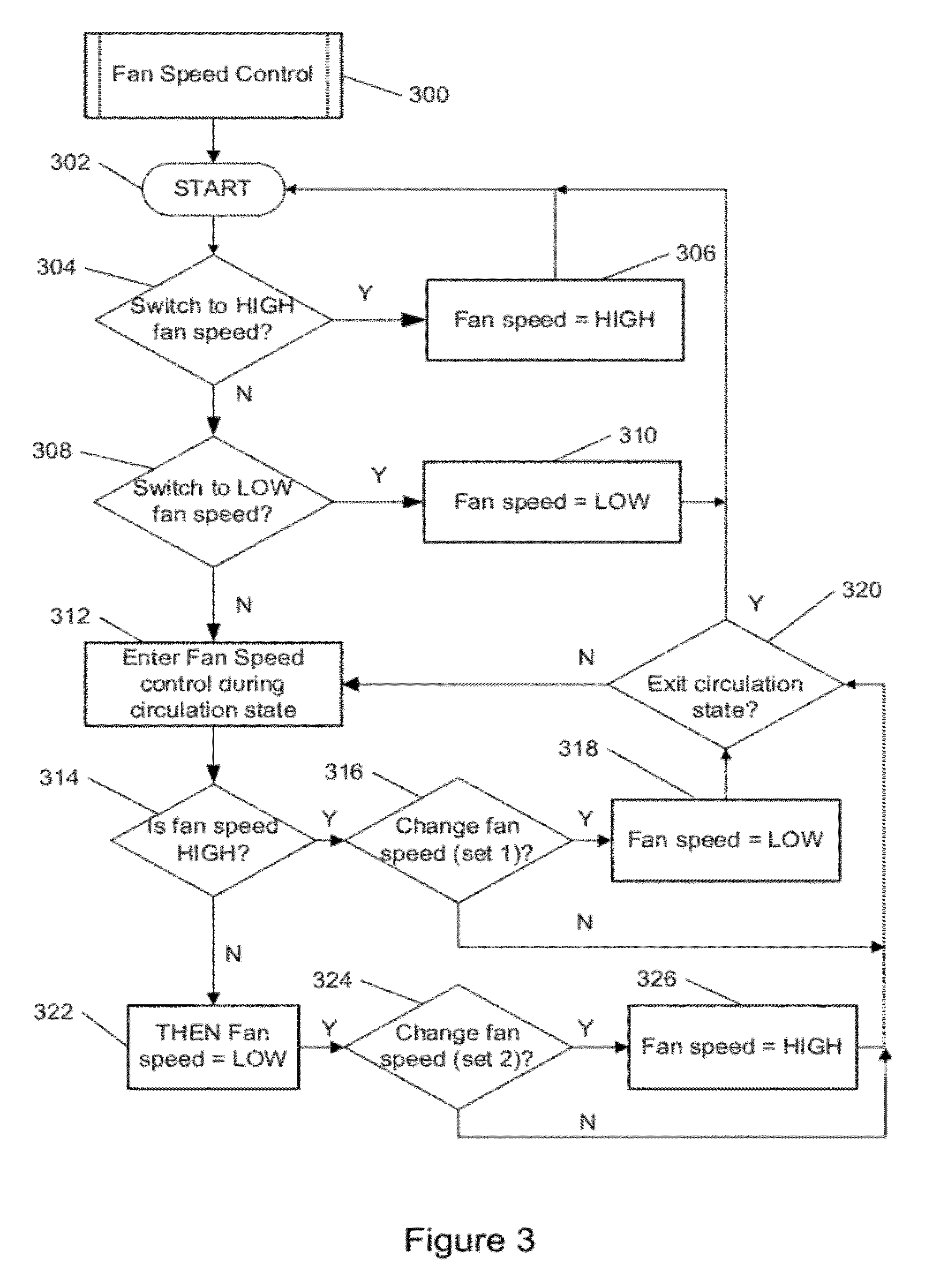

There is a growing need for dehumidification control in refrigerated transport containers with an intermittently operated compressor. The disclosed system and method of dehumidification control, controlling the speed of one or more evaporator fans and a heating unit, meets that need using one or more dehumidification need indicators and one or more condensation indicators. More specifically a system for and method is disclosed, comprising: controlling the operation of the one or more evaporator fans (10) for dehumidification purposes according to: if a need for dehumidification is determined using at least one dehumidification need indicator and if at least one condensation indicator indicates that the evaporator (16) is sufficiently cold respectively too warm for condensation or deposition of water vapor on its external surface, then setting or maintaining the speed of the one or more evaporator fans (10) to a reduced speed (LOW) in order to increase a condensation or deposition rate respectively to an increased speed (HIGH) in order to increase heat load to the evaporator (16), respectively. In other embodiments the system and method controls the heating unit as well.

Owner:A P MOLLER AS

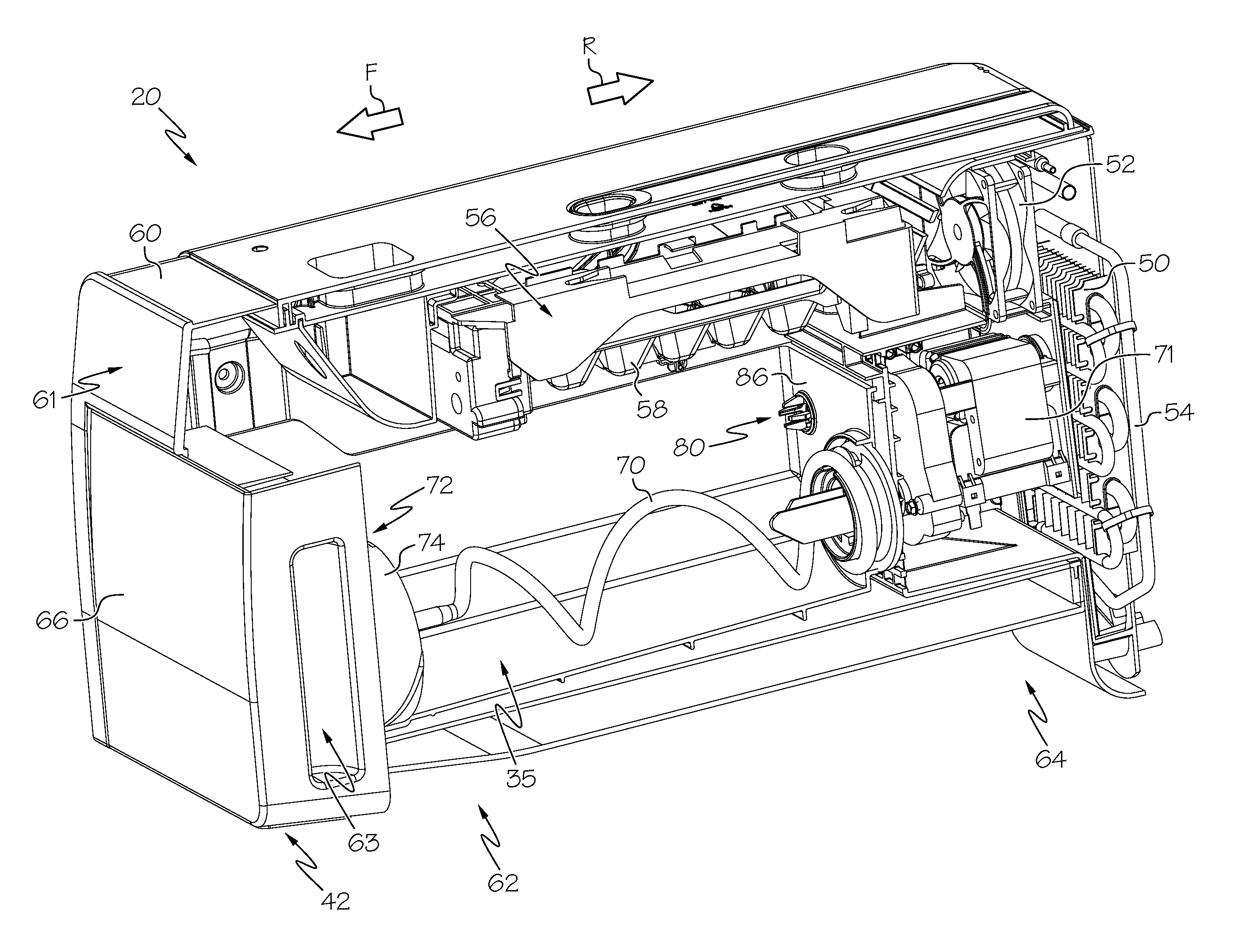

Ice maker for a refrigeration appliance

A refrigeration appliance includes a fresh food compartment, a freezer compartment, and an ice maker within the fresh food compartment for freezing water into ice pieces. In one example, a rotatable auger drives the ice pieces out of a removable ice bin via a driving force applied in a first direction. A latch is configured to apply a resisting force to the ice bin along a second direction. In another example, an air mover is disposed within the ice maker for delivering cooled air from an ice maker evaporator to a region adjacent to the ice bin. At least one air channel is formed into an inside surface of the ice maker chamber. In another example, a method of making ice in the refrigeration appliance is provided. The method includes the steps of operating the air mover and a defrost heating of the ice maker evaporator.

