Slurry bed reactor and reaction system for selective hydrogenation of acetylene to ethylene

A slurry bed and reactor technology, which is applied in the fields of hydrogenation to hydrocarbon production, chemical instruments and methods, organic chemistry, etc., can solve the problems of partial temperature flying of the reaction bed and easy deactivation of catalysts, and achieves lower temperature and enhanced turbulence. The effect of mass transfer with gas-liquid and diameter reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

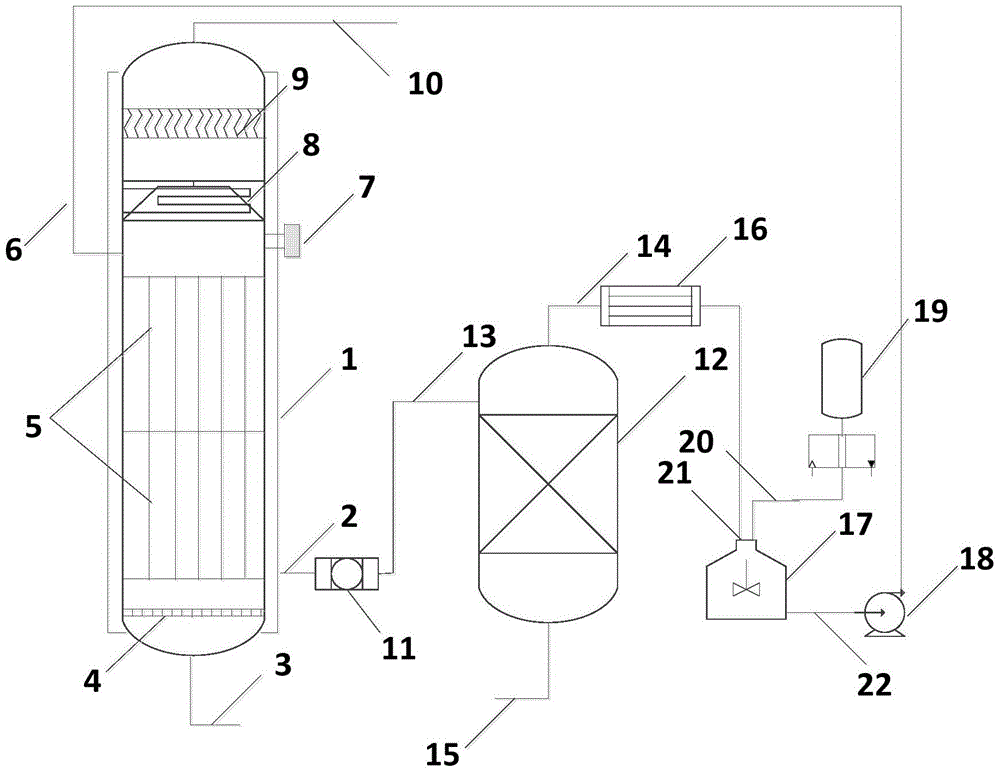

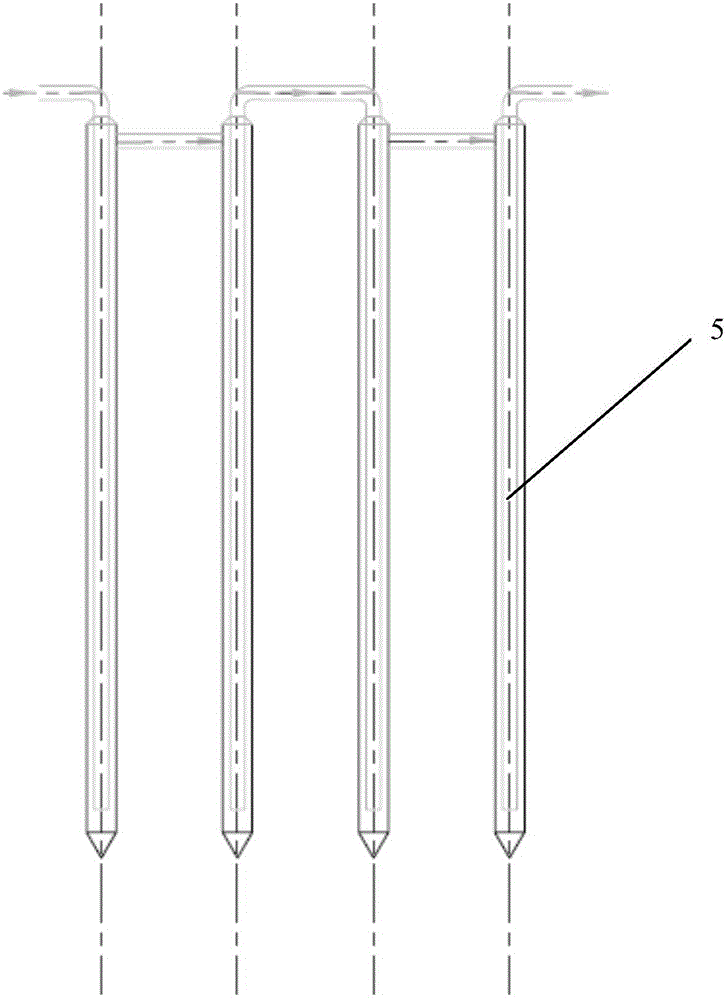

[0042] See figure 1 , a slurry bed reactor for selective hydrogenation of acetylene to ethylene, comprising a slurry bed reactor cylinder 23, surrounded by a jacket 1 outside the cylinder, the jacket is annular, and a heating medium is passed into the jacket, The slurry bed reactor is heated. A gas inlet 3 is provided at the bottom of the slurry bed reactor, and a gas outlet 10 is provided at the top;

