Thermoconditional suit achieving cooling and heating

A dual-purpose, temperature-adjusting technology, applied in clothing, applications, clothing, etc., can solve the problems that the gas-liquid separator needs to be carried together on the body, the body of the wearer is unevenly cooled, and the separation rate of cold and hot gases can be reduced. , to achieve the effect of improving energy separation performance, increasing the convenience of use, and increasing the cooling capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

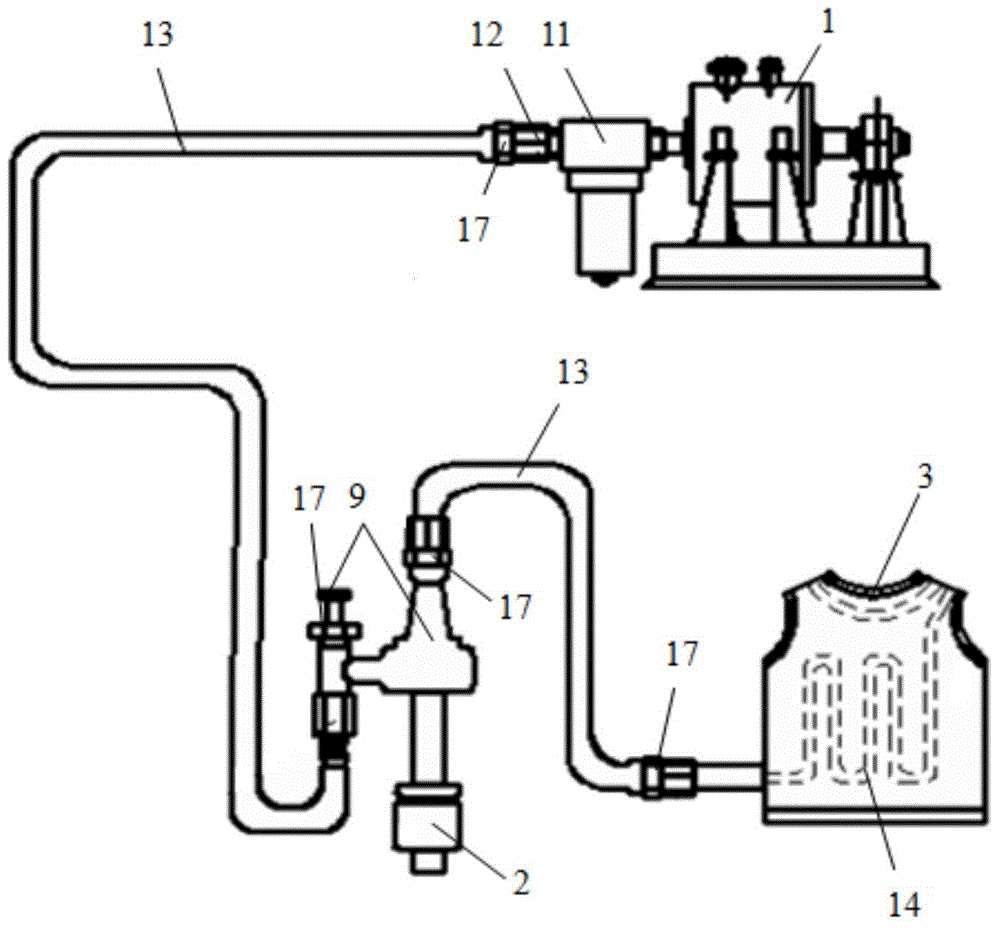

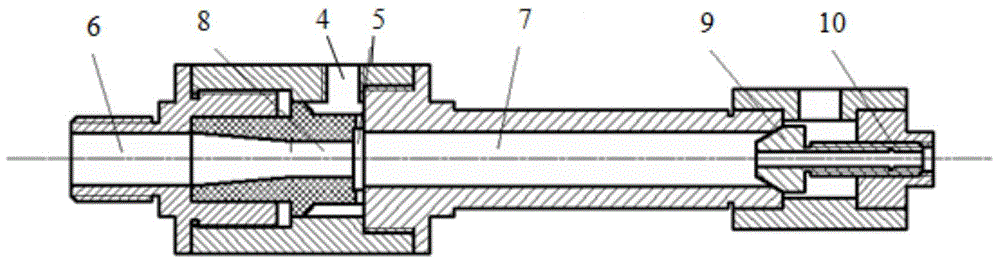

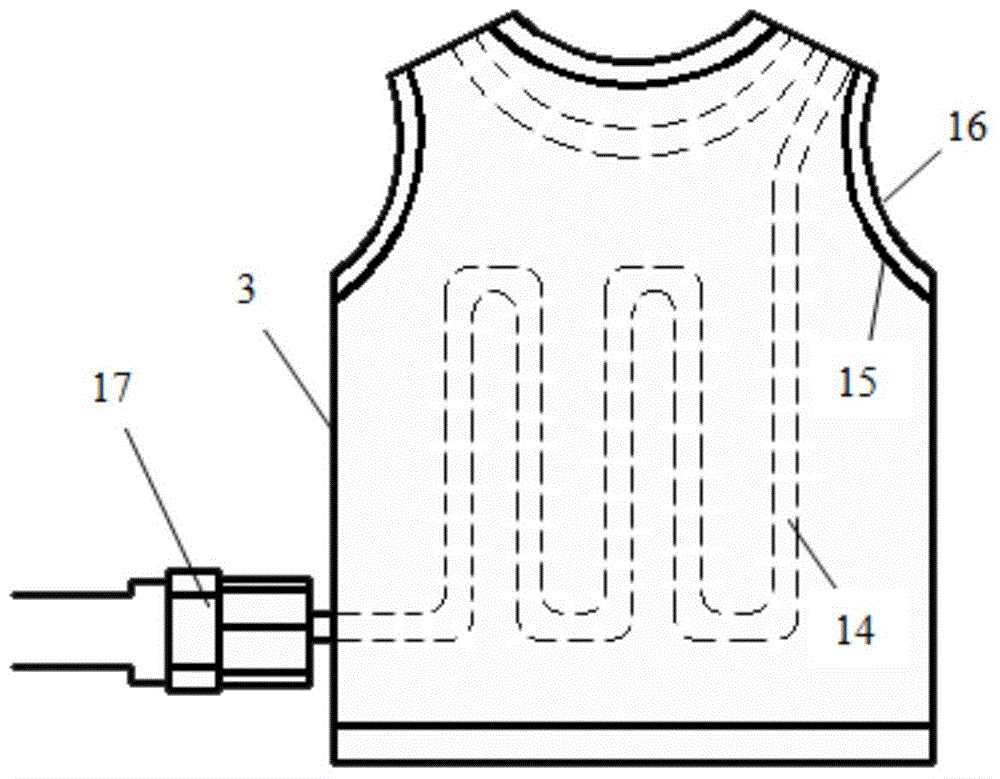

[0023] as attached figure 1 As shown, the side wall of the double-way vortex tube 2 is provided with an air inlet nozzle 4, and the tangential direction edge of the air inlet nozzle 4 is a vortex chamber 5, and one side of the vortex chamber 5 is a cold end pipe 6, and the other side is a hot end pipe 7, and the cold end pipe 7 is formed on the other side of the vortex chamber 5. The end pipe 6 and the hot end pipe 7 are respectively connected with mufflers, the separation orifice 8 is located between the cold end pipe 6 and the vortex chamber 5, the hot end pipe 7 is equipped with a hot end regulating valve 9, and the center of the hot end regulating valve 9 is set There is an additional circuit 10, which can make the feedback gas enter the double-way vortex tube 2, the temperature of the feedback gas is equal to the inlet temperature, and the pressure is relatively small. The experimental results show that the double-way vortex tube with this structure can increase the coolin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com