System for automatically detecting flaws of dialysis tube

An automatic detection and dialysis tube technology, applied in the field of detection system, can solve problems such as drop, low detection efficiency, eye fatigue judgment, etc., and achieve the effect of unifying detection standards, improving work efficiency and shortening detection time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

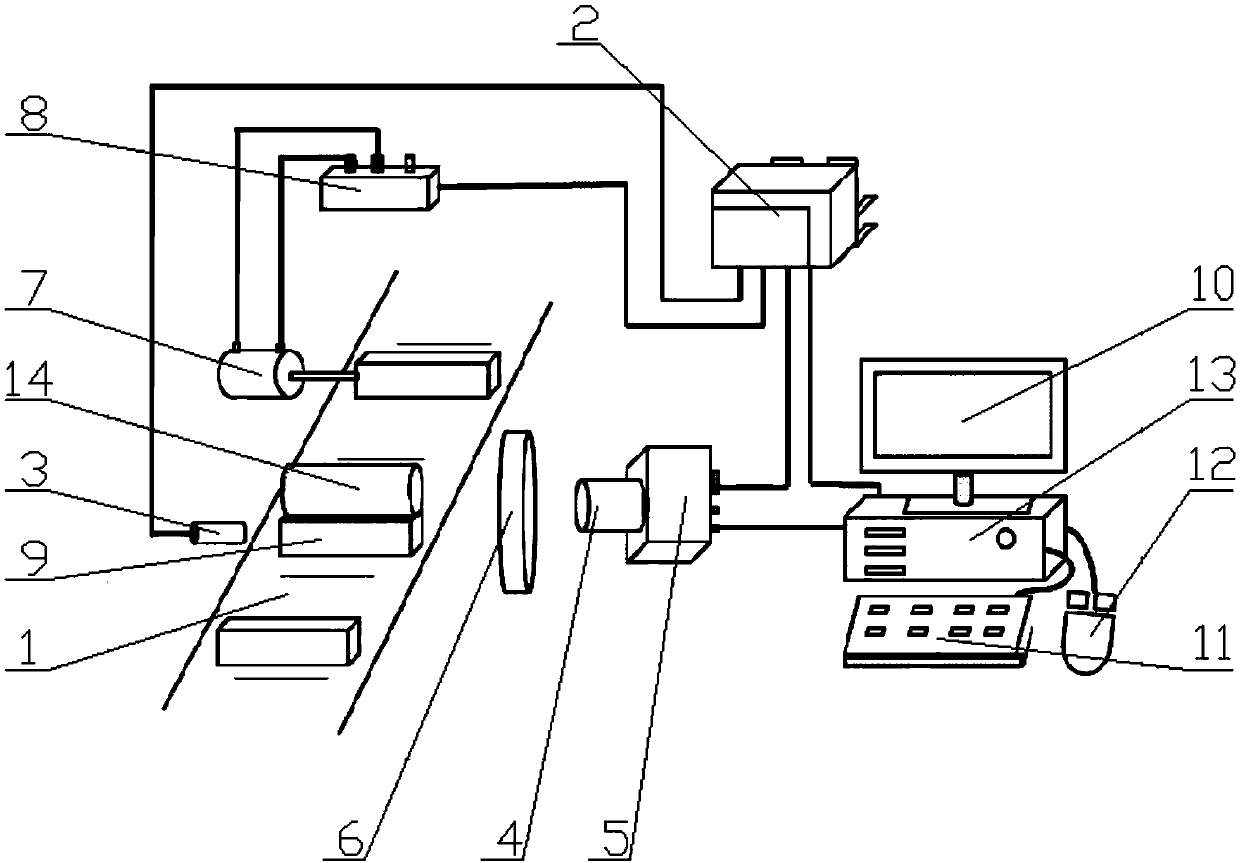

[0027] Such as figure 1 A dialysis tube defect automatic detection system shown, the system includes: transmission track 1, lighting device, PLC2, image acquisition device, image processing device and rejection device; wherein,

[0028] The transmission track 1 is used to place the dialysis tube 14 to be tested;

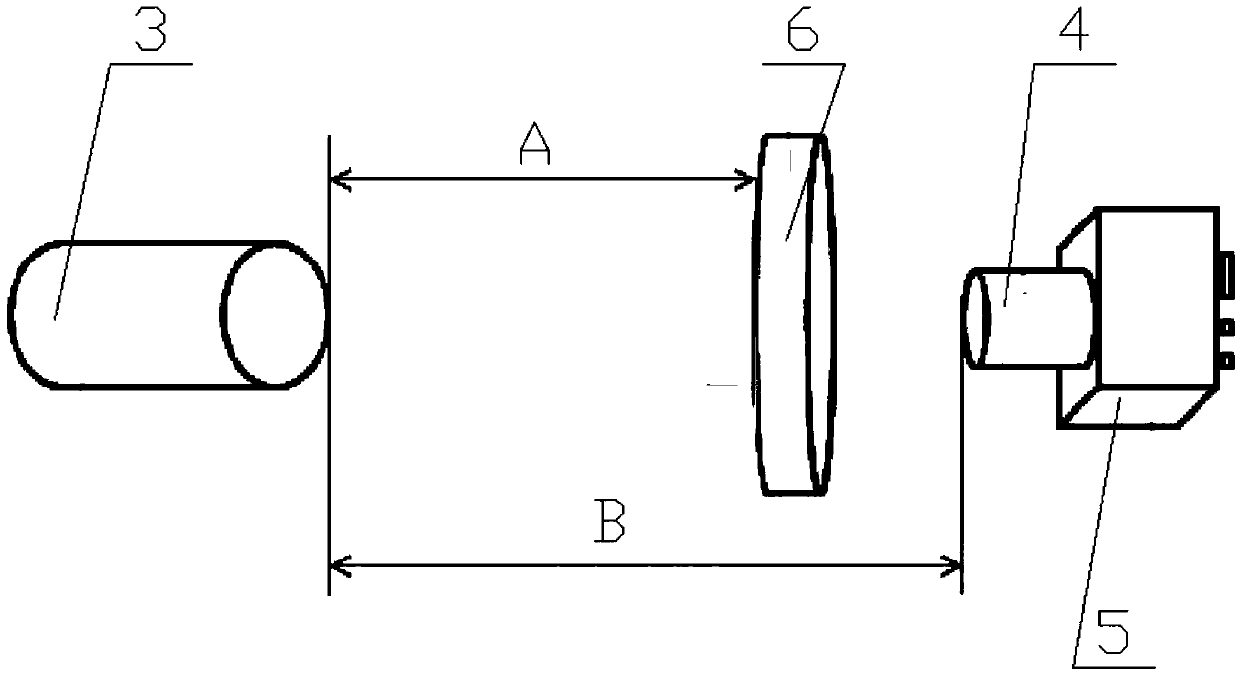

[0029] A lighting device, used to provide lighting for the image acquisition device;

[0030] The image acquisition device is used to collect the original image image of the dialysis tube; it is set corresponding to the lighting device;

[0031] an image processing device, configured to process the original image captured by the image capture device;

[0032] The rejecting device is used for rejecting the defective dialysis tubes indicated by the processing result of the image processing device;

[0033] PLC2 is connected with the image processing device for receiving the image processing result; connected with the rejecting device for controlling the rejecting de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com