Casing pipe and needle dispensing assembly tool and dispensing assembly method

An assembly tooling and trocar technology, applied in the field of workpiece assembly, can solve problems such as slow efficiency and uneven dispensing quality, and achieve the effects of shortening time, improving efficiency, and easy determination of travel parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

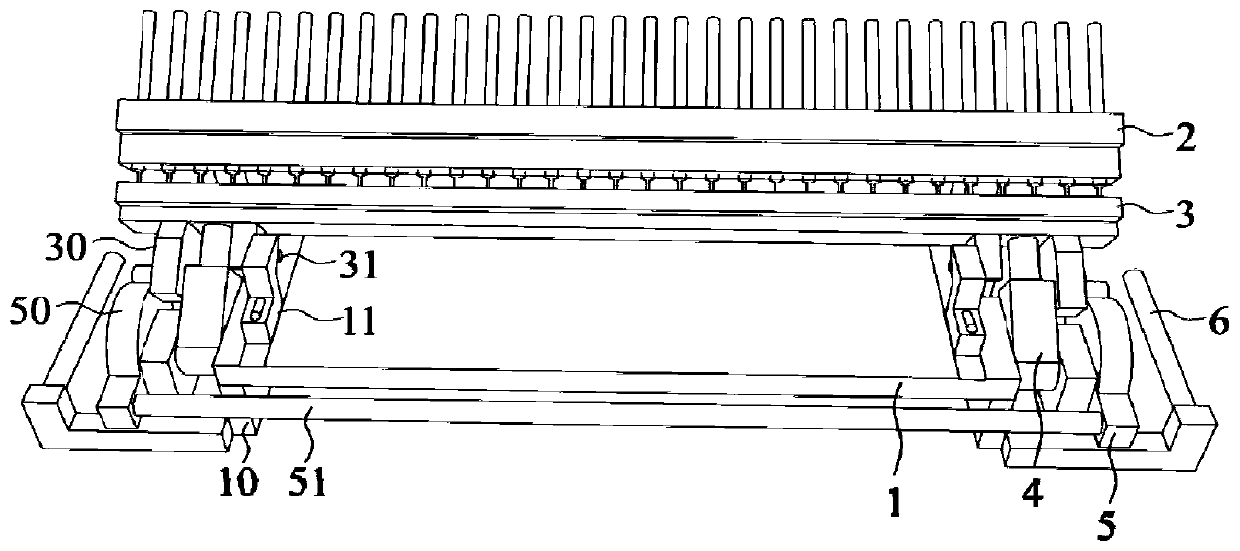

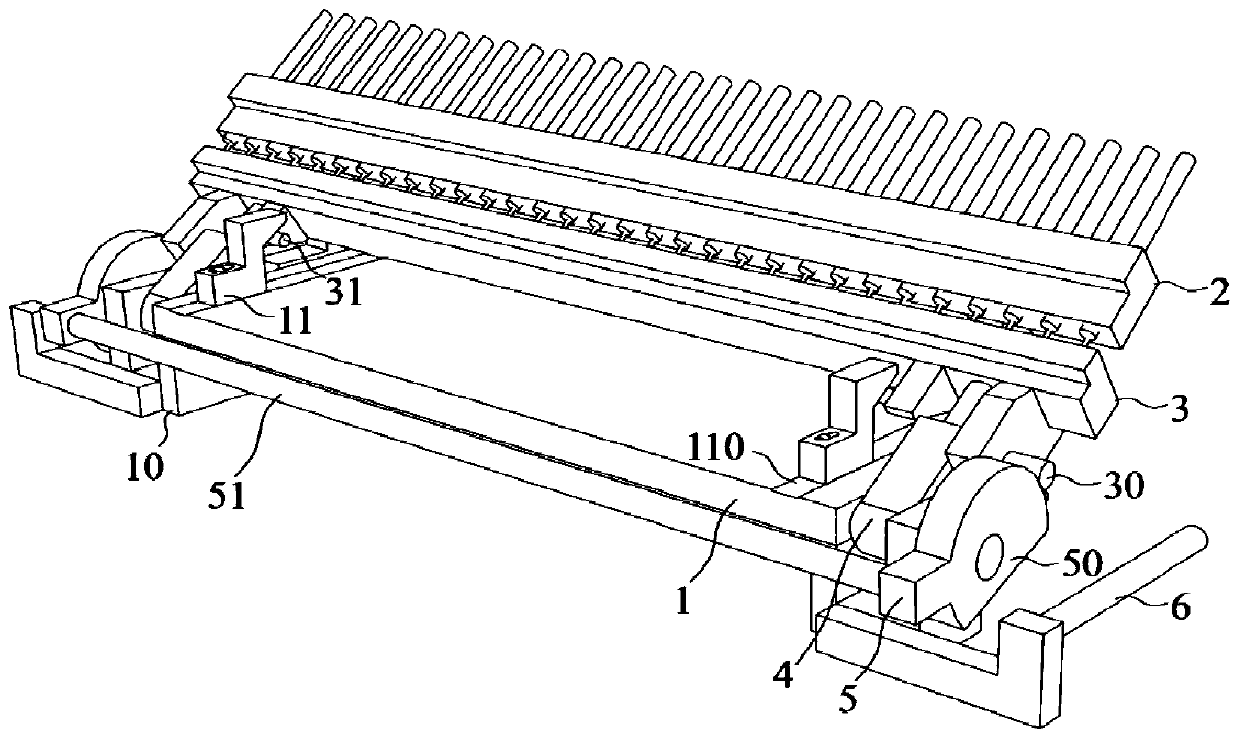

[0087] A trocar dispensing assembly tool, such as figure 1 shown, including:

[0088] pedestal 1;

[0089] The assembly plate 2 is connected to the upper side of the base frame 1, and its length direction is parallel to the length direction of the base frame 1;

[0090] Sleeve assembly hole 20, which is a transverse through hole opened in the assembly plate 2, arranged in parallel along the length direction of the assembly plate 2;

[0091] The needle guide block 3 is connected with the base frame 1 and is located inside the assembly plate 2 .

[0092] There are mainly the following defects in the existing cannula needle assembly process: 1), dispensing with a hand-held cannula needle, the efficiency is slow, and the dispensing effect cannot be guaranteed, and the defective rate is high; 2), The dispensing assembly tooling and dispensing equipment do not cooperate well. Although the dispensing assembly speed has been improved, the dispensing effect is still unsatisfactory; ...