Owner:ELECTROLUX HOME PROD CORP NV

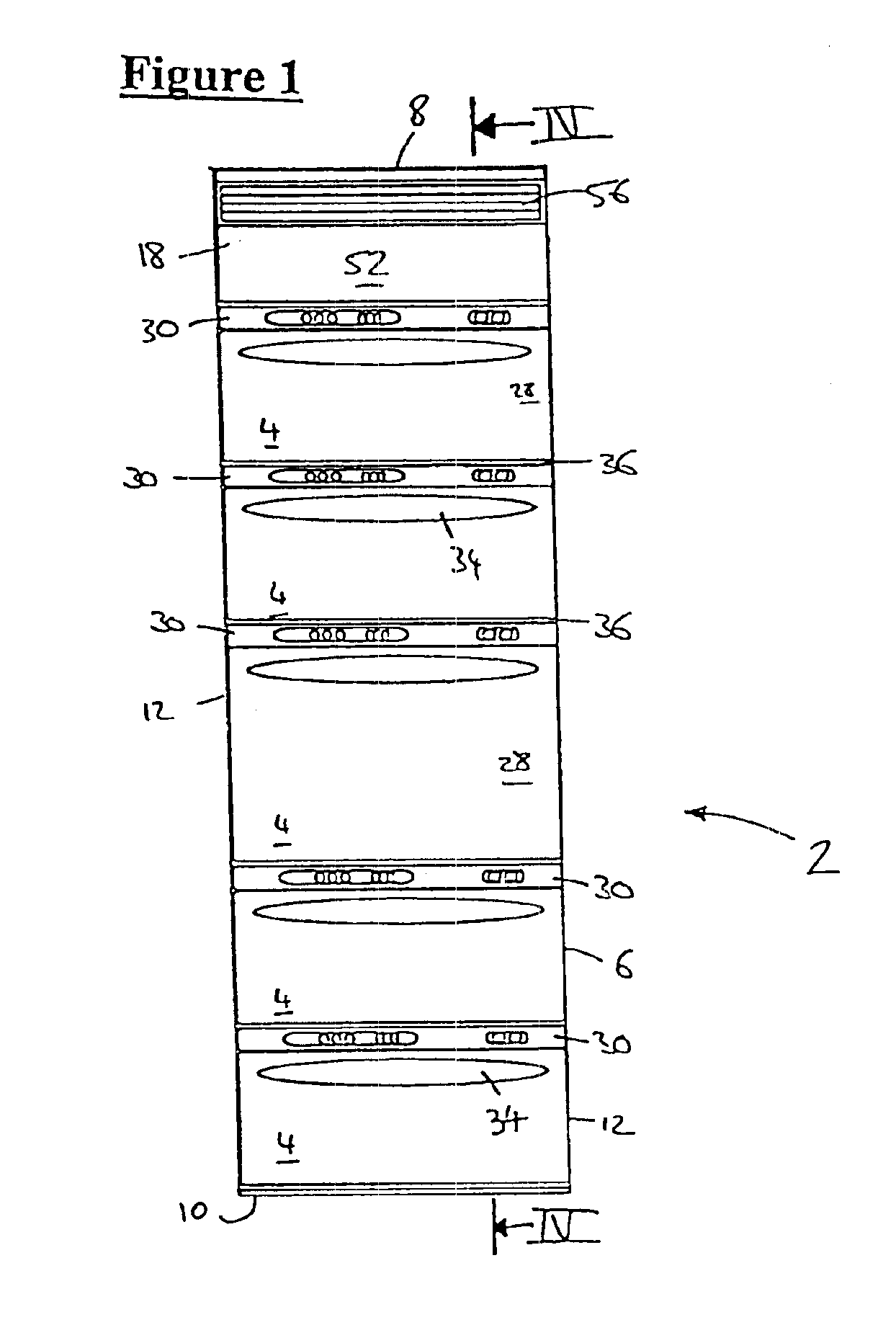

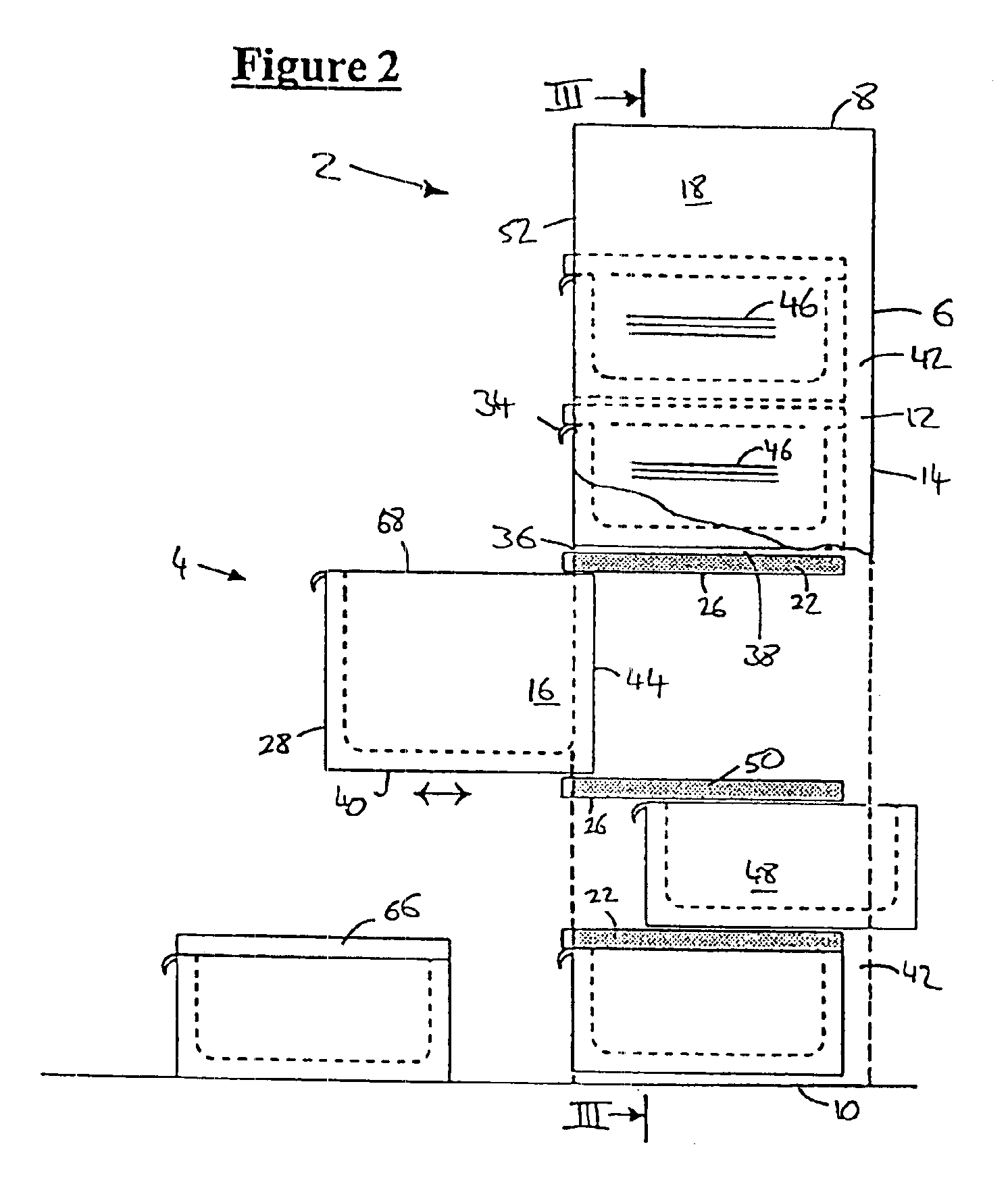

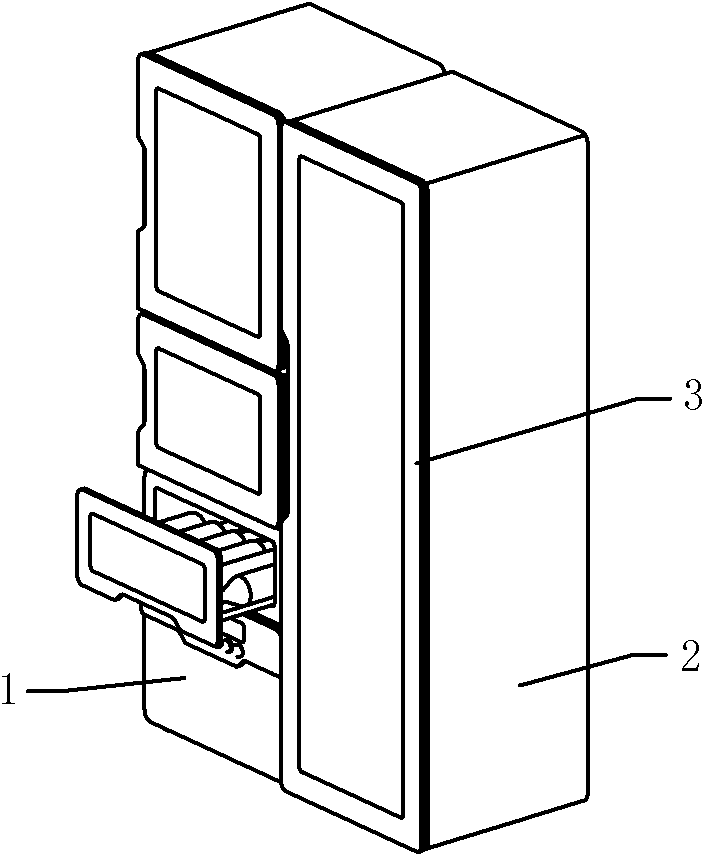

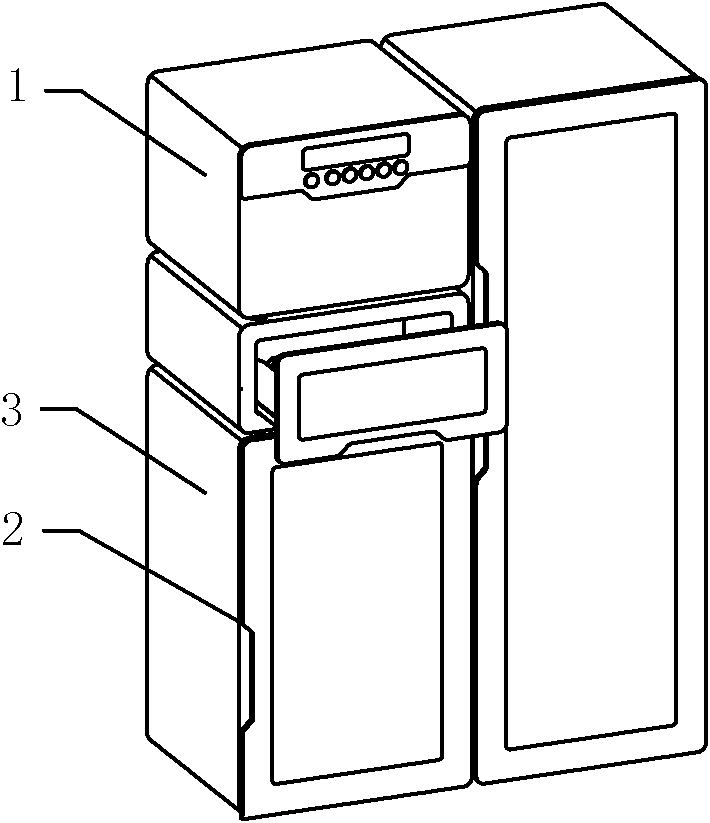

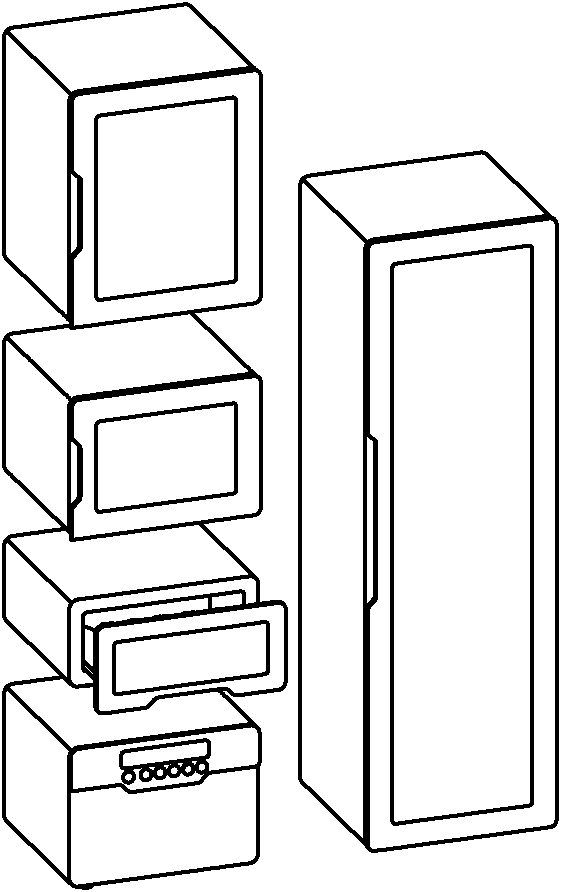

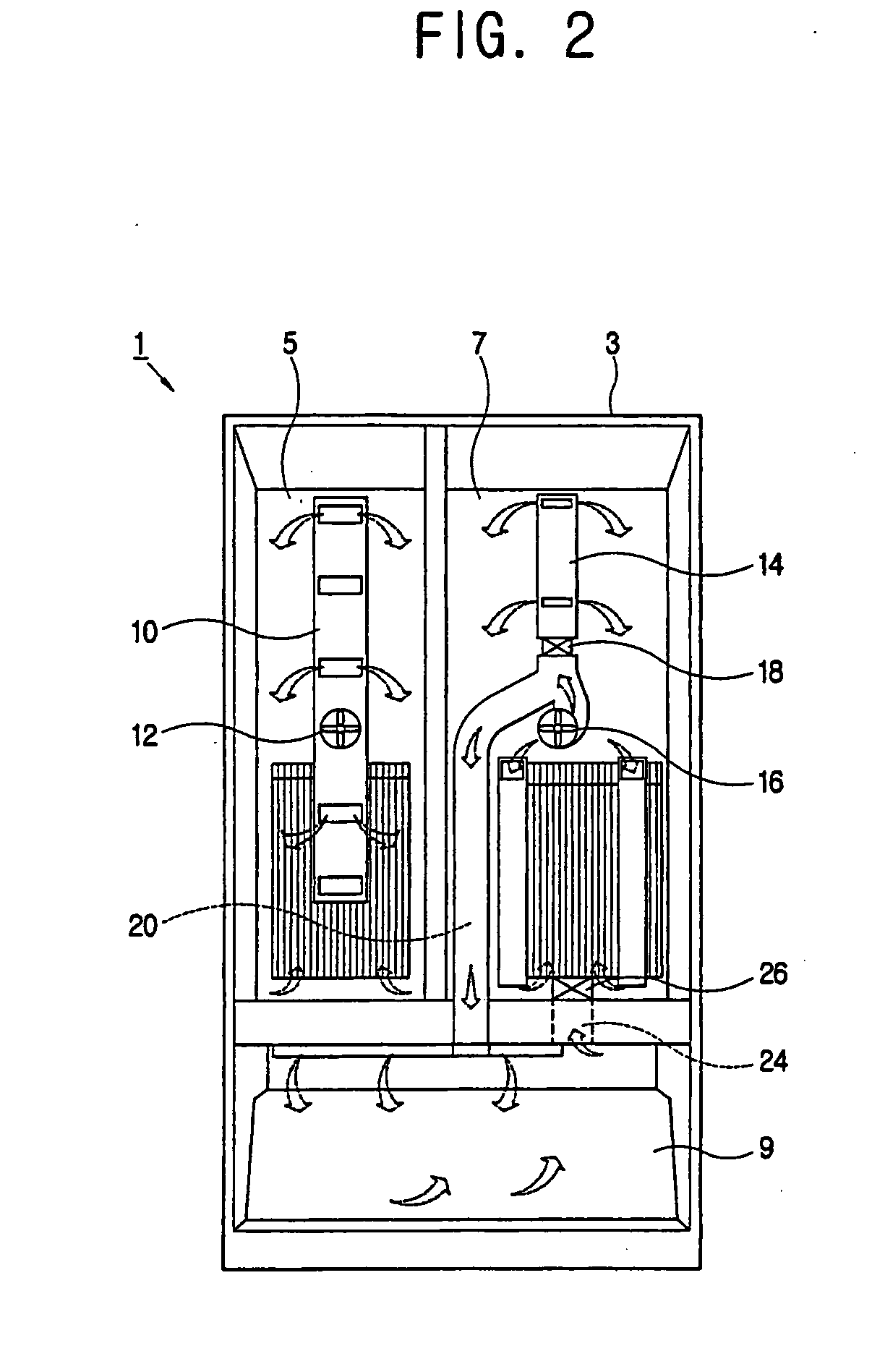

Module combined refrigerator

InactiveCN101915487AMeet usabilityMeet needsLighting and heating apparatusDomestic refrigeratorsComputer moduleElectric control

