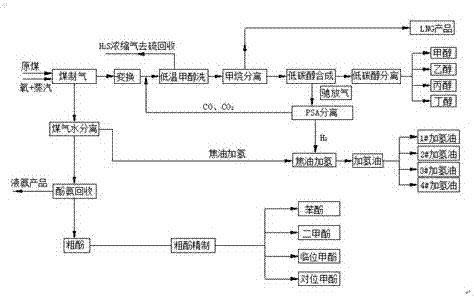

A multi-stage utilization process for producing low-carbon mixed alcohol from coal through synthesis gas

A low-carbon mixed alcohol and synthesis gas technology, applied in the field of multi-stage utilization process, can solve the problems of unsuitable industrialization, difficult to realize, complicated operation and management, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] (1) Preparation and purification of pure syngas

[0061] Using lignite with a moisture content of 25% as raw material, oxygen and water vapor are introduced into the crude coal gasification (gasification pressure 4.5MPa, gasification temperature 1150°C) to produce crude gas. The composition of the crude gas by volume percentage is: CO: 49.85, H 2 : 24.73, CO 2 : 10.21, CH 4 : 14.82, H 2 S: 0.39;

[0062] The crude gas is subjected to sulfur-tolerant conversion at 250°C, 3.0MPa, Qilu Petrochemical QCS-04 catalyst, and the volumetric space velocity calculated by dry gas is 3800h -1 , the converted water / gas molar ratio is 0.30;

[0063] The converted raw gas and low-carbon alcohol purge gas are separated by PSA for H 2 After the gas enters the low-temperature methanol washing together, it is washed with low-temperature methanol at a temperature of -40°C and a pressure of 4.0 MPa, so that the H 2 S down to 0.1ppm, CO 2 2 S concentrated gas is sent to sulfur recover...

Embodiment 2

[0074] (1) Preparation and purification of pure syngas

[0075] Using lignite with a water content of 28% as the raw material, oxygen and water vapor are introduced into the gasification of crushed coal slag (gasification pressure 5.0 MPa, gasification temperature 1250°C) to obtain crude gas. The composition of the crude gas by volume percentage is: CO: 47.67,H 2 : 24.96, CO 2 : 12.01, CH 4 : 15.02, H 2 S: 0.34;

[0076] The crude gas is subjected to sulfur-resistant transformation under the EB catalyst of Hubei Institute of Chemistry at 290°C, 3.5MPa, and the volumetric space velocity calculated by dry gas is 4500h -1 , the converted water / gas molar ratio is 0.36;

[0077] The converted raw gas and low-carbon alcohol purge gas are separated by PSA for H 2 The exhaust gas enters the low-temperature methanol washing together, and is washed with low-temperature methanol at a temperature of -45°C and a pressure of 5.0 MPa to make H 2 S down to 0.1ppm, CO 2 2 S concentrate...

Embodiment 3

[0088] (1) Preparation and purification of pure syngas

[0089] Using bituminous coal as raw material, oxygen and water vapor are introduced to produce crude gas through pressurized gasification of crushed coal (gasification pressure 5.5MPa, gasification temperature 1200°C). The composition of crude gas by volume percentage is: CO: 48.29, H 2 : 23.83, CO 2 : 13.73, CH 4 : 13.94, H 2 S: 0.21;

[0090] The crude gas is subjected to sulfur-resistant transformation under the catalyst of Qingdao Lianxin QDB-04 at 250°C, 3.0MPa, and the volumetric space velocity calculated by dry gas is 4300h -1 , the converted water / gas molar ratio is 0.35;

[0091] The converted raw gas and low-carbon alcohol purge gas are separated by PSA for H 2 After the gas enters the low-temperature methanol washing together, the H 2 S down to 0.1ppm, CO 2 2 S concentrated gas is sent to sulfur recovery;

[0092] The crude gas washed with low-temperature methanol enters into methane for cryogenic sepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com