Patents

Literature

69results about How to "Unified testing standards" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Automatic detection system for quality of traditional Chinese medicine

ActiveCN102435713AImprove identification efficiencyPromote circulationMaterial analysis by optical meansTesting medicinal preparationsProcess engineeringData science

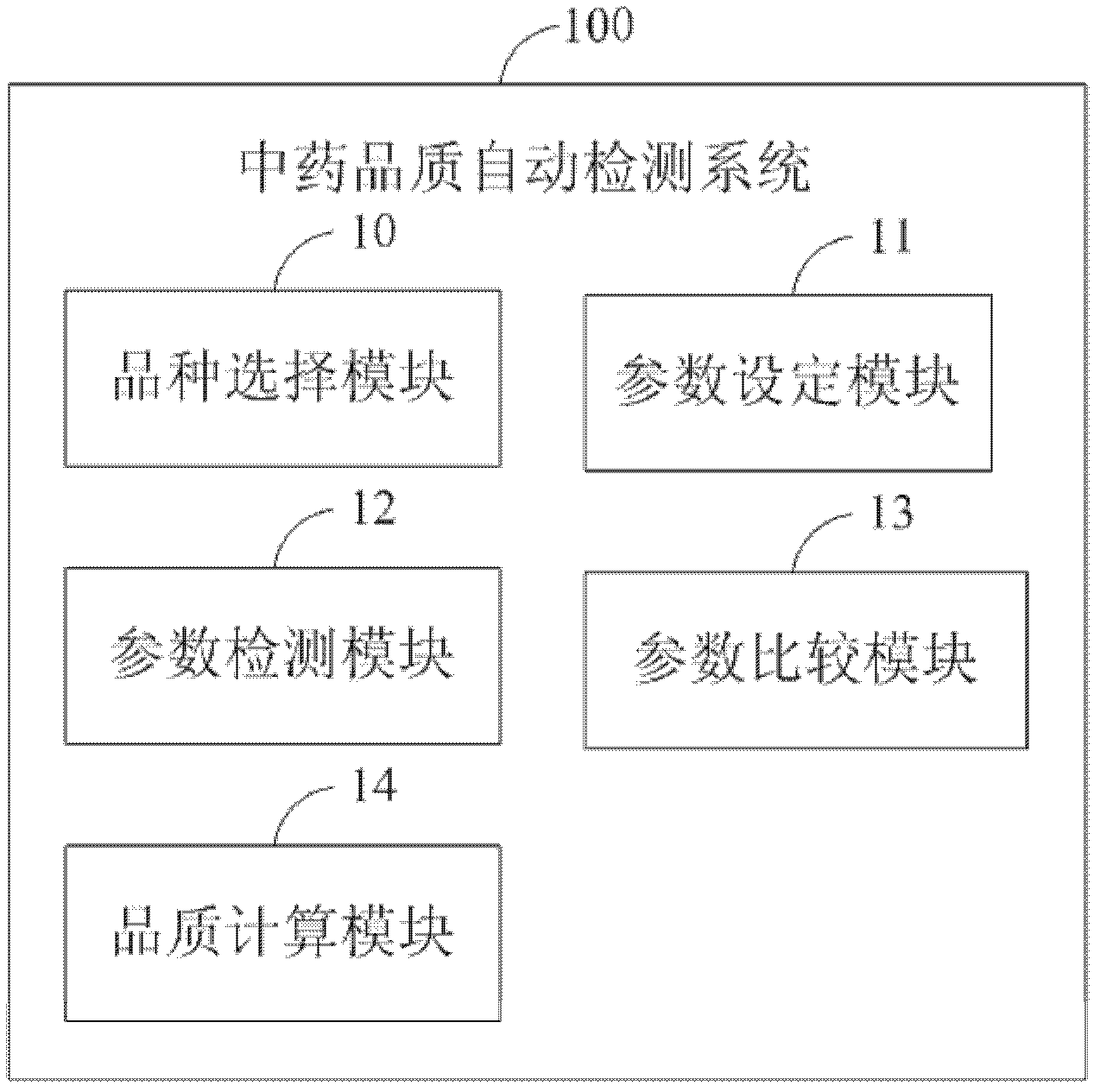

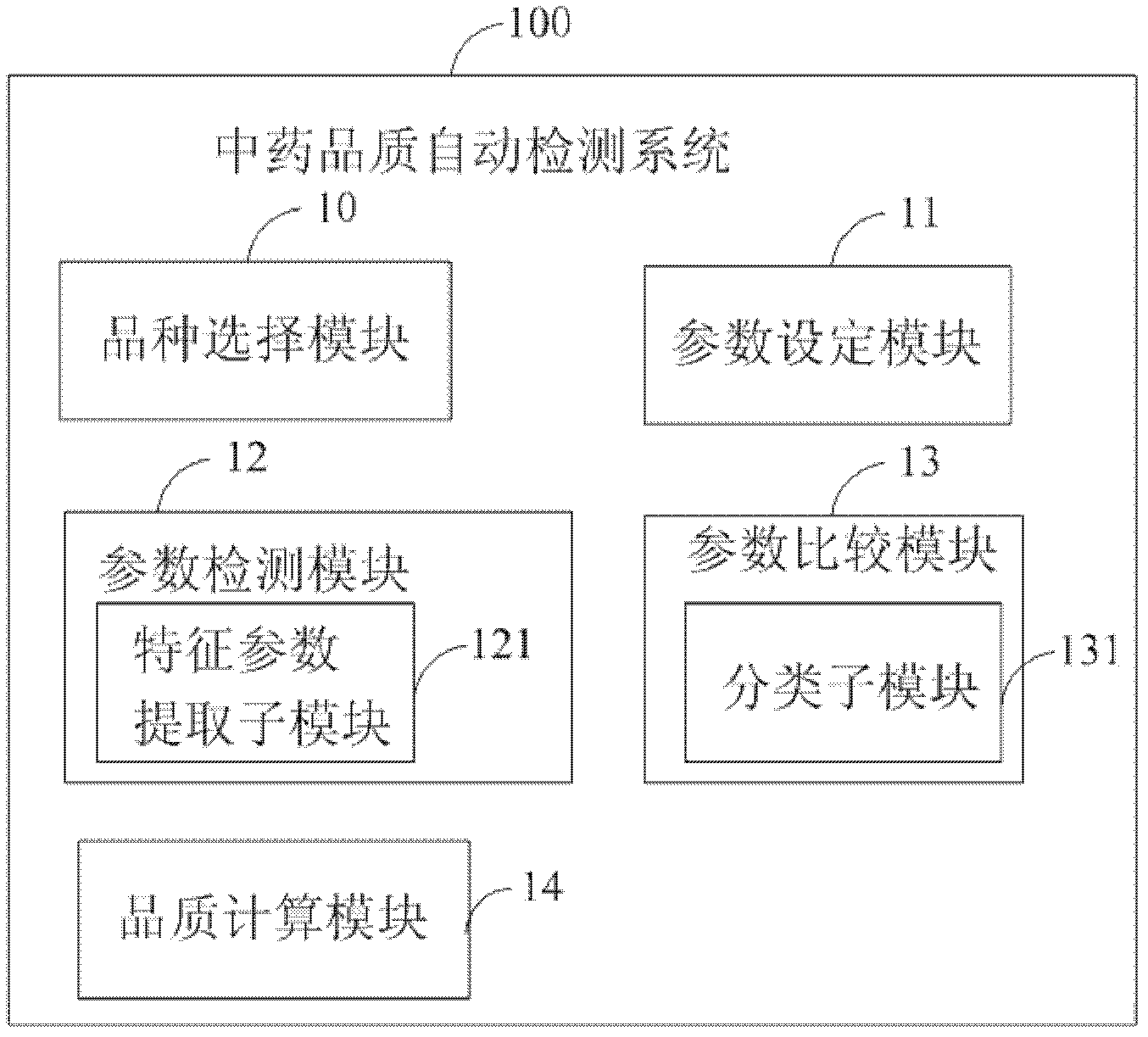

The invention provides an automatic detection system for quality of traditional Chinese medicine and a traditional Chinese medicine processing system and a traditional Chinese medicine extracting system thereof. The automatic detection system for quality of traditional Chinese medicine comprises a variety selection module used for selecting a traditional Chinese medicine variety required to be detected and confirming the traditional Chinese medicine variety required to be detected and quality related parameters thereof as well as the weight coefficients of the parameters in quality, a parameter setting module used for setting characteristic parameters and parameter quality values of the traditional Chinese medicine variety required to be detected, a parameter detecting module used for detecting shape, color, smell and taste parameters of the traditional Chinese medicine, a parameter comparison module used for comparing the detection parameter values with the characteristic parameters and the parameter quality values in the parameter setting module to obtain variety authenticity and relative parameter quality value of the detected traditional Chinese medicine, and a quality calculation module used for calculating according to the relative parameter quality values and the weight coefficients to obtain the quality value. Therefore, automatic and accurate detection for the qualityof the traditional Chinese medicine is realized.

Owner:CHENGDU UNIV OF TRADITIONAL CHINESE MEDICINE

Automatic detection system for traditional-Chinese-medicine quality

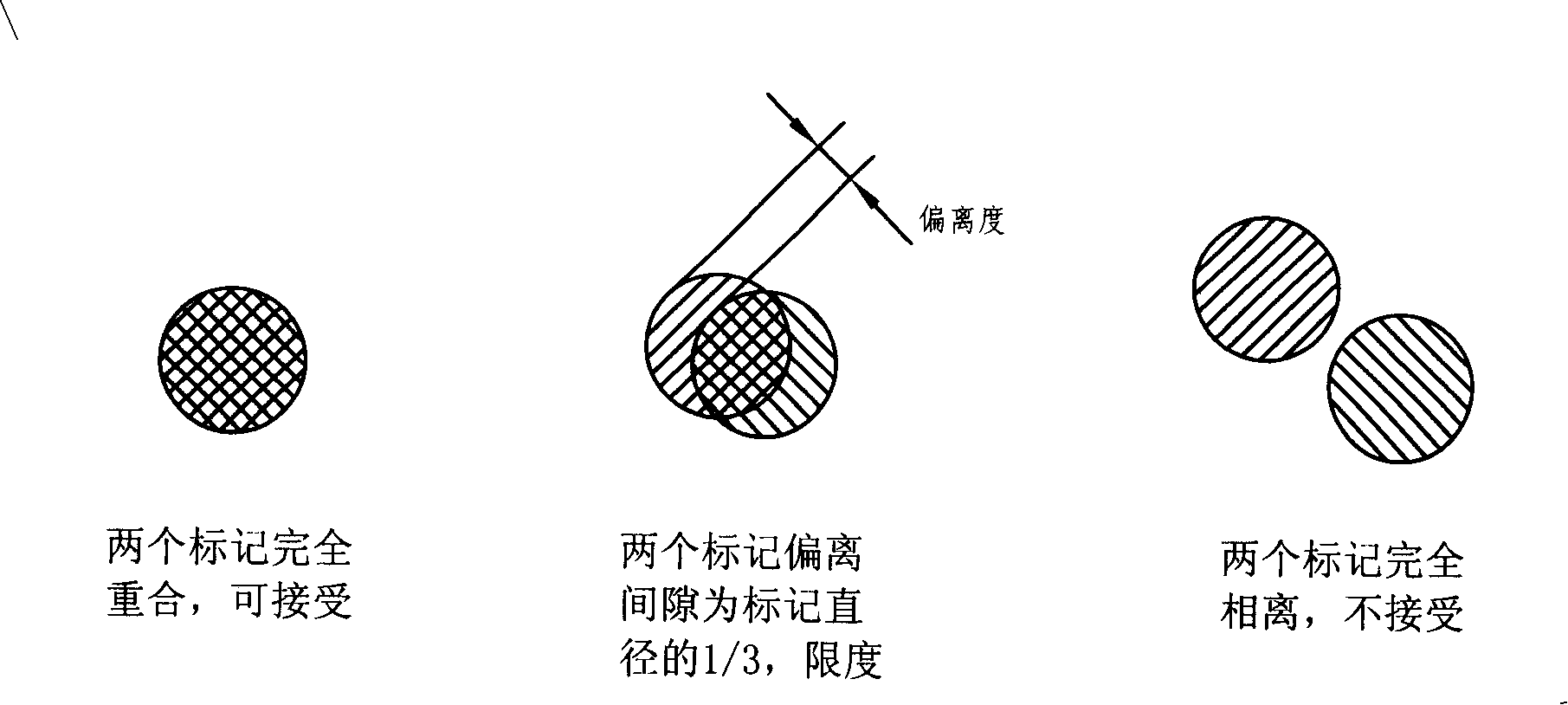

InactiveCN105973858AObjective testing standardUnified testing standardsImage enhancementImage analysisPattern recognitionMicroscopic image

The invention discloses an automatic detection system for the traditional-Chinese-medicine quality. Traditional-Chinese-medicine original images are collected, outlines of target areas are partitioned, the images are subjected to noise removing, a neural network PCNN corresponds to the images, central neuron corresponds to pixel points of the images, multi-wavelength LED lamps are illumed respectively, several LED lamps capable of motivating remarkable fluorescence signals are selected and alternately illumed, traditional-Chinese-medicine samples with fluorescence spectrums of 300 nm-1,100 nm are collected, the one-dimensional time-series signal characteristics of all two-dimensional images are extracted, characteristic information is stored, the airspace characteristics of traditional-Chinese-medicine microscopic images are extracted, and the traditional-Chinese-medicine quality is detected. According to the automatic detection system, the traditional-Chinese-medicine external parameters are synthetically evaluated with the electronic technology, the traditional-Chinese-medicine inherent quality is automatically detected by combing traditional-Chinese-medicine chemical-component content parameters, safety detection parameters and conventional detection parameters, the detection standard is objective and uniform, and accurate medicine making can be achieved.

Owner:YICHUN UNIVERSITY

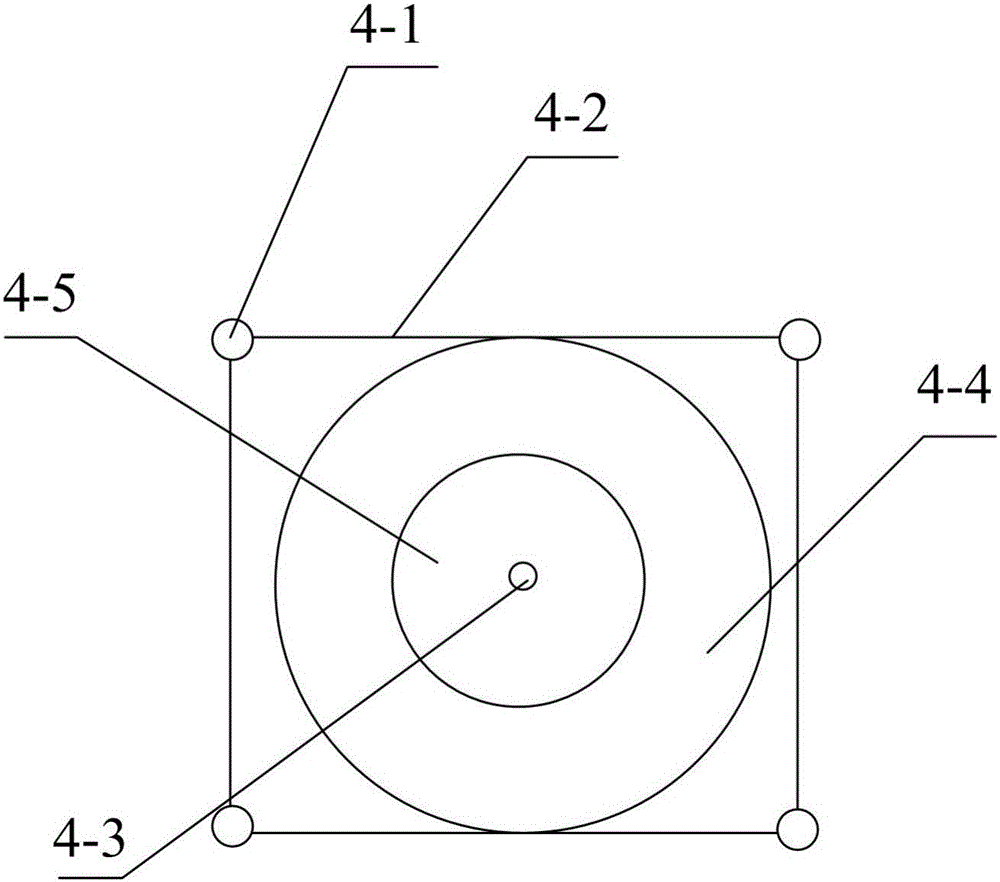

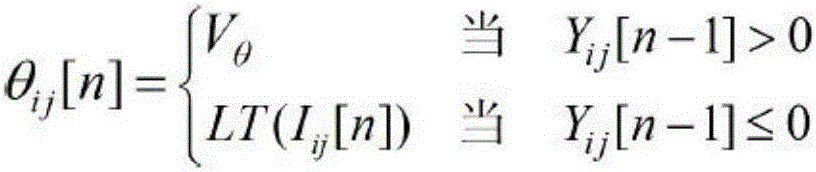

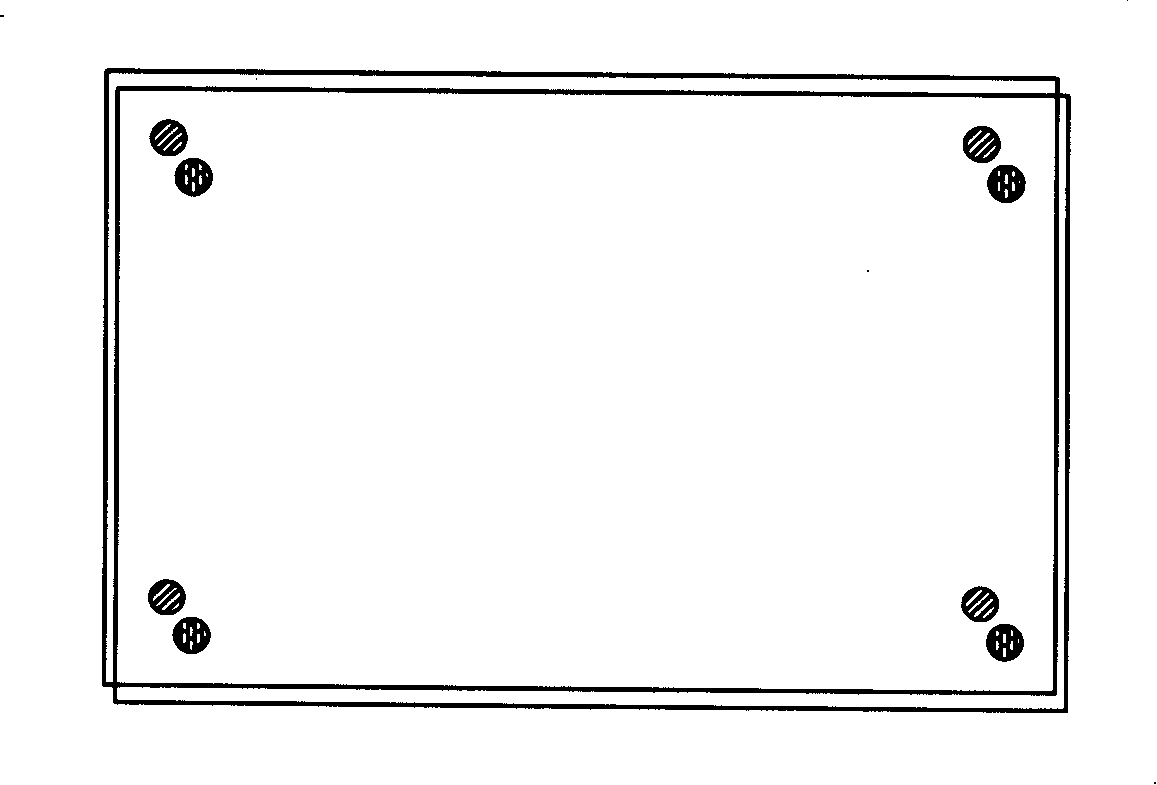

Method for detecting inter-layer displacement of multi-layer flexible printed circuit board

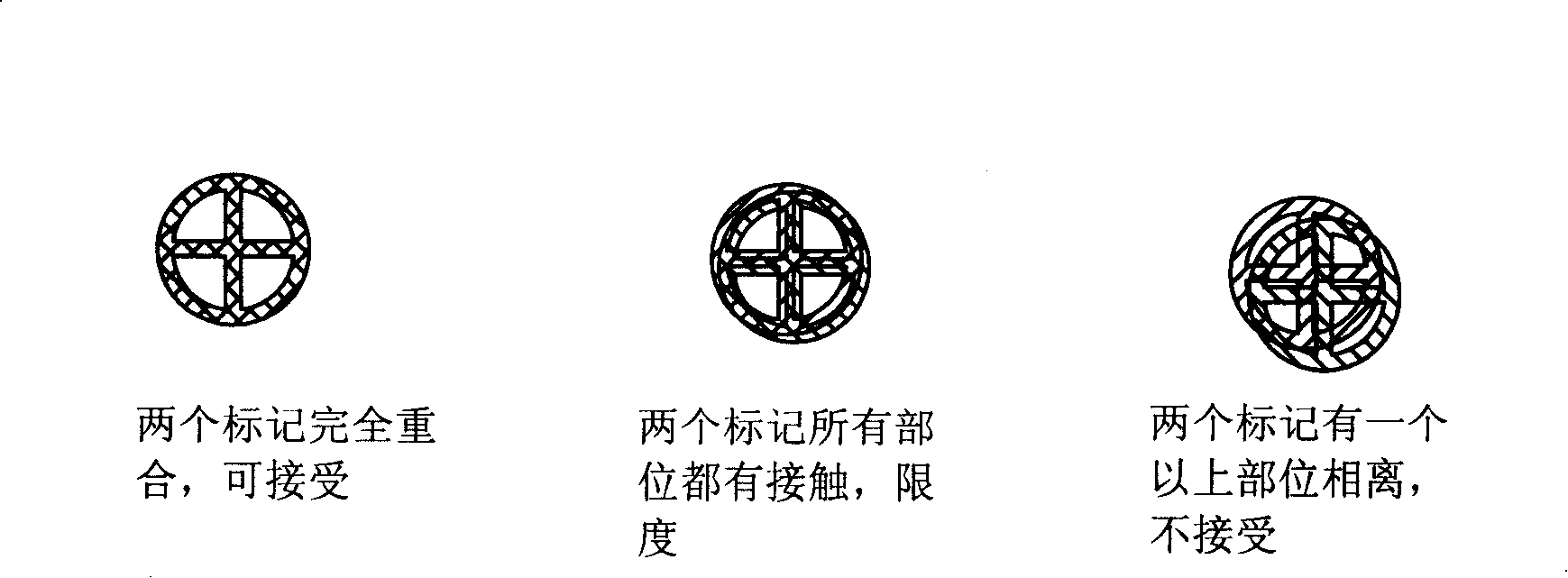

InactiveCN101212859ALower capability requirementsUnified testing standardsMeasurement devicesPrinted circuit detailsLine widthPrinted circuit board

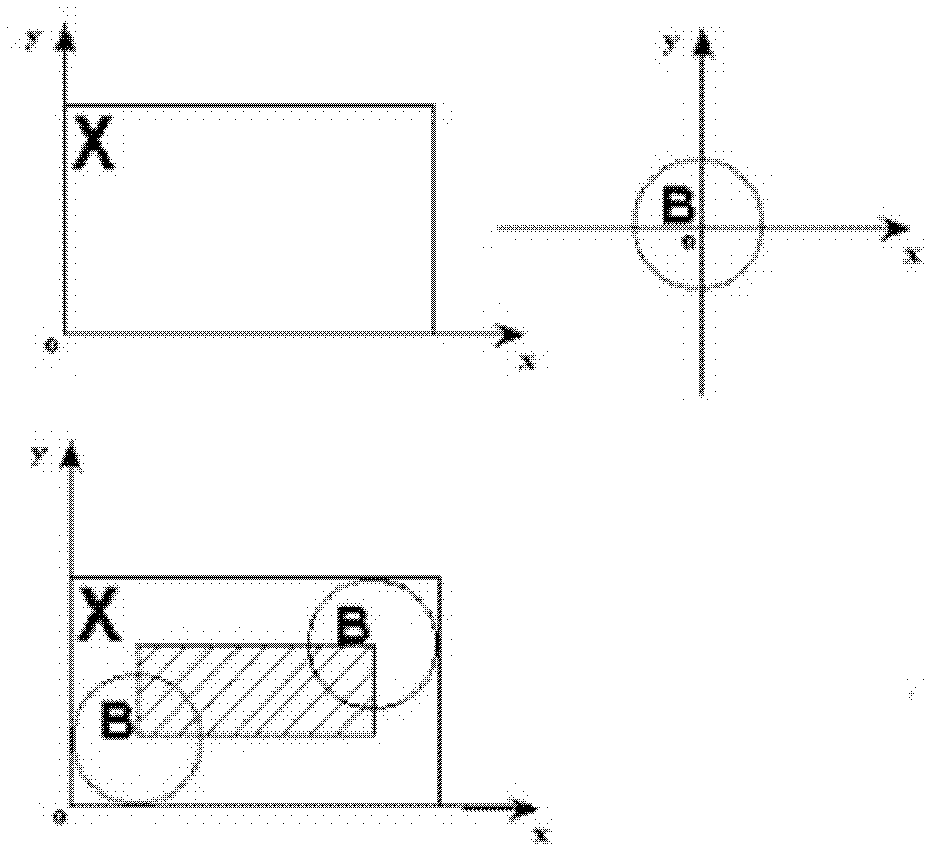

The invention discloses a method for detecting positional deviation between multilayer flexible printed wiring boards, which includes the following steps: A) a registration mark is respectively arranged at the same positions of layers that need paraposition on the multilayer flexible printed wiring boards; B) the registration marks of layers that need paraposition are compared to judge if the registration marks are at least partially overlapping; if so, the positional deviation among layers is considered within an acceptable range; otherwise, the positional deviation among layers is not considered within an acceptable range. The registration mark in the step A is a line mark which can detect the deviation amount between two axial locations which are mutually vertical on a surface; the line width of the line mark has the same size as that of the registration mark which need paraposition. The method has the advantages that the of digitally quantifying detecting result is digitally quantified,; meeting the detecting requirement of paraposition of arbitrary precision is met and raising the detecting efficiency is raised.

