Glue dispensing control method, glue dispenser and related device

A technology of dispensing device and control device, which is applied to devices and coatings for coating liquid on the surface, can solve the problems of unstable air pressure, difficult to precisely control, uncertain colloid viscosity, etc., achieve uniform dispensing and improve production. Efficient, accurate dispensing control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

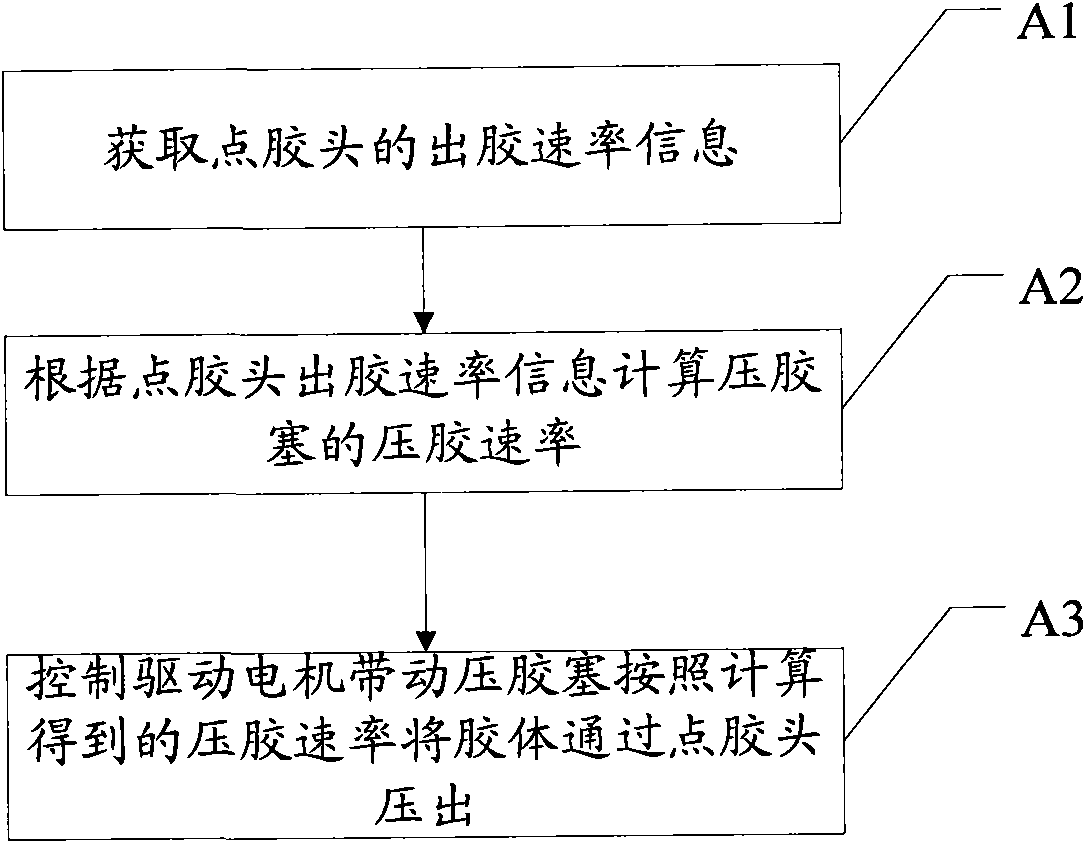

[0043] Embodiment 1. A dispensing control method, the flow chart is as follows figure 1 shown, including:

[0044] A1, obtain the glue output rate information of the dispensing head;

[0045] In this embodiment, the glue output rate information can be obtained and pre-configured according to the user's needs. When performing gluing, accurate calculation can be performed according to the pre-configured gluing rate, and then precise gluing can be completed. The glue rate information can be expressed by the glue volume per unit time.

[0046] A2, calculate the glue pressure rate of the pressure glue plug according to the glue discharge rate information of the dispensing head;

[0047] In the embodiment of the present invention, the gluing method adopts electric control gluing, and the constraint relationship between the glue output rate and the gluing rate is clear, and is not affected by the viscosity of the glue. The specific calculation process is as follows:

[0048] In t...