The invention provides a module combined refrigerator which comprises a refrigeration system and an electric control system, wherein, the refrigerator is composed of a mainframe room and two or more cold rooms, and the mainframe room and the cold rooms are independent and separated from each other; the cold rooms comprise door bodies and insulation boxes; the mainframe room is internally equipped with two or more refrigeration system interfaces and electric control system interfaces, and the cold rooms are internally equipped with refrigeration system joints and electric control system joints which are correspondingly connected with the refrigeration system interfaces and the electric control system interfaces in the mainframe room; and the mainframe room is equipped with a compressor, a condenser, a capillary tube and a main controller, and the cold rooms are equipped with evaporators. By means of a plurality of combined module units in the mainframe room, the module combined refrigerator can simultaneously meet the combined use requirements for a refrigerating room, a cold room, a soft-freezing room, a wine cabinet and the like, thus meeting the personalized need of customers, reducing development expense, shortening design and production cycle, saving warehousing floor space, and facilitating storage and transportation.

Owner:广东安博基业电器有限公司

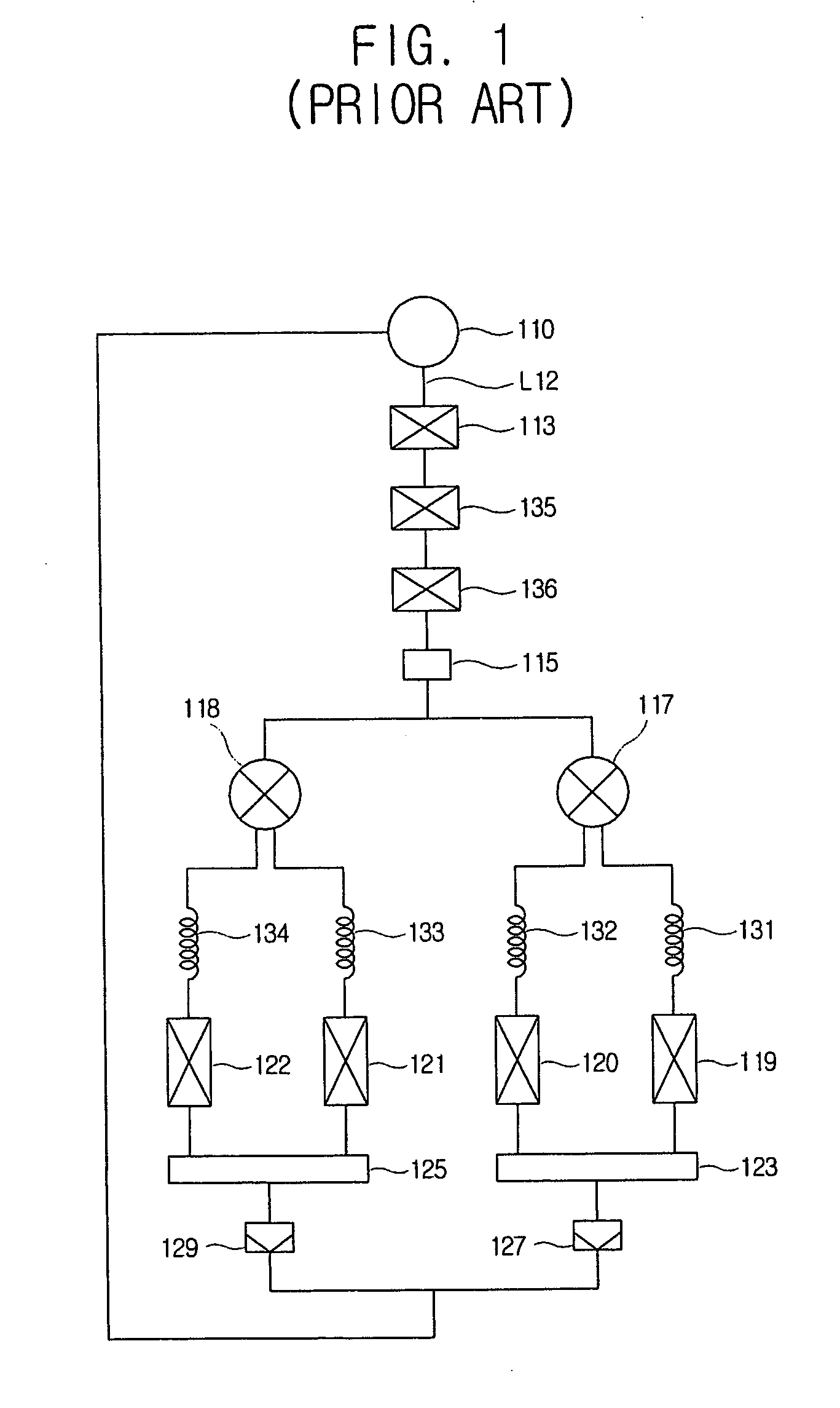

Method for controlling operation of refrigerator

InactiveUS20060144063A1Avoid temperatureReduction in electricityMechanical apparatusCompression machines with non-reversible cycleElectricityRunning time

A method for controlling operation of a refrigerator to enable independent cooling of a freezing chamber and a refrigerating chamber. The method prevents temperature rising of the refrigerator by controlling a refrigerant passage switching valve after stopping operation of a compressor, thereby reducing electricity consumption and increasing humidification effects of the refrigerator by controlling an operating time point of a refrigerating chamber fan. The method for controlling operation of the refrigerator, having a plurality of storage chambers, a plurality of evaporators installed in the respective storage chambers, and a refrigerant passage switching valve to switch refrigerant passages extending to the evaporators, includes the steps of sensing temperatures of the plurality of storage chambers and stopping operation of the compressor if the temperatures reach preset temperatures, and controlling the refrigerant passage switching valve after stopping operation of the compressor to close refrigerant passages to the plurality of evaporators.

Owner:SAMSUNG ELECTRONICS CO LTD

Ice maker for a refrigeration appliance

A refrigeration appliance includes a fresh food compartment, a freezer compartment, and an ice maker within the fresh food compartment for freezing water into ice pieces. In one example, a rotatable auger drives the ice pieces out of a removable ice bin via a driving force applied in a first direction. A latch is configured to apply a resisting force to the ice bin along a second direction. In another example, an air mover is disposed within the ice maker for delivering cooled air from an ice maker evaporator to a region adjacent to the ice bin. At least one air channel is formed into an inside surface of the ice maker chamber. In another example, a method of making ice in the refrigeration appliance is provided. The method includes the steps of operating the air mover and a defrost heating of the ice maker evaporator.