Owner:深圳市合力泰光电有限公司

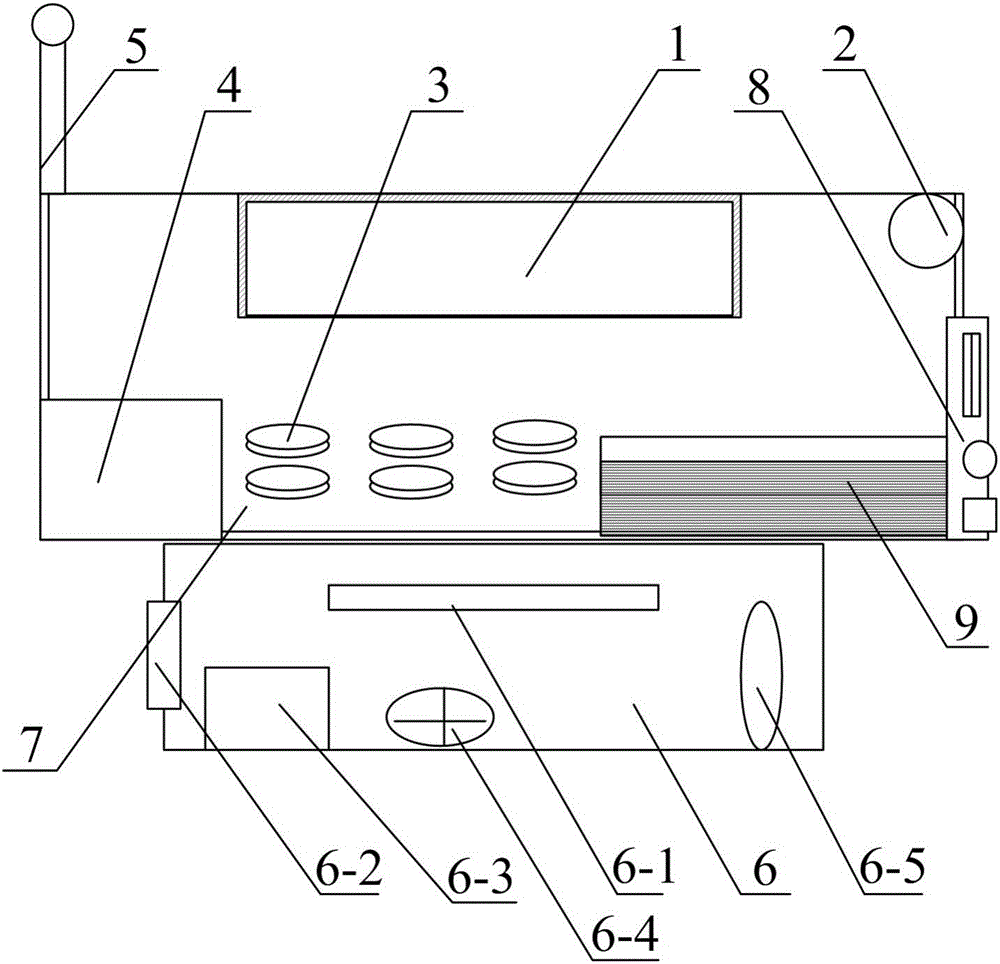

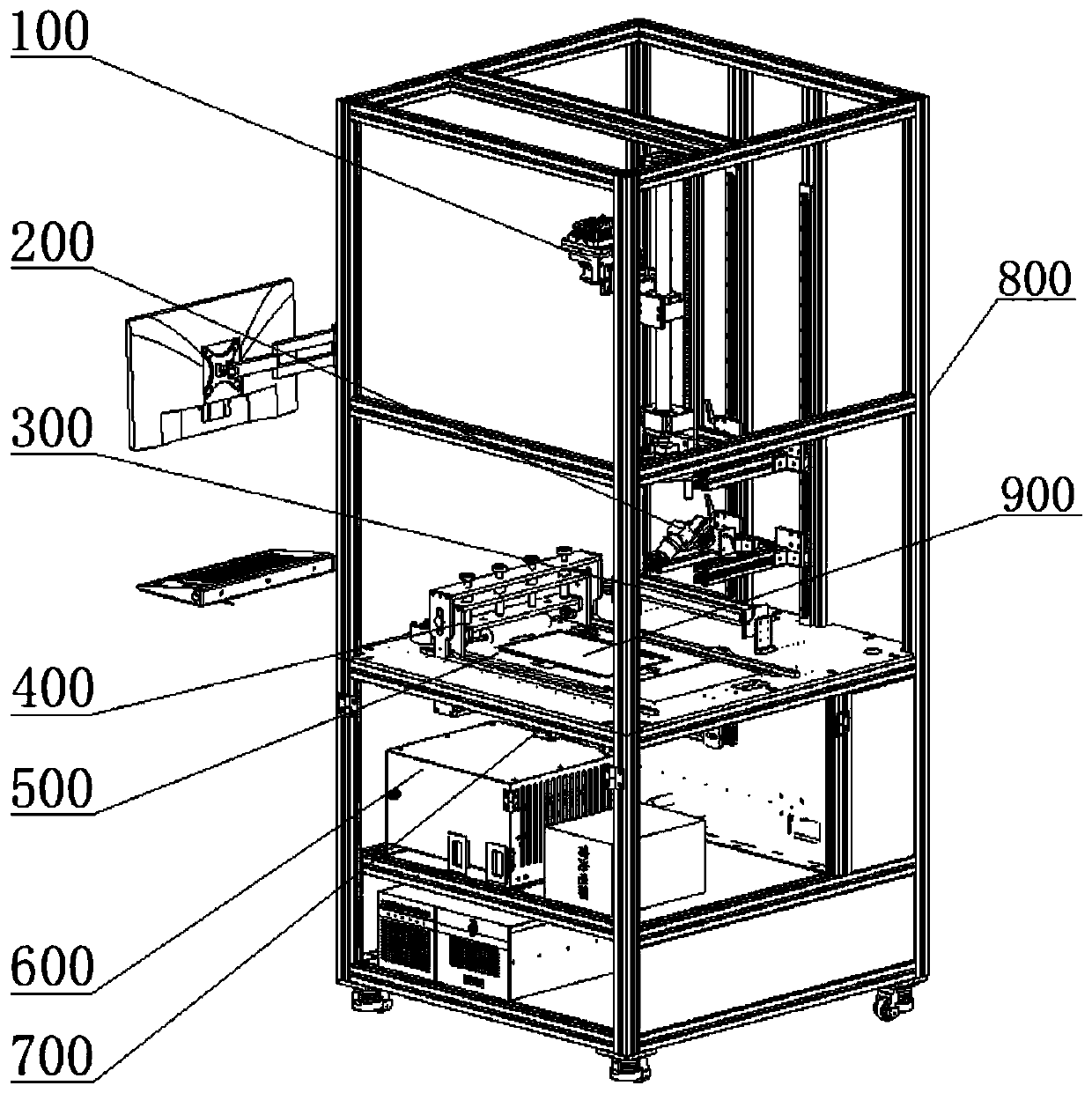

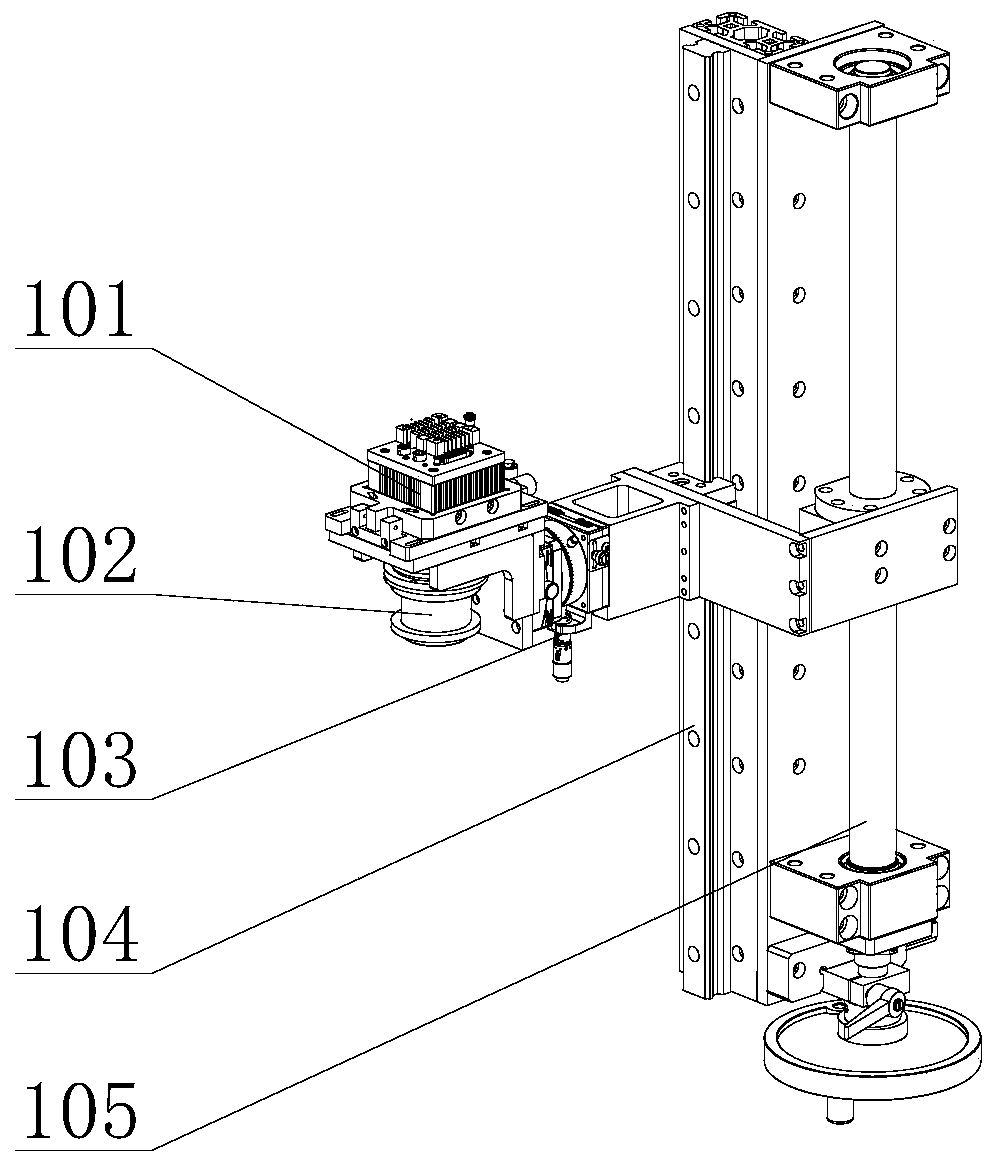

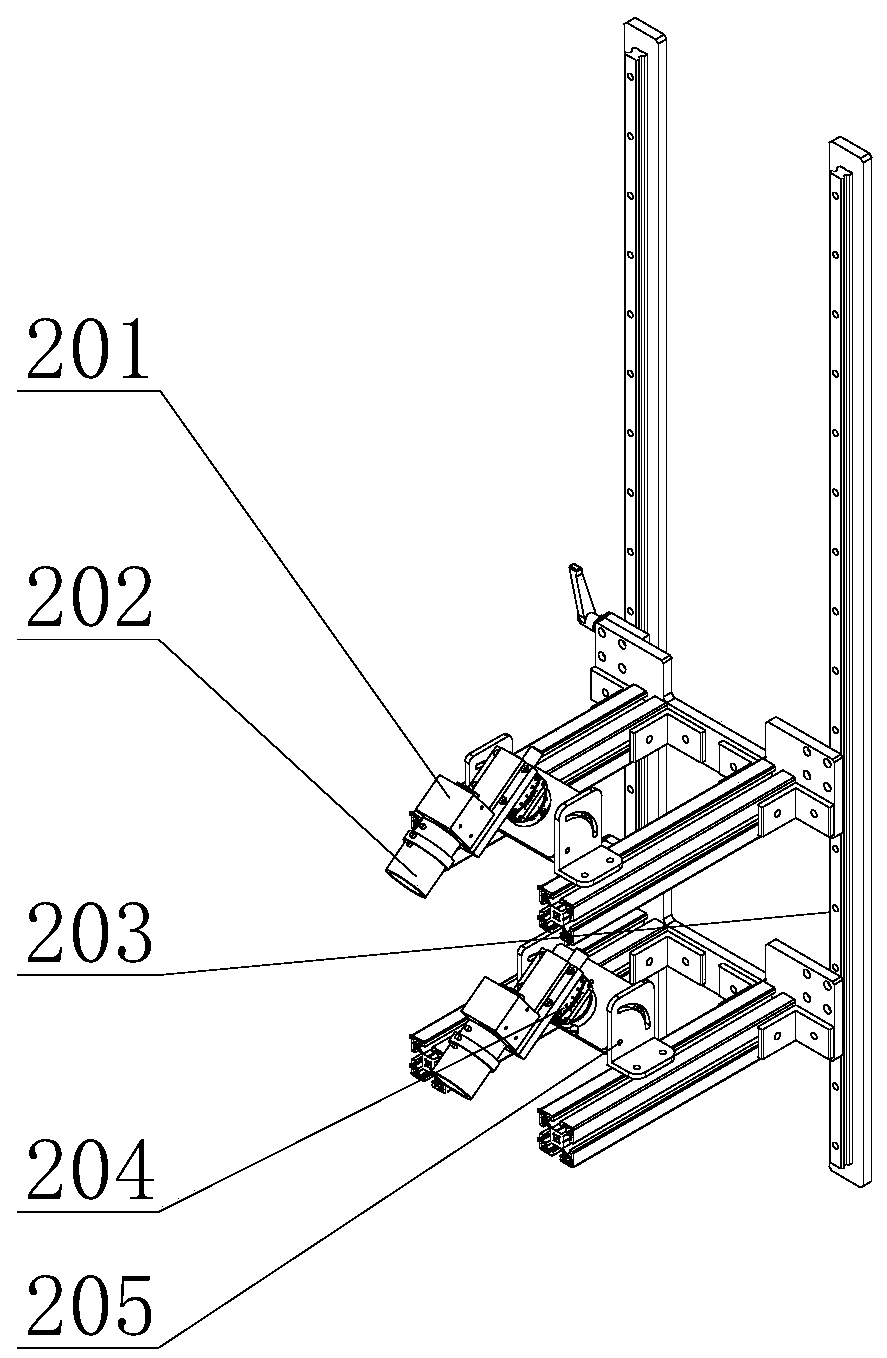

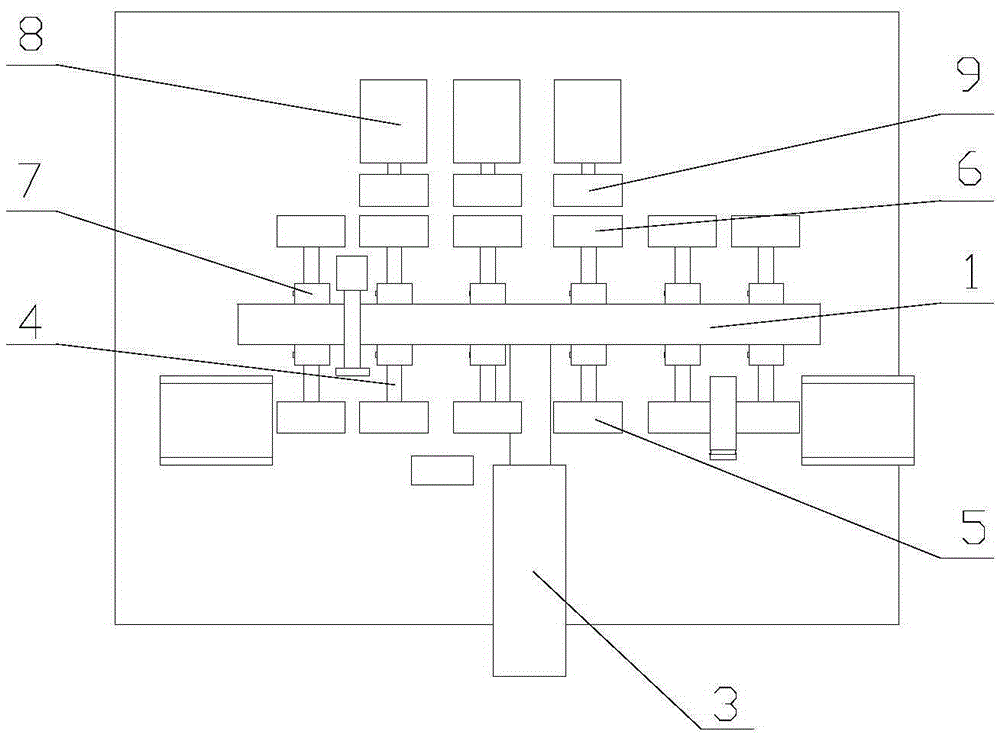

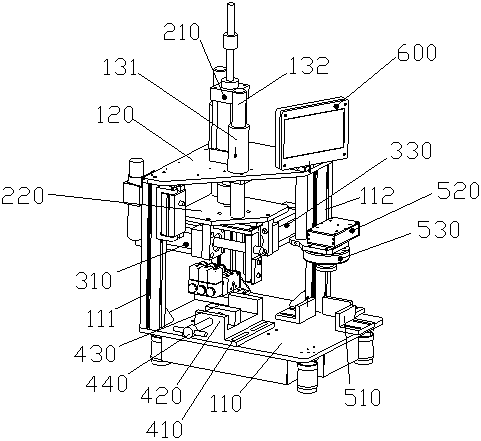

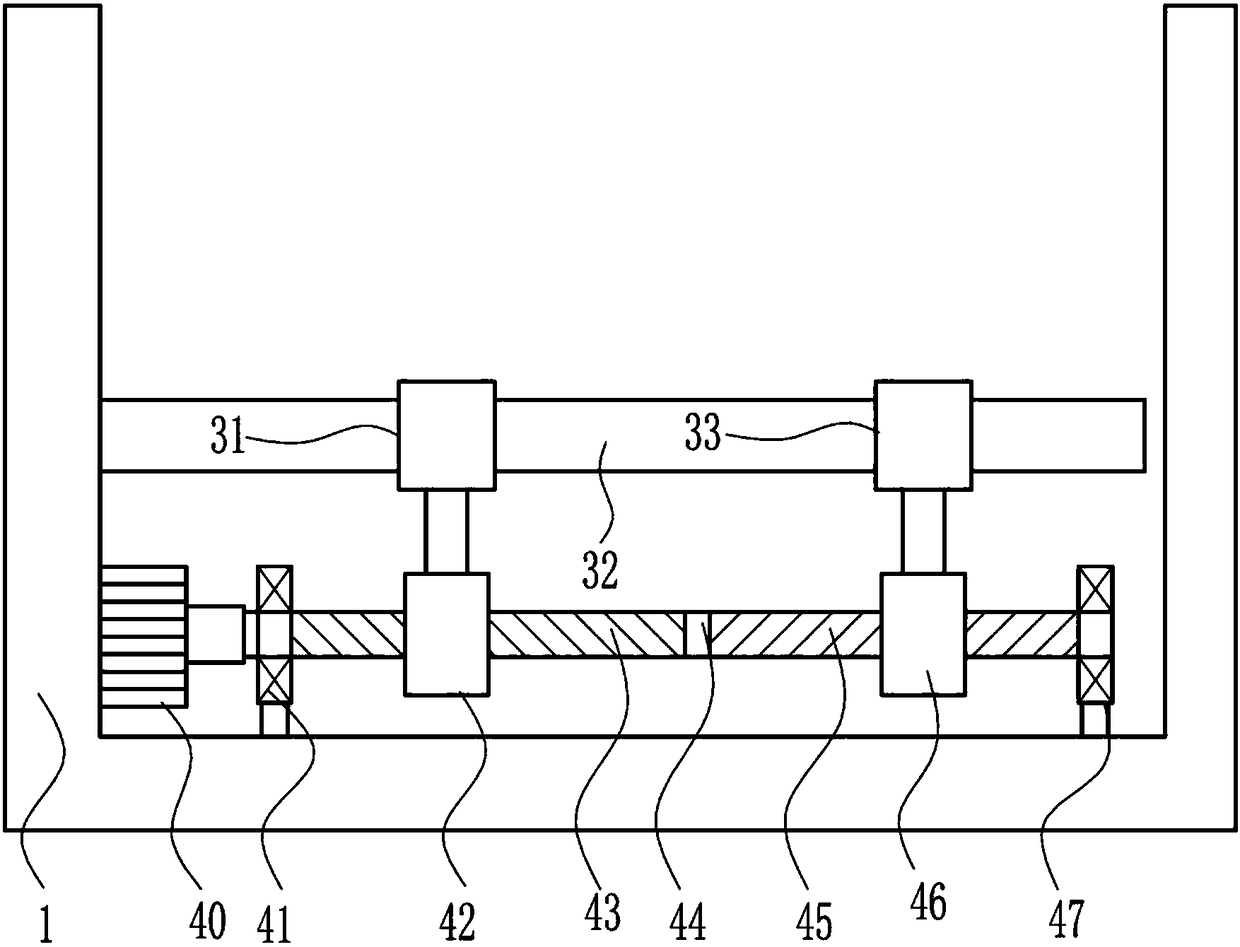

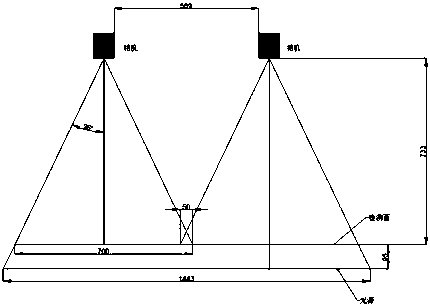

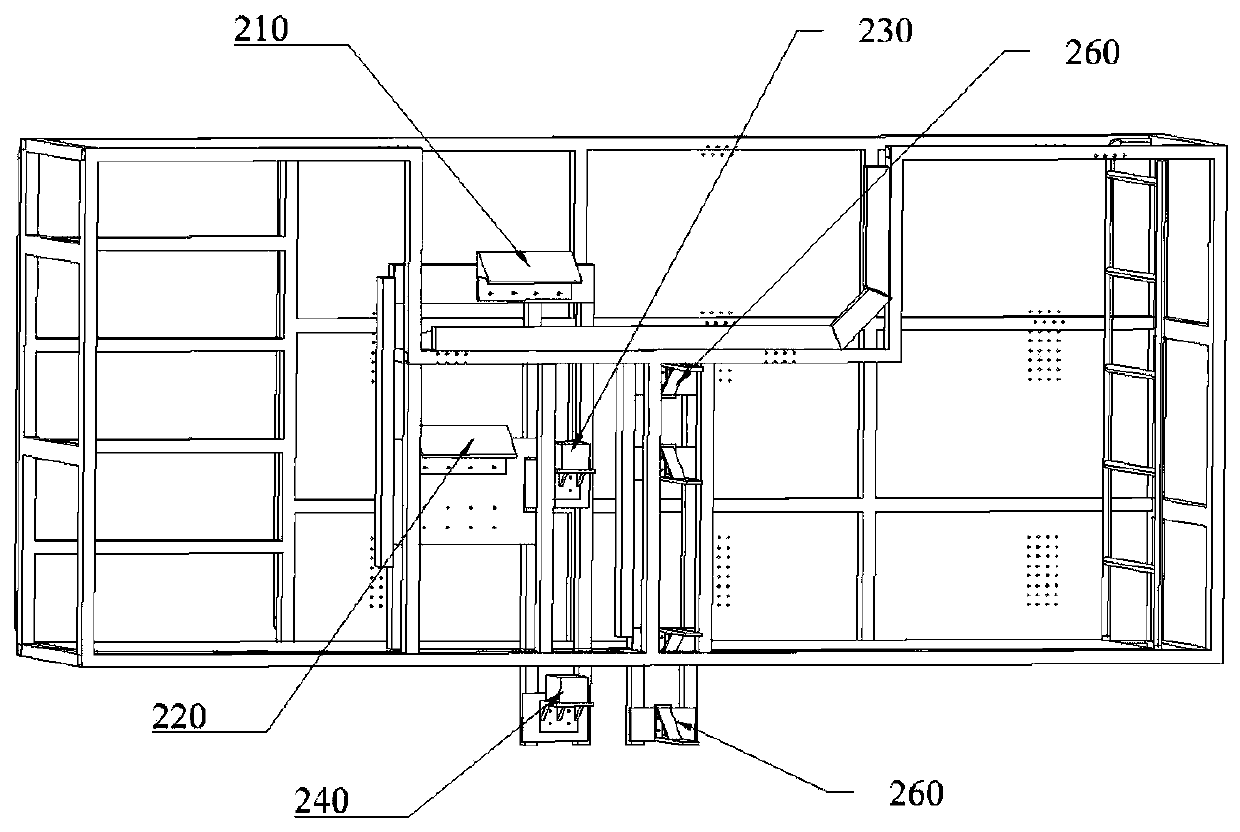

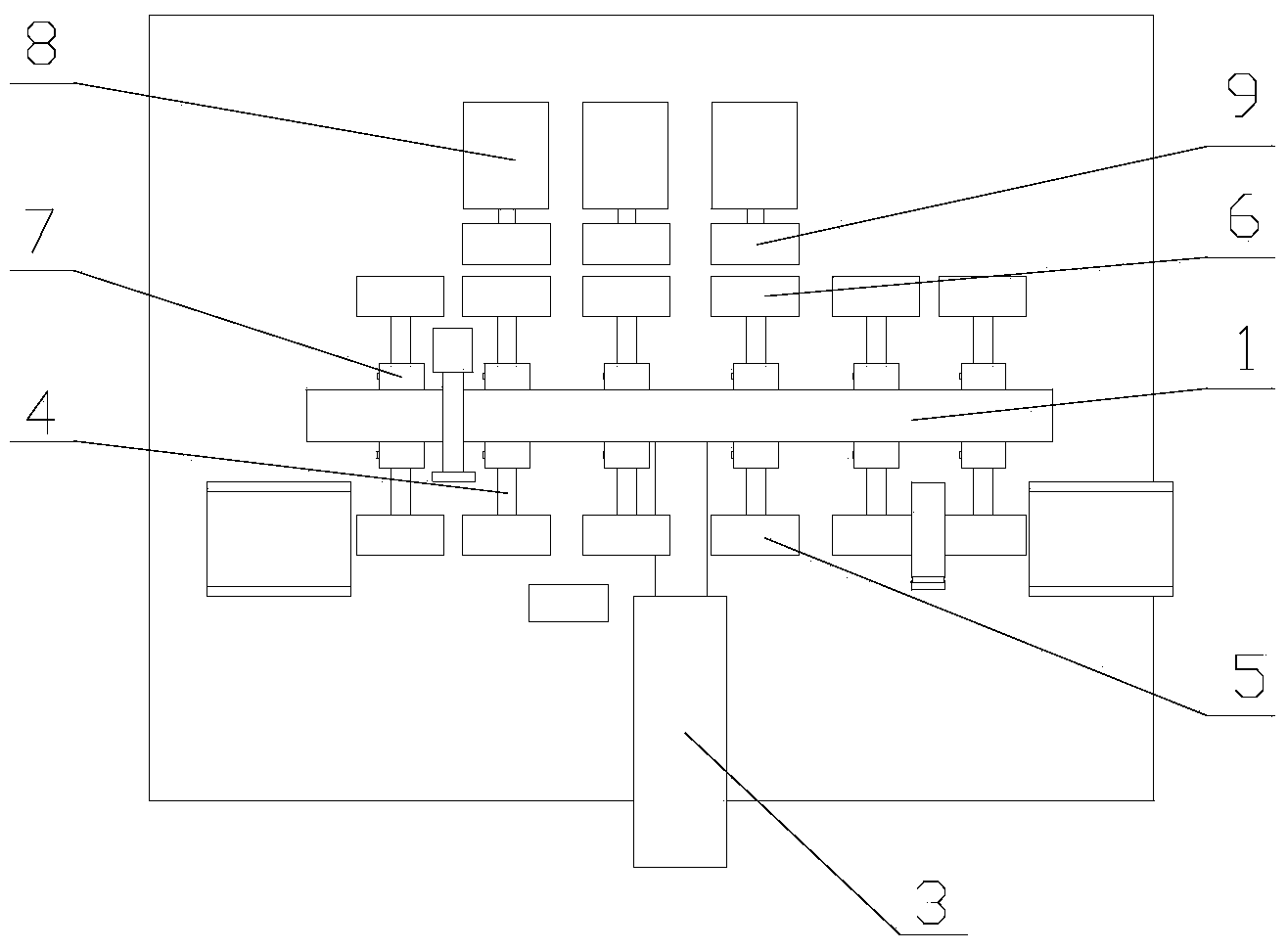

Multi-camera standard machine for defect detection of backlight module

The invention discloses a multi-camera standard machine for defect detection of a backlight module. The multi-camera standard machine comprises a rack, a tool module, an automatic code-reading module,a side light source illumination module, a camera detection module, a dedusting module and an automatic optical detection module, the tool module comprises a tool, a crimping member and a cylinder, the automatic code-reading module is used for reading a bar code pasted on the backlight module and transmitting the information to the automatic optical detection module, the dedusting module is usedfor dedusting the surface of the backlight module, the camera detection module comprises a fin-tuning slide table assembly and a camera, the camera shoots the backlight module, converts an obtained optical image to a digital signal and transmits the digital signal to the automatic optical detection module, and the automatic optical detection module performs analysis and comparison with a saved standard image so that defect detection of the backlight module is realized and whether the backlight module is qualified is determined. According to the multi-camera standard machine, the accuracy and the efficiency of defect detection of the backlight module and the yield of the backlight module of the whole production line are improved, and the labor and time costs are greatly reduced.