Embodiment 2

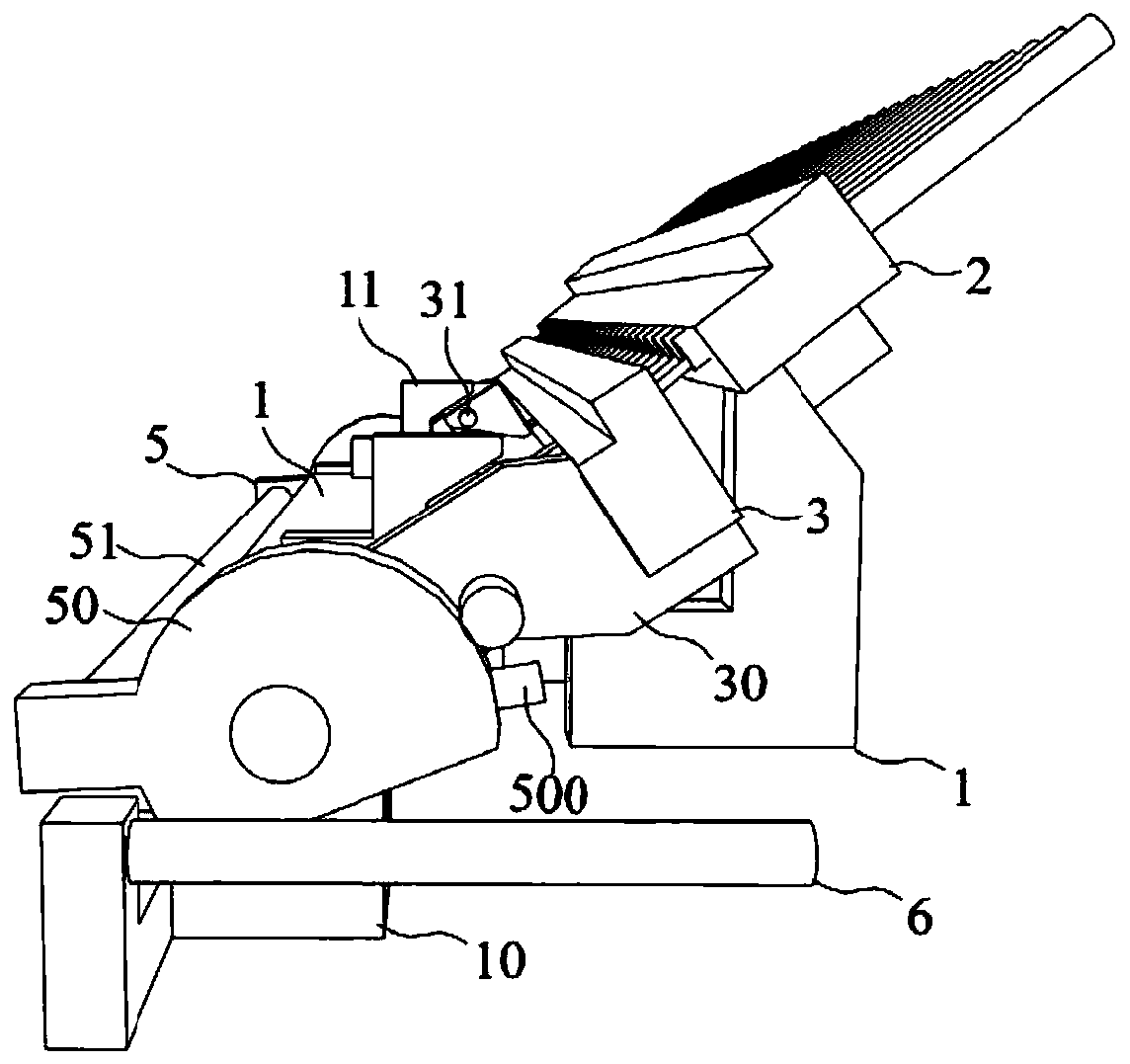

[0098] A trocar dispensing assembly tooling of the present embodiment is further improved on the basis of Embodiment 1, such as figure 1 As shown, the sleeve assembly hole 20 is set obliquely to the horizontal plane; the needle guide block 3 is movably connected to the base frame 1 .

[0099] The oblique setting of the forehead in this embodiment means that the angle between the assembly hole 20 and the horizontal plane is not equal to 0°, that is, the angle between the axis of the casing assembly hole 20 and the horizontal plane is not equal to 0°, and the traditional glue dispenser points The glue end is vertically downward. When the casing and the needle are filled in the dispensing assembly tool of this embodiment, this setting makes the dispensing surface greatly increase relative to the horizontal dispensing surface of the casing and the needle, further enhancing The effect of dispensing glue.

[0100] When dispensing glue, if the glue is placed on the part where the ne...

Embodiment 3

[0106] A kind of trocar dispensing assembly tooling of the present embodiment is further improved on the basis of embodiment 2, such as Figure 5 , Figure 6 and Figure 7 As shown, it also includes a cannula limiting step 21 , which is arranged on the assembly plate 2 near the end of the needle guide block 3 to limit the movement of the cannula in the cannula assembly hole 20 .

[0107] When the casing assembly hole 20 is set obliquely, the loaded casing may slip out of the casing assembly hole 20 during the assembly process, which will affect the dispensing process. Therefore, this embodiment sets the casing limit Level 21, restricting the tendency of the casing to slide out toward the direction of the needle guide block 3, the structure of the casing limiting step 21 in this embodiment is as follows Figure 5 , Figure 6 and Figure 7 As shown, it is an angle steel structure, one side is connected to the end of the assembly plate 2, and the other side is blocked between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com