Owner:ELECTROLUX HOME PROD CORP NV

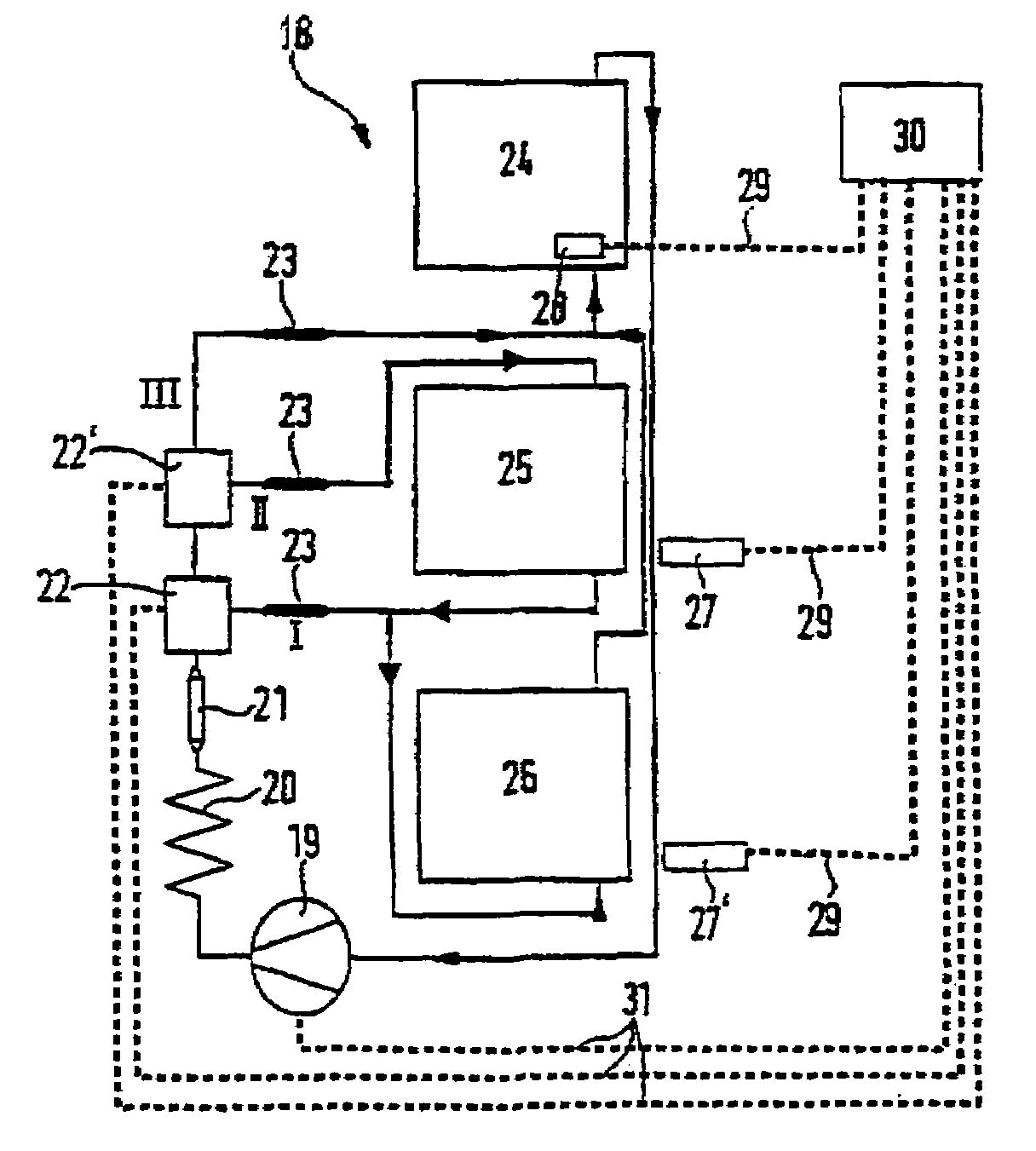

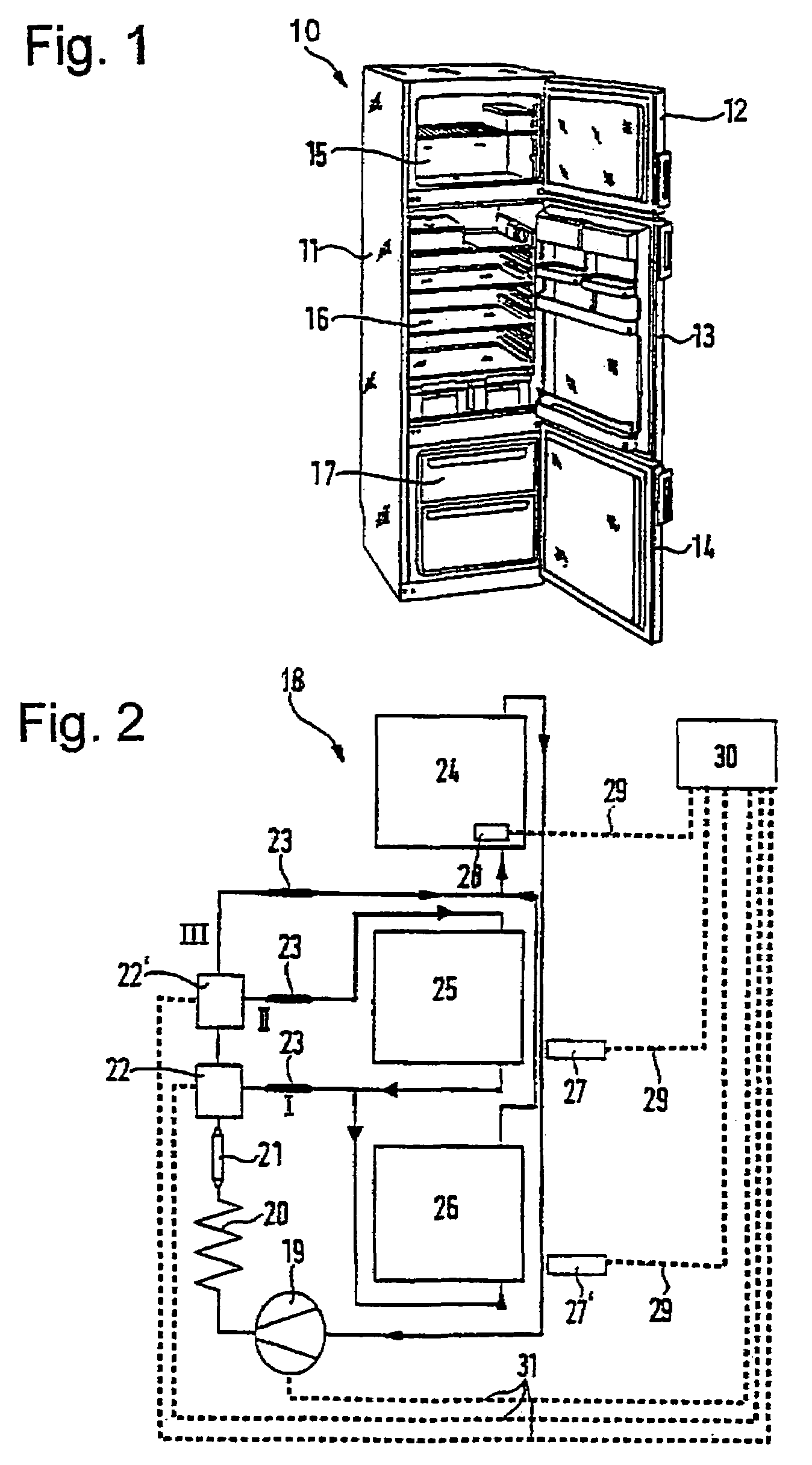

Combination refrigerating appliance and evaporators for same

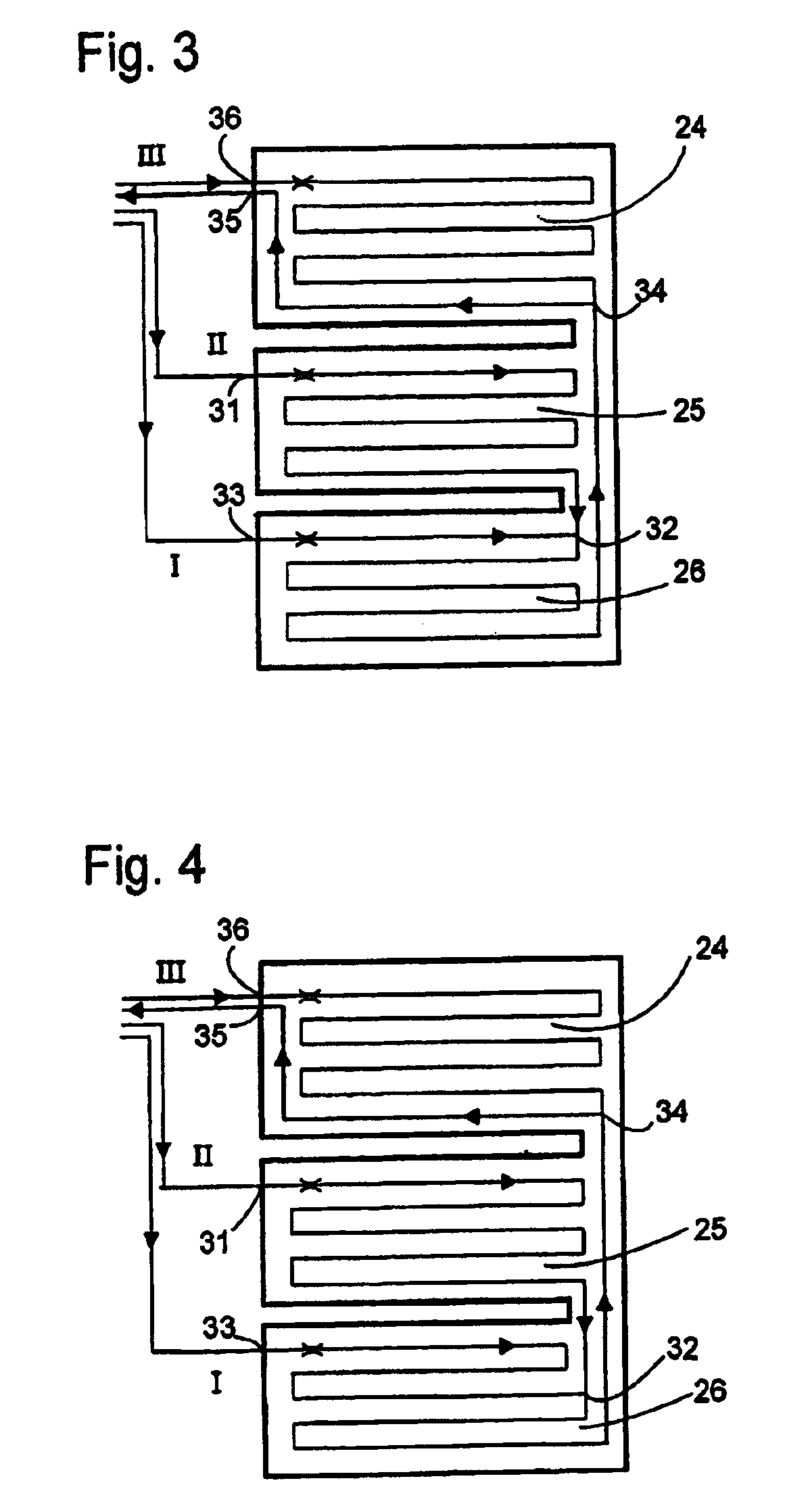

InactiveUS7181921B2Shorten operation timeReduce energy consumptionDomestic refrigeratorsEvaporators/condensersEngineeringRefrigerant

The refrigerating appliance comprises at least one first, second and third refrigerating area for a low, medium or high storage temperature, whereby each refrigerating area has an evaporator (24, 25, 26). The refrigerating appliance also comprises a compressor (19), a refrigerant circuit for supplying compressed refrigerant to the evaporators (24, 25, 26) and for returning expanded refrigerant to the compressor (19), and comprises at least one switching element (22, 22′) for directing, as desired, the refrigerant through one of two branches (I, II) of the refrigerant circuit. In the first branch (I), the evaporators (24, 26) of the first and the third refrigerating areas are connected in series. In the second branch (II), The evaporators (24, 25, 26) of all three refrigerating areas are connected in series.