Embodiment 2

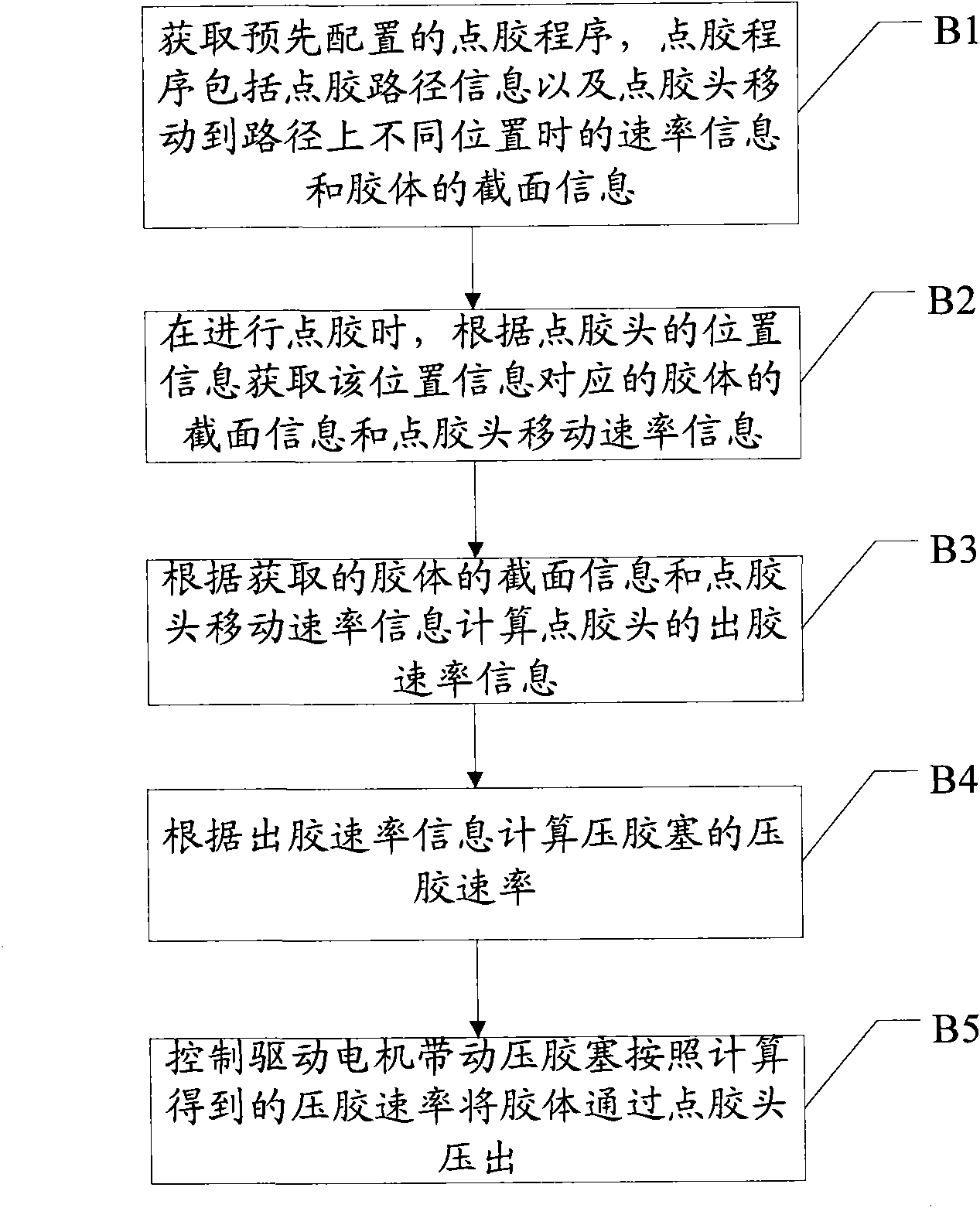

[0060] Embodiment 2, a dispensing control method, the flow chart is as follows figure 2 shown, including:

[0061] B1, obtain the pre-configured dispensing program, the dispensing program includes the dispensing path information, the speed information when the dispensing head moves to different positions on the path, and the section information of the colloid;

[0062] B2, when dispensing, according to the position information of the dispensing head, the section information of the colloid corresponding to the position information and the moving speed information of the dispensing head are obtained;

[0063] B3, calculating the glue output rate information of the dispensing head according to the obtained cross-sectional information of the colloid and the moving speed information of the dispensing head;

[0064] B4, calculating the glue pressing rate of the glue pressing plug according to the glue output rate information;

[0065] Specifically, the method of calculating the g...

