Glue dropping method

A technology of dispensing and dispensing device, applied in installation, optics, instruments, etc., can solve the problems of large amount of glue, affecting the quality of lens module, uneven dispensing, etc., and achieve the effect of uniform dispensing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The following example illustrates a dispensing method that can improve the uniformity of dispensing of the lens module.

[0015] The dispensing method of the first embodiment includes the following steps.

[0016] In the first step, a lens module 10 to be glued and a glue dispensing device 30 are provided.

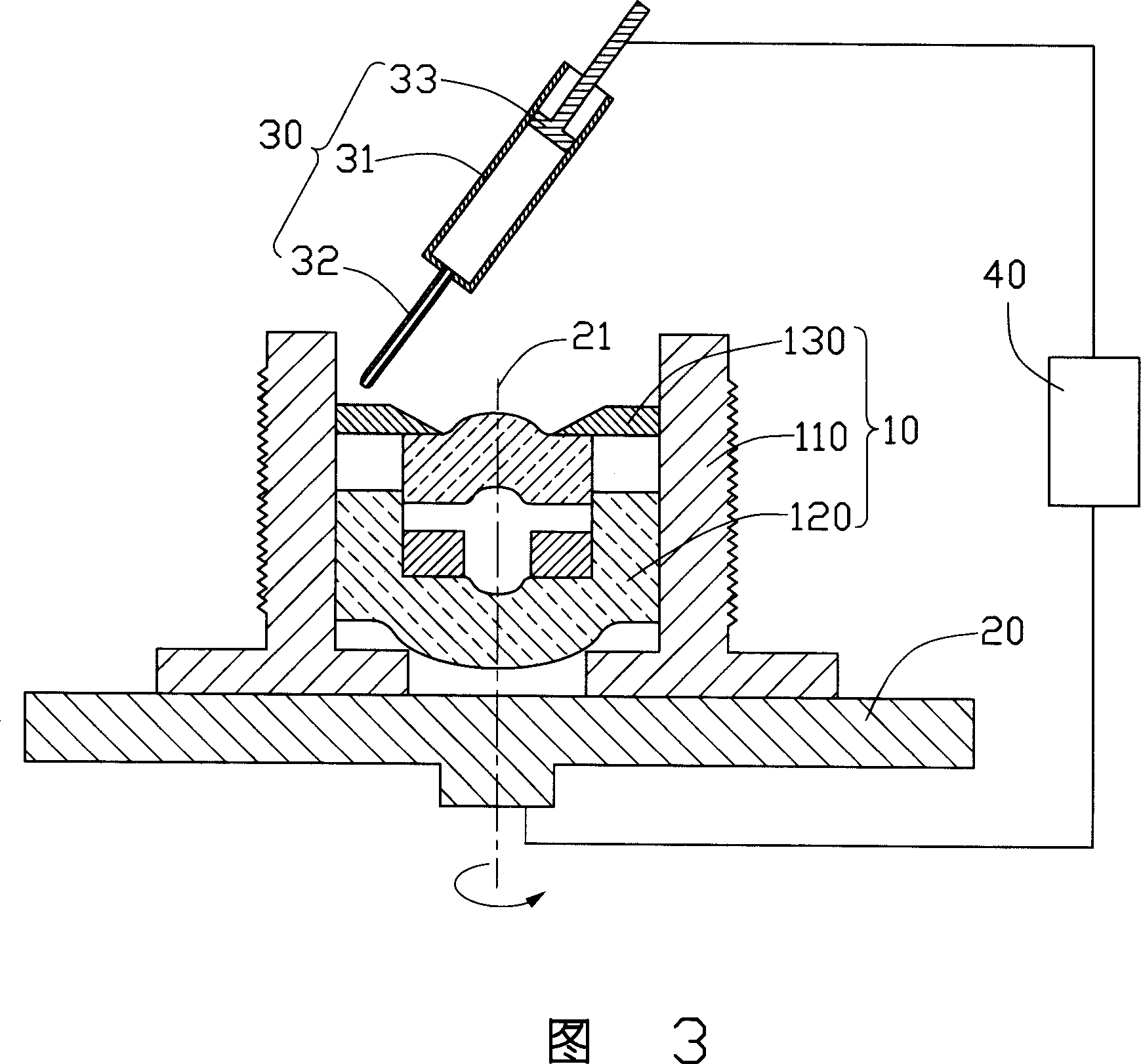

[0017] Referring to FIG. 3 , the lens module 10 to be glued includes a lens barrel 110 , a lens group 120 and a spacer ring 130 . The lens group 120 and the spacer ring 130 are sequentially fixed in the lens barrel 110 along the optical axis direction. The outer wall of the lens barrel 110 can be provided with threads, which match with the threads provided in the lens mount (not shown), and can be screwed into the lens mount for fixing.

[0018] The dispensing device 30 includes a glue cartridge 31 , a needle 32 and a pressure applying device 33 . The glue cartridge 31 is used for containing glue. The needle 32 communicates with the glue cartridge 31 for dispens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com