Multi-liquid hot melting glue dispenser

A dispensing machine and melting point technology, which is applied to the surface coating liquid device, coating, etc., can solve the problem that the dispensing machine cannot use multiple glues at the same time, the hot melt state of the glue is inconsistent, and cannot meet the diverse needs And other problems, to achieve good dispensing effect, ensure hot melt effect, and ensure the effect of flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

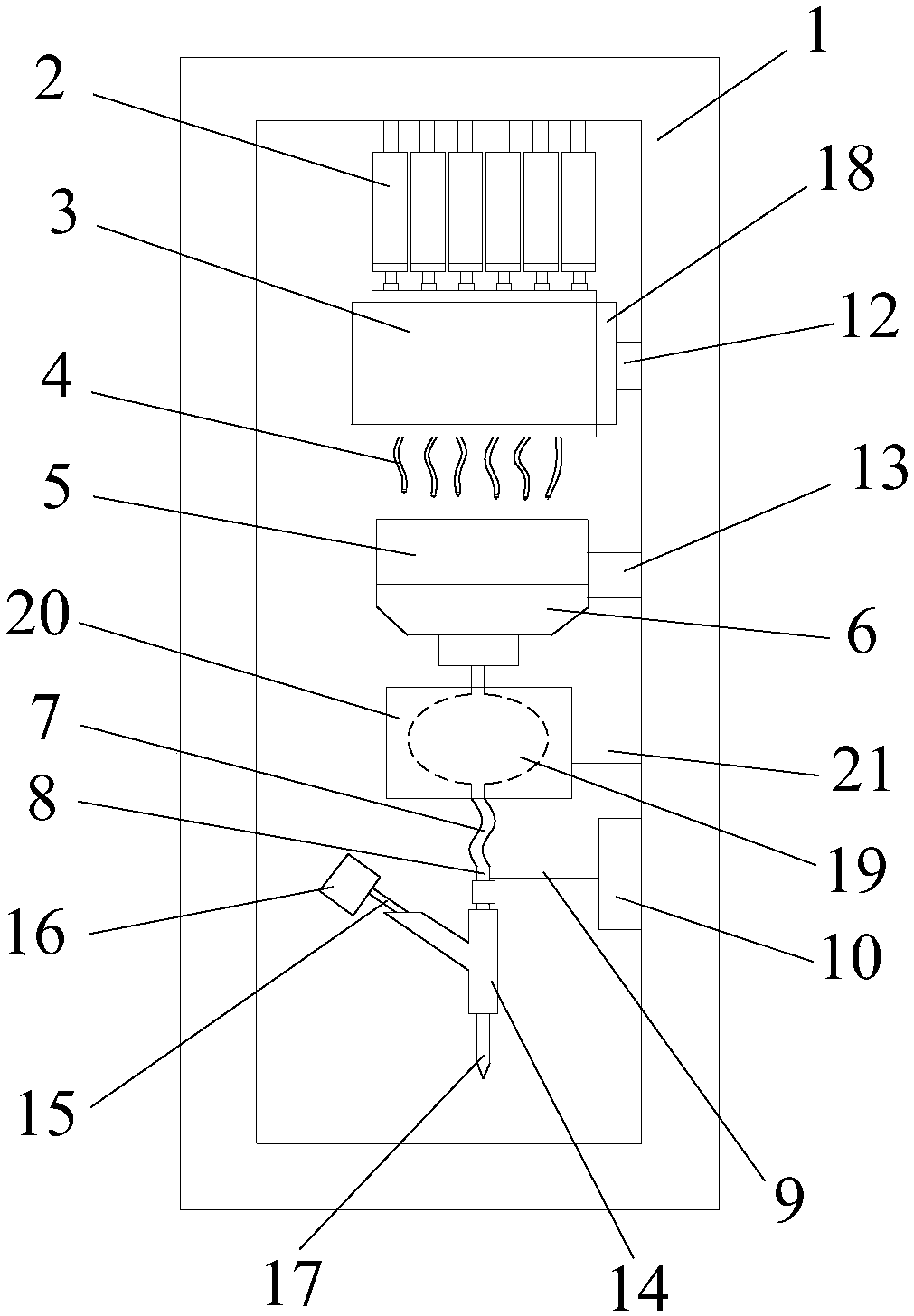

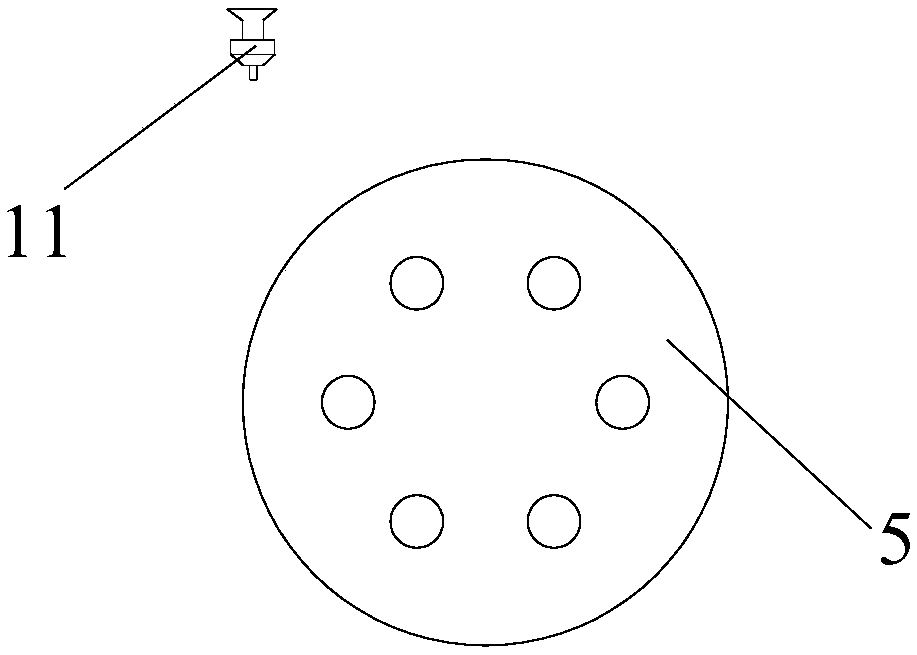

[0022] As shown in the figure, this embodiment discloses a multi-liquid hot-melt glue dispensing machine, which includes a glue dispenser frame 1, and a plurality of glue barrels 2 are fixed on the top of the glue dispenser frame 1, and the outlets of the glue barrels 2 The glue opening is connected with a glue feeding adjustment assembly 3 capable of adjusting the amount of glue feeding. The outer wall of the glue feeding adjustment assembly 3 is provided with a pre-heating sleeve 18. The glue feeding adjustment assembly 3 is provided with a plurality of The fluorine rubber guide tube 4 connected to the glue outlet of the barrel 2, the glue outlet of the fluorine rubber guide tube 4 is connected to the glue inlet of the mixed glue temporary storage component 5, and the outlet of the mixed glue temporary storage component 5 The glue port is connected to the glue inlet of the glue delivery pump 6, and the glue outlet of the glue delivery pump 6 is connected to the glue inlet of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com