Unit for assembling and/or treating components

A component, technology for processing locations, applied in the field of equipment for manufacturing and/or processing flexible pipes, assembly of pipe components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

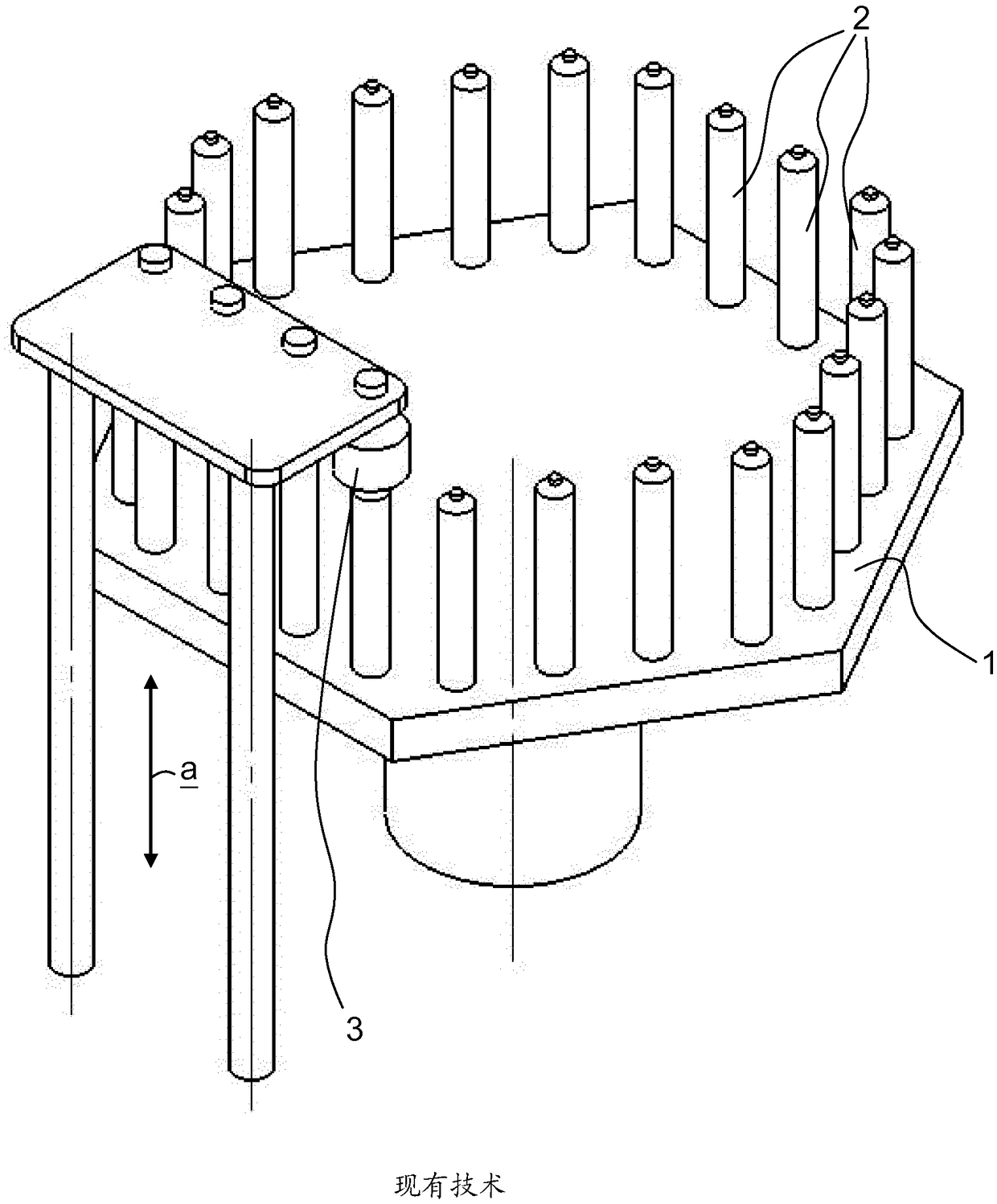

[0053] In the following, a device for manufacturing and filling flexible pipes, more particularly a device for assembling flexible pipes, will be described; however, it is obvious that the assembling device according to the invention can be adapted to assemble any type of components without beyond the scope of the present invention.