Owner:WUHAN JINGLI ELECTRONICS TECH +1

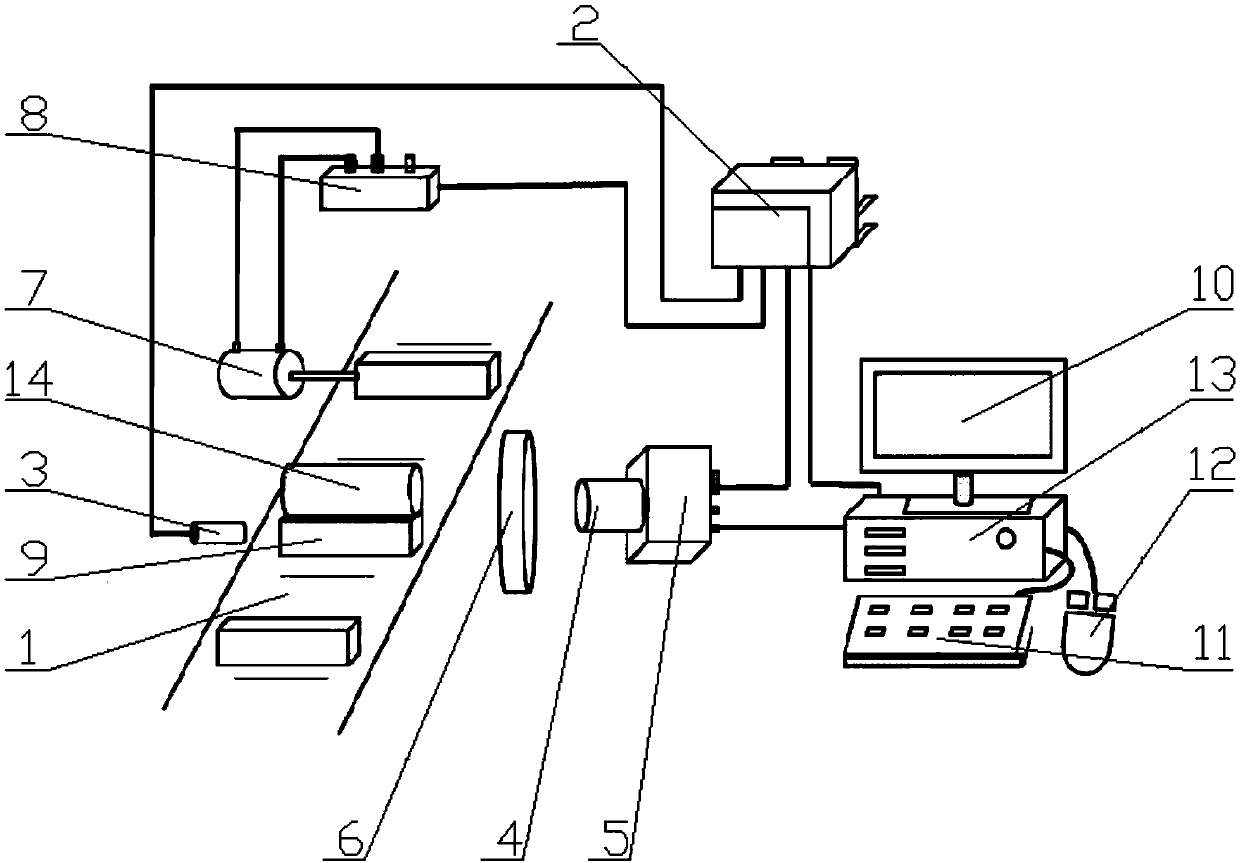

Communication-in-moving antenna tracking performance detecting method based on six-freedom-degree swinging table

ActiveCN103986533AStandard Test ConditionsComprehensive testing conditionsTransmission monitoringCoaxial cableEngineering

The invention relates to a communication-in-moving antenna tracking performance detecting method based on a six-freedom-degree swinging table and belongs to the field of communication-in-moving antenna detecting field. A system used in the method comprises the six-freedom-degree swinging table, a spectrometer and a data processing upper computer. A tested communication-in-moving antenna is arranged on the six-freedom-degree swinging table. Down-going signals (output by an LNB) of the communication-in-moving antenna are connected with the spectrometer through a coaxial electric cable. The data processing upper computer is connected with the spectrometer through an LAN interface. According to the method, the detecting standard is unified, detecting is comprehensive, accuracy is high, and universality is high.

Owner:BEIJING AEROSPACE WANDA HIGH TECH CO LTD

Optical automatic detection system for TFT-LCD defects

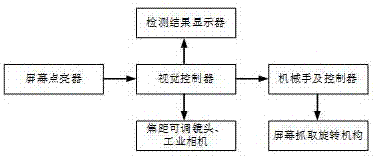

PendingCN107966836AImprove detection accuracyImprove efficiencyNon-linear opticsManipulatorScreen capture

An optical automatic detection system for TFT-LCD defects comprises an automatic focal length adjustable lens, an industrial camera, a screen capture rotating mechanism, a screen lightening device, avision controller, a detection result displayer, a mechanical hand and a controller. When TFT-LCD defects are automatically detected, the screen lightening device firstly drives the TFT-LCD to displaya first detection picture, meanwhile, an instruction is transmitted to the vision controller, the vision controller receives the instruction and then controls the industrial camera to take a picture,and a picture processing procedure of the corresponding detection picture is operated. Then, a second detection picture is detected, and circular operation is sequentially performed till all the TFT-LCD detection pictures are displayed and detection is completed. Finally, the result is sent to the detection result displayer. In order to improve the detection accuracy, the vision controller controls the focal length adjustable lens to perform automatic focusing. In order to improve the detection efficiency, the screen capture rotating mechanism at the tail end of the mechanical hand performs rapid picking and placing. The system has the advantages of being high in detection accuracy rate and detection efficiency.

Owner:NANCHANG INST OF TECH

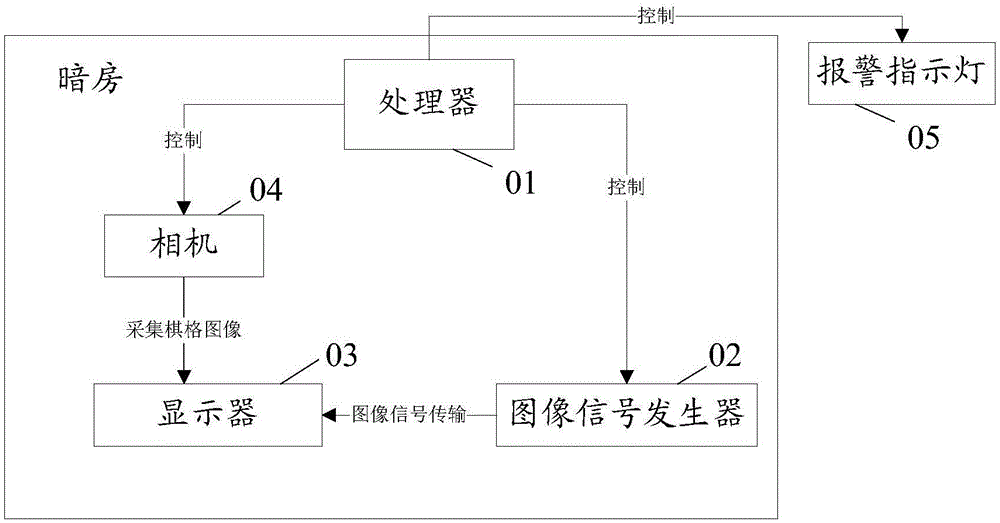

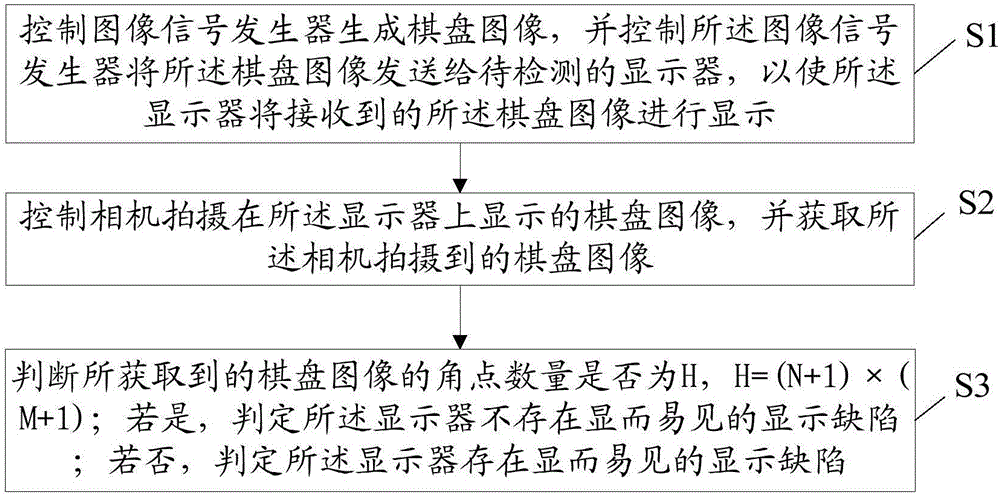

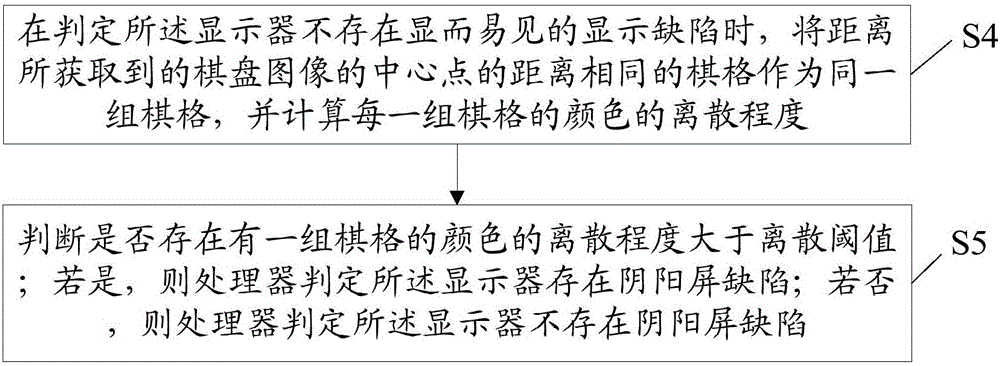

Method and device for detecting display

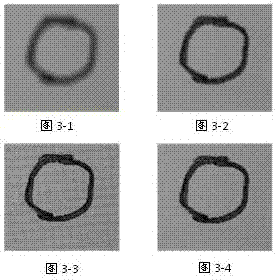

ActiveCN106412575AAccurate locationImprove accuracyStatic indicating devicesTelevision systemsComputer graphics (images)Angular point

The invention discloses a method and a device for detecting a display. The method is characterized by comprising the steps of controlling an image signal generator to generate a chessboard image, and controlling the image signal generator to send the chessboard image to the to-be-detected display, so that the display displays the received chessboard image; controlling a camera to shoot the chessboard image displayed on the display, and obtaining the chessboard image shot by the camera; judging whether the number of angular points of the obtained chessboard image is H, H=(N+1)*(M+1); if yes, judging the display does not exist an apparent display defect; and if no, judging the display exists the apparent display defect; and correspondingly, the invention further discloses a device for detecting the display. By adopting the method and the device disclosed by the embodiment of the invention, as an automation standard is adopted for detecting, the accuracy is high, and whether the display exists the display defect can be detected out accurately.

Owner:GUANGZHOU SHIYUAN ELECTRONICS CO LTD

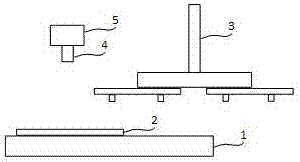

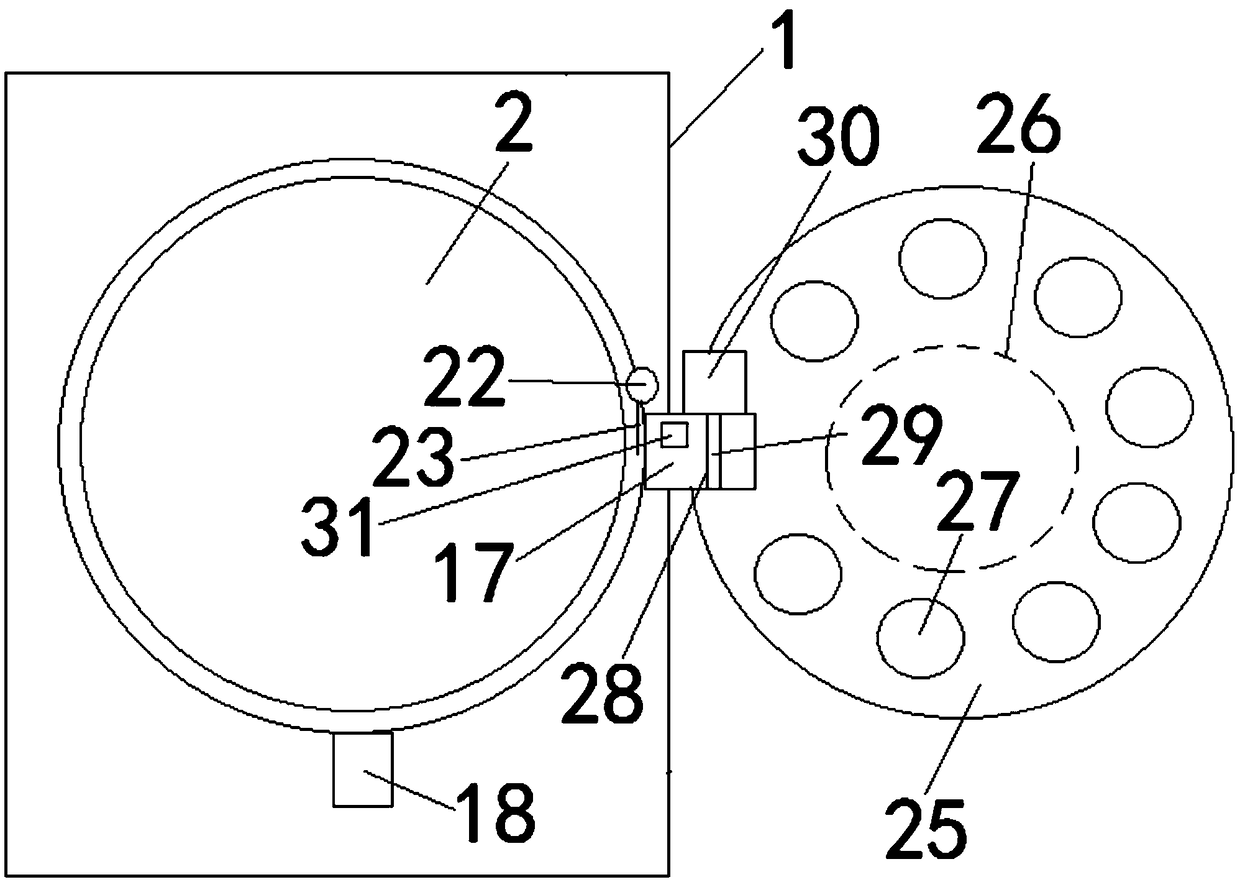

A rotary transmission device used for precision detection mechanism of pharmaceutical glass bottle production line

Owner:INST OF APPLIED MATHEMATICS HEBEI ACADEMY OF SCI

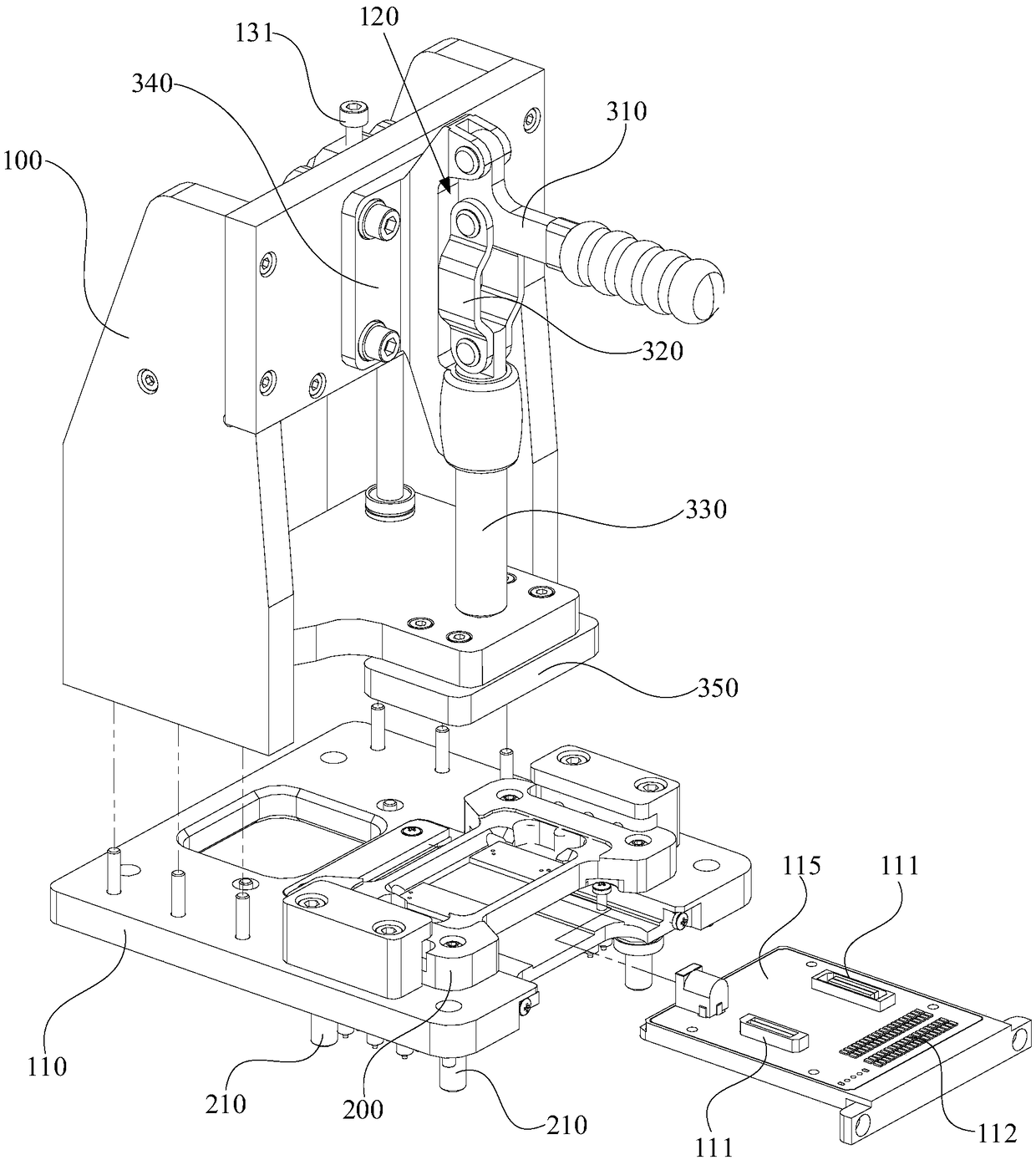

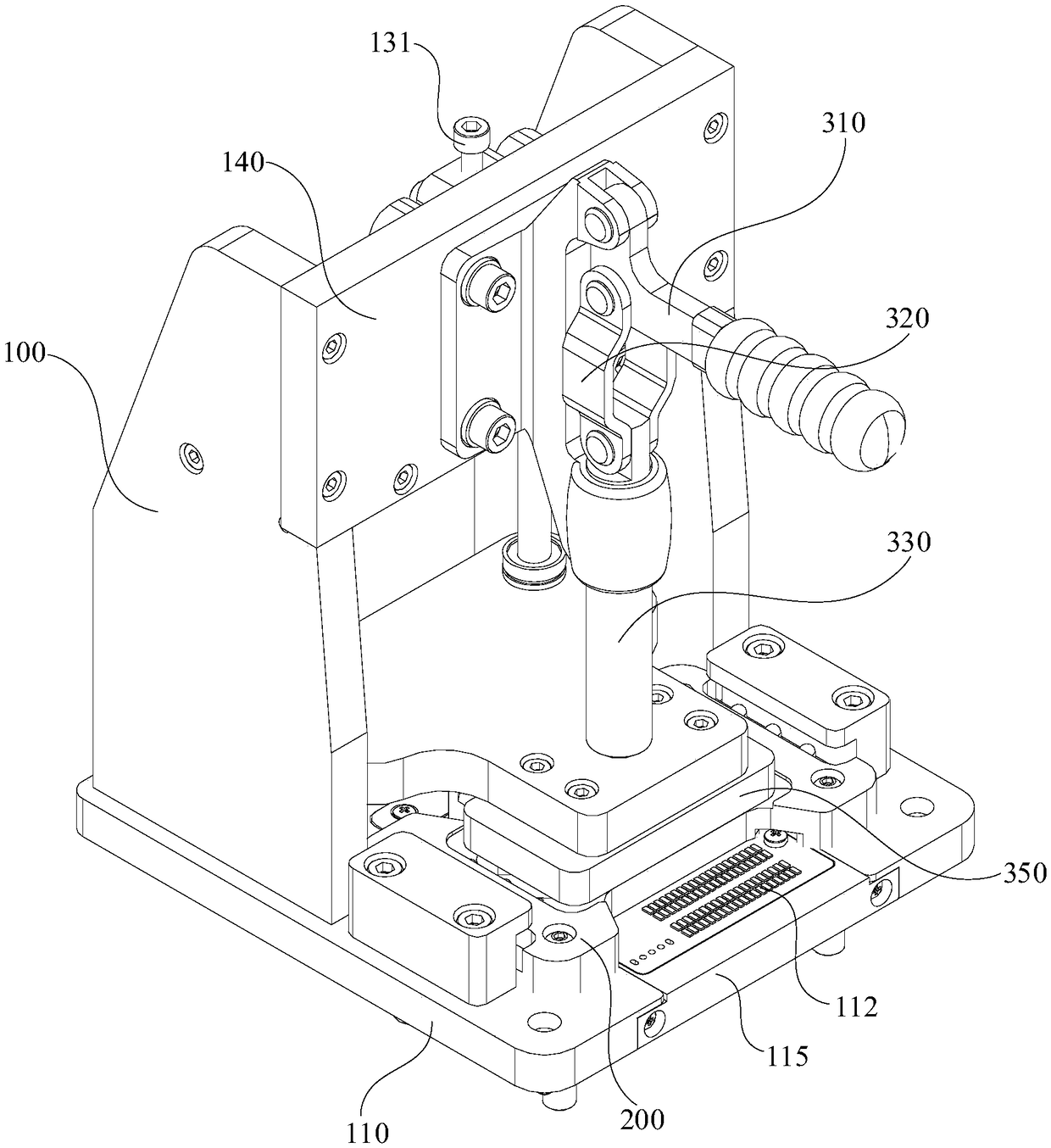

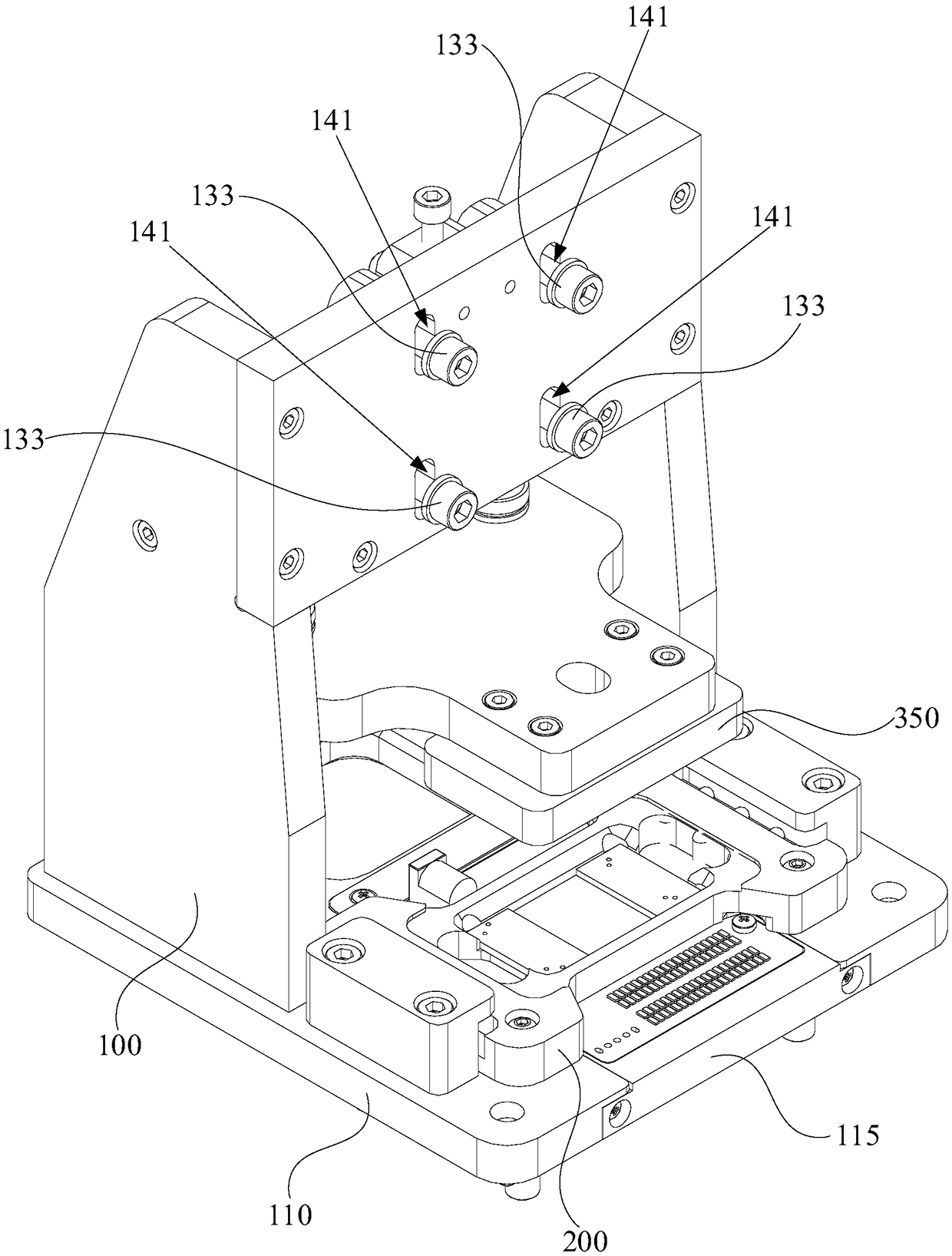

Welding quality detection device and detection method thereof

ActiveCN108760819AUnified testing standardsImprove detection efficiencyMaterial analysis by electric/magnetic meansElectrical testingInstabilitySoftware engineering

