Glue dispensing device for electronic component

A technology of electronic components and dispensing devices, which is applied to the device and coating of the surface coating liquid, can solve problems such as operation errors, component clamping damage, and large clamping force, so as to prevent clamping damage and ensure Good uniformity and dispensing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

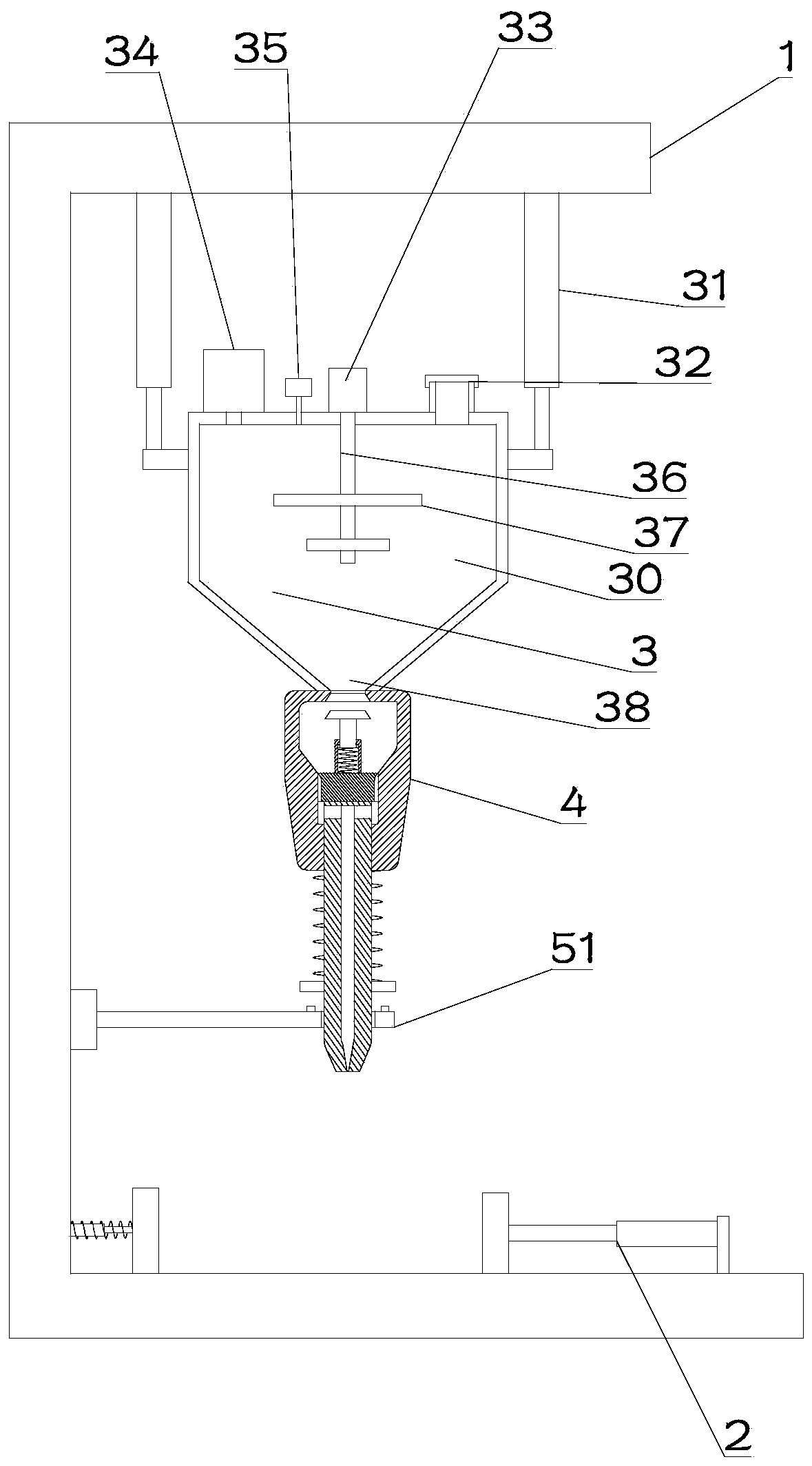

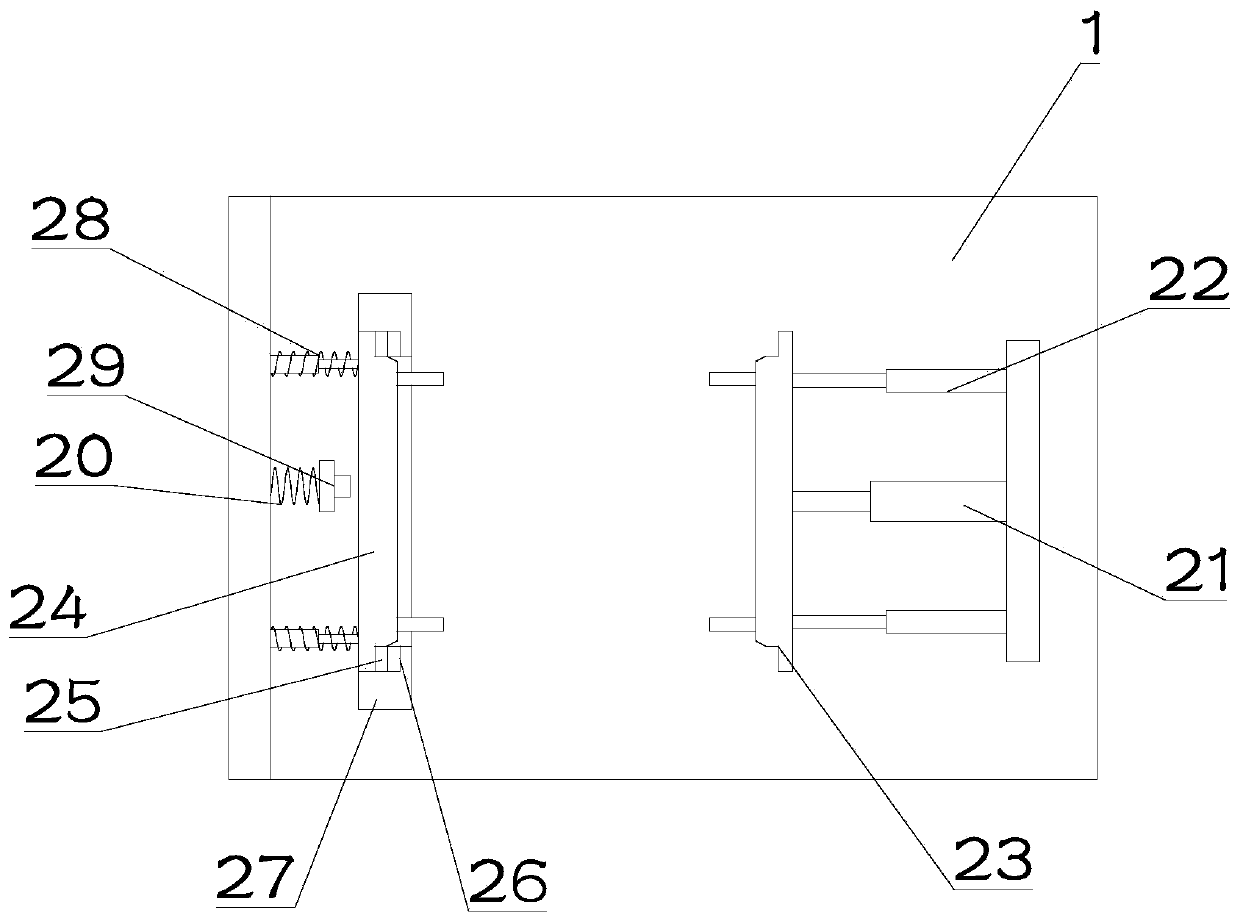

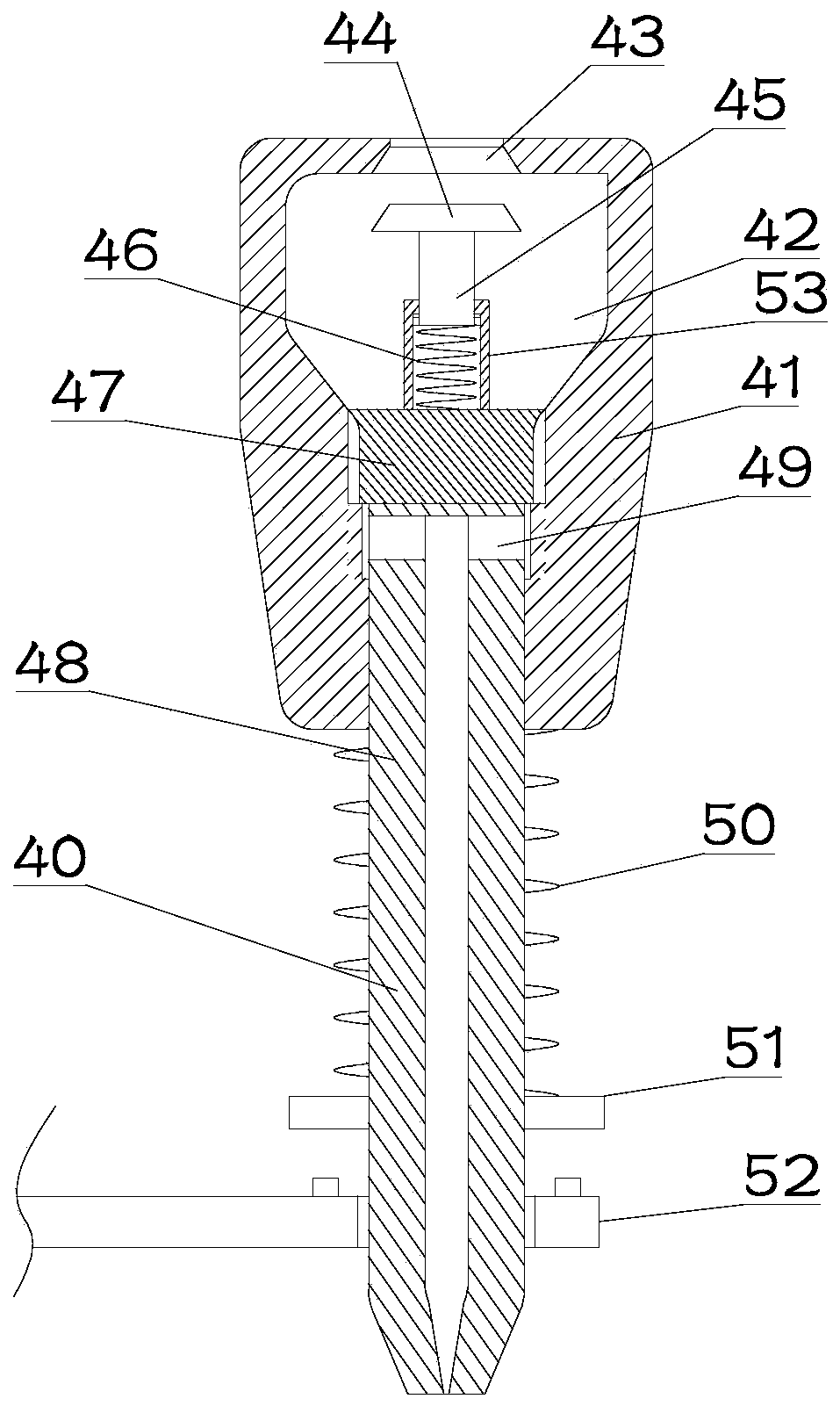

[0023] see Figure 1~2 , in Embodiment 1 of the present invention, a dispensing device for electronic components, including a frame 1, the bottom of the frame 1 is provided with a clamping part 2 for clamping components, and the top of the clamping part 2 is provided with The discharge part 4, the discharge part 4 is installed