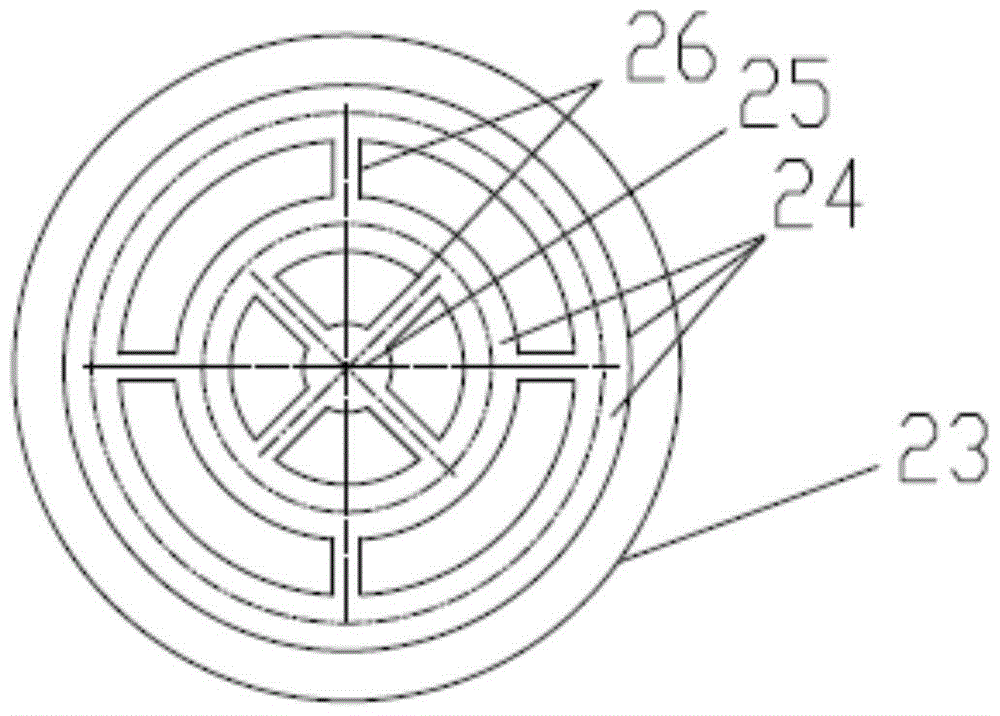

[0043] The bottom of the slurry bed reactor is provided with a gas distributor ( figure 2 ), connected with the gas inlet 3; the gas distributor includes three concentric annular gas distribution pipes 24 on the same horizontal plane, the distance between the centers of adjacent concentric circles is 70mm, and the diameter of the annular gas distribution pipes is 50mm. The bottom of the annular gas distribution pipe 24 has a hole with a diameter of 3mm, and the total opening rate on the annular gas distribution pipe is 12%; The central air pipe 25 perpendicular to the plane...

Embodiment 2

[0047] A slurry bed reactor for selective hydrogenation of acetylene to produce ethylene, comprising a reactor shell, the shell is surrounded by a jacket, the jacket is ring-shaped, and a heating medium is passed into the jacket, for the slurry bed reactor for heating. There is a gas inlet at the bottom of the slurry bed reactor and a gas outlet at the top;

[0048] A gas distributor is provided below the slurry bed reactor, which is connected to the gas inlet; the gas distributor includes 5 concentric annular gas distribution pipes on the same horizontal plane, with holes at the bottom of the annular gas distribution pipes, the diameter of which is 5 mm, and the diameter of the annular gas distribution pipes The total opening ratio is 10%, the distance between the centers of adjacent annular gas distribution pipes is 60mm, and the diameter of the annular gas distribution pipes is 50mm. The annular gas distribution pipe is in communication with the gas distributor connecting ...

Embodiment 3

[0053] The acetylene selective hydrogenation ethylene system ( figure 1 ): comprising a slurry bed reactor, a regeneration tower 12, and a slurry storage tank 17;

[0054] The slurry outlet 2 at the lower part of the cylinder of the slurry bed reactor is connected to the catalyst filter 11. The catalyst filter is two cluster-type automatic filters connected in parallel, with a filtration accuracy of 0.5 μm. The two cluster-type automatic filters are used alternately and regeneration.

[0055] The catalyst filter 11 is connected to the regeneration tower 12; a heater is arranged in the regeneration tower. The heater vaporizes the liquid phase solvent in the slurry bed, and the green oil in the liquid phase is deposited at the bottom of the regeneration tower and discharged.

[0056] A tower top condenser 16 is arranged on the top of the regeneration tower, and the condensate outlet of the tower top condenser 16 is connected to the liquid phase solvent inlet 21 of the slurry s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com