The invention relates to a welding quality detection device and a detection method thereof. The welding quality detection device comprises a mounting rack, a loading piece and a driving mechanism, wherein the mounting rack is provided with a detection platform; the detection platform is provided with a detection plug; the detection plug is provided with a detection slot; the groove of the detection slot is internally provided with an inserting part and a testing probe. The detection method comprises the following steps: firstly moving the loading piece to a first preset position by the drivingmechanism so that the welding part of a product to be detected is matched with the inserting part, and then moving the loading piece to a second preset position by the driving mechanism so that the welding part of the product to be detected is matched with the testing probe so as to test whether welding is qualified. Due to the fact that the welding part is firstly matched with the inserting part, if the problem such as welding instability exists in the welding part, frictional force generated in the inserting process can enable an instable part to fall off, and the welding part cannot be passed when the welding part is matched with the testing probe for testing in later period, so that the testing result whether the welding part is qualified is obtained. Artificial viewing of naked eyesis not needed by using the mechanism, so that the welding detection efficiency is improved, and the production cost is also reduced.

Owner:GUANGZHOU FASTPRINT CIRCUIT TECH +2

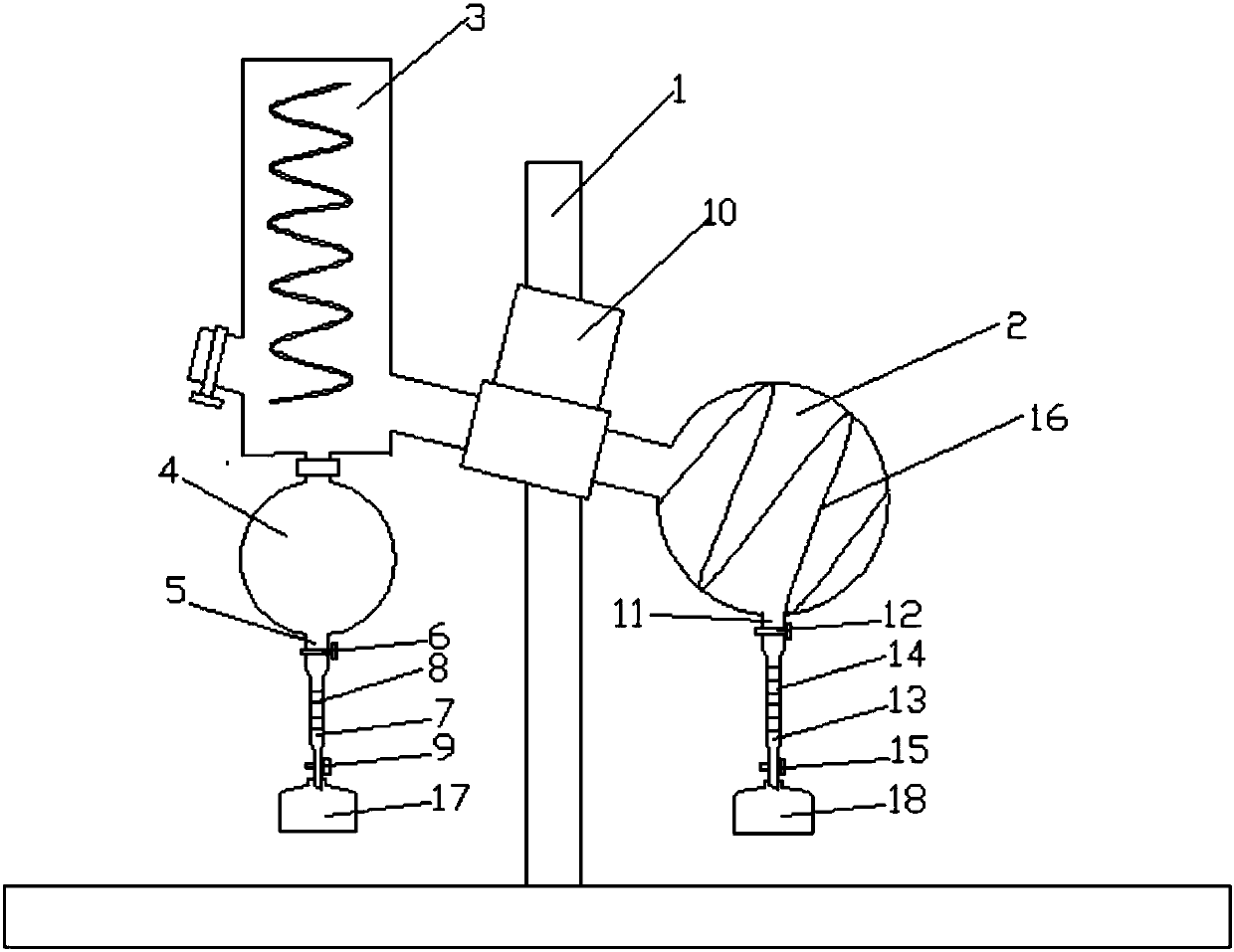

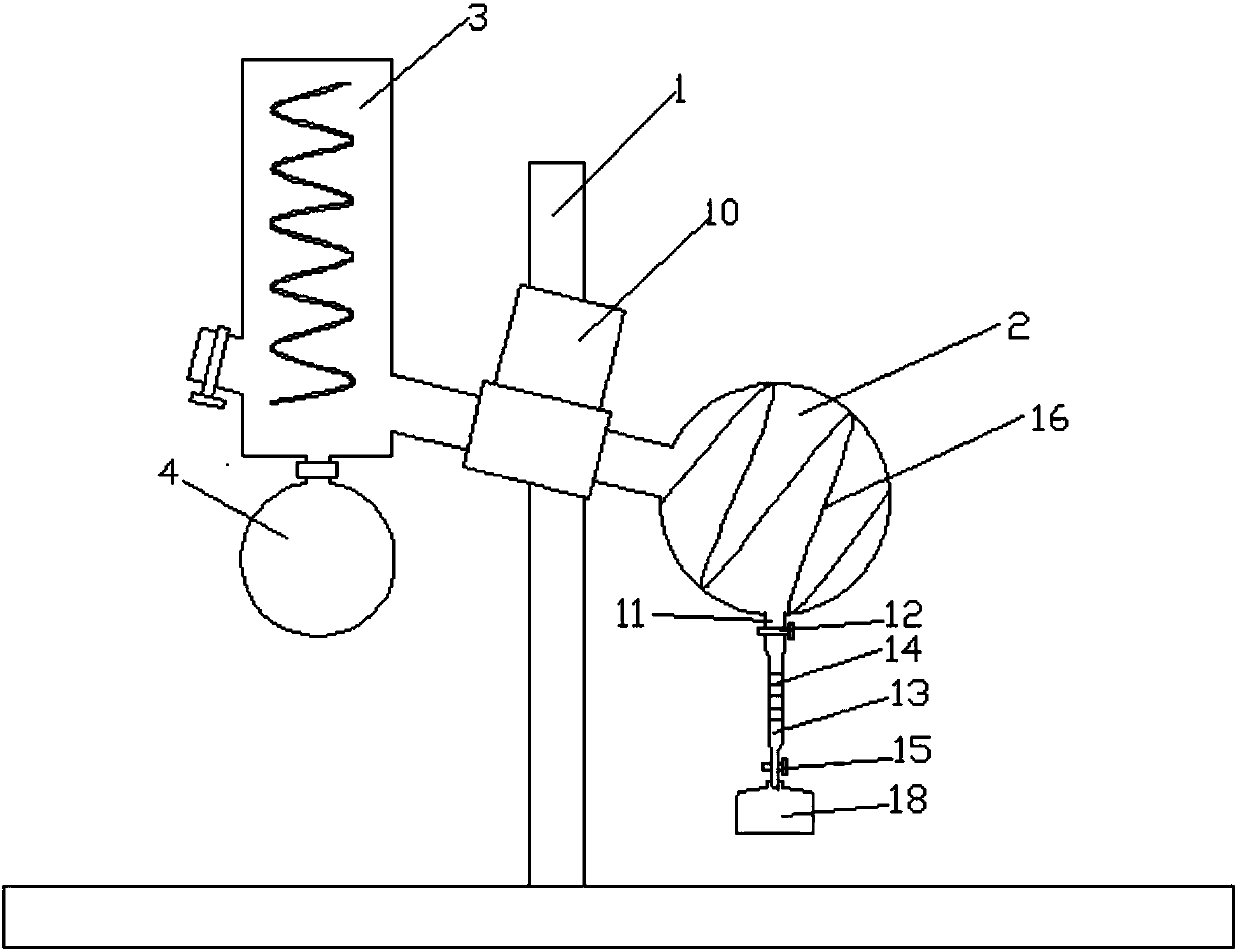

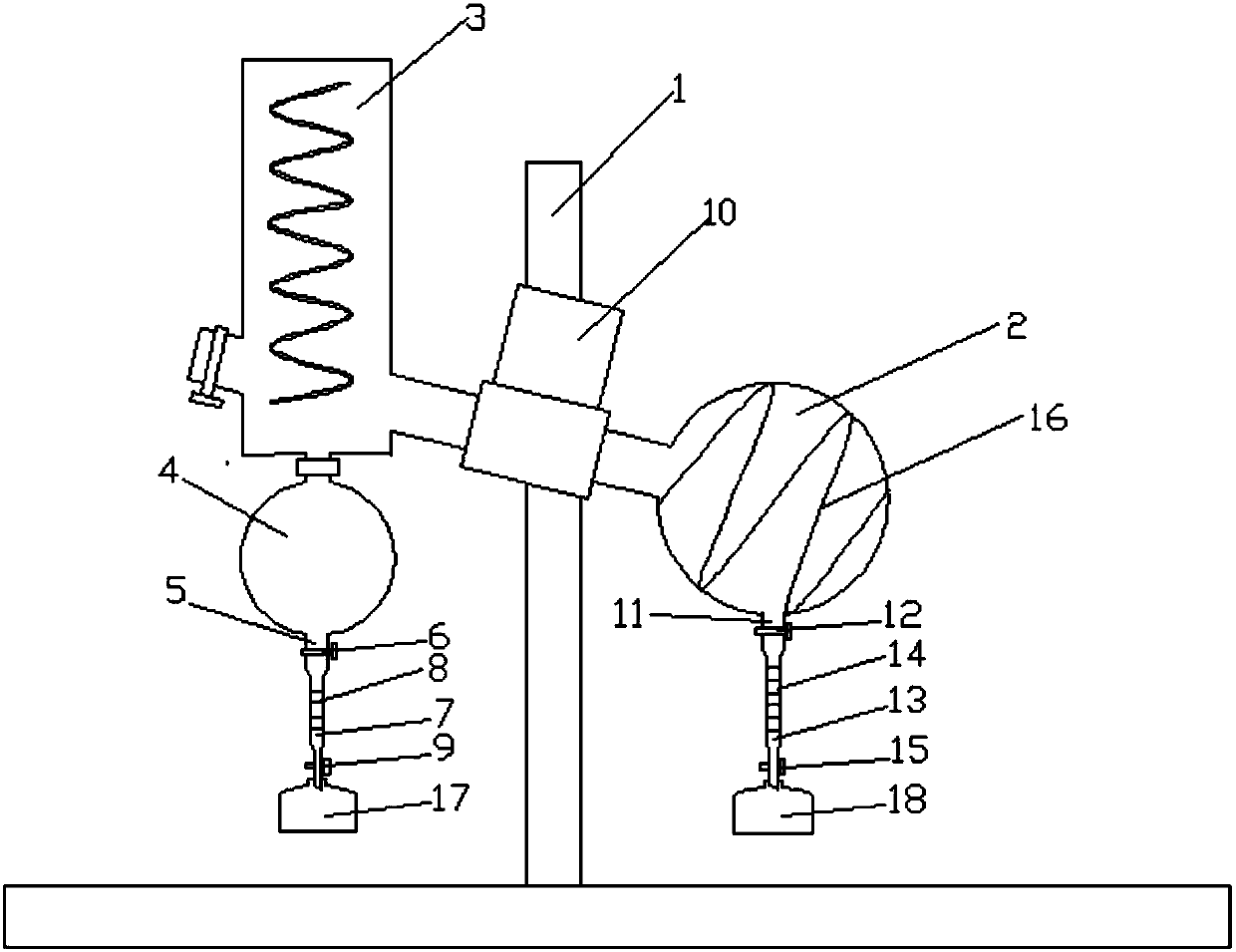

Rotary evaporator capable of accurately achieving fraction quantification

ActiveCN108043058AReduce volumeReduce heating water consumption and oil consumptionDistillation regulation/controlDistillation in rotating vesselsRotary evaporatorDistillation

The invention relates to the technical field of chemical experiment equipment, in particular to a rotary evaporator and in particular to a rotary evaporator capable of accurately achieving fraction quantification. The invention provides the rotary evaporator capable of accurately achieving fraction quantification. According to the rotary evaporator, a conventional spherical collection bottle is improved into a structure that a liquid discharge hole is formed in the bottom of the collection bottle, so that a fraction liquid can be discharged under a condition that the collection bottle is not detached down; meanwhile, due to a metering tube with scales in the position of the liquid discharge hole, variations of fraction quantities can be visibly observed, distillation can be immediately stopped when a fraction meets a designed accurate quantity, the precisely quantified fraction can be accurately discharged, components of fractions and indexes for reflecting quality of the fractions canbe tested, property differences of fractions of a same distillation sample at different distillation stages can be studied, and unification of detection standards can be achieved.

Owner:BEIJING NORMAL UNIVERSITY

Rotary evaporator capable of accurately achieving quantification of concentrated liquid

ActiveCN108043059AQuantitatively accuratePrecision releaseDistillation regulation/controlDistillation in rotating vesselsRotary evaporatorDistillation

The invention relates to the technical field of chemical experiment equipment, in particular to a rotary evaporator and in particular to a rotary evaporator capable of accurately achieving quantification of a concentrated liquid. According to the rotary evaporator capable of accurately achieving quantification of the concentrated liquid, a distillation bottle is improved into a structure that a liquid discharge hole is formed in the bottom, so that a concentrated liquid can be discharged on premise that the distillation bottle is not detached and the negative pressure inside a distillation system is not greatly affected; meanwhile, due to a metering tube with scales in the position of the liquid discharge hole, variations of quantities of the concentrated liquid can be visibly observed, distillation can be immediately stopped when the quantity of the concentrated liquid meets a designed accurate quantity, the precisely quantified concentrated liquid can be accurately discharged, indexes such as reaction yield can be tested, unification of detection standards can be achieved, properties of different concentrated liquids of same yield and properties of a same sample of different concentration degrees can be studied and compared.

Owner:BEIJING NORMAL UNIVERSITY

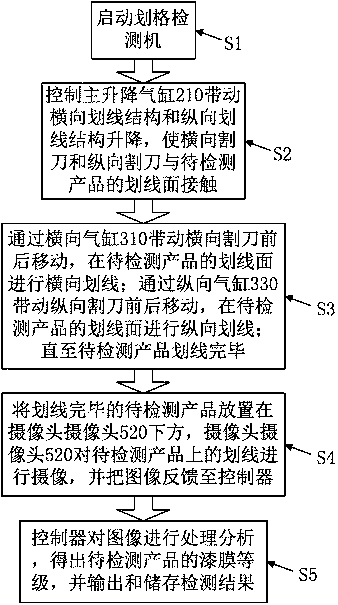

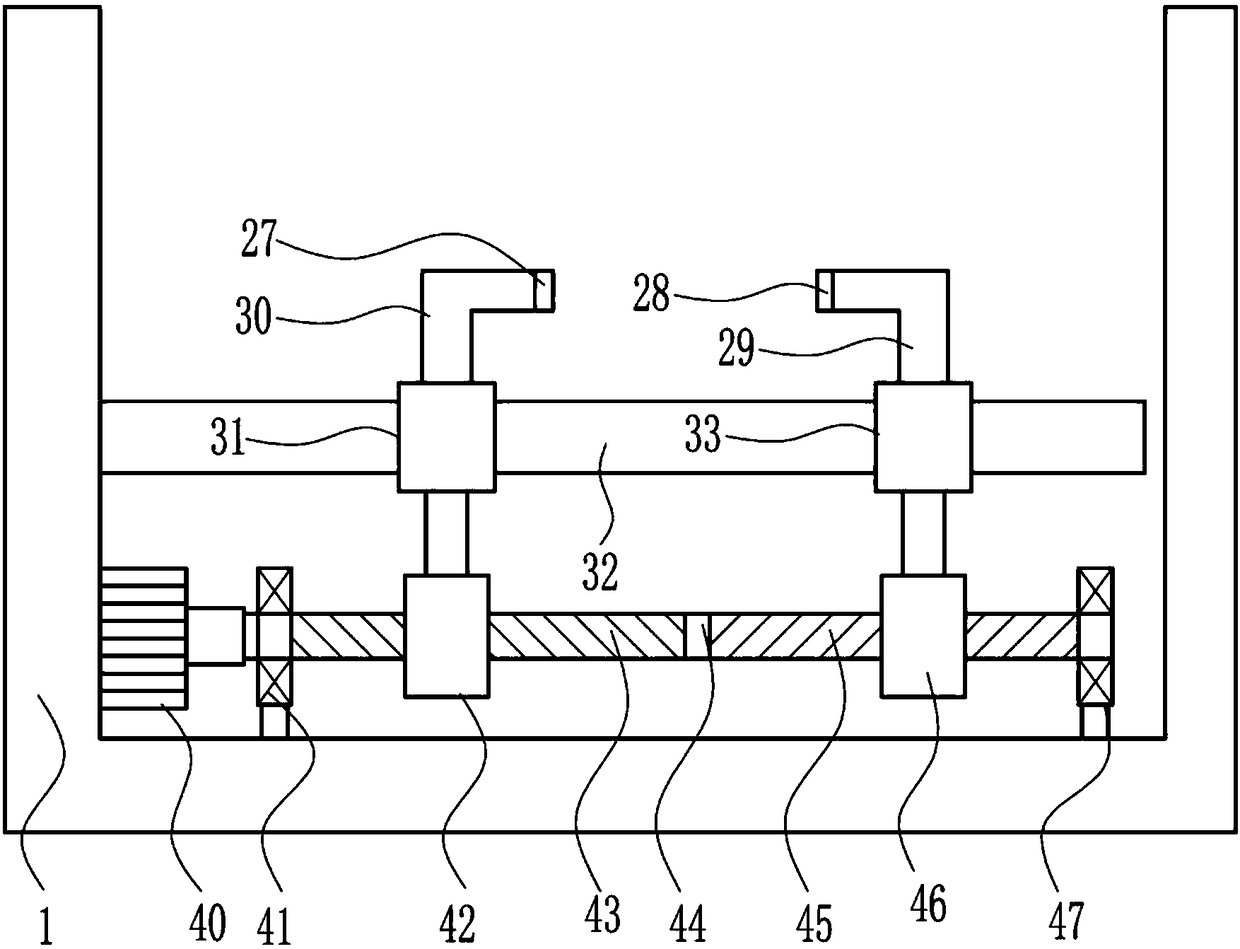

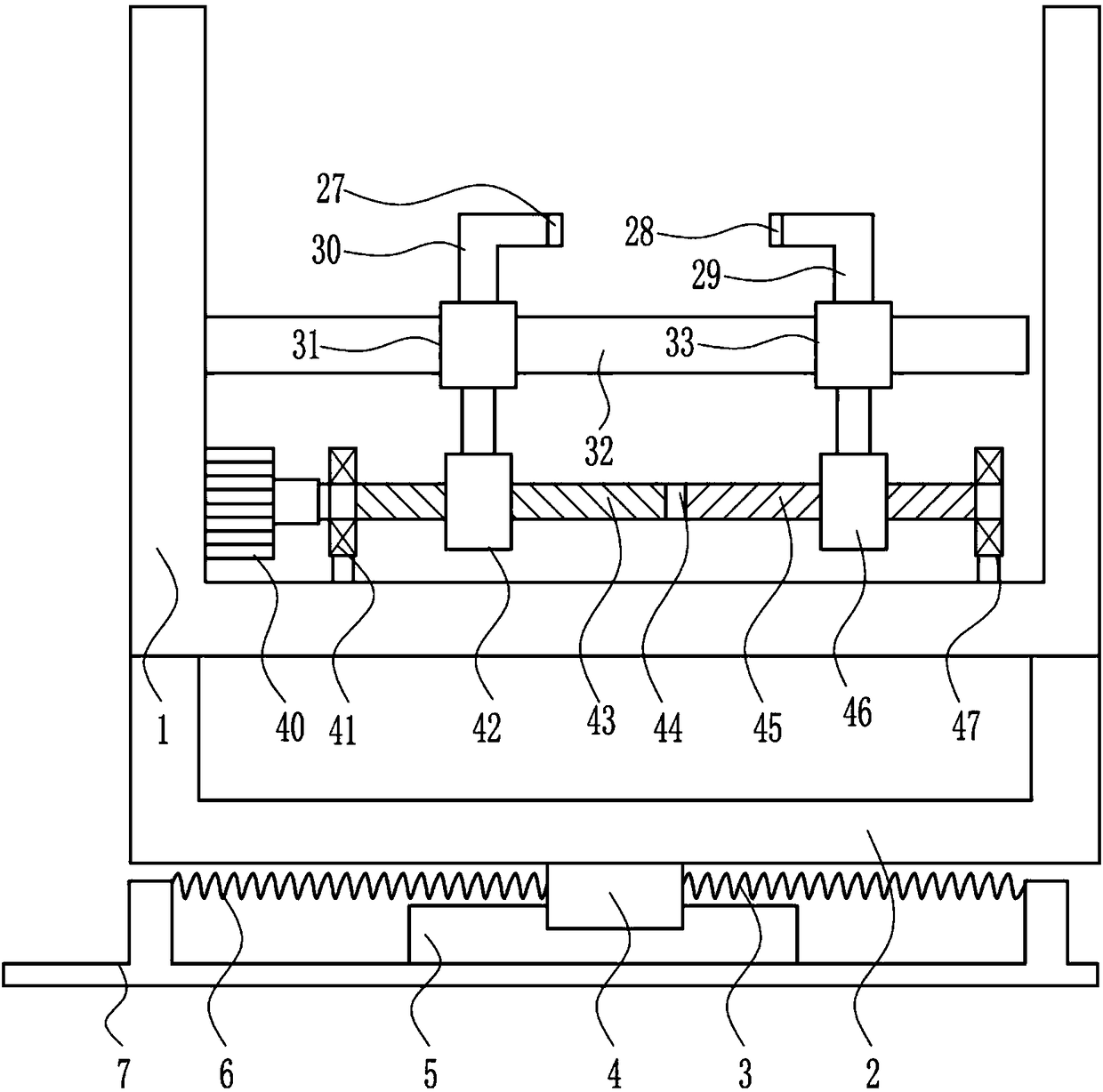

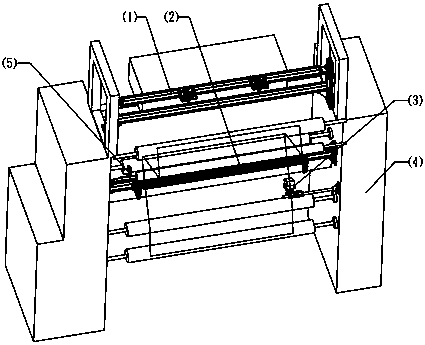

Cross-cut testing machine and method

PendingCN108593480AGuarantee the quality of useHigh degree of automationInvestigating abrasion/wear resistanceInvestigating machinabilityCross cutAutomation

The invention discloses a cross-cut testing machine and method. Crossed grids are cut on the surface of a product to be tested by a utility knife, the cut crossed grids are shot by a camera, images are fed back to a controller and processed and analyzed by the controller to obtain the grade of a surface film of the product to be tested, and the quality of the film is acquired. The whole testing process is automatically finished by the machine without artificial participation, automation degree is high, time and labor are saved, and efficiency is high. Moreover, testing standards are unified, and the subsequent use quality of the product to be tested can meet requirements.