under the material storage part 3, and the discharge part 4 communicates with the storage part 3, and the storage part 3 is installed on the frame 1; the clamping part 2 Including the A clip 23 and the B clip 24 provided in cooperation with each other, the A clip 23 and the B clip 24 are set for clamping components, and the B clip 24 is arranged on the mounting hole on the mounting part 27, And the two sides of the B clip 24 are provided with an adsorption part 1 25 that cooperates with the adsorption part 2 26 on the mounting part 27, the adsorption part 1 25 and the adsorption part 2 26 are sucked together, and the adsorption part 2 26 is fixedly insta...

Embodiment 2

[0026] see Figure 1~3 The main difference between this embodiment 2 and embodiment 1 is that the storage part 3 includes a storage shell 30 and a B telescopic cylinder 31 connected to the storage shell 30, and the extended end of the B telescopic cylinder 31 is fixedly installed on the On the material storage case 30 , the fixed end is connected to the frame 1 . The B telescopic cylinder 31 is set to provide power for the storage shell 30 to lift up and down.

[0027] A stirring mechanism is arranged inside the storage case 30, which ensures the quality of the glue.

[0028] The storage shell 30 is also provided with a feeding port 32, a pressure gauge 35 and a surge tank 34, and the surge tank 34 is provided to ensure that the internal pressure of the storage shell 30 ensures uniform feeding. A pressure gauge 35 is provided to facilitate observation of the internal pressure of the storage case 30 .

[0029] Described agitating mechanism comprises agitating shaft 36, agita...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com