Owner:BSH BOSCH & SIEMENS HAUSGERAETE GMBH

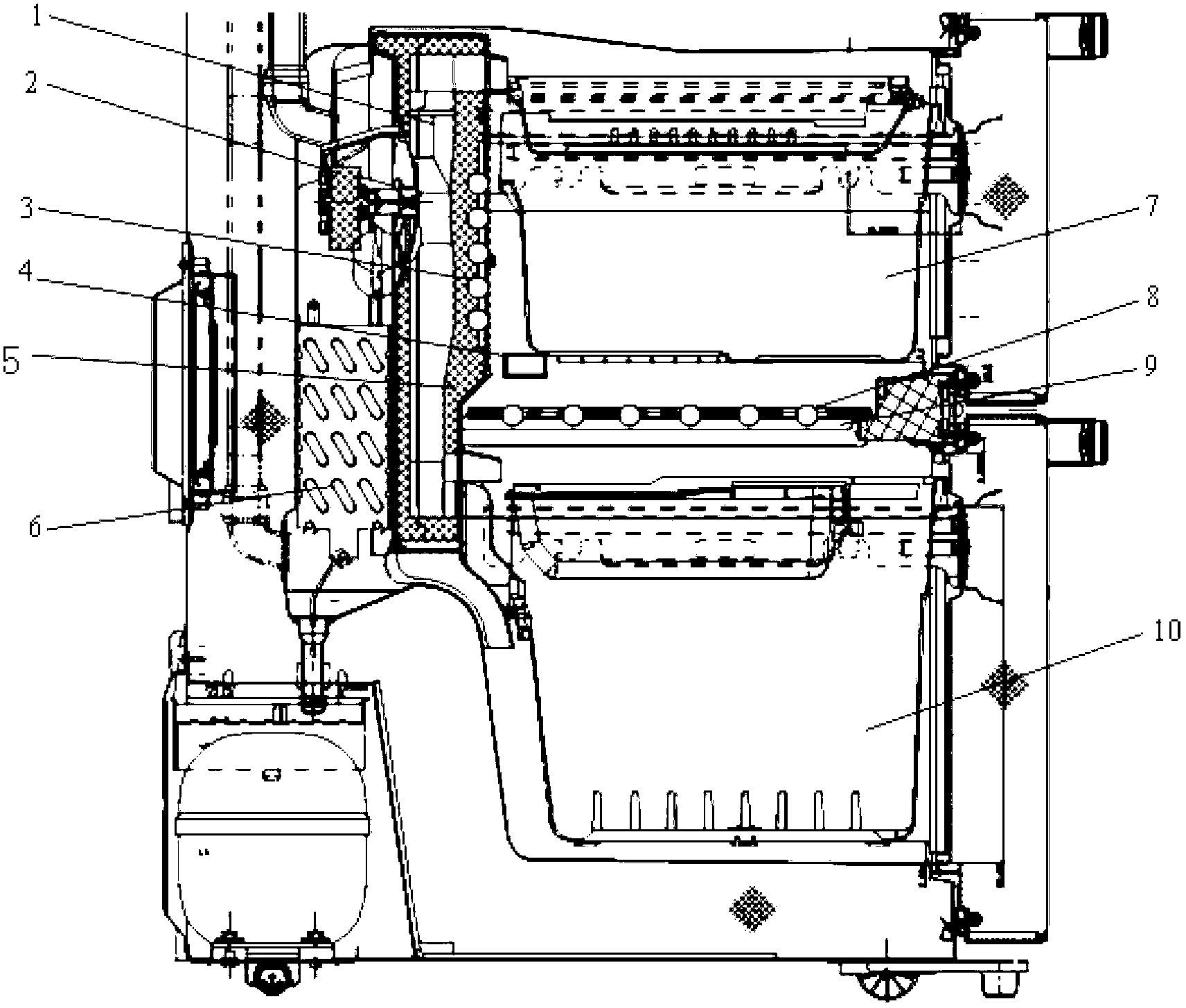

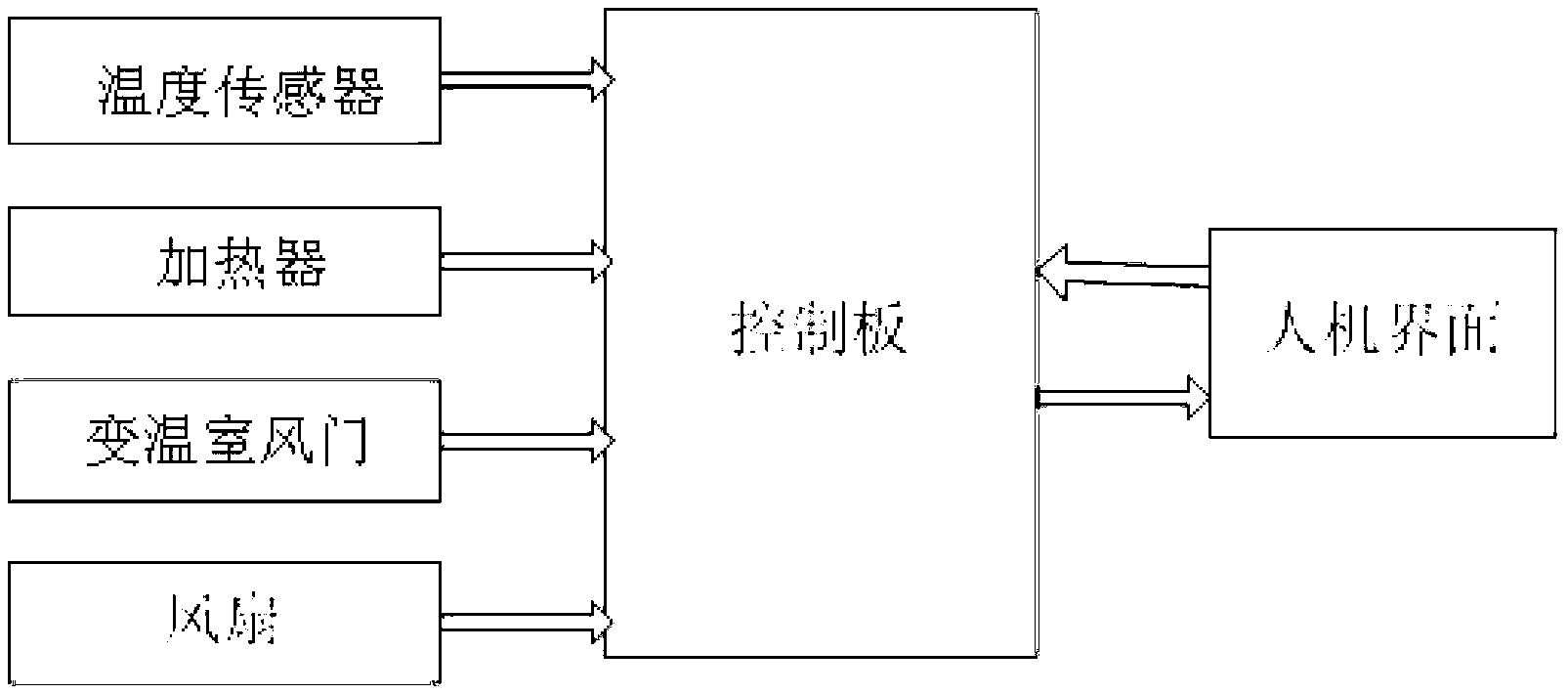

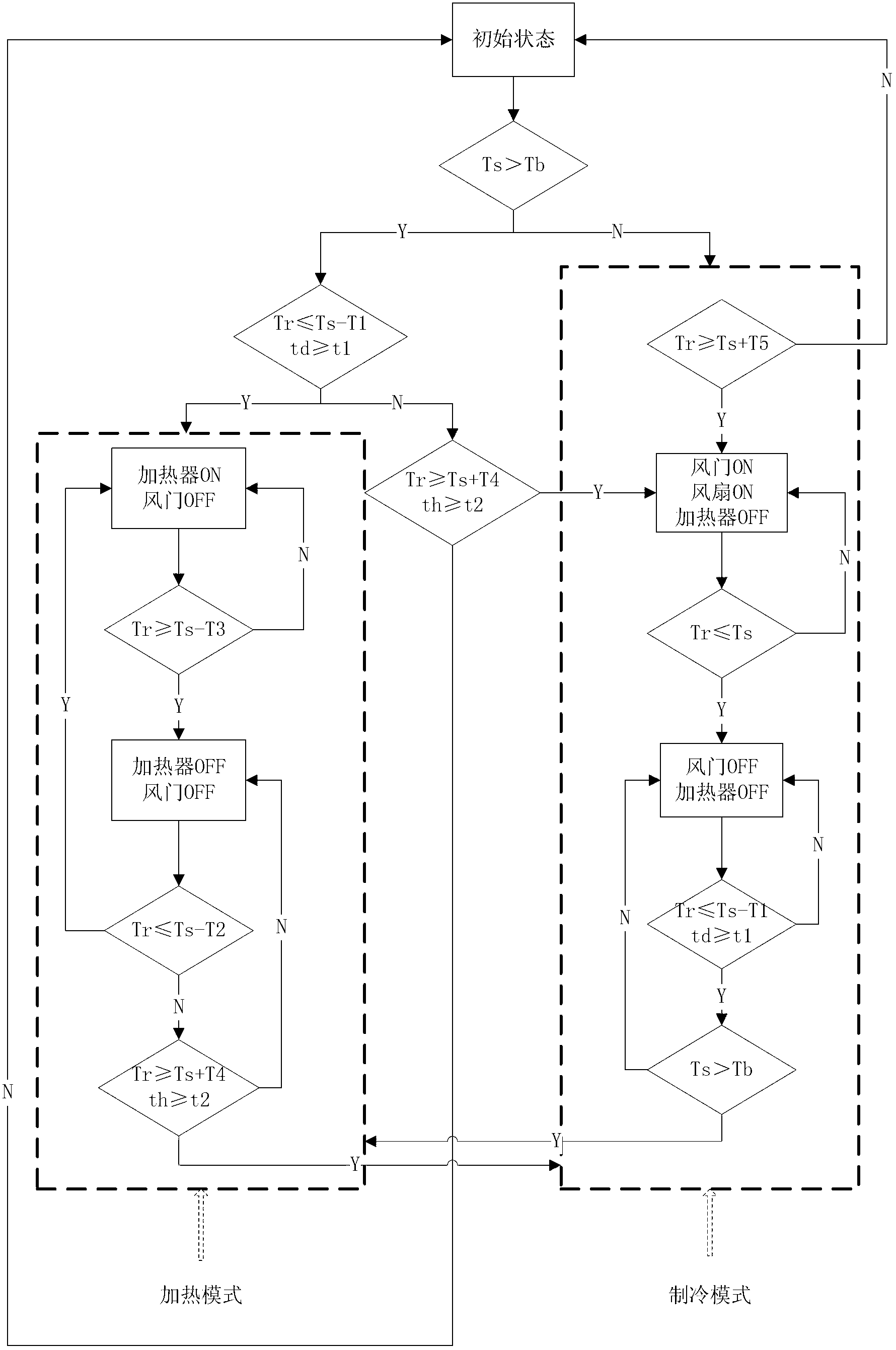

Refrigerator and control method for temperature-changing chamber of refrigerator

ActiveCN102706069AUniform temperatureStable temperatureLighting and heating apparatusDomestic refrigeratorsTemperature controlThermodynamics

The invention relates to a refrigerator and a control method for a temperature-changing chamber of a refrigerator. The refrigerator comprises the temperature-changing chamber and a control panel for controlling the temperature of the temperature-changing chamber, wherein a cabinet liner of an evaporator is separated into an upper temperature-changing chamber and a lower refrigerating chamber by a heat-insulating separating plate; an air flue is arranged on the rear part of the temperature-changing chamber and the refrigerating chamber; the evaporator is located on the rear part of the air flue; an air door of the temperature-changing chamber and a fan are arranged in the air flue; a first heater is arranged on the heat-insulating separating plate in the temperature-changing chamber; a second heater is arranged on a position corresponding to the rear part of the temperature-changing chamber in the air flue; a temperature sensor is arranged on an inner side wall of the temperature-changing chamber; and the temperature is controlled by the temperature-changing chamber in refrigerating and heating two modes. The suitable heater and mounting position are selected by the refrigerator and an effective control method is used for realizing the adjustment for the temperature-changing chamber in a wide temperature scope under a wide weather condition, under the condition of saving power consumption, so that diverse and individual selections are supplied to users and the food storage requirement is met.

Owner:HISENSE RONGSHENG YANGZHOU REFRIGERATOR CO LTD

Refrigerator ice maker with improved air impingement

An insulated ice making compartment is provided in the fresh food compartment of a bottom mount refrigerator. The ice making compartment may be integrally formed with the liner of the fresh food compartment, or alternatively, may be modular for installation anywhere in the fresh food compartment. A removable bin assembly with a front cover normally seals the ice making compartment to maintain the temperature in the compartment. A cold air duct formed in the rear wall of the refrigerator supplies cold air from the freezer compartment to the ice making compartment. A return air duct directs a portion of the air from the ice making compartment back to the freezer compartment. An air vent in the ice making compartment directs another portion of air into the fresh food compartment. A control system provides for controlling refrigerator functions in a manner that promotes energy efficiency. The icemaker has improved air impingement to enhance ice making.

Owner:MAYTAG

Refrigerator and defrosting method thereof

InactiveCN102997534AReduce power consumptionMuch less power consumptionLighting and heating apparatusDomestic refrigeratorsEnergy consumptionWaste management

The invention discloses a refrigerator and a defrosting method thereof. A defrosting channel air inlet and a defrosting channel air outlet which are communicated with the outside are arranged at the back of a refrigerator body, the defrosting channel air inlet and the defrosting channel air outlet are arranged on the lower portion and the upper portion of an evaporator respectively, two groups of insulation devices are fixed to the defrosting channel air inlet and the defrosting channel air outlet respectively in a moving mode and are blocked to the defrosting channel air inlet and the defrosting channel air outlet respectively, or two groups of insulation devices are blocked to a duct air outlet and a duct air inlet respectively. By the aid of the refrigerator and the method, the heat exchange between the hot air outside the refrigerator body and the evaporator is conducted to defrost, the energy consumption is low, the refrigerator and the method are safe and reliable and things stored in the refrigerator body cannot be affected.