Owner:佛山市质量计量监督检测中心 +1

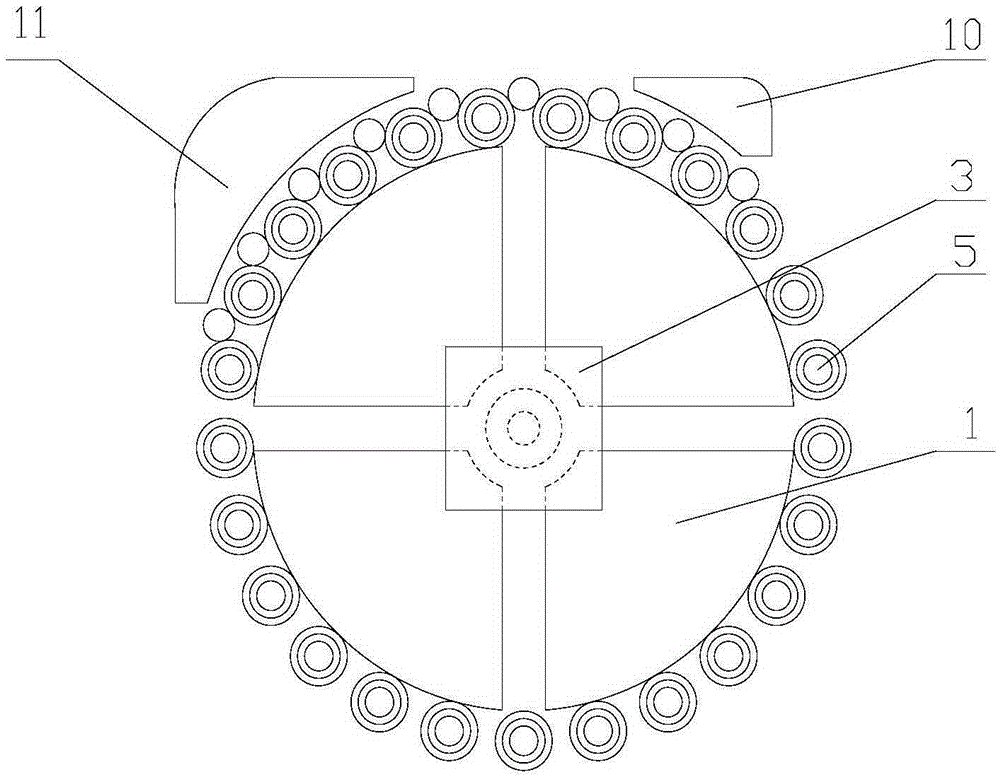

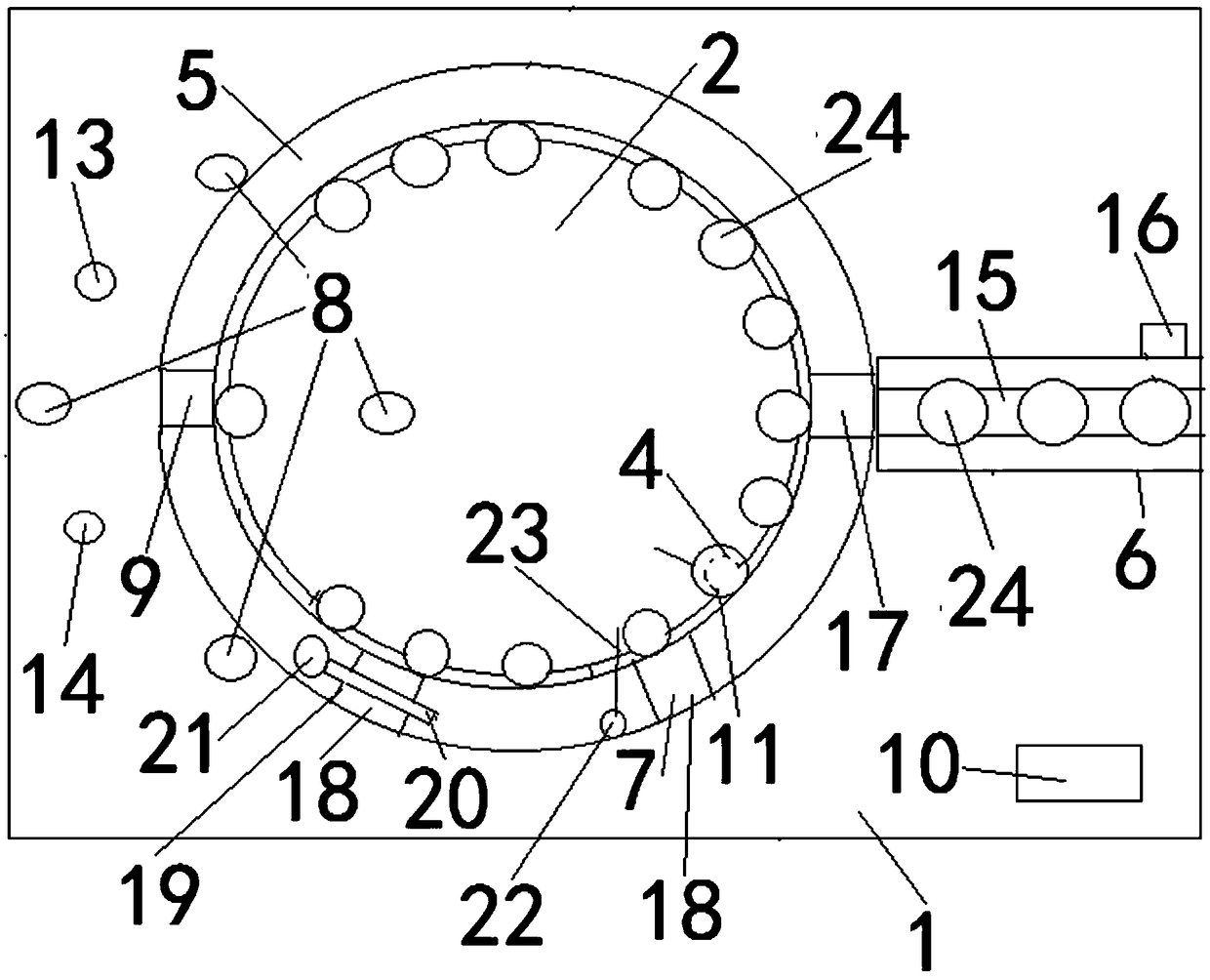

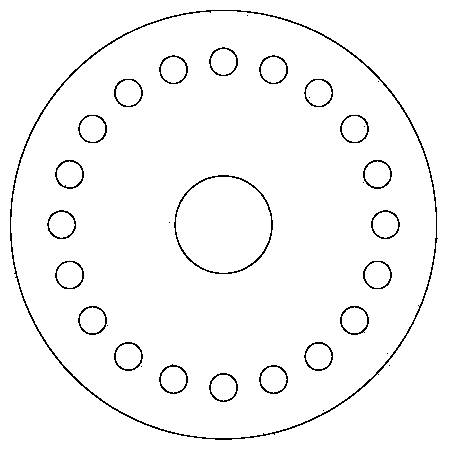

Vehicle fastener online detection device

InactiveCN108722894AEnsure uniform testing standardsReduce manual interventionSortingFastenerEngineering

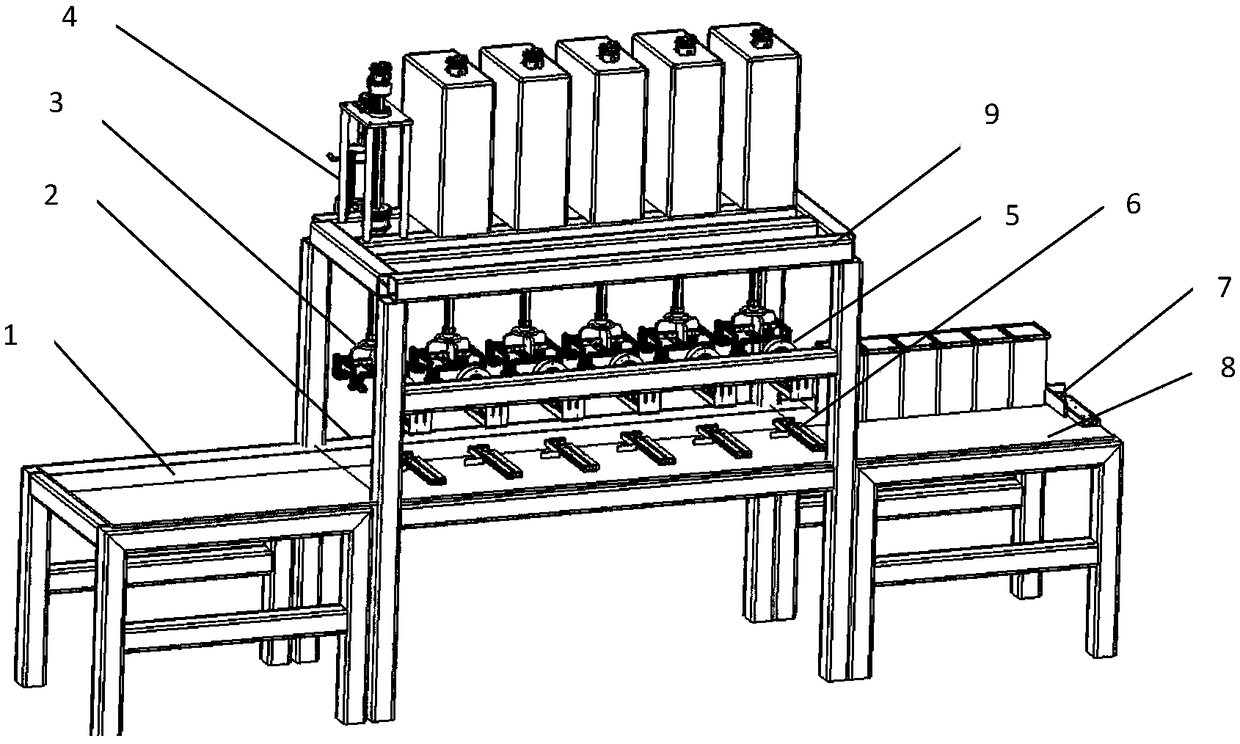

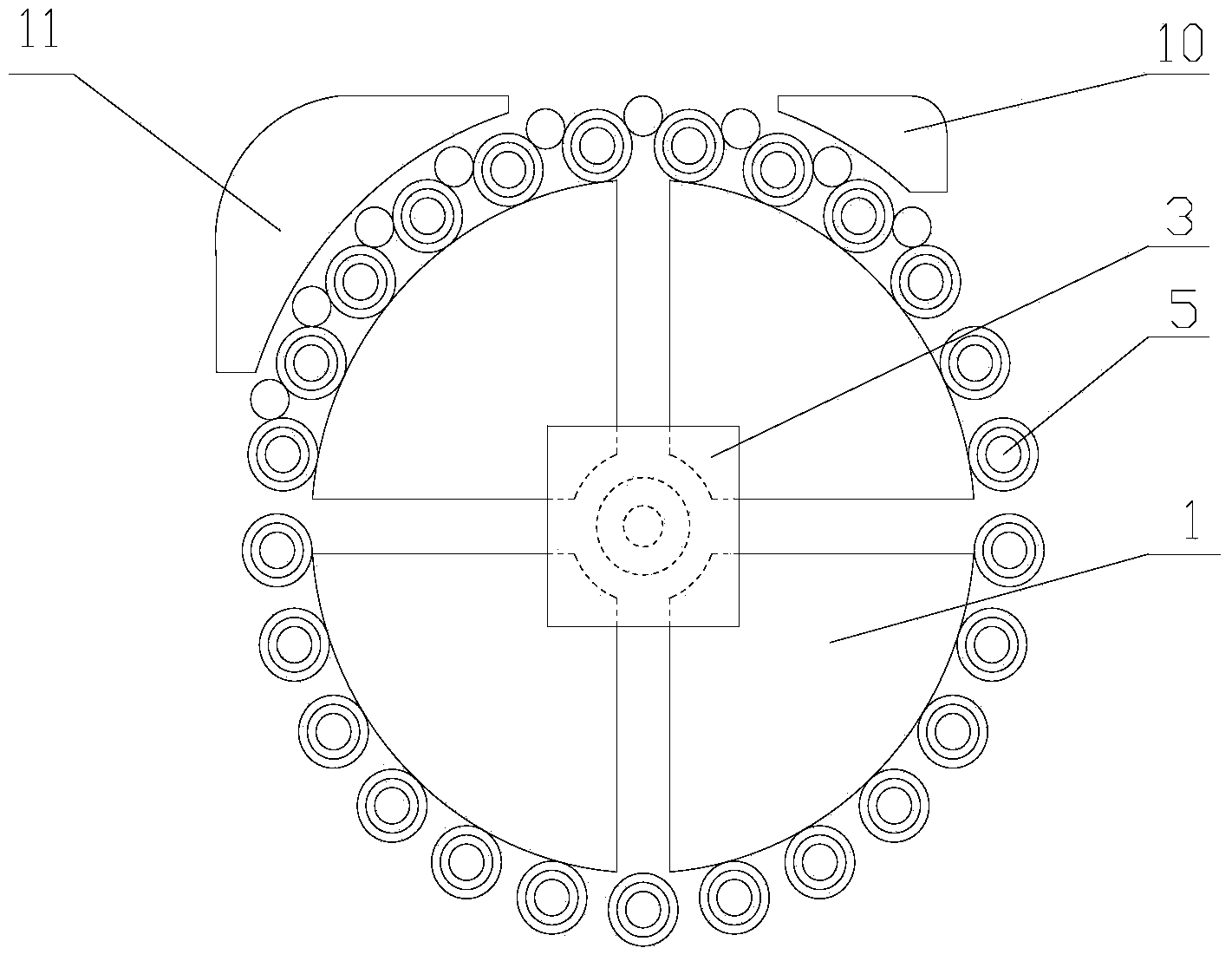

The invention provides a vehicle fastener online detection device used for the technical field of vehicle fastener production equipment. The vehicle fastener online detection device comprises a systemframework (1), the system framework (1) is provided with a fastener conveying disc (2) and a limiting ring (5); a plurality of fastener clamping grooves (4) are formed in the outer ring of the fastener conveying disc (2) in a clearance mode; the limiting ring (5) is arranged on the outer ring of the fastener conveying disc (2); the system framework (1) is provided with a plurality of fastener body detection sensors (8); and each fastener body detection sensors (8) is of a structure capable of aligning a corresponding fastener detection position (9). According to the vehicle fastener online detection device and an online detection method, the vehicle fastener can be conveniently detected after machining, accuracy of the detection result is improved; and meanwhile, good quality fasteners meeting requirements and inferior-quality fasteners can be respectively collected, automation is improved and scale production requirements are met.

Owner:芜湖强振汽车紧固件有限公司

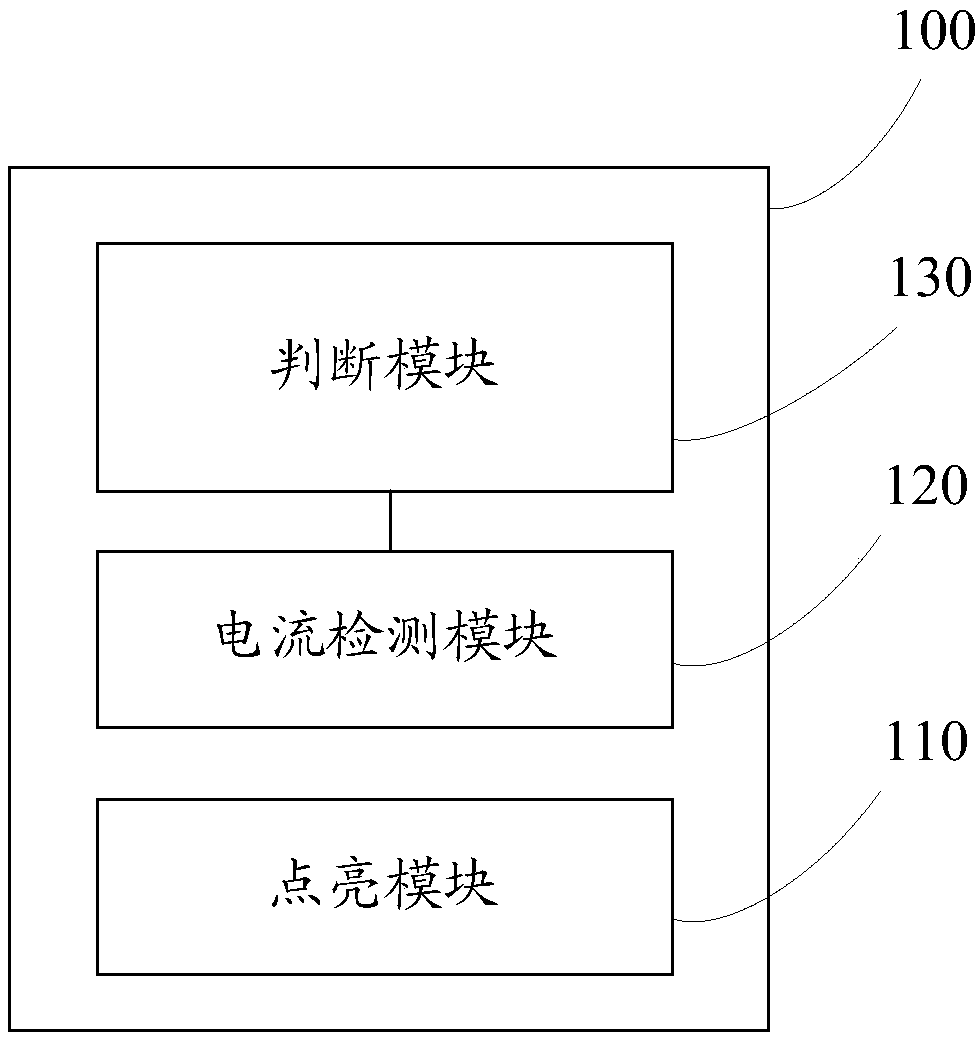

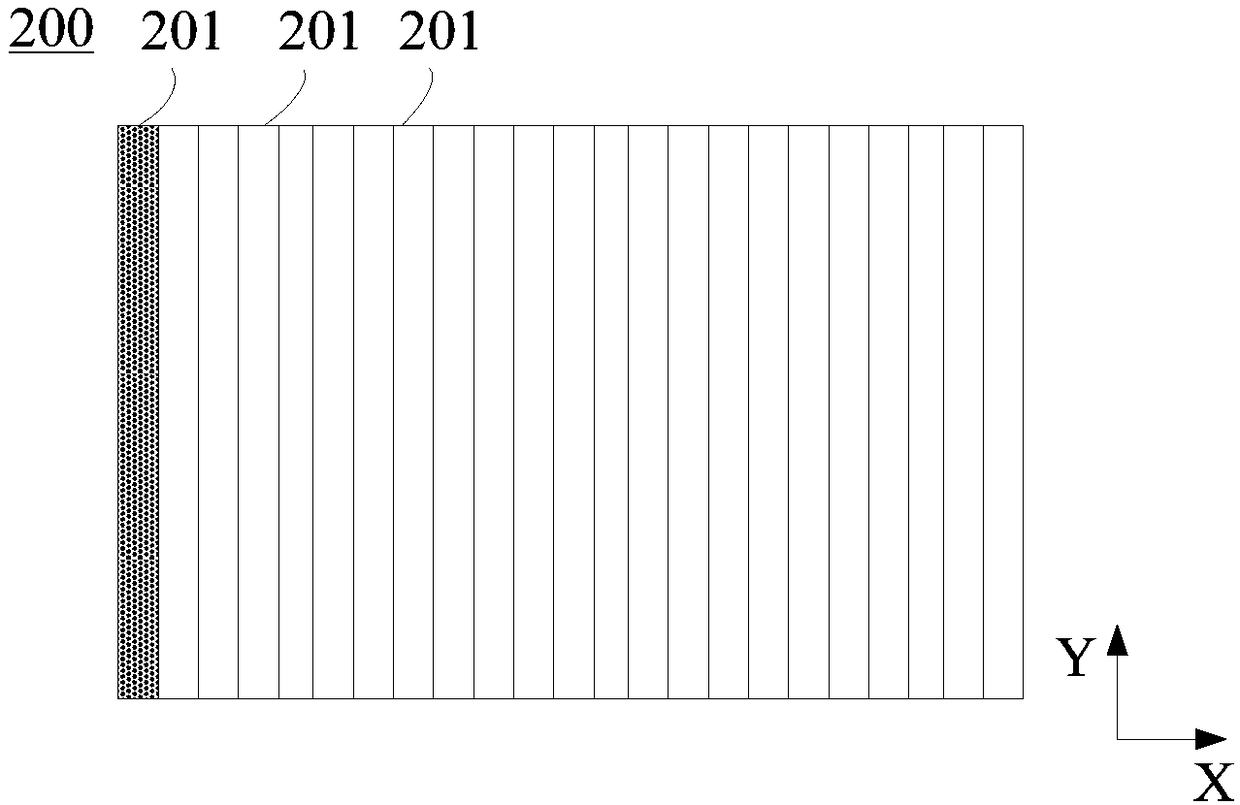

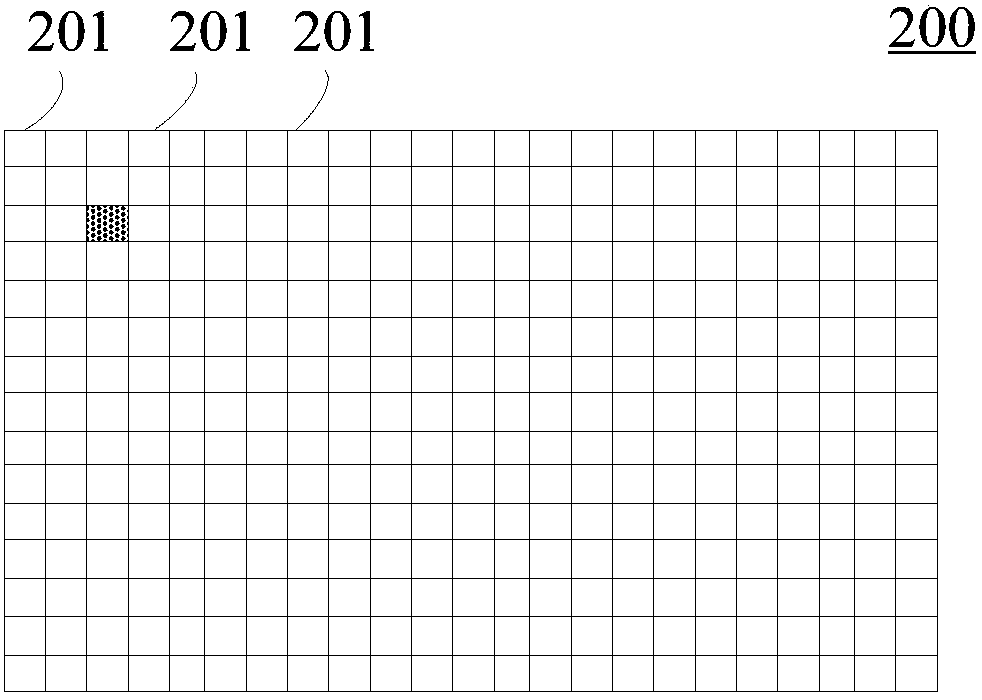

Detection device and method, repairing device, repairing method and repairing system for AMOLED (active matrix organic light-emitting diode) display devices

PendingCN108281102AImprove detection efficiencyChange brightnessStatic indicating devicesElectrical testingDriving currentActive matrix

The invention discloses a detection device and method, a repairing device, a repairing method and a repairing system for AMOLED (active matrix organic light-emitting diode) display devices, and belongs to the field of AMOLED display devices. The detection device comprises a lighting module, a current detection module and a judging module; the lighting module is used for sequentially lightning multiple detection areas of a screen of an AMOLED display device, the screen is divided into multiple detection areas, and each detection area includes at least one light-emitting unit; the current detection module is used for acquiring detection current, the detection current is a sum of driving currents of the light-emitting units in the detection areas that are lit; the judging module is used for judging whether the detection areas are bad areas according to the detection current. The screen of the AMOLED display device is divided into the multiple detection areas which are lit, the detection current of the detection areas is acquired, and whether the detection areas are bad areas is judged according to the detection current; accordingly, brightness uniformity of the AMOLED display device is detected, the detection efficiency is high, detection standards are uniform, and the accuracy is high.

Owner:BOE TECH GRP CO LTD +1

Motor detection device for automobile manufacturing

ActiveCN108226778AConvenience to workAccurate requirementsMeasurement instrument housingDynamo-electric machine testingFixed frameCar manufacturing

The invention relates to a detection device, particularly to a motor detection device for automobile manufacturing. The invention aims to solve a technical problem of providing a motor detection device for automobile manufacturing, which is capable of replacing manual operation to detect a motor, and is consistent in detection standard, and convenient and quick to use. In order to solve the technical problem, the invention provides the motor detection device for automobile manufacturing, which comprises a fixing frame, a first sliding sleeve, a sliding rod, a second sliding sleeve, a second motor, a second bearing and the like, wherein the second motor is mounted on the right side of the left wall of the fixing frame; a first lead screw is mounted on an output shaft of the second motor; aconnecting shaft is mounted at the right end of the first lead screw. The device is capable of replacing manual operation to detect a motor, and is consistent in detection standard, and convenient andquick to use; with the adoption of the device, whether the motor is qualified can be detected within a short time; the device is convenient to use and simple to operate, extremely facilitates the work of detection workers, is rigorous in design and simple in structure, and meets the accuracy requirement of a factory.

