Ultrasonic probe piezoelectric wafer automatic glue-dispensing and chip-mounting machine

A piezoelectric chip and automatic glue dispensing technology, which is applied in the manufacture/assembly of piezoelectric/electrostrictive devices, devices for coating liquid on the surface, coating, etc., can solve the problem of poor mounting effect and poor dispensing effect , low degree of automation and other issues, to achieve the effect of high dispensing speed, convenient replacement and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

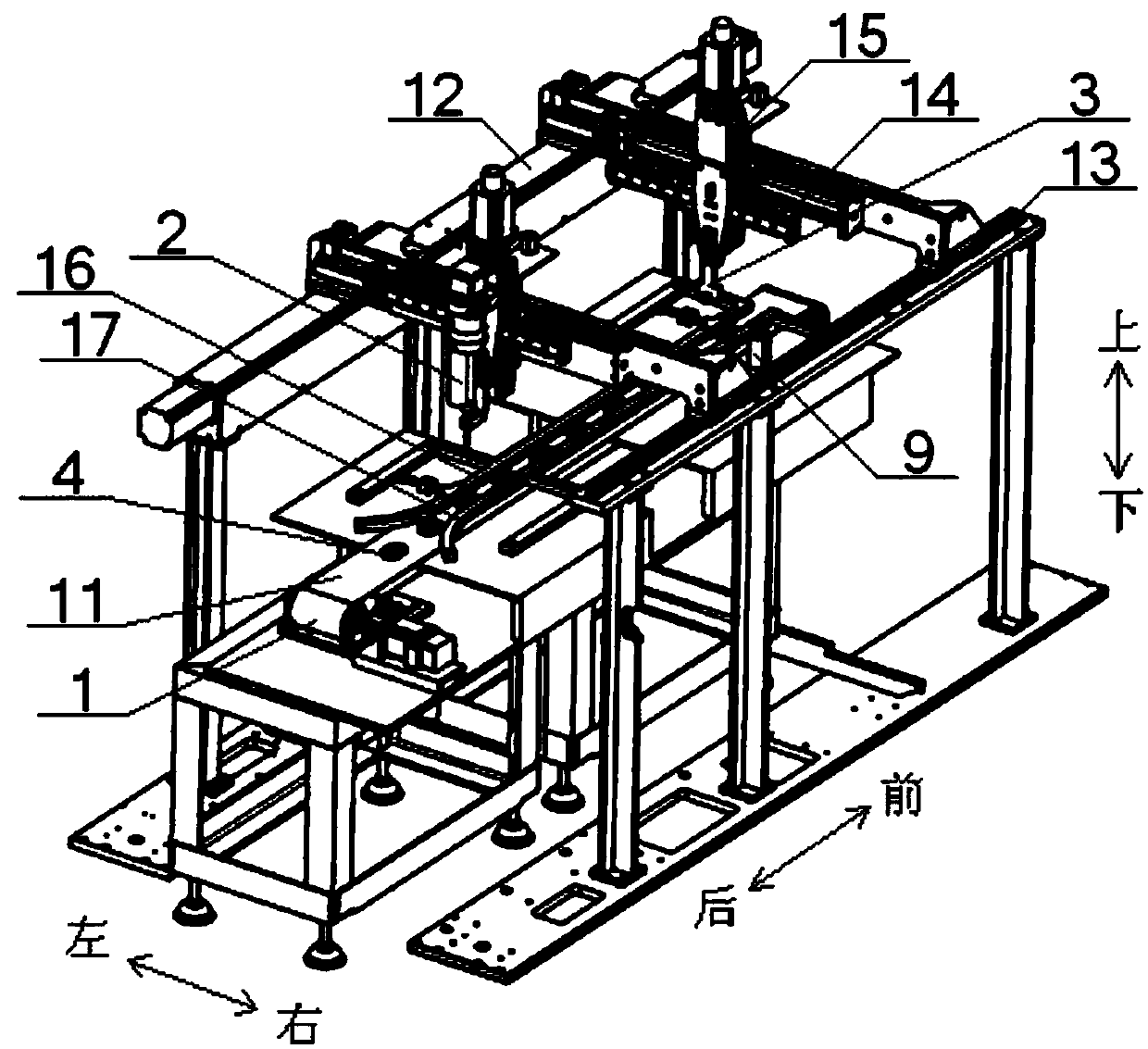

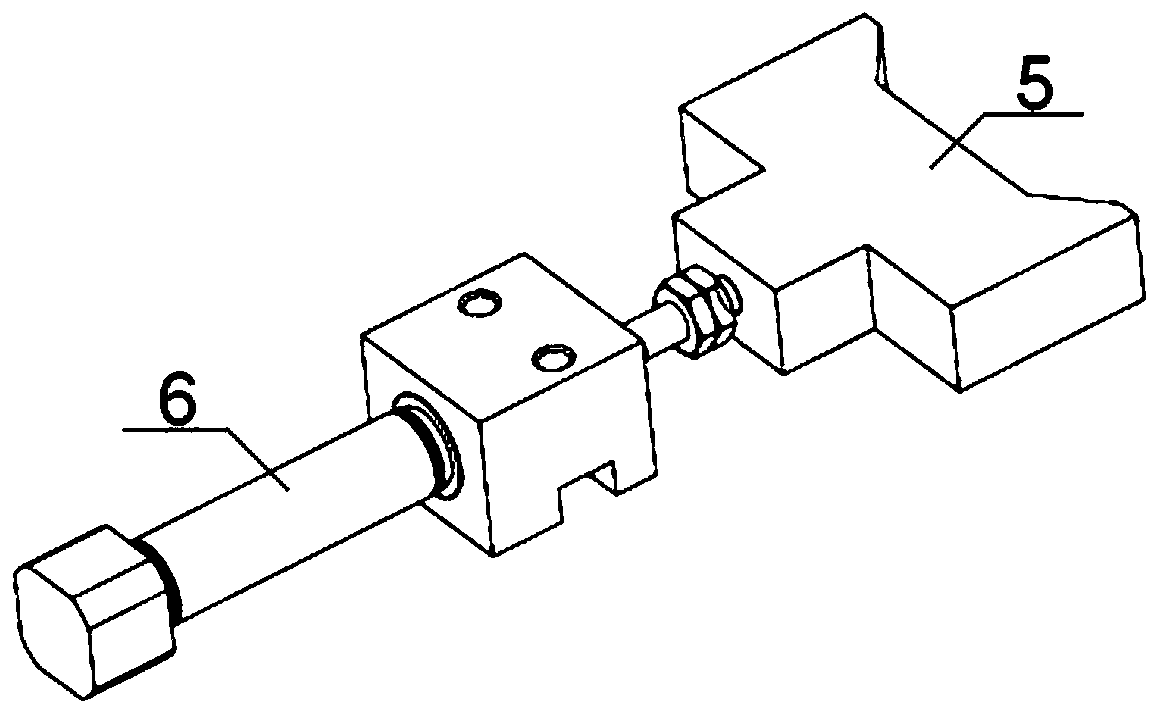

[0064] see Figure 1 to Figure 3 , an ultrasonic probe piezoelectric chip automatic dispensing and mounting machine, comprising a conveying device 1, a glue dispensing machine 2, and a placement machine 3, and the conveying device 1 includes a belt 11 and No. 1 guide rails 12, 2 No. 1 guide rail 13, No. 1 guide rail 12, and No. 2 guide rail 13 are slidably connected with two No. 1 guide posts 14, and both No. 1 guide posts 14 are slidably connected with guide posts 15. The guide columns 14 are perpendicular to each other, and the dispenser 2 and the chip mounter 3 are respectively slidably connected to two guide columns 15; above the belt 11, a No. 1 limit guide rail 16 and