Owner:GREE ELECTRIC APPLIANCES INC

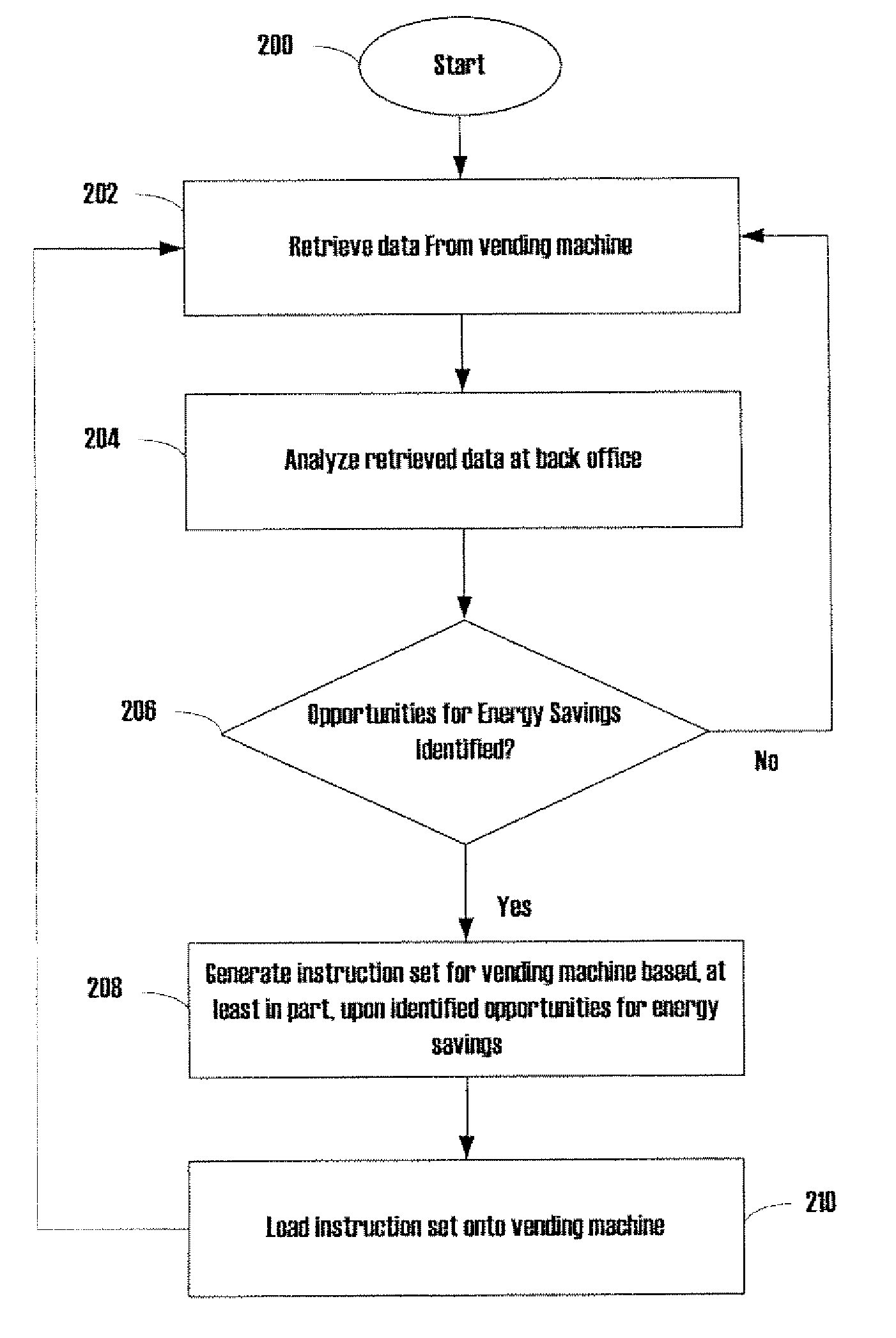

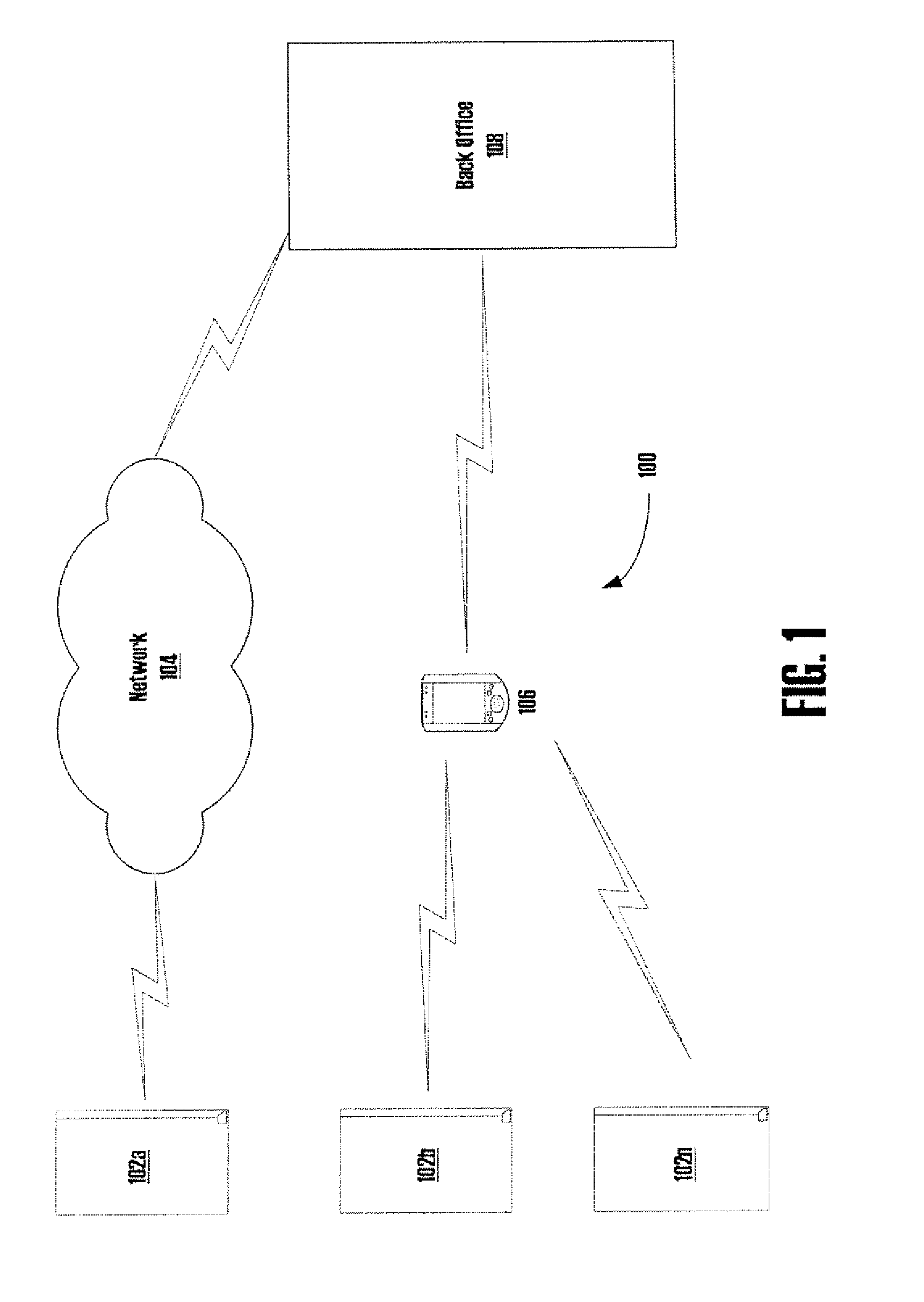

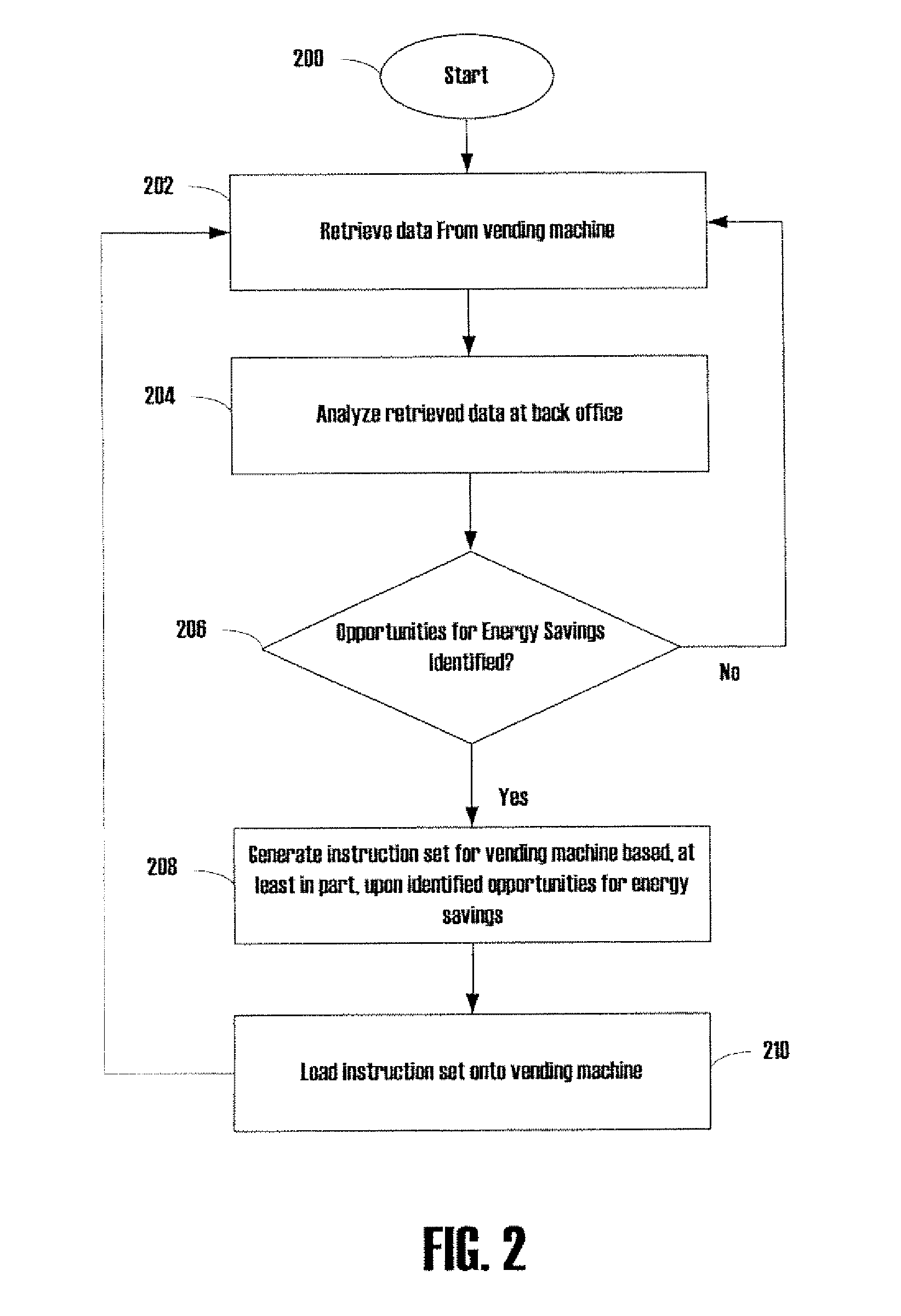

Systems, Methods, And Apparatuses For Energy Management In Vending Machines, Appliances, And Other Store Or Dispense Equipment

ActiveUS20080077275A1Mechanical power/torque controlLevel controlElectrical devicesEnergy management system

The present invention provides systems, methods, and apparatuses for energy management in store or dispense equipment for food and / or beverages. Such store or dispense equipment may allow for food and / or beverages to be heated, cooled, or maintained near the ambient temperature, or a combination thereof. The store or dispense equipment may include vending machines, appliances, coolers, dispensers such as food dispensers and beverage dispensers (e.g., fountain drink dispenser), and other like electrical equipment. Demand data may be retrieved from the vending machine, appliance, cooler, dispenser, or other store or dispense equipment. Demand data may include sales, usage, and / or occupancy information for the respective vending machines, appliances, coolers, dispensers, and other store or dispense equipment. This demand data may then analyzed to determine whether there are demand patterns such that there are opportunities for energy conservation or energy management. If there are opportunities for energy conservation or energy management, an instruction set may be prepared, where the instruction set is based at least in part on this analyzed data. The instruction set is loaded onto the vending machine, appliance, or other equipment, which operates in accordance with the instruction set. While the following embodiments of the present invention may be discussed with respect to a vending machine for illustrative purposes, they are equally applicable to appliances, coolers, dispensers, and other store or dispense equipment,

Owner:THE COCA-COLA CO

Refrigerator with improved water fill tube for ice maker

An insulated ice making compartment is provided in the fresh food compartment of a bottom mount refrigerator. The ice making compartment may be integrally formed with the liner of the fresh food compartment, or alternatively, may be modular for installation anywhere in the fresh food compartment. A removable bin assembly with a front cover normally seals the ice making compartment to maintain the temperature in the compartment. A cold air duct formed in the rear wall of the refrigerator supplies cold air from the freezer compartment to the ice making compartment. A return air duct directs a portion of the air from the ice making compartment back to the freezer compartment. An air vent in the ice making compartment directs another portion of air into the fresh food compartment. A control system provides for controlling refrigerator functions in a manner that promotes energy efficiency. The refrigerator has an improved water fill tube for the ice maker.