Embodiment 3

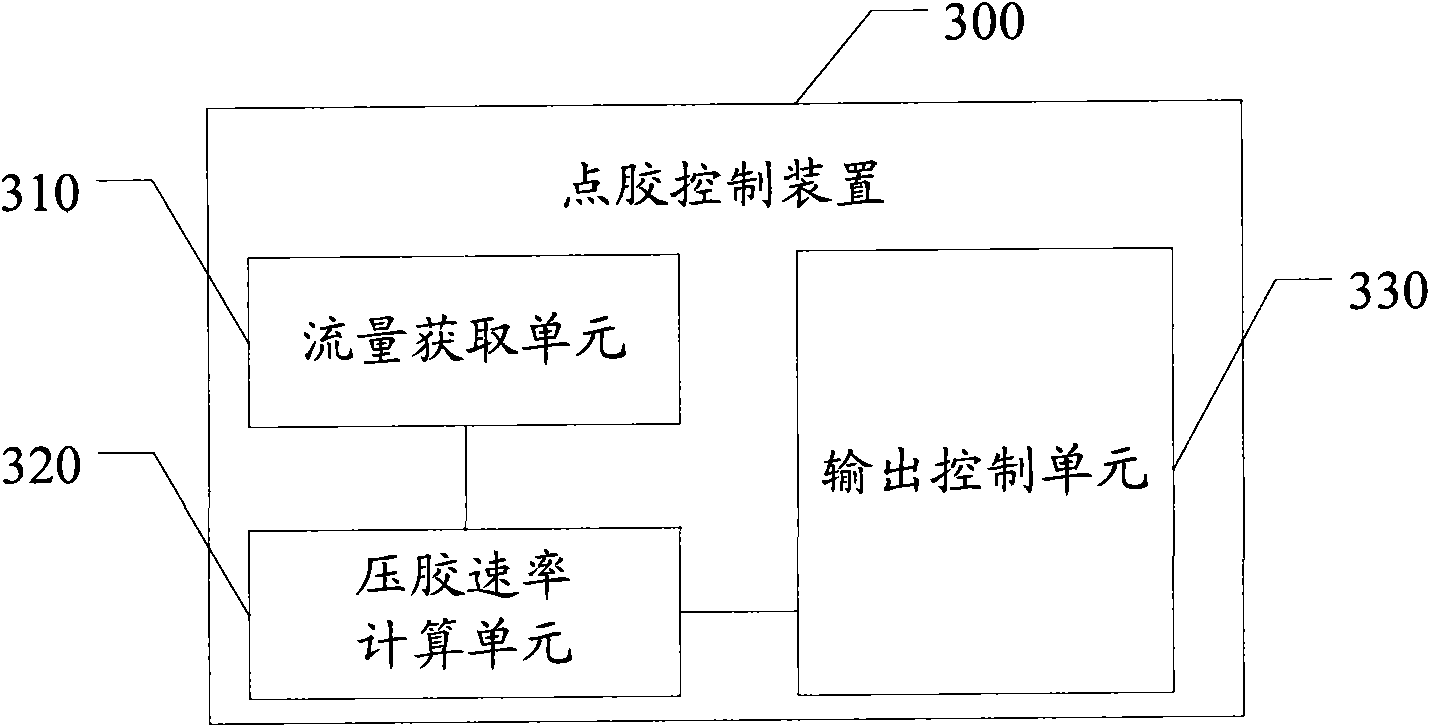

[0071] Embodiment 3, a dispensing control device 300, the structure diagram is as follows image 3 shown, including:

[0072] A flow acquisition unit 310, configured to acquire the glue output rate information of the dispensing head;

[0073] The glue pressing rate calculation unit 320 is used to calculate the glue pressing rate of the glue pressing plug according to the glue discharge rate information of the dispensing head acquired by the flow information acquiring unit 310;

[0074] The output control unit 330 is used to control the driving motor to drive the glue plug to press the glue out through the glue dispensing head according to the calculated glue pressing rate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com