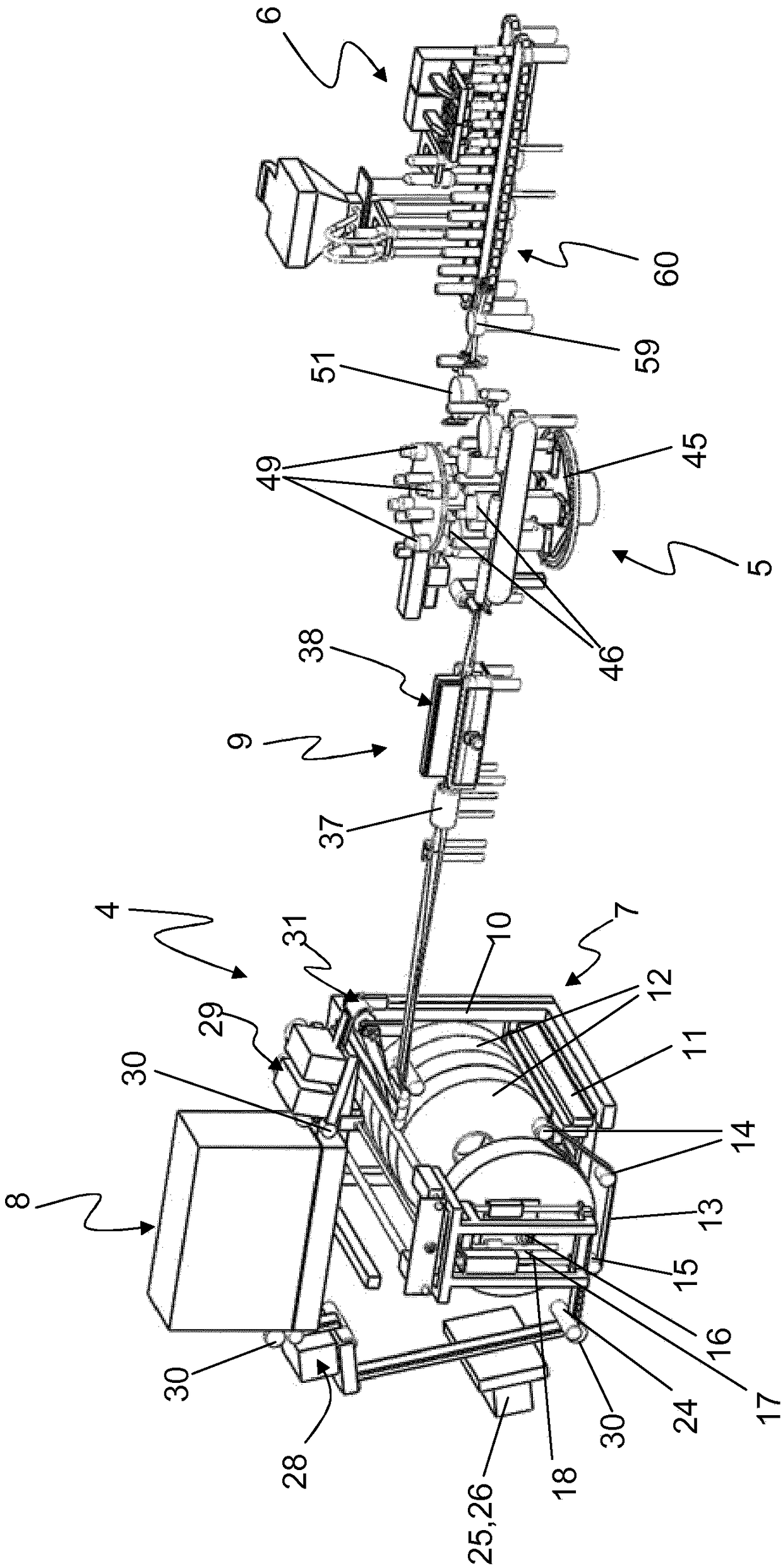

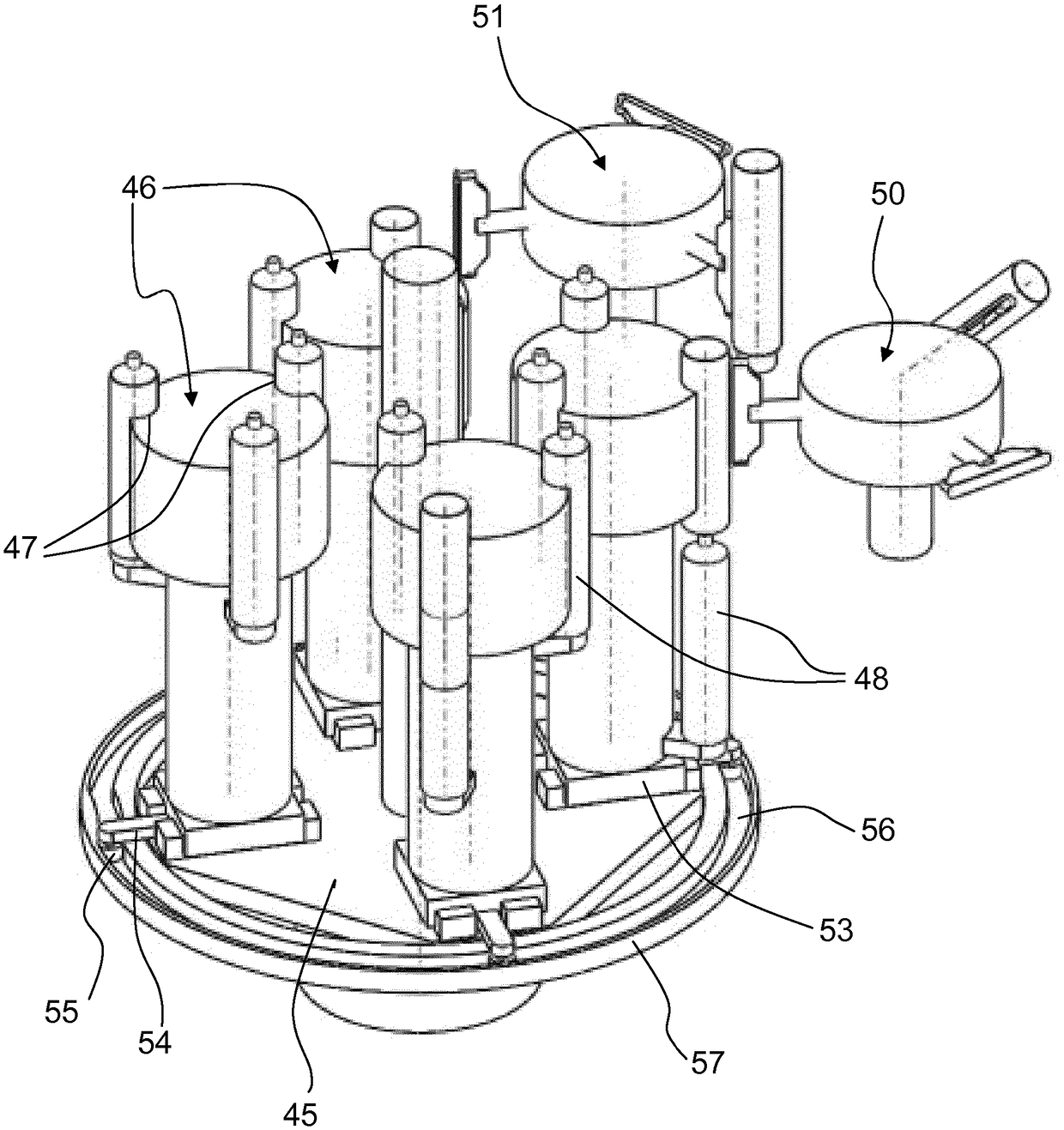

[0054] refer to figure 2 , the device for manufacturing and filling flexible pipes according to the invention consists of a manufacturing device 4 , an assembling device 5 and a filling device 6 .

[0055] refer to figure 2 and Figure 8 , the manufacturing equipment 4 includes a winding device 7 , a printing unit 8 and a tubular body manufacturing unit 9 . Said winding device 7 consists of a frame 10 comprising at its bottom on the one hand a lateral slide 11 and on the other hand a drive belt 13 on which the layers used in the manufacture of the flexible pipe are arranged The reel 12 of the pressed part, on which the reel of the laminate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com