Owner:MAYTAG

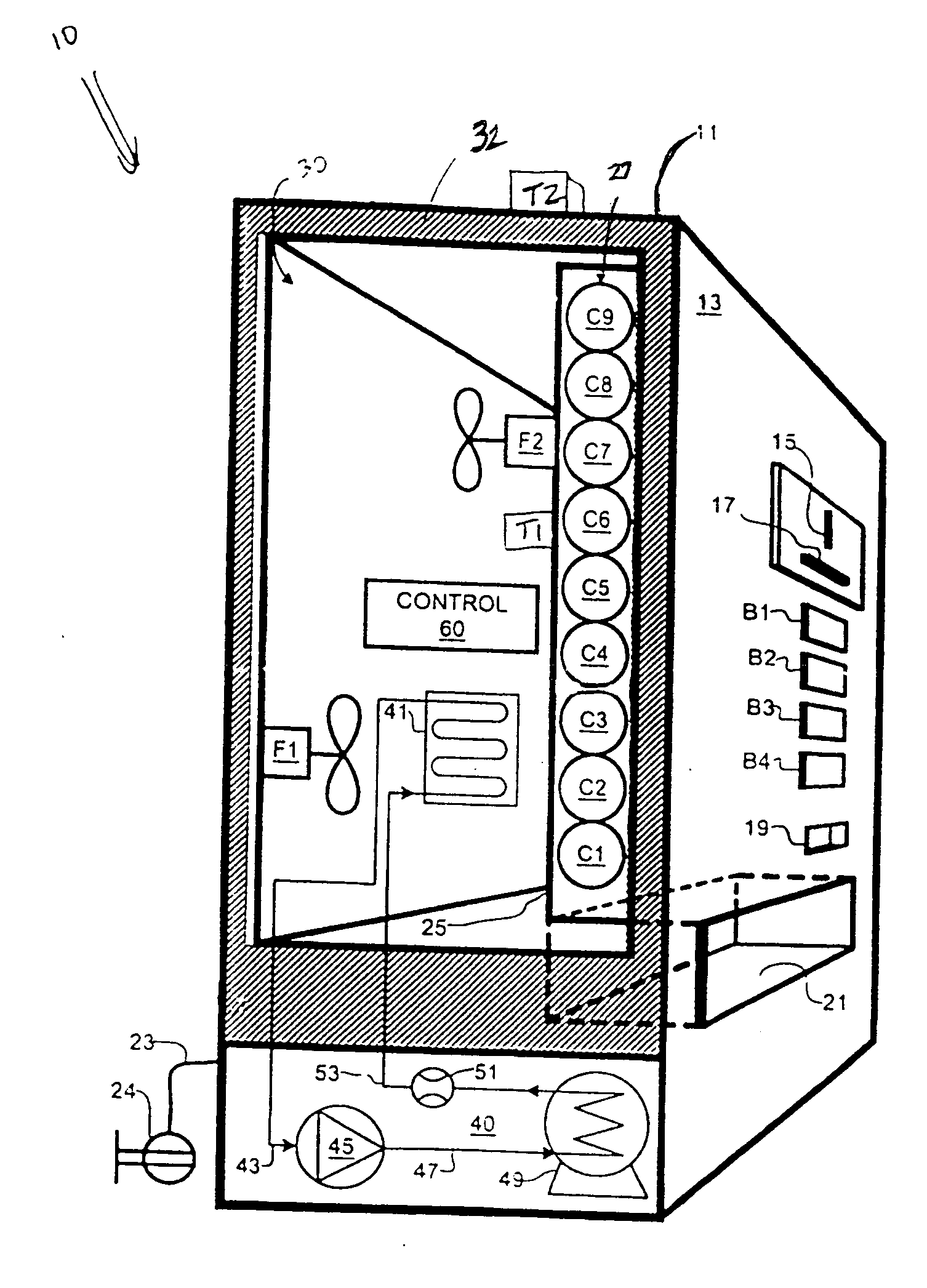

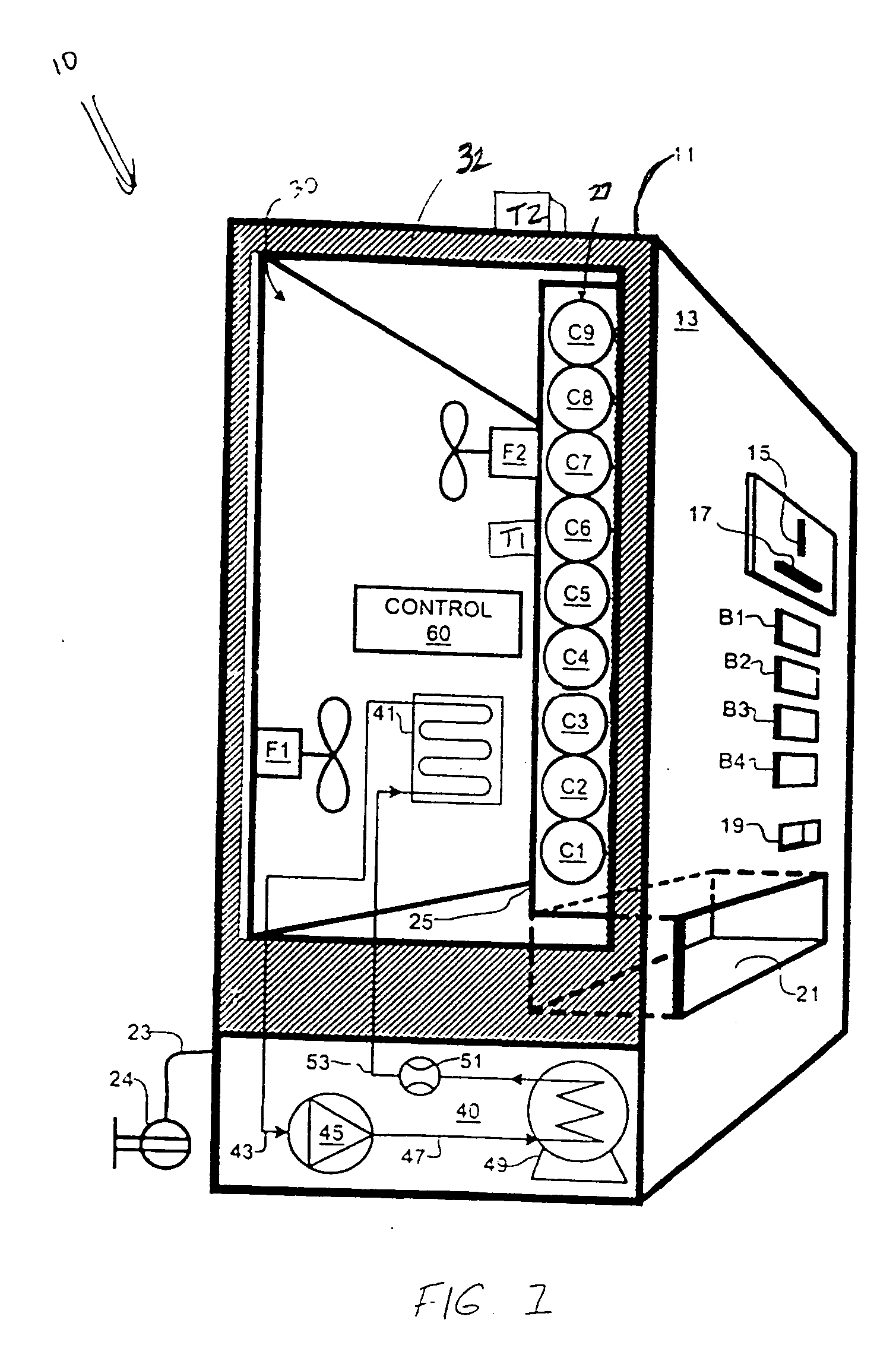

Method and apparatus for conserving power consumed by a refrigerated appliance utilizing audio signal detection

ActiveUS20050178135A1Efficient power conservationLevel controlTemperatue controlEvent dataData signal

A refrigerated appliance that dispenses items for use with a power source and includes a cooling system. Power control circuitry is electrically coupled between the power source and components (for example, a compressor and one or more circulating fans of the cooling system) of the appliance. A controller, which is operably coupled to the power control circuitry, is adapted to manage the supply of electrical power to such components by intelligently transitioning between a normal-operation mode and at least one power-conserving mode. To achieve efficient power conservation, an audio signal detector is provided that generates at least one dispensing event signal that represents the occurrence of one or more sound-based dispensing events. The controller automatically transitions between the power-conserving mode(s) and the normal-operation mode based upon at least one dispensing event data signal supplied to the controller by the audio signal detector, and possibly other data signals supplied to the controller.