a No. Limiting guide rail 17, the position between the No. 1 limiting guide rail 16 and the No. 2 limiting guide rail 17 on the belt 11 is provided with a piezoelectric wafer shell 4, and No. 1 opening slot and No. 2 opening are provided on the No. 1 limiting guide rail 16. No. 1 opening slot is provided w...

Embodiment 2

[0070] Basic content is the same as embodiment 1, the difference is:

[0071] see figure 1 , Figure 4, the dispenser 2 includes the No. 3 pneumatic cylinder 21, injection cylinder 22, and injection head 23 connected in sequence, the No. 3 pneumatic cylinder 21 is connected with the No. 1 guide plate 24, and the No. 1 guide plate 24 is connected with the guide sliding column 15 is slidably connected, the injection barrel 22 is provided with glue; the No. 1 guide plate 24 is connected with an injection head replacement arm 25, and the injection head replacement arm 25 is connected with a positioning block 26 for the injection head 23;

[0072] see figure 1 , Figure 5 , the placement machine 3 includes a No. 2 guide plate 31 and a vertical arm 32, the No. 2 guide plate 31 is slidably connected with the guide column 15, and one end of the vertical arm 32 is connected with the No. 2 guide plate 31, vertically The other end of the arm 32 is connected with an electromagnet 33 t...

