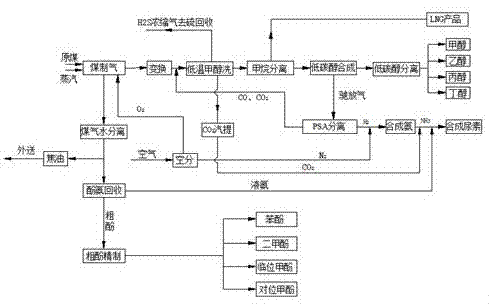

A process for producing low-carbon mixed alcohols from syngas and co-producing urea and natural gas

A low-carbon mixed alcohol and synthesis gas technology, which is applied in the preparation of hydroxyl compounds, the preparation of organic compounds, and gas fuels, etc., can solve the problems of unsuitable industrialization, complex operation and management, and difficulty in real implementation. Single process and the effect of saving investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] (1) Preparation and purification of pure syngas

[0055] Using lignite with a water content of 26% as raw material, oxygen and water vapor are introduced to produce crude gas through pressure gasification of crushed coal (gasification pressure 4.0 MPa, gasification temperature 1150°C). The composition of the crude gas by volume percentage is: CO: 46.35, H 2 : 26.73, CO 2 : 16.77, CH 4 : 9.94, H 2 S: 0.21;

[0056] The crude gas is subjected to sulfur-resistant transformation under the catalyst of Qingdao Lianxin QDB-04 at 260°C, 3.5MPa, and the volumetric space velocity calculated by dry gas is 4000h -1 , the converted water / gas molar ratio is 0.32;

[0057] The converted raw gas and low-carbon alcohol purge gas are separated by PSA for H 2 After the gas enters the low-temperature methanol washing together, the H 2 S down to 0.1ppm, CO 2 2 S concentrated gas sent to sulfur recovery, CO 2 sent to the synthetic urea unit;

[0058] The crude gas washed with low-t...

Embodiment 2

[0069] (1) Preparation and purification of pure syngas

[0070] Using bituminous coal as raw material, feed oxygen and water vapor through a crushed coal slag gasifier (gasification pressure 4.5MPa, gasification temperature 1200°C) to produce crude gas. The composition of crude gas by volume percentage is: CO: 47.14, h 2 : 26.49, CO 2 : 15.55, CH 4 : 10.69, H 2 S: 0.13;

[0071] The crude gas is subjected to sulfur-tolerant conversion at 280°C, 4.0MPa, Qilu Petrochemical QCS-04 catalyst, and the volumetric space velocity calculated by dry gas is 4500h -1 , the converted water / gas molar ratio is 0.35;

[0072] The converted raw gas and low-carbon alcohol purge gas are separated by PSA for H 2 After the gas enters the low-temperature methanol washing together, the H 2 S down to 0.1ppm, CO 2 2 S concentrated gas sent to sulfur recovery, CO 2 sent to the synthetic urea unit;

[0073] The crude gas washed by low-temperature methanol enters the methane cryogenic separation...

Embodiment 3

[0084] (1) Preparation and purification of pure syngas

[0085] Using lignite with a water content of 28% as raw material, oxygen and water vapor are introduced to produce crude gas through pressure gasification of crushed coal (gasification pressure 5.5 MPa, gasification temperature 1350°C). The composition of the crude gas by volume percentage is: CO: 46.41,H 2 : 25.38, CO 2 : 17.17, CH 4 : 10.89, H 2 S: 0.15;

[0086] The crude gas is subjected to sulfur-resistant transformation under the EB catalyst of Hubei Institute of Chemistry at 340°C, 4.0MPa, and the volumetric space velocity calculated by dry gas is 4800h -1 , the converted water / gas molar ratio is 0.38;

[0087] The converted raw gas and low-carbon alcohol purge gas are separated by PSA for H 2 After the gas enters the low-temperature methanol washing together, the H 2 S down to 0.1ppm, CO 2 2 S concentrated gas sent to sulfur recovery, CO 2 sent to the synthetic urea unit;

[0088] The crude gas washed b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com