Owner:QINGDAO AIPU INTELLIGENT INSTR

Detection system of PVDF membrane

PendingCN108931530ASimple structureImprove practicalityOptically investigating flaws/contaminationProduction lineSimulation

The invention provides a detection system of a PVDF membrane. The system comprises: a light source assembly arranged on a PVDF membrane production line and comprising at least one light source for illuminating a PVDF membrane to be detected; a camera assembly arranged on the PVDF membrane production line and comprising at least one camera for shooting the PVDF membrane to be detected; a marking assembly arranged on a PVDF membrane production line and used for marking a defect position on the PVDF membrane to be detected; a length counter assembly arranged on the PVDF membrane production line and used for detecting the conveying distance of the PVDF membrane to be detected; and a computer respectively connected the light source assembly, the camera assembly, the marking assembly and the length counter assembly, used for triggering the at least one camera based on the conveying distance, detected by the length counter assembly, of the PVDF membrane and an actual production line speed inorder to shoot the PVDF membrane to be detected, and also used for receiving and processing a picture taken by the at least one camera, identifying the defect and controlling the marking assembly to perform code spraying marking on the defect position on the PVDF membrane to be detected. The detection system is suitable for the quality detection of the PVDF membrane, improves the production efficiency and reduces the production cost.

Owner:HANGZHOU LIPO SCI & TECH

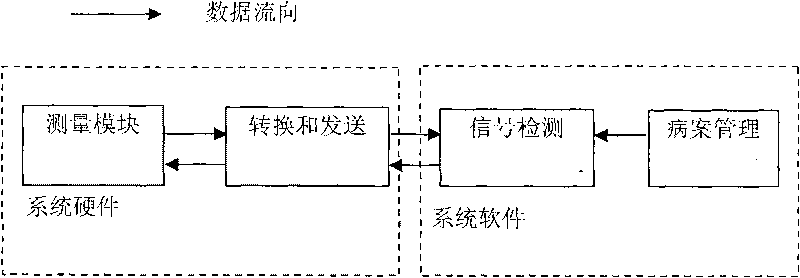

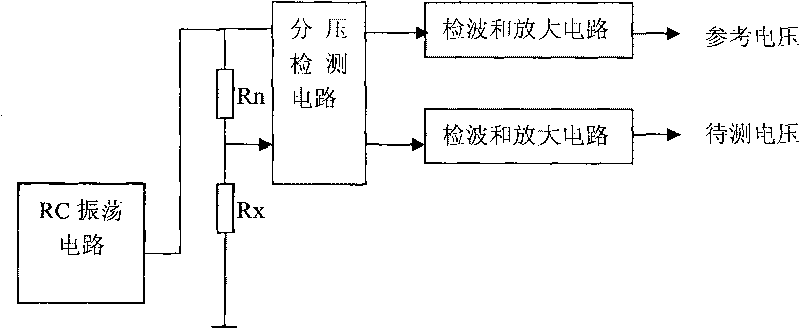

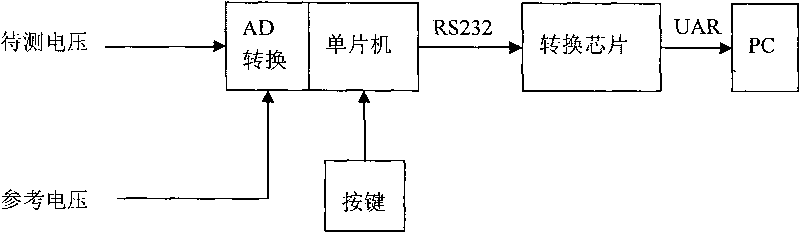

Auricular point detection system

InactiveCN101690661AReduce volumeEasy to carryDiagnostic recording/measuringSensorsElectrical resistance and conductanceMicrocontroller

An auricular point detection system belongs to the technical field of auricular point impedance detection and is characterized by comprising a measurement part and a single chip part which are mutually connected in serial, wherein the measurement part comprises a measurement probe pen, an RC oscillating circuit, a partial pressure measuring circuit and a demodulation amplifying circuit which are orderly connected in serial; and the single chip part comprises an MCU single chip, a UART level conversion chip and a signal detecting module arranged in the MCU single chip, which are orderly connected in serial. The auricular point detection system uses the auricular point resistance distribution graph to display the measurement result and uses red to represent the low resistance area of the auricular point resistance so as to position a focus area; and meanwhile, the hardware circuit of the system is greatly simplified so as to increase the quantitative accuracy and precision.

Owner:TSINGHUA UNIV

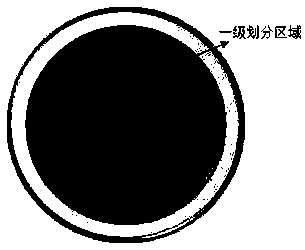

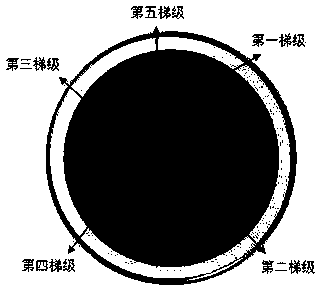

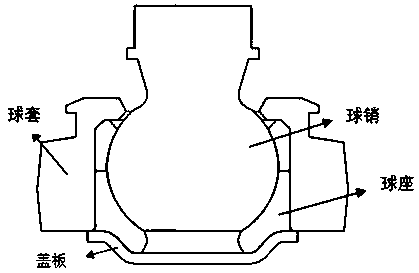

Ball seat coating area for spherical hinge and partition detecting method of coating zone fitting degree

ActiveCN108257168ASolve the problem of large errors in the judgment of the coloring areaAvoid the problem of poor detection data stabilityGeometric CADImage analysisPre treatmentComputer vision

The invention provides a ball seat coating area for a spherical hinge and a partition detecting method of coating zone fitting degree. The method includes steps of acquiring a vertical view of a ballseat assembled and coated by the spherical hinge by a gray camera; traversing all pixel points of the vertical view under a Matlab environment; after removing noise through image pretreatment, performing edge detection on the gray level image on the basis of a regional growth method of a seed point so as to solve the coordinate value of every pixel point where a boundary line of the ball seat coating area locates; further carrying out secondary partitioning on the zone in the boundary line; finally confirming the zone of the inner spherical face of the ball seat represented by different fitting degrees in the ball seat coating zone on the basis of the gray value of the pixel point. The detecting method has good stability of detecting result, real and reliable data; meanwhile, the method provides real and effective basic data for the other related experiments of the spherical hinge; therefore, the detecting efficiency of the whole detecting chain of the spherical hinge product is also improved.

Owner:JIANGSU JUJIE ELECTROMECHANICAL CO LTD

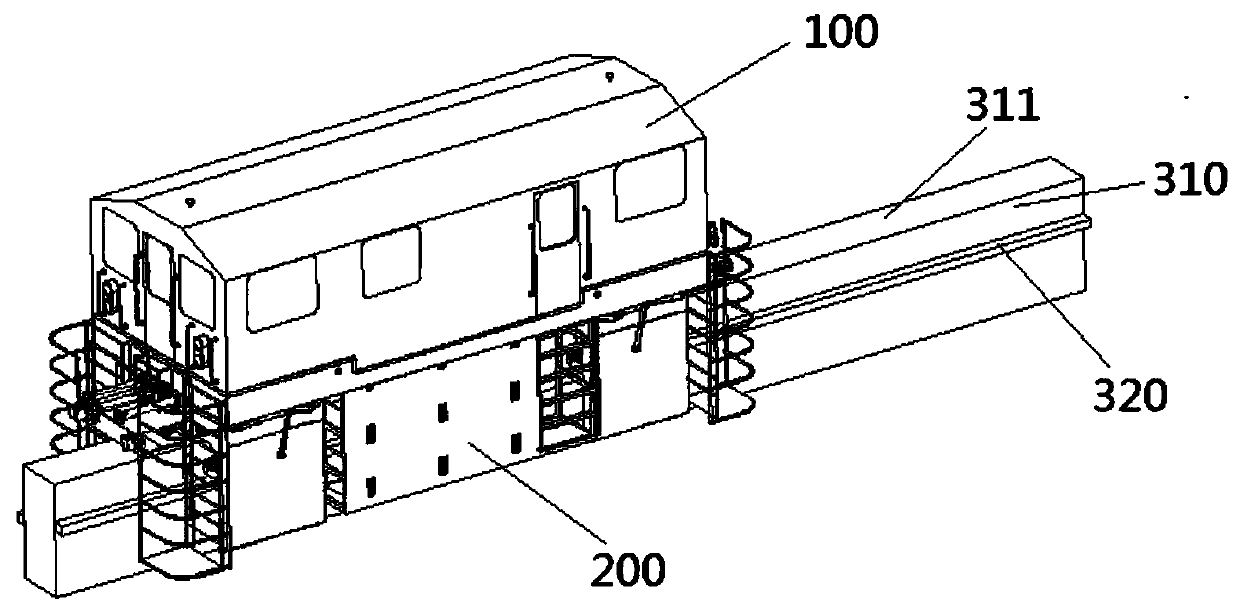

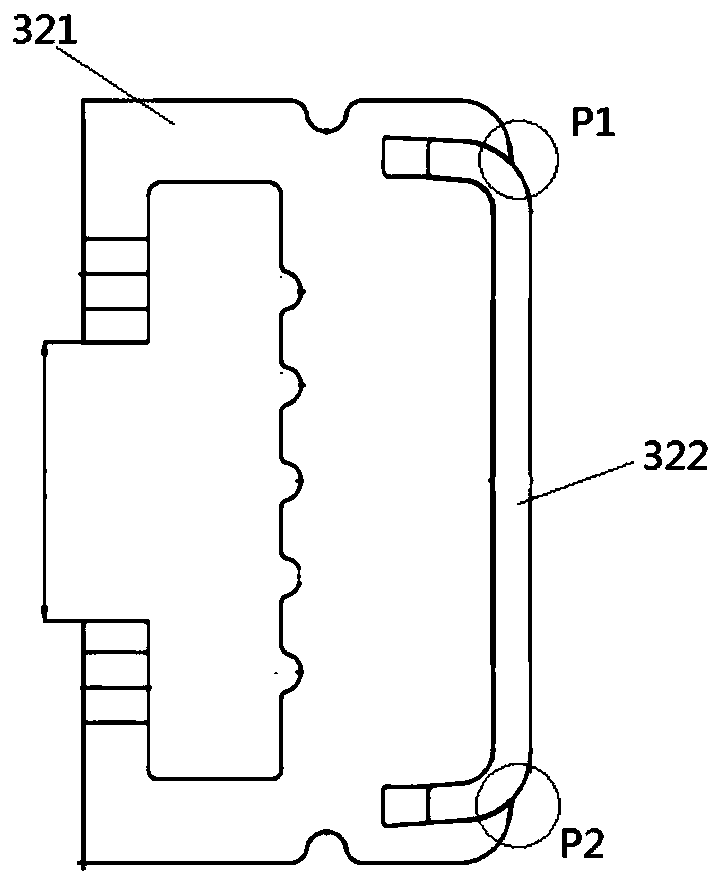

Detection system for straddle type monorail inspection engineering vehicle

InactiveCN111256586AAvoid deviations in inspection resultsInspection results are reliableOptically investigating flaws/contaminationUsing optical meansTrackwayMonorail

The invention relates to the technical field of monorail inspection, and particularly relates to a battery, the invention relates to a detection system for a straddle type monorail inspection engineering vehicle which comprises a contact rail information acquisition device which is used for acquiring images of a rail beam and a contact rail, a rail beam information acquisition device which is usedfor acquiring images of the surface of the rail beam, and a detection system host which analyzes whether the rail beam has defects or not and analyzes the installation position and the abrasion degree of the contact rail according to the acquired images. The detection system integrates the functions of contact rail detection and track beam detection, replaces a traditional manual inspection mode,saves manpower and time, improves the detection efficiency and is more uniform in detection standard and avoids inspection result deviation caused by different personal experiences of inspection personnel and enables the detection result to be more reliable.

Owner:CRRC HANGZHOU CO LTD +1

Alficetin eye solution detection method

InactiveCN101216472AUnified testing standardsEasy to produceMaterial analysis by observing effect on chemical indicatorComponent separationEye drops solutionCHLORAMPHENICOL TOXICITY

The invention discloses a method for determining an ophthalmic chloramphenicol solution, which comprises all detection items of chloramphenicol eye drop in Chinese Pharmacopoeia. The determination of rosmarinic acid is added in the determination items. Compared with the prior art, the method can determine rosmarinic acid influencing the validity period of chloramphenicol eye drop, thus ensuring the validity period of chloramphenicol eye drop above 2 years. Accordingly, the method facilitates unification of determination standard of chloramphenicol eye drop and facilitates production and sale for manufactures as well as usage for consumers.

Owner:方南

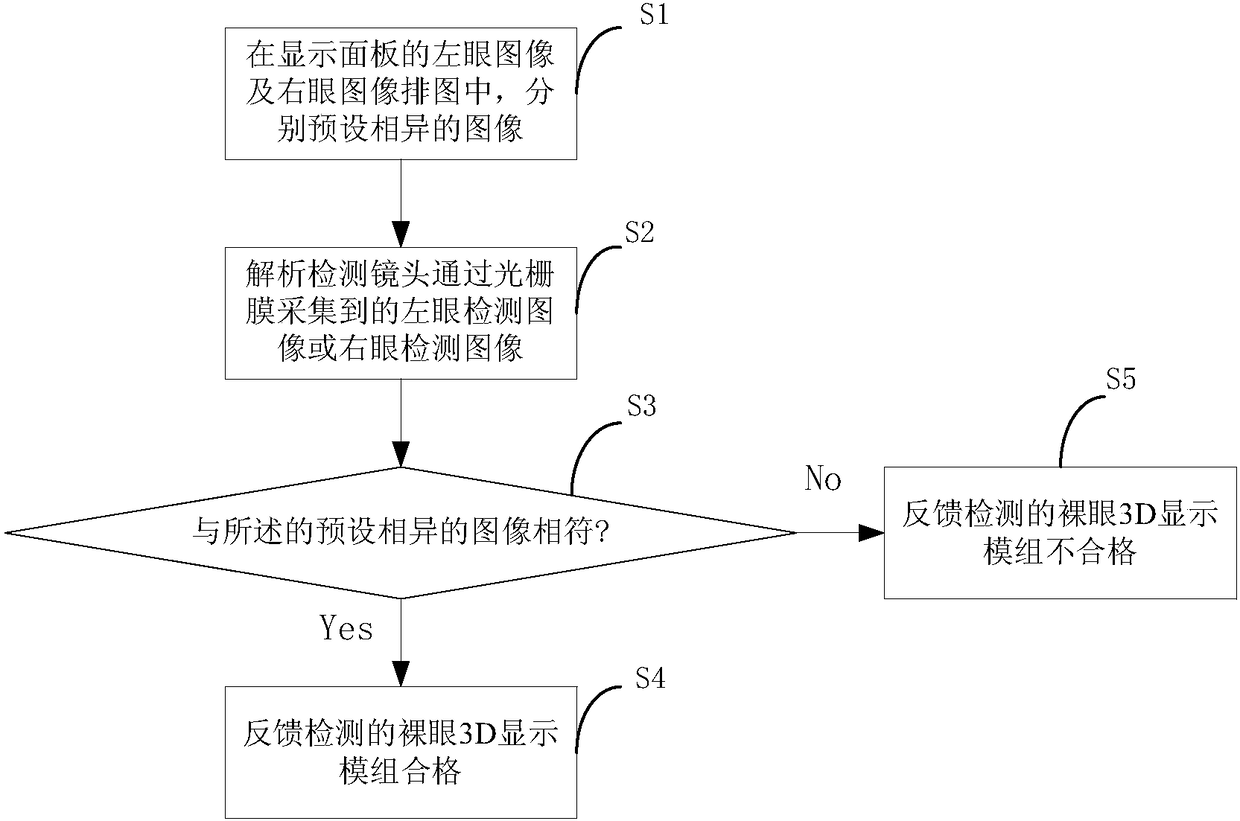

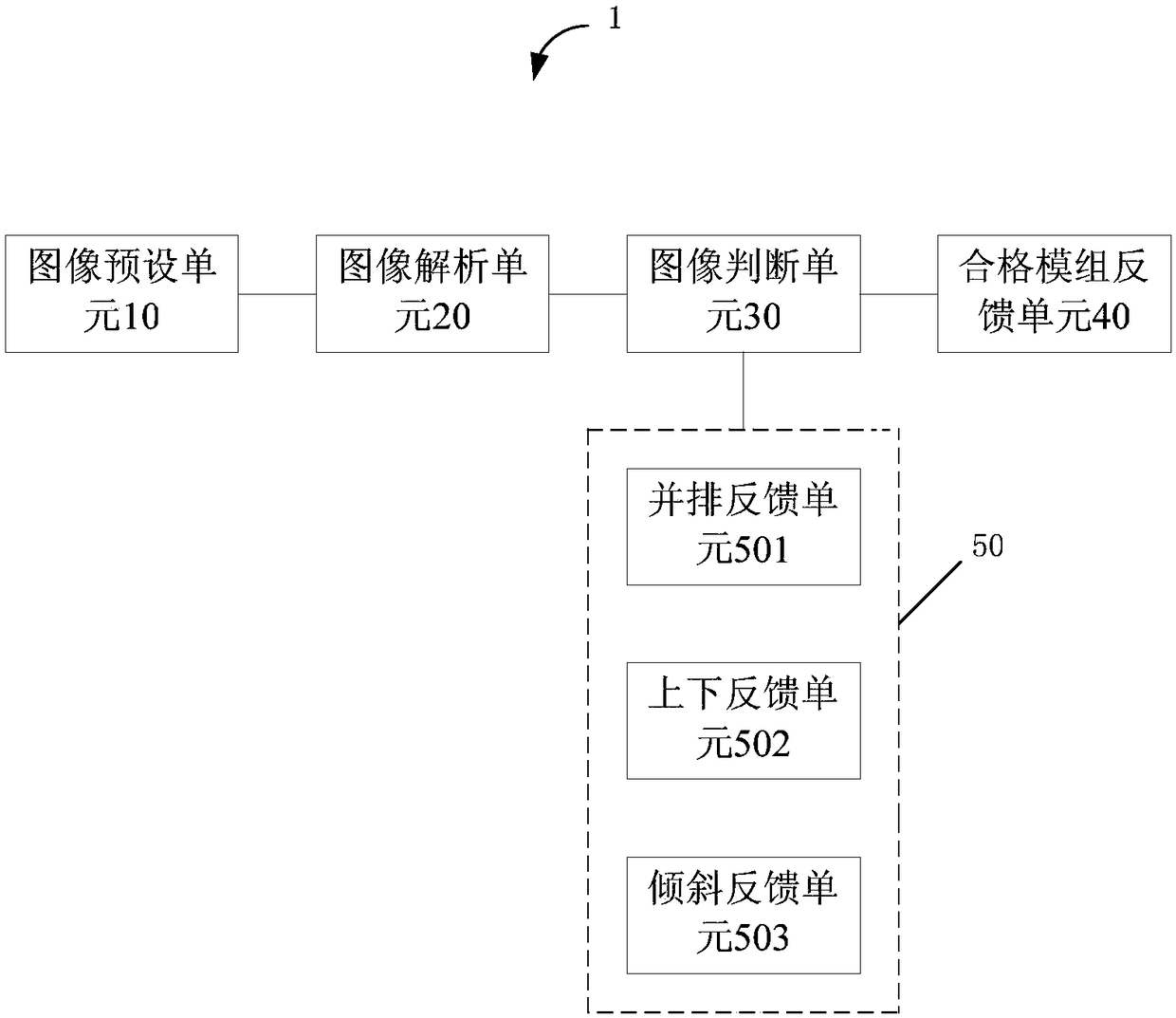

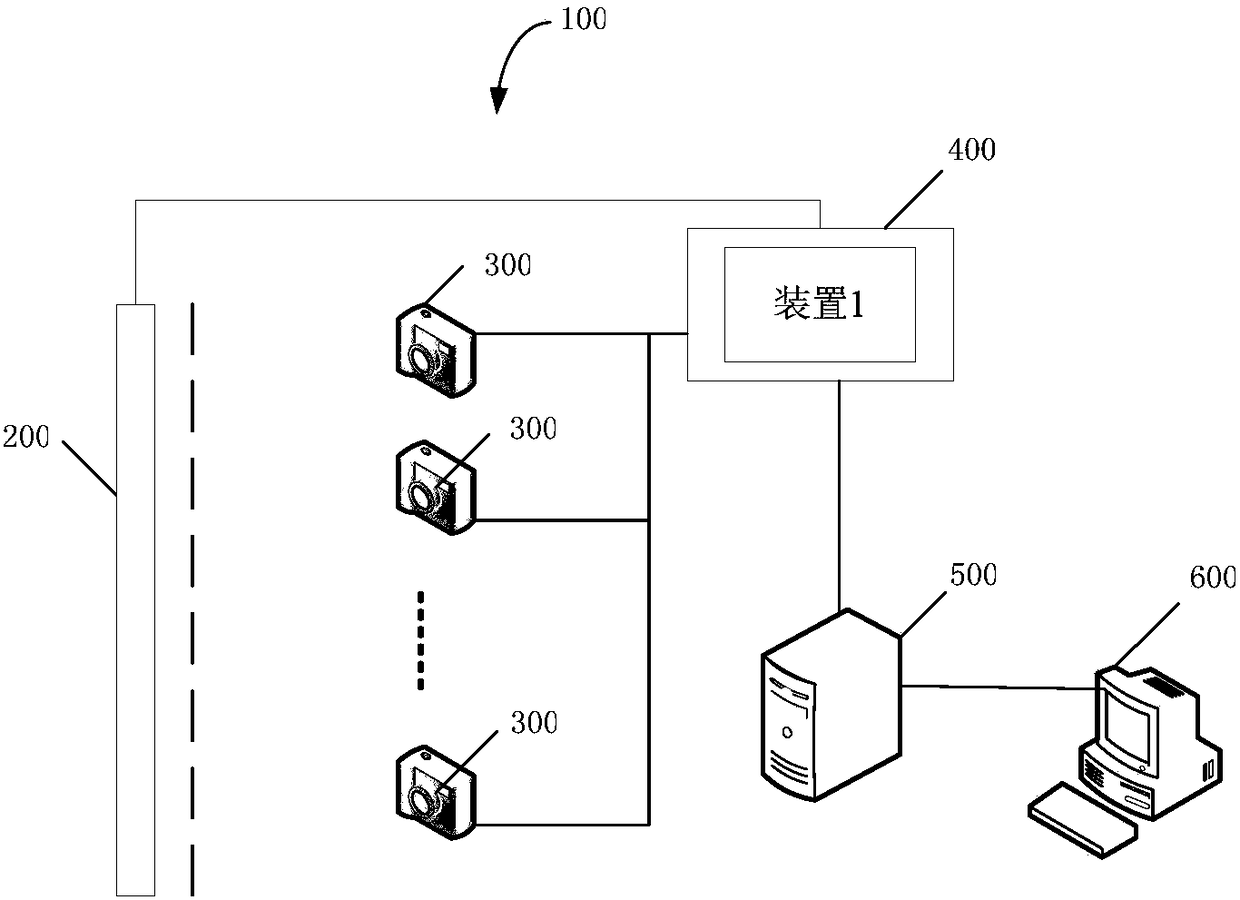

Glass-free 3d display module detection method, device and system

ActiveCN108696743AHighly subjectiveDifferent standardsTelevision systemsSteroscopic systemsCamera lensGrating

The invention provides a glass-free 3d display module detection method. The method comprises the steps of first, separately presetting different images for left eye images and right eye images in a display panel; second, parsing a left eye detection image or a right eye detection image collected by a detection lens through a grating membrane; third, determining whether the left eye detection imageor the right eye detection image is consistent with the preset different images, if yes, performing a fourth step, if not, performing a fifth step; fourth, feeding back information that the detectedglass-free 3D display module is qualified; and fifth, feeding back information that the detected glass-free 3D display module is not qualified. The invention further discloses a glass-free 3d displaymodule detection device and system. Through adoption of the glass-free 3d display module detection method, device and system, automatic detection is realized, the detection standards are unified, andthe detection efficiency is high.

Owner:深圳市易快来科技股份有限公司

Long shelf life chloromycetin eyedrops detection method

InactiveCN101216476AUnified testing standardsEasy to produceComponent separationColor/spectral properties measurementsIsoflavonesChloramphenicol eye drops

The invention discloses a method for determining an ophthalmic chloramphenicol solution with long shelf life, which comprises all detection items of chloramphenicol eye drop in Chinese Pharmacopoeia. The determination of soybean isoflavone is added in the determination items. Compared with the prior art, the method can determine soybean isoflavone influencing the validity period of chloramphenicol eye drop, thus ensuring the validity period of chloramphenicol eye drop above 2 years. Accordingly, the method facilitates unification of determination standard of chloramphenicol eye drop and facilitates production and sale for manufactures as well as usage for consumers.