Embodiment 3

[0078] Basic content is the same as embodiment 1, the difference is:

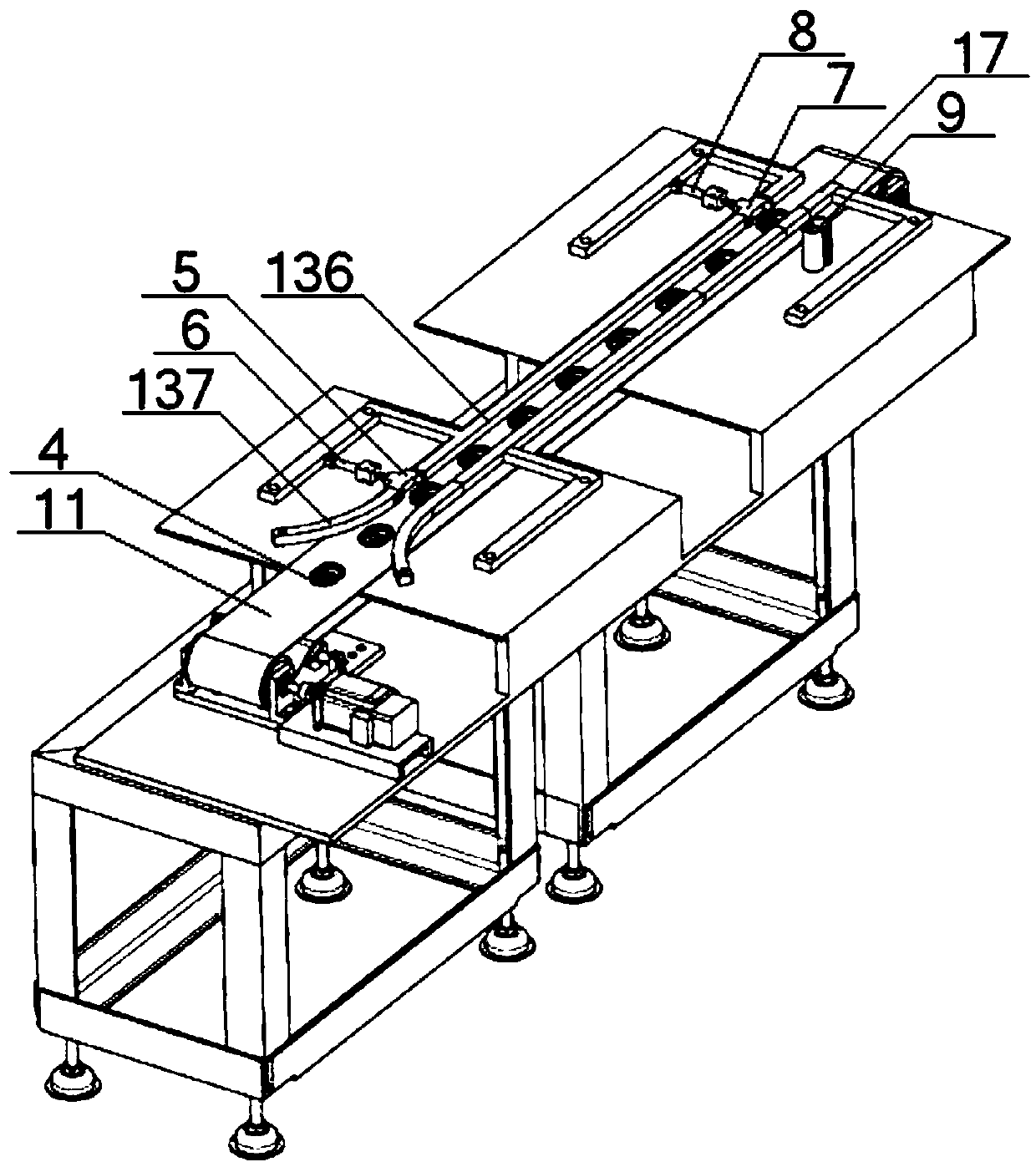

[0079] see figure 1 , figure 2 , the No. 1 limit guide rail 16 and the No. 2 limit guide rail 17 all include a straight guide rail 136 and an arc guide rail 137, and the straight guide rail 136 of the No. 1 limit guide rail 16 and the straight guide rail 136 of the No. 2 limit guide rail 17 are arranged in parallel Above the belt 11 , the arc-shaped guide rail 137 of the No. 1 limit guide rail 16 and the arc-shaped guide rail 137 of the No. 2 limit guide rail 17 are arranged above the belt 11 in a figure-eight shape.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com