Internal air circulation control in a refrigerated transport container

a technology for refrigerated transport containers and air circulation control, which is applied in the direction of refrigerators/freezers, refrigeration devices, sustainable buildings, etc., can solve the problems of hardware damage, energy consumption is not efficient, and the risk of increasing the temperature distribution throughout the container's transport volume, so as to minimize the risk of temperature-abuse, and save energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

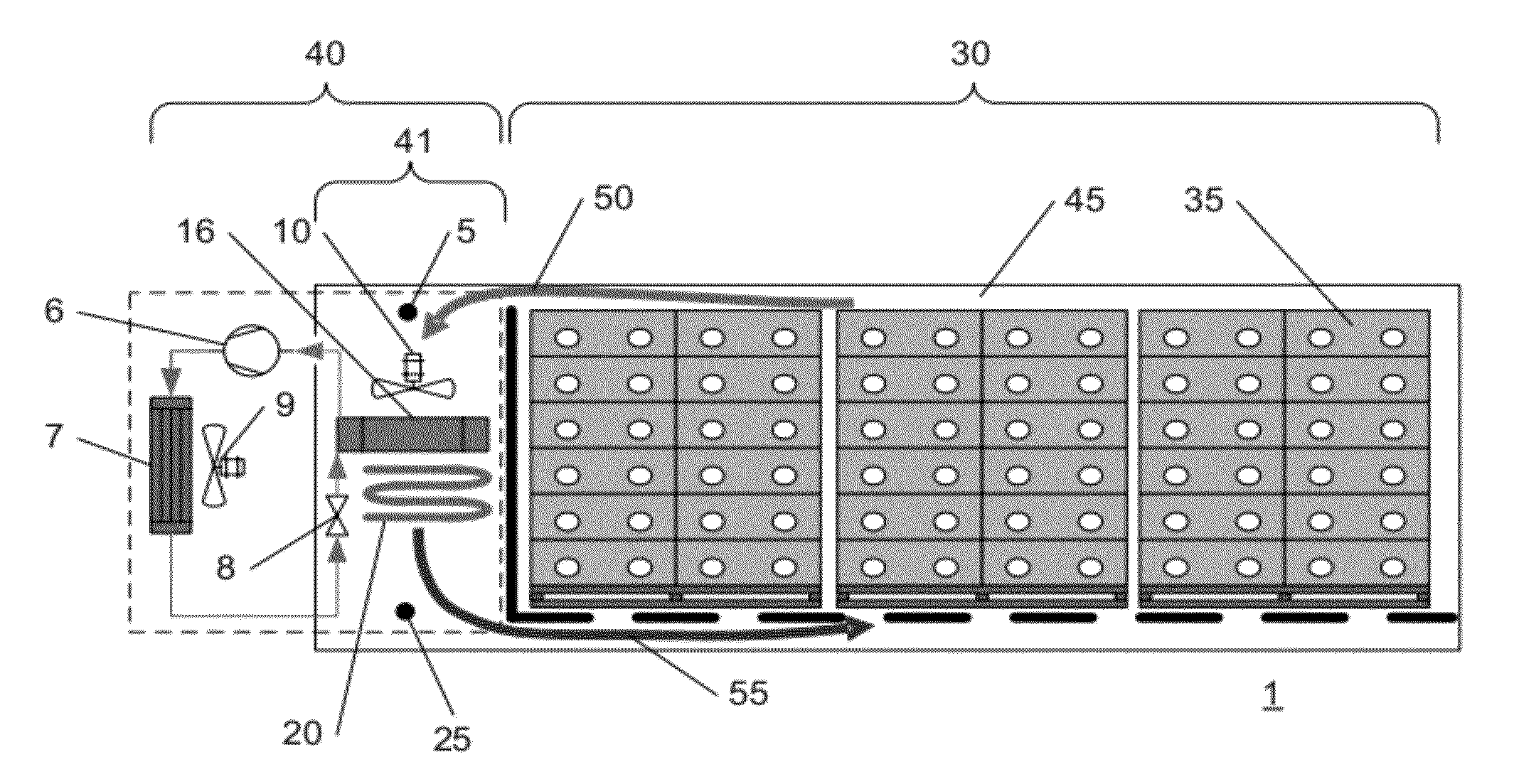

[0108]FIG. 1 is a simplified side cross-sectional view of a refrigerated transport container. FIG. 1 illustrates one example of a refrigerated transport container 1 wherein the described fan speed control method and / or system may be used. The fan speed control method and / or system may also be used in connection with other refrigerated spaces connected with a refrigeration unit. In the present specification, the term “fan speed” means evaporator fan speed.

[0109]FIG. 1 illustrates a refrigerated transport container 1 comprising a frontal section having a refrigeration unit or system 40 and a load or cargo section 30. The load or cargo section 30 of the refrigerated transport container 1 comprises a commodity load e.g. comprising a plurality of stackable transport boxes 35 arranged within a transport volume 45 such as to leave appropriate clearance at a ceiling and a floor structure for air flow passages above and beneath the commodity load.

[0110]The refrigeration unit 40 in this examp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com