Owner:方南

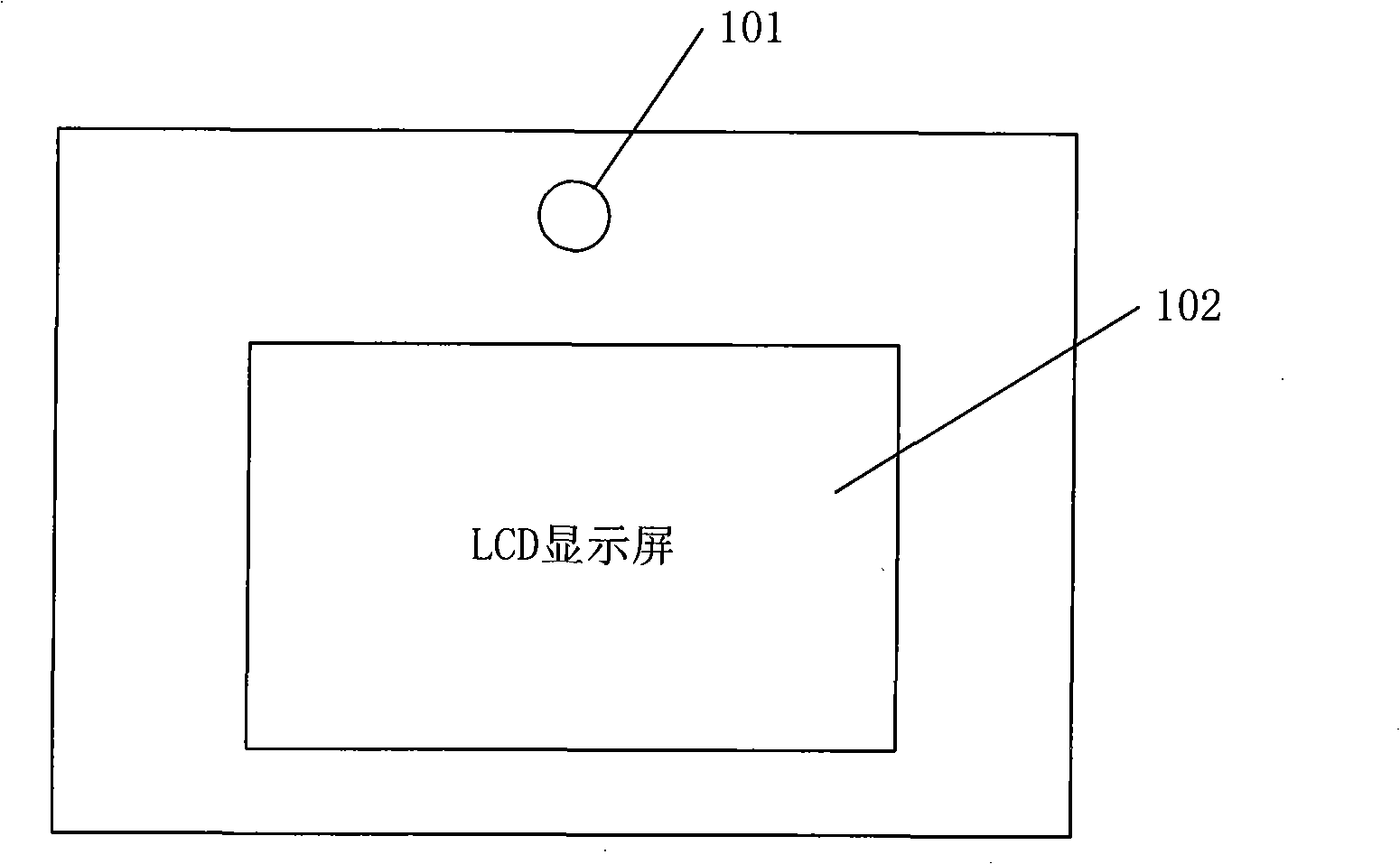

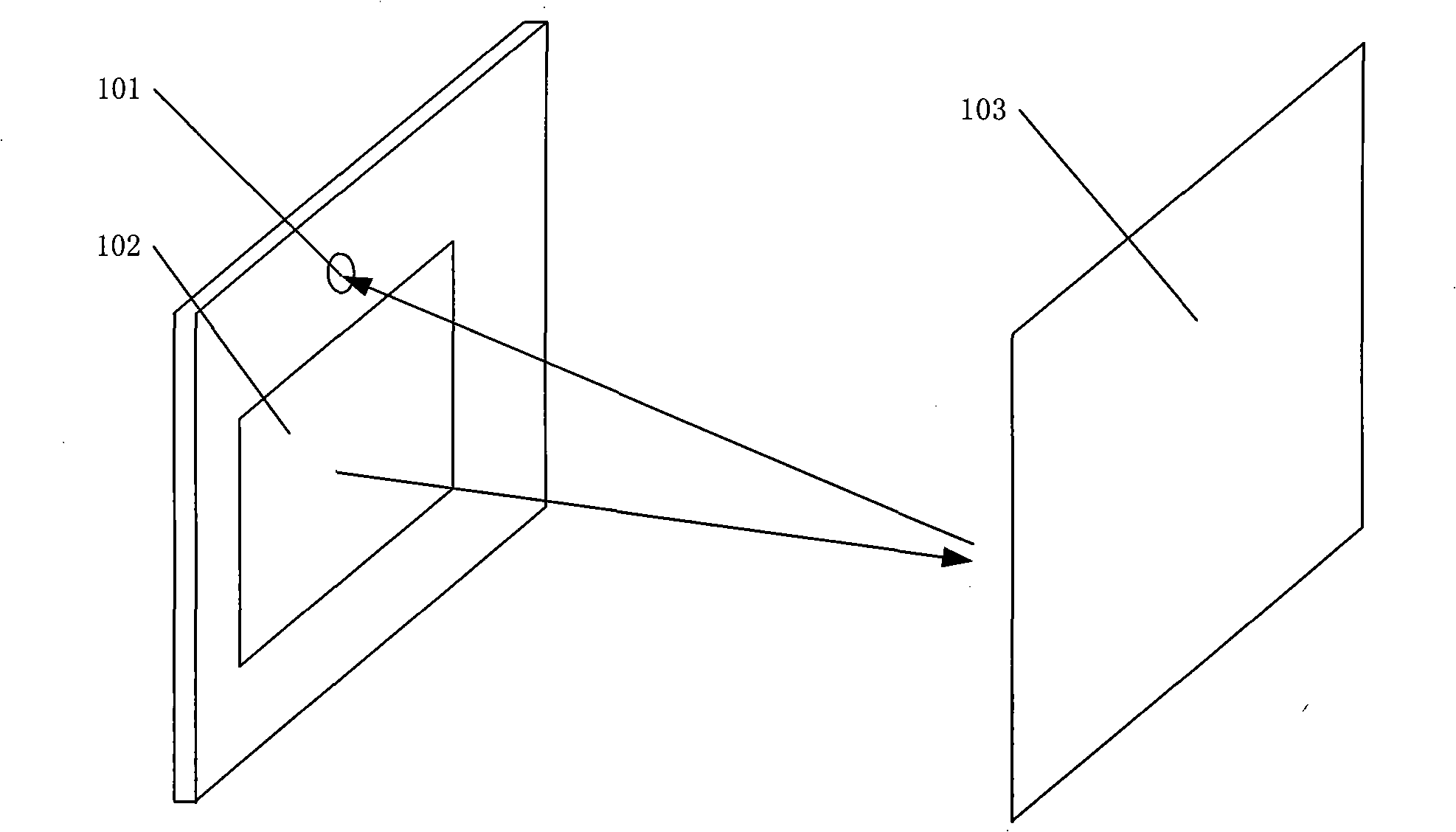

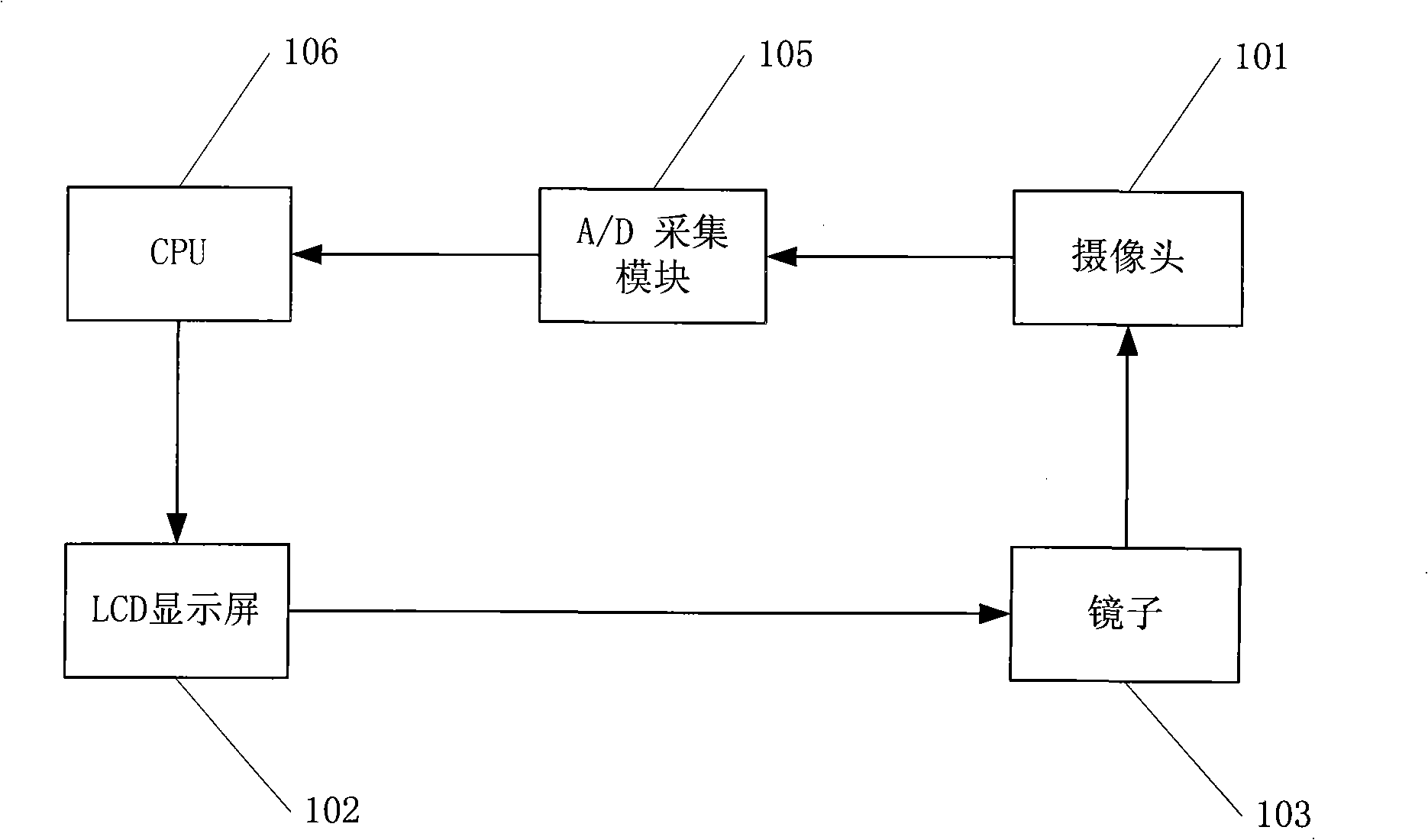

Self-test method for LCD display with camera

InactiveCN101867787BEffective judgmentEfficient testingClosed circuit television systemsNon-linear opticsCamera lensComputer science

Owner:TCL CORPORATION

System for automatically detecting flaws of dialysis tube

PendingCN108037141AAvoid mixingEven reflectionMaterial analysis by optical meansImaging processingComputer science

The invention relates to a system for automatically detecting flaws of a dialysis tube. The system comprises a transmission rail, a lighting device, a PLC, an image acquisition device, an image processing device and a removing device, wherein the transmission rail is used for placing a to-be-detected dialysis tube; the lighting device is used for providing lighting for the image acquisition device; the image acquisition device is used for acquiring the original image of the dialysis tube and arranged in a position corresponding to the lighting device; the image processing image is used for processing the original image acquired by the imaging acquisition device; the PLC is connected with the image processing device and used for receiving the image processing result; the PLC is connected with the removing device and used for controlling the dialysis tube with the flaws prompted by the processing result of the image processing device; the PLC is connected with the image acquisition device and used for controlling the image acquisition device to acquire the original image on the surface of the dialysis tube. The system has the following beneficial effects: the detection time can be shortened, continuous operation can be conducted and the working efficiency is improved; automatic detection is adopted, the detection standard is uniform and the accuracy is high.

Owner:德清炬诚电子科技有限公司

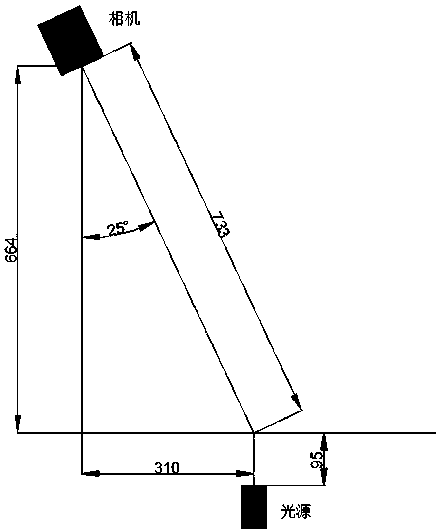

Solar backboard detection system

PendingCN106814085AImprove detection accuracyImprove detection efficiencyOptically investigating flaws/contaminationCamera lensEngineering

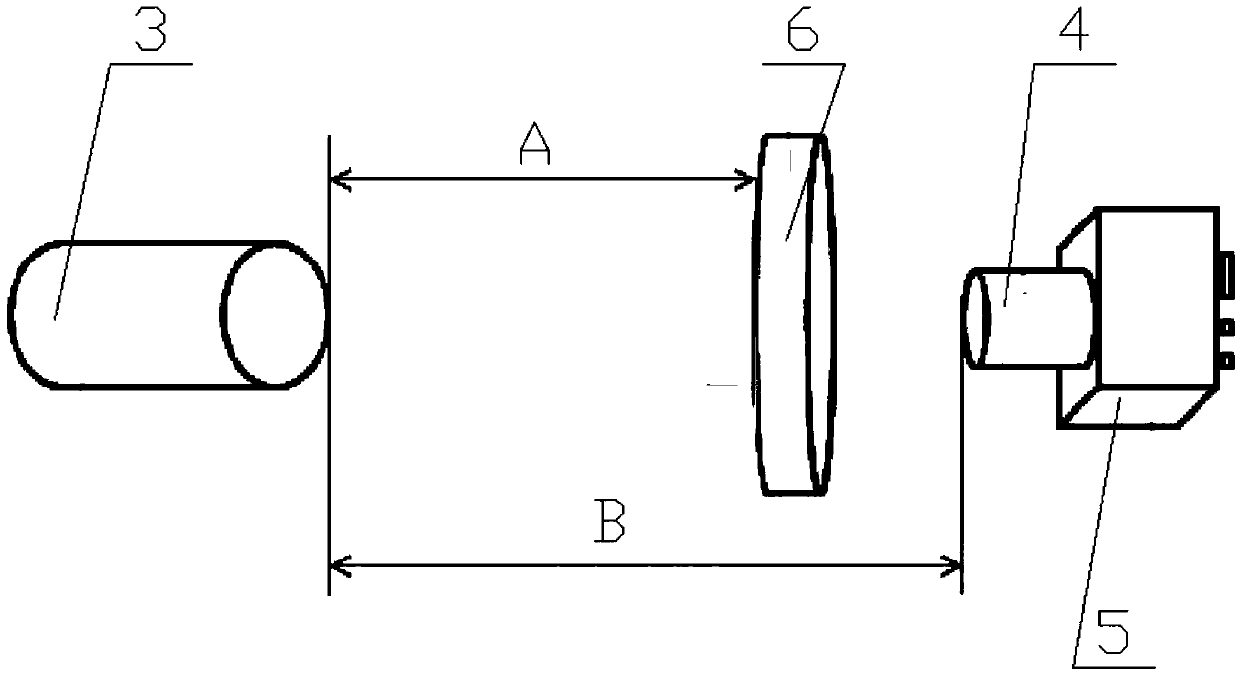

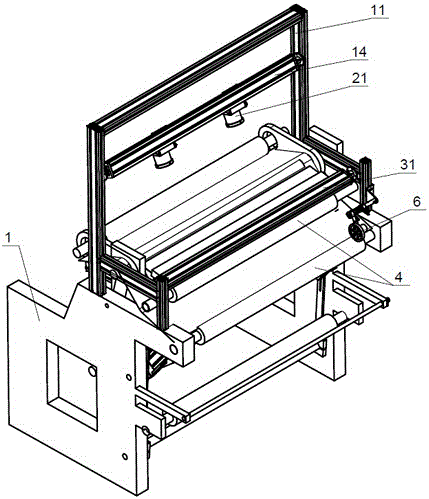

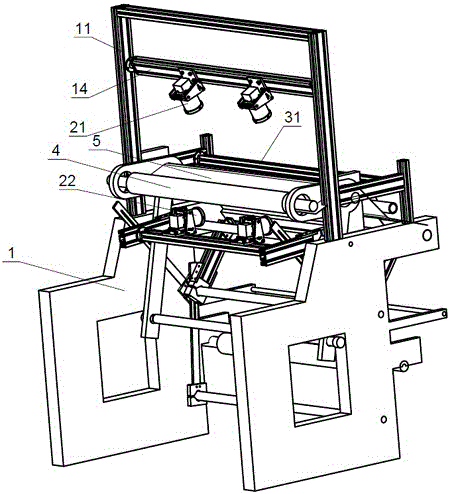

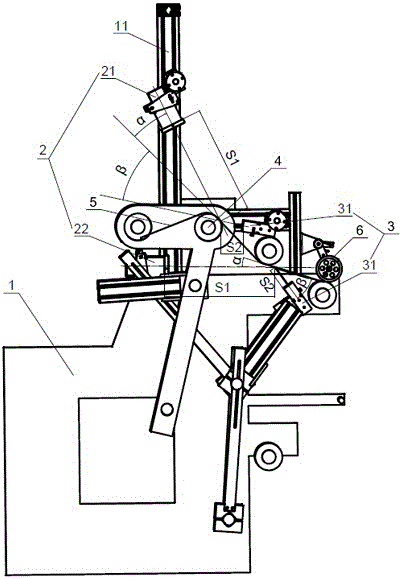

The invention relates to the technical field of flat sheet surface defect detection and in particular discloses a solar backboard detection system. Line sources and photographing cameras are arranged on the front surface and the back surface of a solar backboard to synchronously detect the surface defects on the front surface and the back surface of the solar backboard; the distances S1 from the lenses of the cameras to photographing regions are 420-430mm, the photographing angles alpha of the lenses of the cameras relative to the solar backboard plane are 16-18 degrees, the distances S2 from the line sources to irradiating regions are 78-80mm, and the included angles beta between the light of the line sources and the solar backboard plane are 35-39 degrees. Multiple threshold values can be adjusted while the surface defects on the front surface and the back surface of the solar battery are precisely detected, so that one piece of equipment can meet detection of different products. The detection system replaces a conventional manual detection mode and has the advantages of being high in detection precision, uniform in detection standard, high in detection efficiency and low in manual cost.

Owner:HANGZHOU LIPO SCI & TECH

Cover-pressing detection device for wine box

The invention discloses a cover-pressing detection device for a wine box, belongs to the technical field of packing box detection devices. The device comprises a conveying line and a plurality of visual detection units, the conveying line comprises a feeding conveying section, a detection conveying section and a rejecting conveying section which are connected in sequence, the structures of the plurality of visual detection units are same. Each visual detection unit comprises a driving mechanism, a pressing mechanism, a shooting mechanism and a positioning mechanism, wherein the driving mechanism and the shooting mechanism are arranged on the upper part and the middle part of a detection mounting bracket in sequence, the pressing mechanism is arranged on the outlet end of the driving mechanism, the driving mechanism can drive the pressing mechanism to rotate and vertically move, the pressing mechanism is used for pressing the upper part of the four sides of the wine box, the positioningmechanism is used for positioning the wine box to be detected on the detecting conveying section, the rejecting mechanism is arranged on ones side of the rejecting conveying section and is used for rejecting the wine box which does not meet the standard of cover pressing. According to the device, the visual detection units are used for replacing manual work to detect the quality of the cover pressing and the detection efficiency is high.