Owner:CANTALOUPE INC

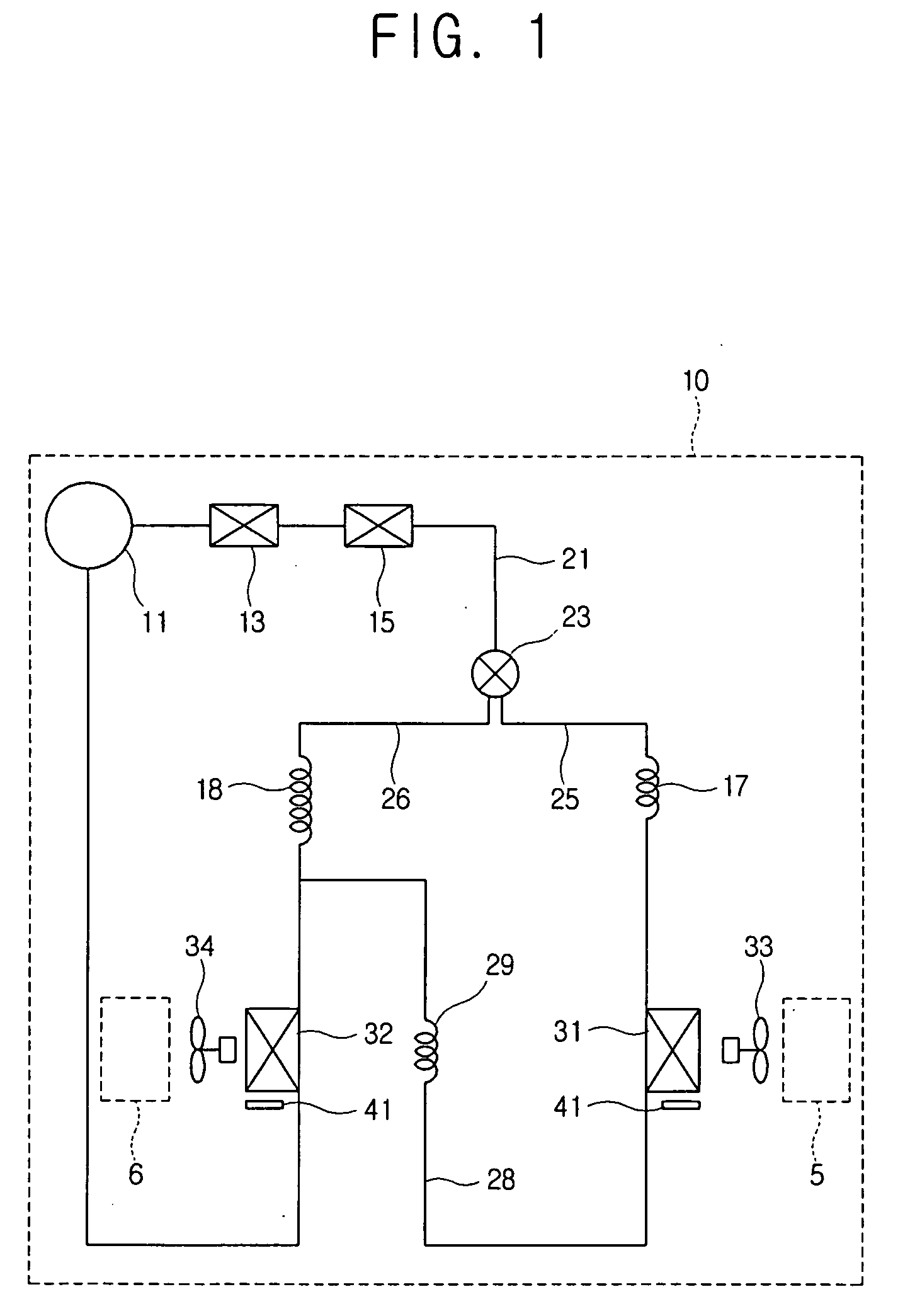

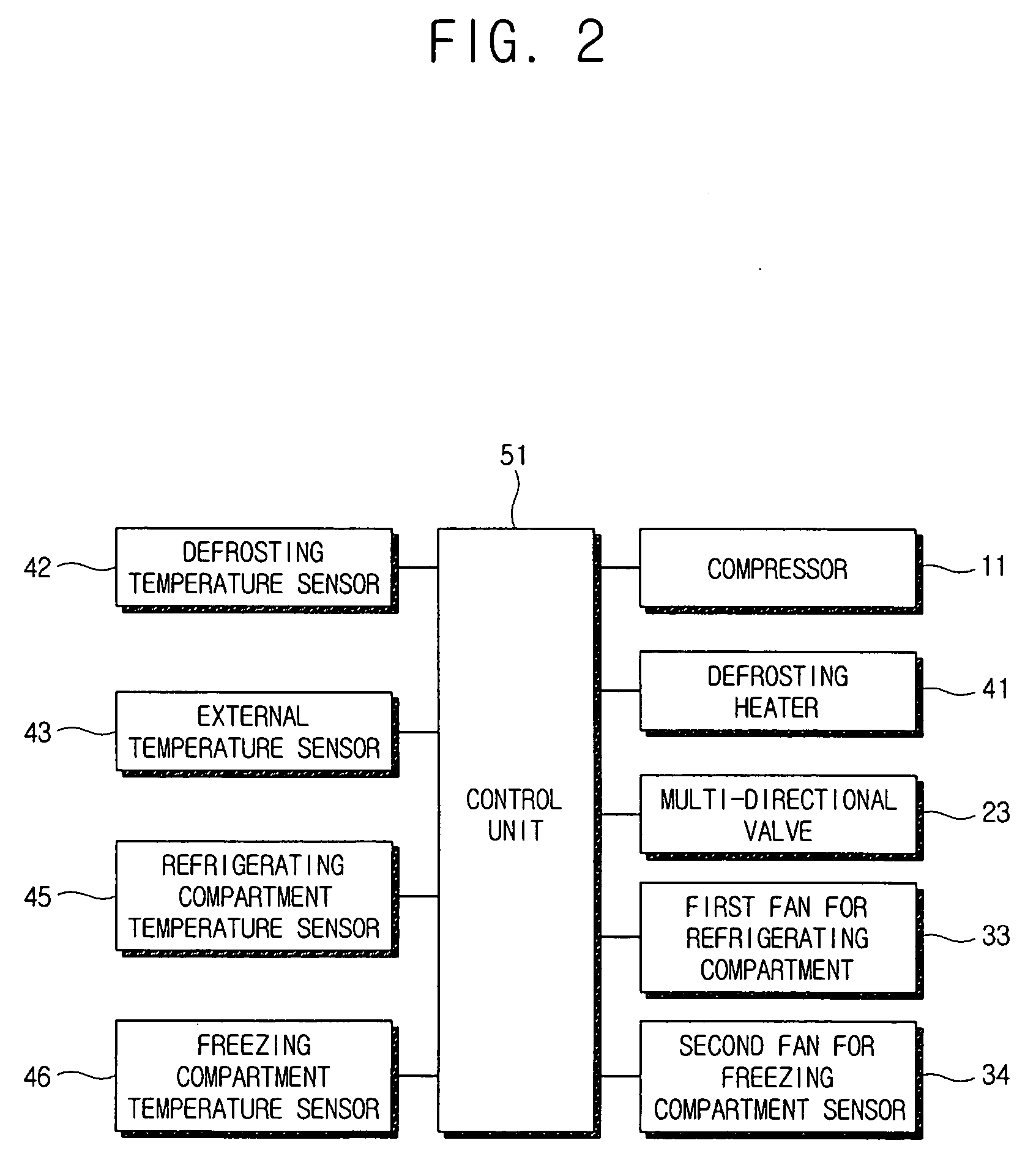

Refrigerator and method for controlling the same

InactiveUS20070068180A1Avoid condensationMechanical apparatusDomestic refrigeratorsEngineeringCold store

A refrigerator which includes a refrigerating compartment and a freezing compartment, a first evaporator and a second evaporator corresponding to the refrigerating compartment and the freezing compartment, respectively, a compressor compressing refrigerant to be supplied to the first and second evaporators, a first fan and a second fan supplying cool air to the compartments, respectively, an external temperature sensor detecting an external temperature of the refrigerator, a multi-directional valve supplying the refrigerant to at least one of the evaporators, and a control unit operating the compressor and the multi-directional valve, and driving the first fan and the second fan until temperatures of the compartments reach a predetermined reference temperature. When the detected external temperature meets a low temperature condition, the control unit controls the multi-directional valve to supply the refrigerant to the first evaporator such that the compressor is operated and an operation of the first fan is halted.

Owner:SAMSUNG ELECTRONICS CO LTD

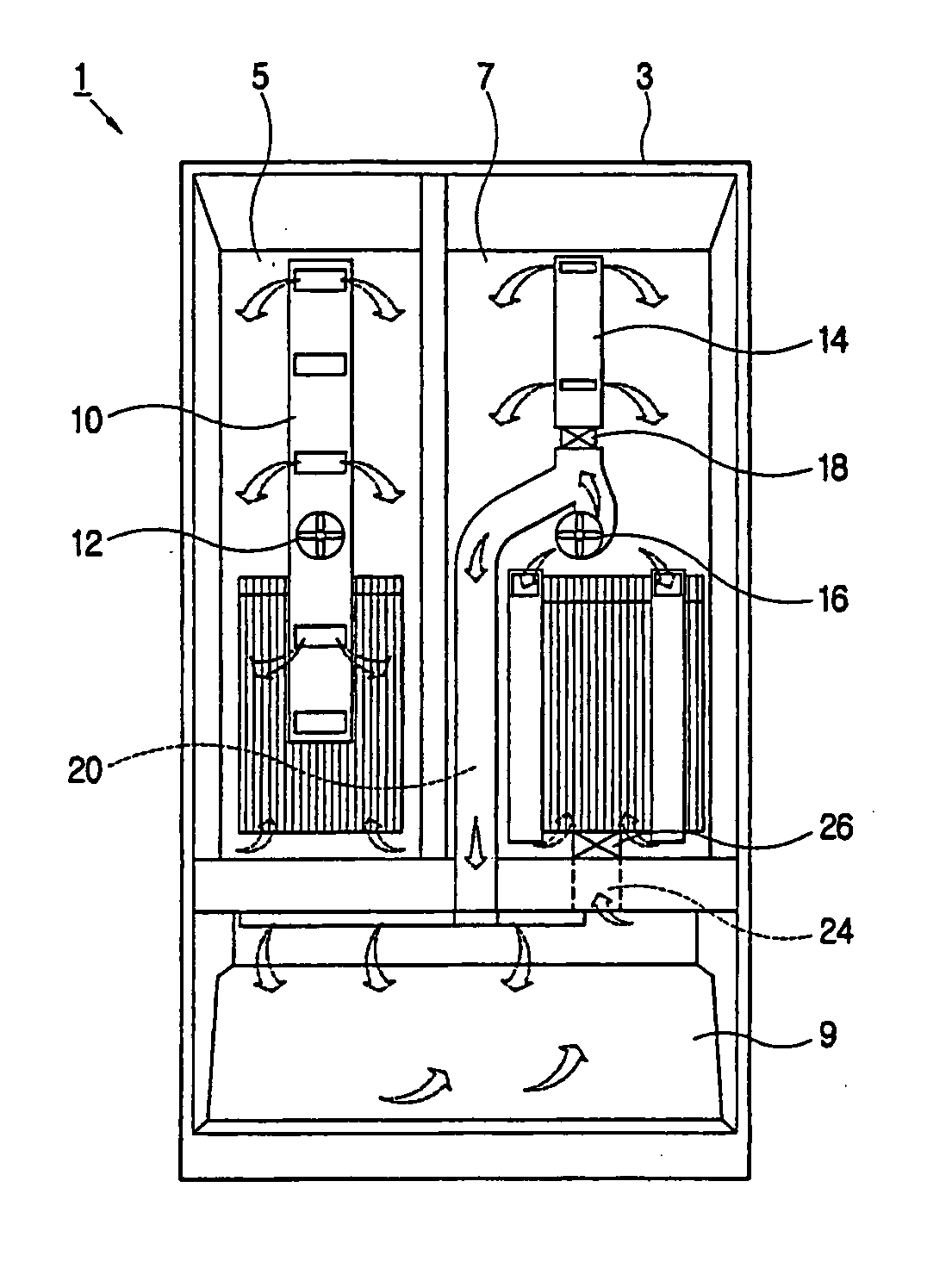

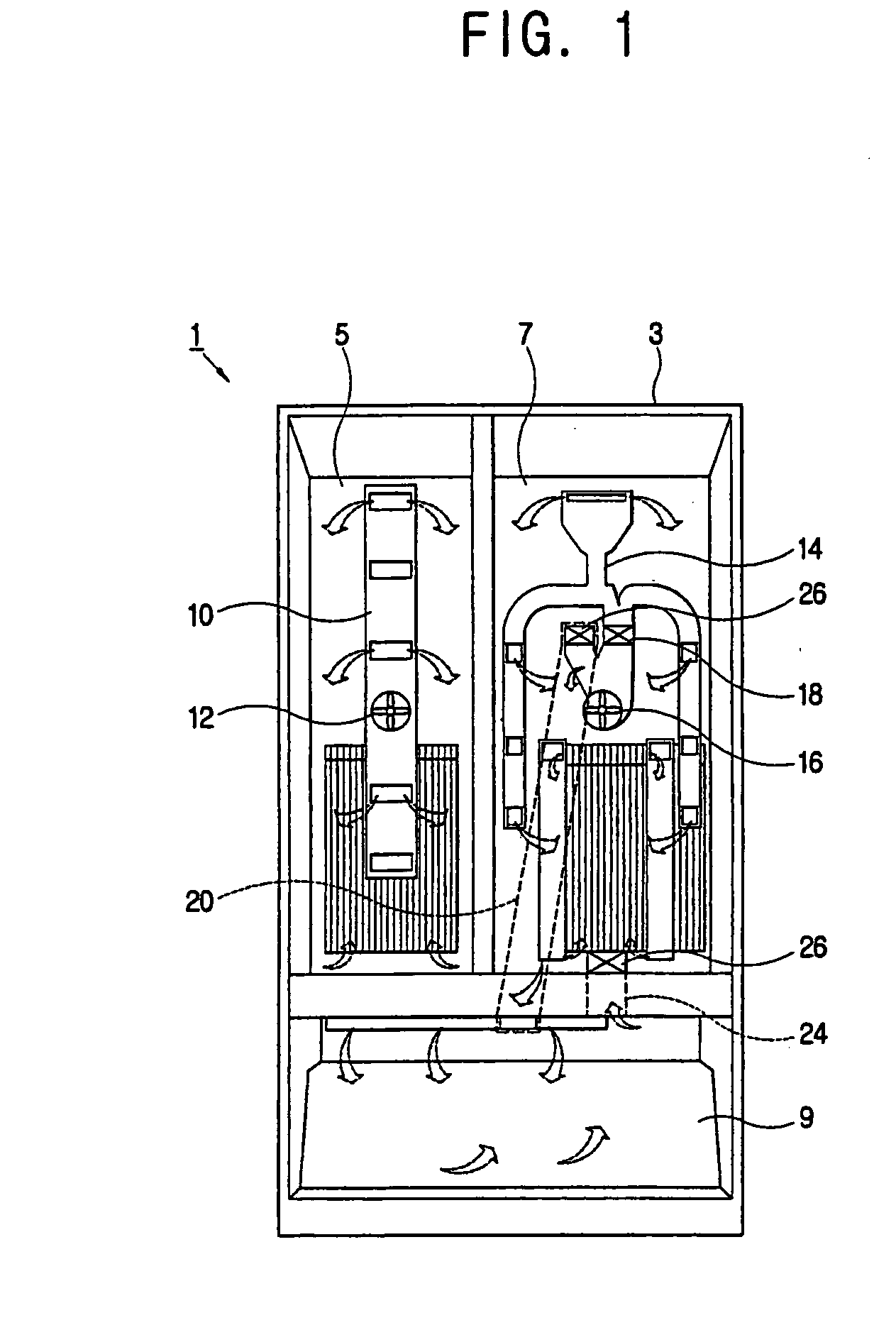

Refrigerator and method of controlling the same

InactiveUS20050126207A1Improve cooling effectDomestic refrigeratorsRefrigeration componentsEngineeringCold store

A refrigerator including [comprising a main body forming a refrigerator compartment and a freezer compartment, each of a freezer compartment main duct and a refrigerator compartment main duct comprising at least one exiting hole and one returning hole communicating respectively with the freezer compartment and the refrigerator compartment, a freezer compartment evaporator and a refrigerator compartment evaporator provided in the freezer compartment main duct and the refrigerator compartment main duct, respectively, and generating cooling air, and a freezer compartment fan and a refrigerator compartment fan provided in the freezer compartment main duct and the refrigerator compartment main duct, respectively, to let out the cooling air generated in the freezer compartment evaporator and the refrigerator compartment evaporator, respectively, through the exiting hole and to return the cooling air in the freezer compartment and the refrigerator compartment through the returning hole, comprising:] an auxiliary storage provided in a main body; an auxiliary supply duct, branched off from one of a freezer compartment main duct and a refrigerator compartment main duct, to supply the cooling air transferred by a corresponding fan to a auxiliary storage; an auxiliary returning duct returning the cooling air in the auxiliary storage to a corresponding main duct; and an auxiliary damper in at least one of the auxiliary supply duct and the auxiliary returning duct, to open and close to respectively supply and block the cooling air to the auxiliary storage.

Owner:SAMSUNG ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com