Owner:ANHUI HISEED ROBOT CO LTD

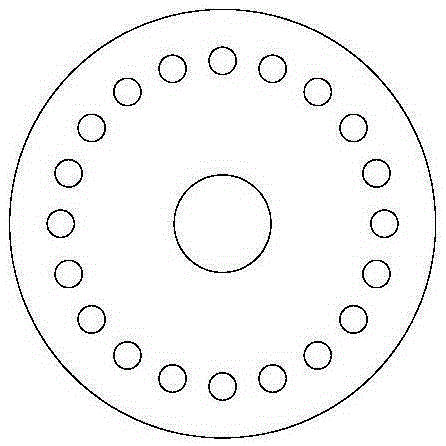

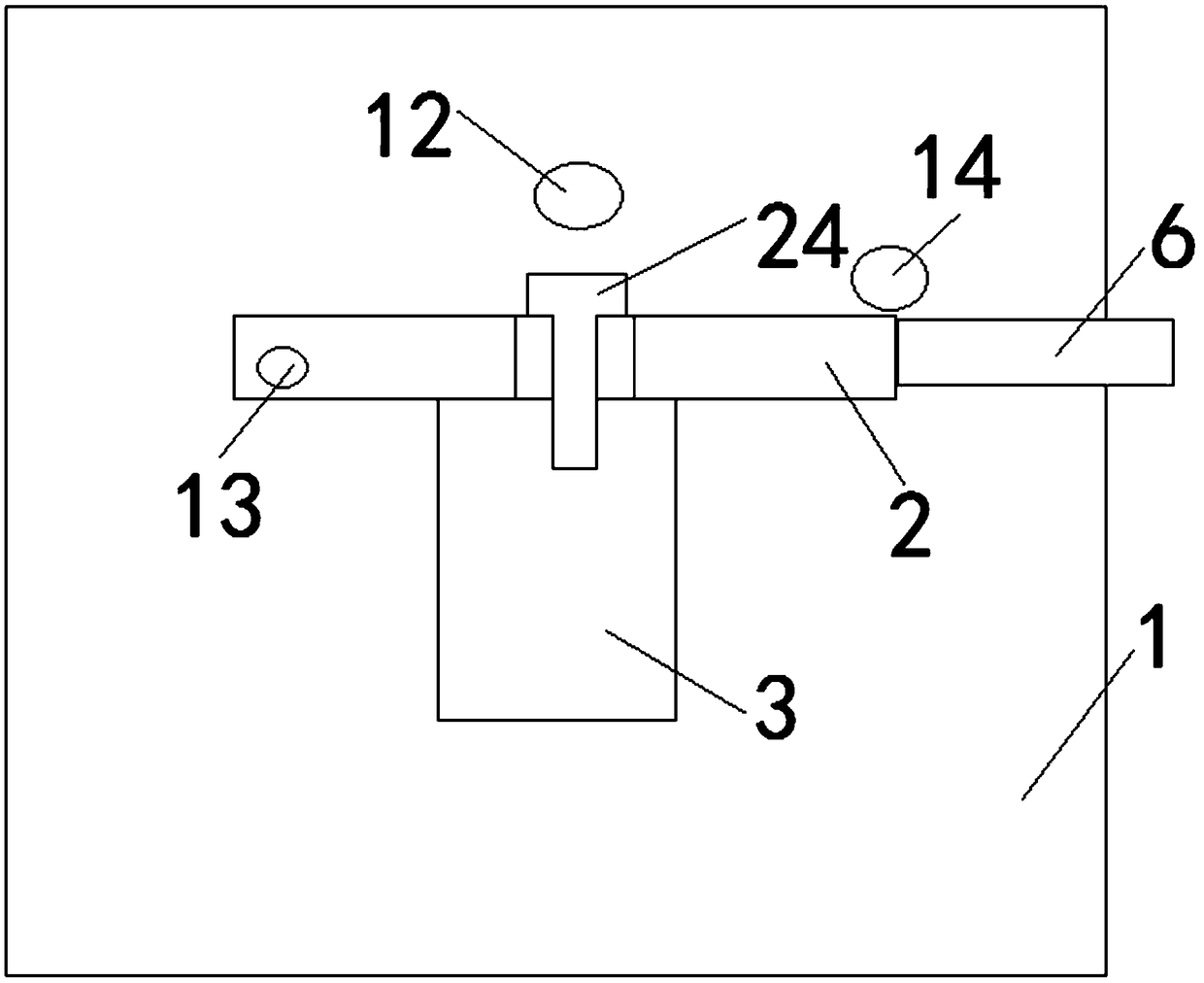

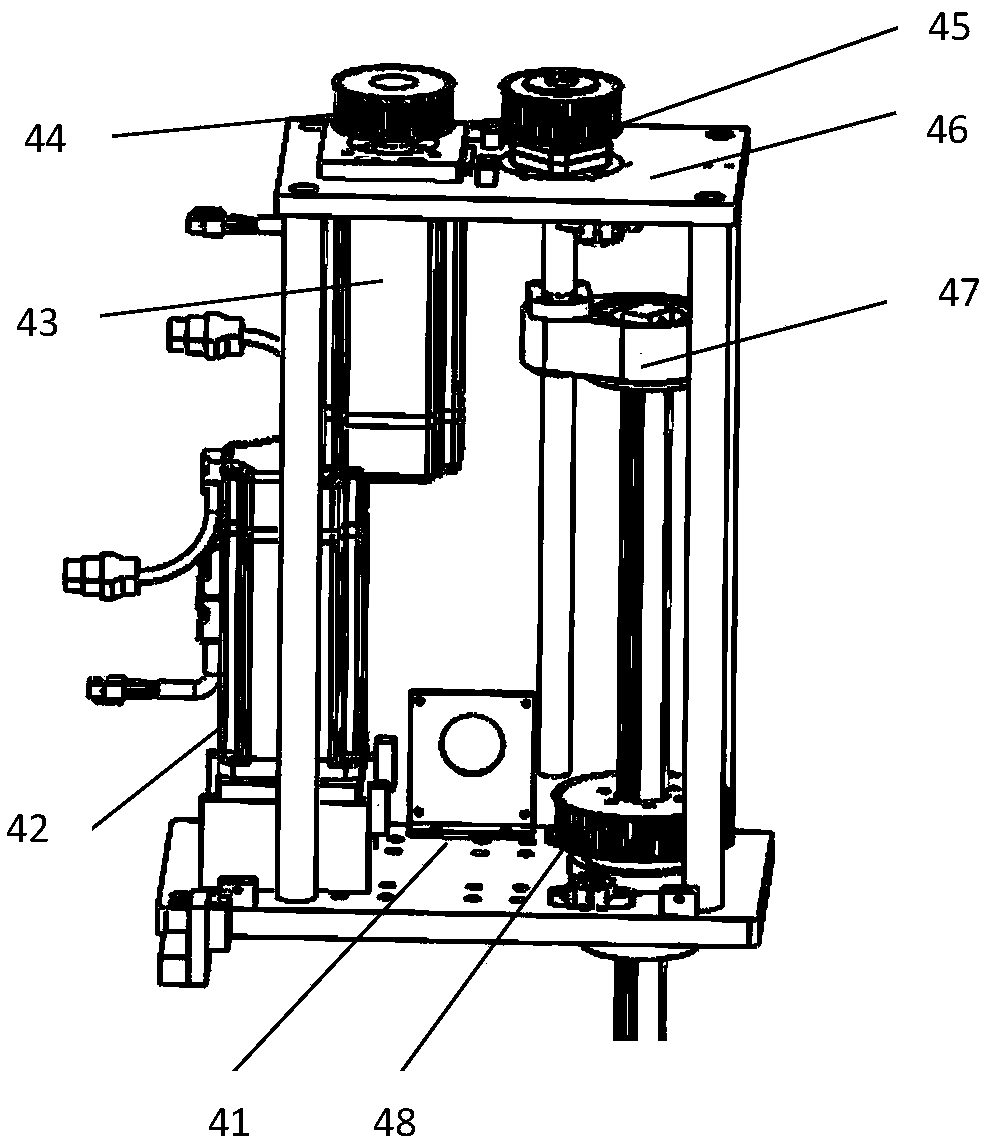

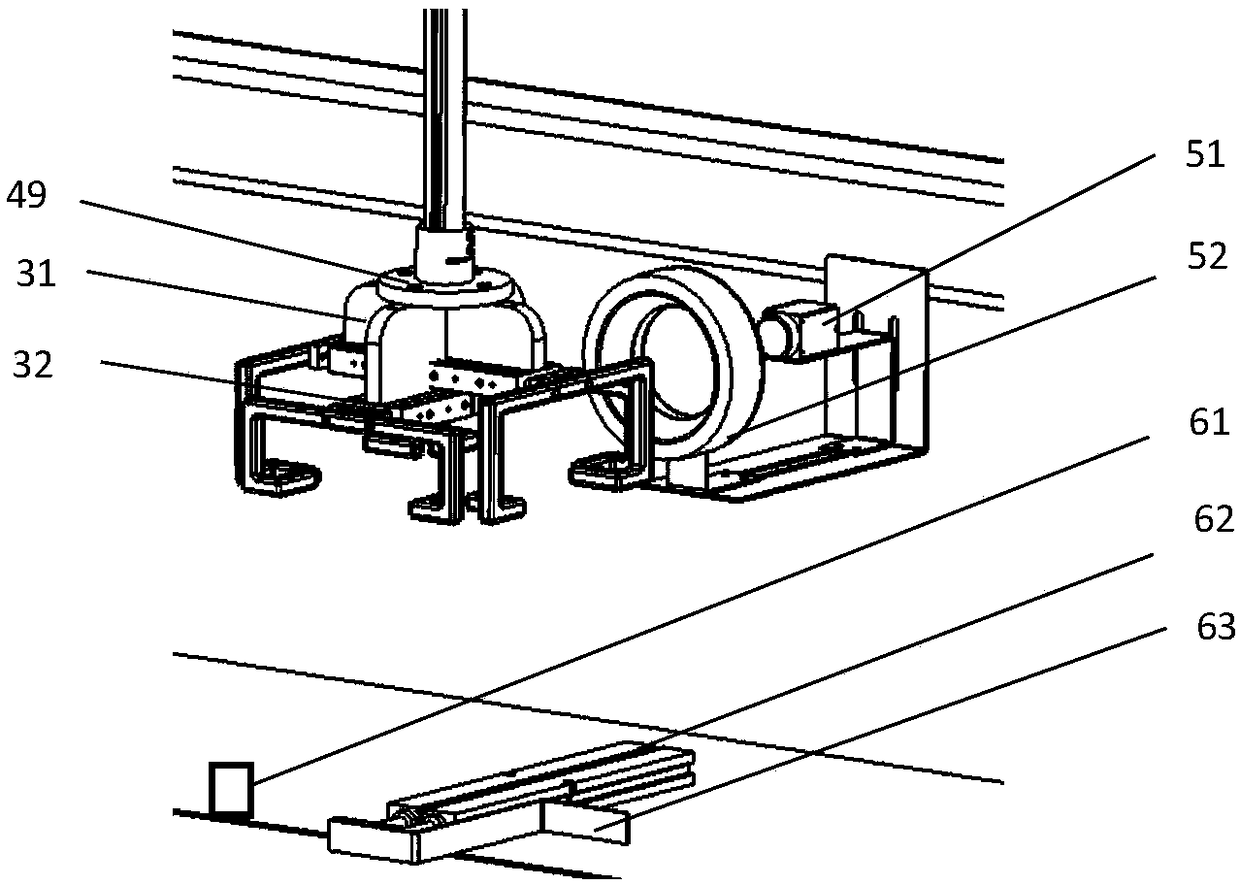

Rotating conveyer used for precise detection mechanism of medicinal glass bottle production line

ActiveCN103935755AFully automatedUnified testing standardsConveyor partsProduction lineRolling-element bearing

The invention discloses a rotating conveyor used for a precise detection mechanism of a medicinal glass bottle production line. The rotating conveyor comprises a rotating disc, bottle rolling devices and a rotating disc motor, wherein the rotating disc is a disc arranged vertically, the multiple bottle rolling devices are fixed to the side wall of the periphery of the rotating disc, and a rotating shaft is fixed in the center of the rotating disc and connected with an output shaft of the rotating disc motor; each bottle rolling device comprises a roller, a front idler wheel and a rear idler wheel, wherein the front idler wheel and the rear idler wheel are fixed to the two ends of the roller respectively, a magnet is fixed in the rear idler wheel, the roller is further sleeved with a rolling bearing, and the rolling bearing is fixed to the side wall of the periphery of the rotating disc. Mechanical friction does not exist in the detection process of medicinal glass bottles, equipment abrasion is reduced, and the service life of equipment is prolonged.

Owner:INST OF APPLIED MATHEMATICS HEBEI ACADEMY OF SCI

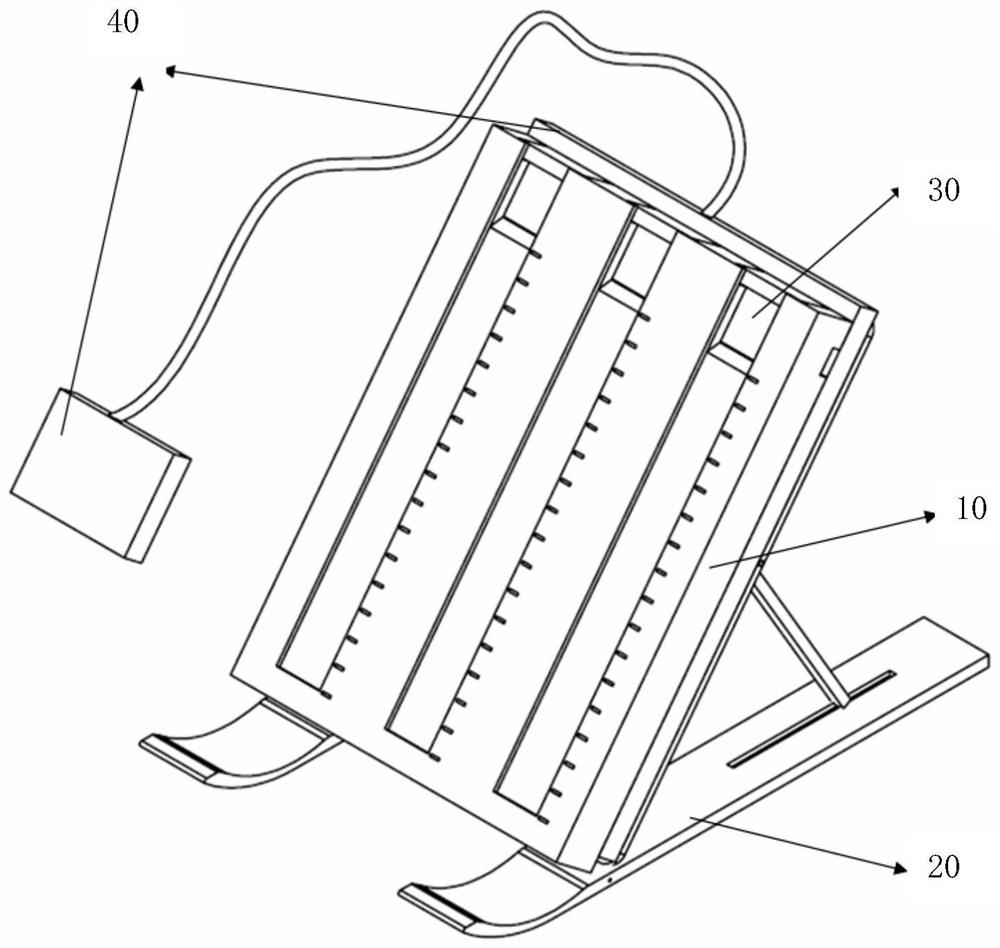

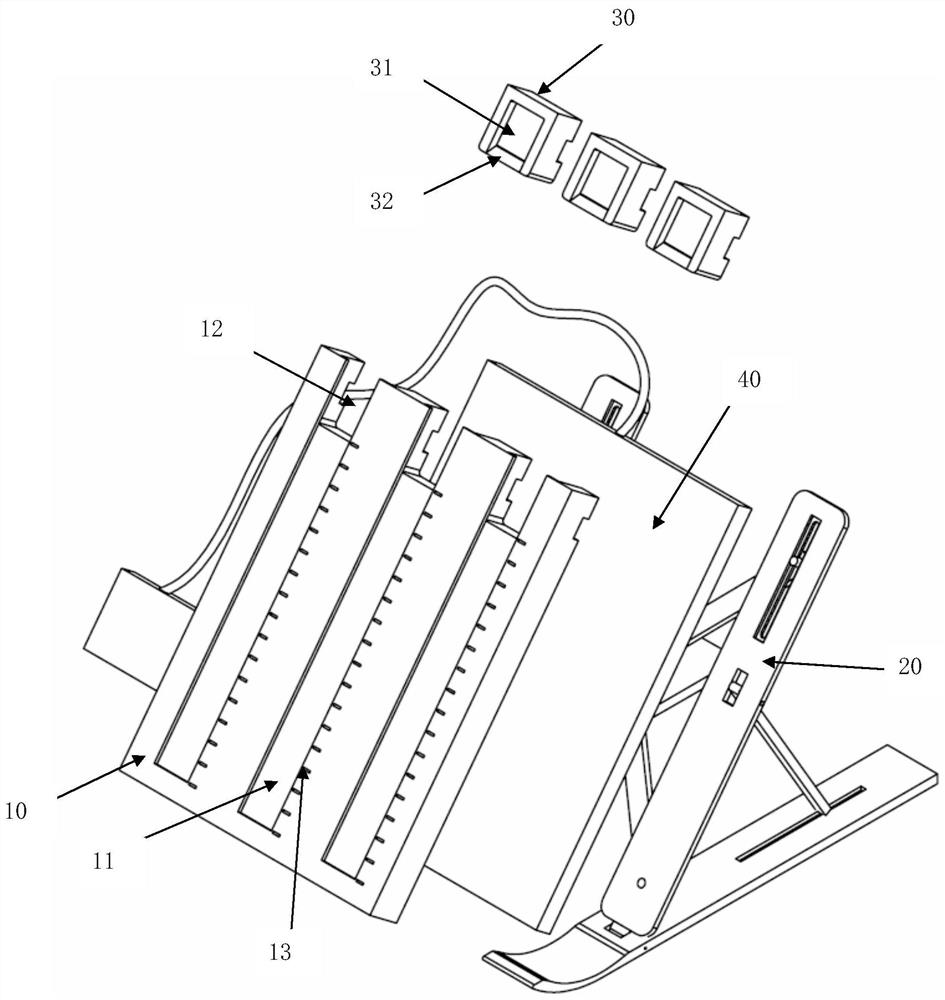

Color line fluidity detection device

The invention discloses a color line fluidity detection device. The color line fluidity detection device comprises a detection platform for color lines to flow, a color line accommodating mechanism, atemperature adjusting mechanism and an angle adjusting mechanism, wherein the detection platform is provided with a flow channel for a color line to flow, a distance measurement structure for measuring the flow distance of the color line and a mounting groove for placing a color line accommodating mechanism, the color line accommodating mechanism is at least used for accommodating the color lineto be detected, and the color line accommodating mechanism is detachably arranged in the mounting groove; the temperature adjusting mechanism is connected with the detection platform in a heat conduction mode, the detection platform is connected with the color line accommodating mechanism in a heat conduction mode, the angle adjusting mechanism comprises an angle-adjustable supporting frame, and the detection platform is fixedly arranged on the supporting frame. The color line fluidity detection device provided by the embodiment of the invention is simple in structure, convenient to assemble and use, and capable of accurately formulating research, development and production standards.

Owner:苏州圣瑞赛标识科技有限公司

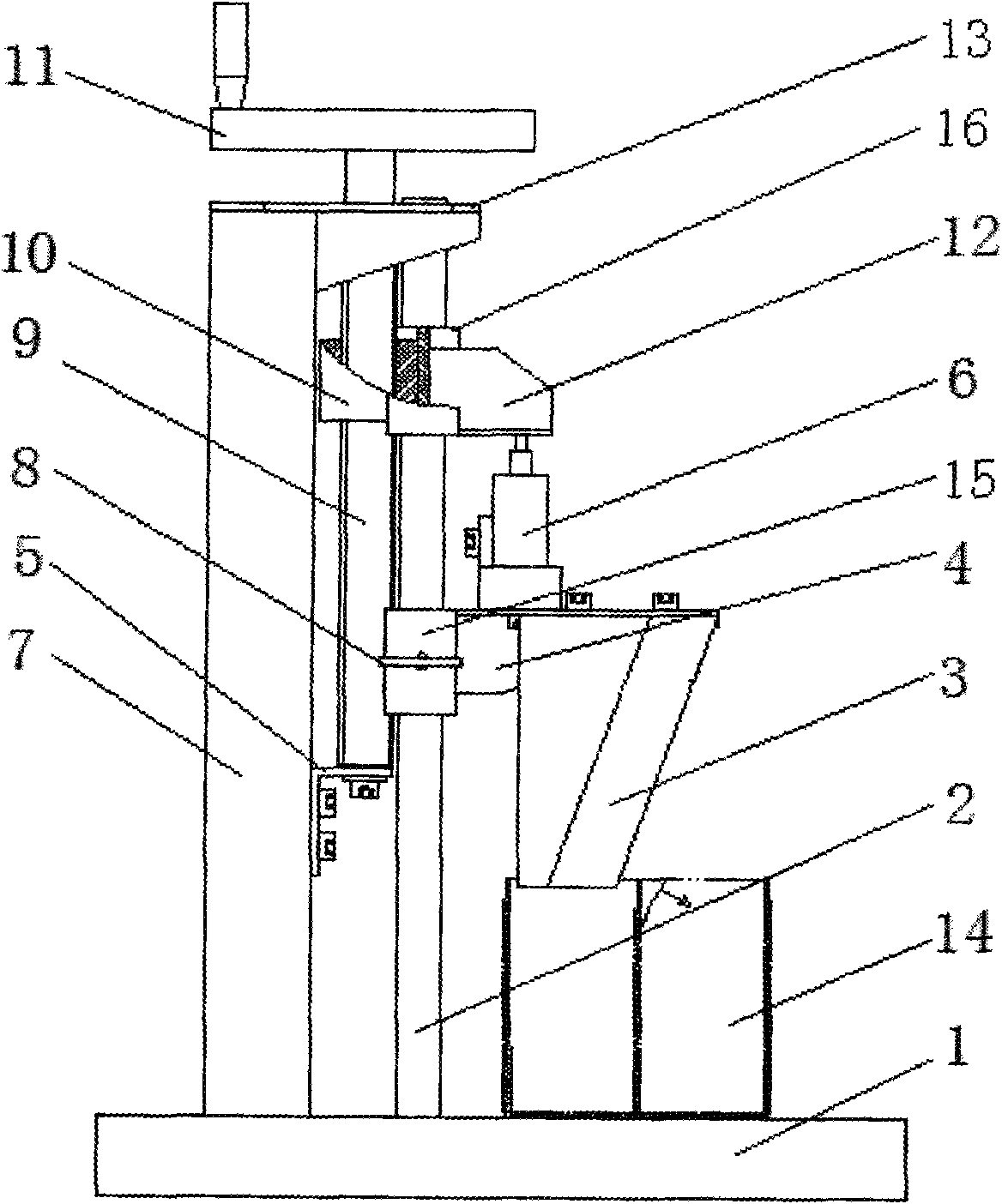

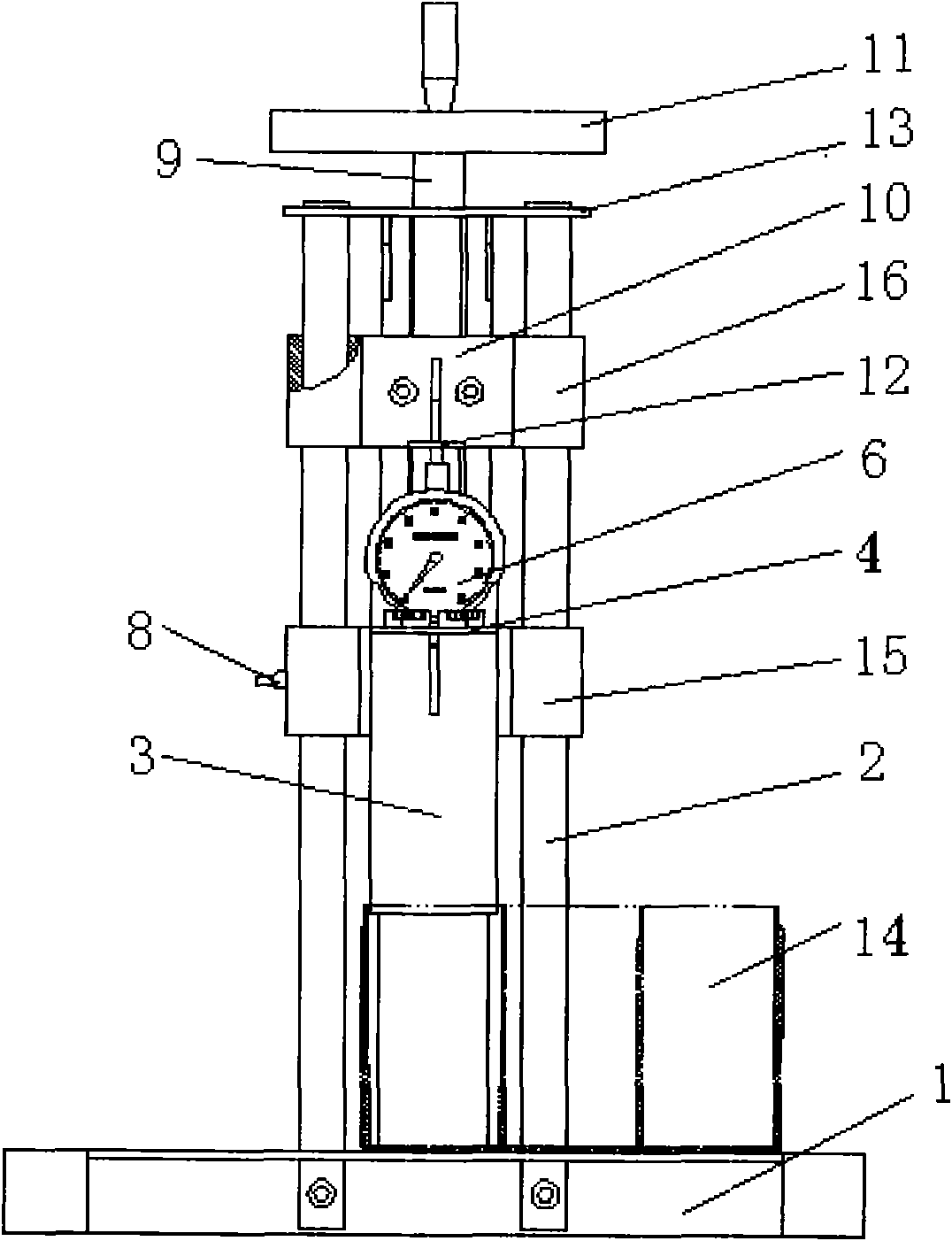

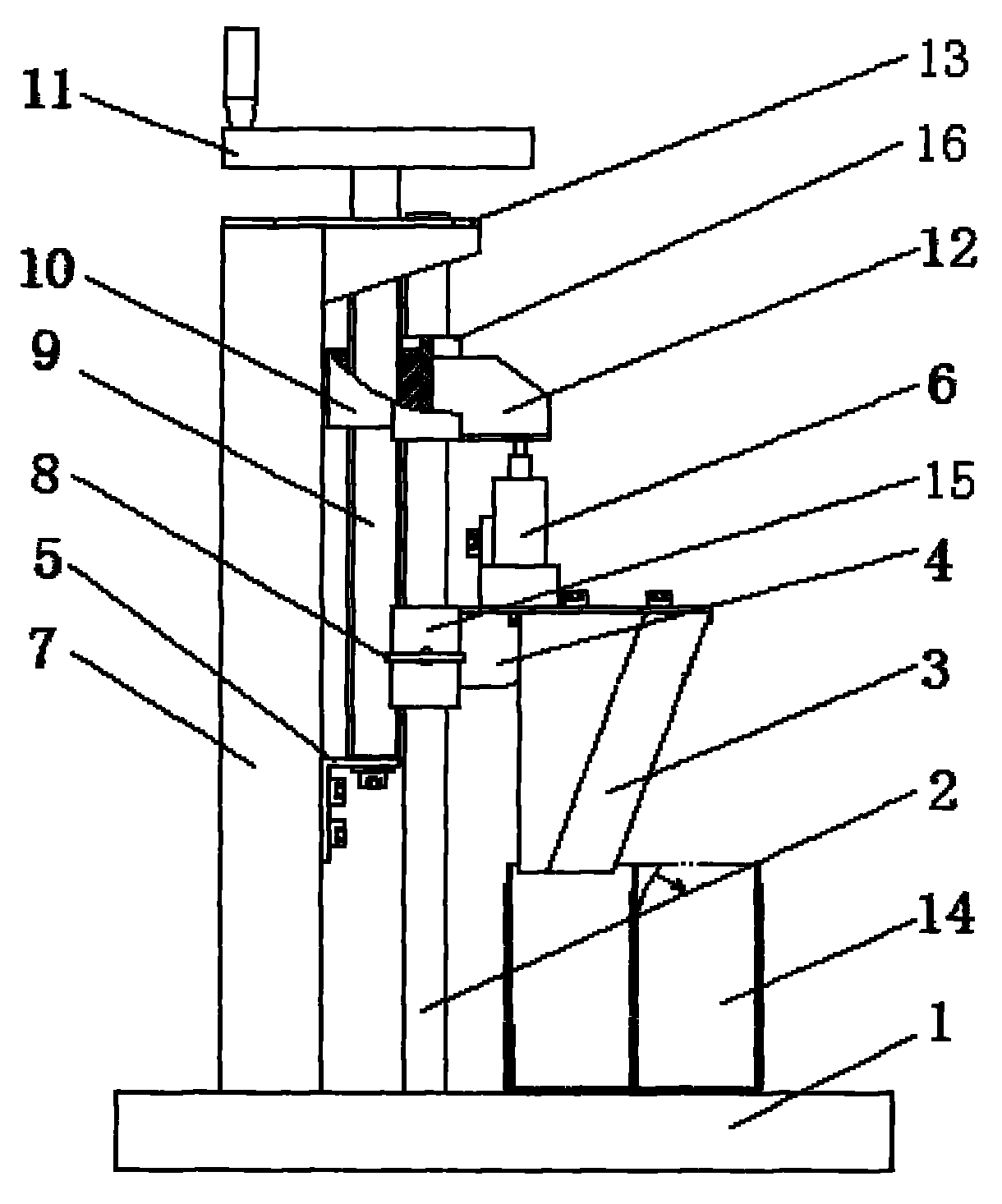

Opening strength detector for storage battery

ActiveCN101923023AAvoid damageThe detection process is fastMaterial strength using tensile/compressive forcesEngineeringUltimate tensile strength

The invention discloses an opening strength detector for a storage battery, comprising an upright post and a guide post, wherein the upright post is arranged between an upper worktable and a lower worktable; the guide post is movably connected with an upper sliding press block and a lower sliding press block; the upper sliding press block is in threaded connection with a screw rod arranged on the upright post; the lower sliding press block below the upper sliding press block is provided with a pressure gauge; during detection, the upper sliding press block is pressed on a contact of the pressure gauge; and an inclined press block is arranged below the lower sliding press block. The opening strength detector has high detection speed and unified detection standard. By using the opening strength detector, partition boards which do not meet the quality requirement can be checked in time and the defects that the qualities for net work procedure and the later batteries are influenced because the partition board between battery cells is triggered by a thumb of an operator is damaged in the process of polar group manual grooving can be avoided.

Owner:ZHEJIANG TIANNENG BATTERY JIANGSU +3

A zonal detection method for the coloring area of the ball seat of a ball joint and the fitting degree of the coloring area

ActiveCN108257168BSolve the problem of large errors in the judgment of the coloring areaAvoid the problem of poor detection data stabilityGeometric CADImage analysisComputer visionMATLAB

The invention provides a partition detection method for the painted area of a ball seat of a ball joint and the bonding degree of the painted area. A grayscale camera is used to obtain a top view of the assembled ball seat that has been painted by the ball pin. In the Matlab environment, all the pixels of the overhead view are traversed, and after image preprocessing to eliminate noise, edge detection is performed on the gray image above based on the region growth method of seed points, so as to obtain the distance of each pixel where the boundary line of the painted area of the ball seat is located. Coordinate values, and further divide the area within the above boundary line twice, and finally determine the area of the inner spherical surface of the ball seat represented by the different fit degrees in the colored area of the ball seat based on the size range of the gray value of the pixel point. The detection results obtained by the detection method of the present invention have good stability and true and reliable data, and at the same time provide real and effective basic data for other related experiments on ball joints, thus improving the detection efficiency in the entire detection chain of ball joint products .

Owner:JIANGSU JUJIE ELECTROMECHANICAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com