Method for detecting inter-layer displacement of multi-layer flexible printed circuit board

A printed circuit board and flexible technology, which is applied in the field of multilayer flexible printed circuit board manufacturing, can solve the problems of uneven inspection results, misjudgment of defective products into good products, and reduced production efficiency, so as to reduce the capacity Requirements, unified testing standards, and the effect of improving testing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings.

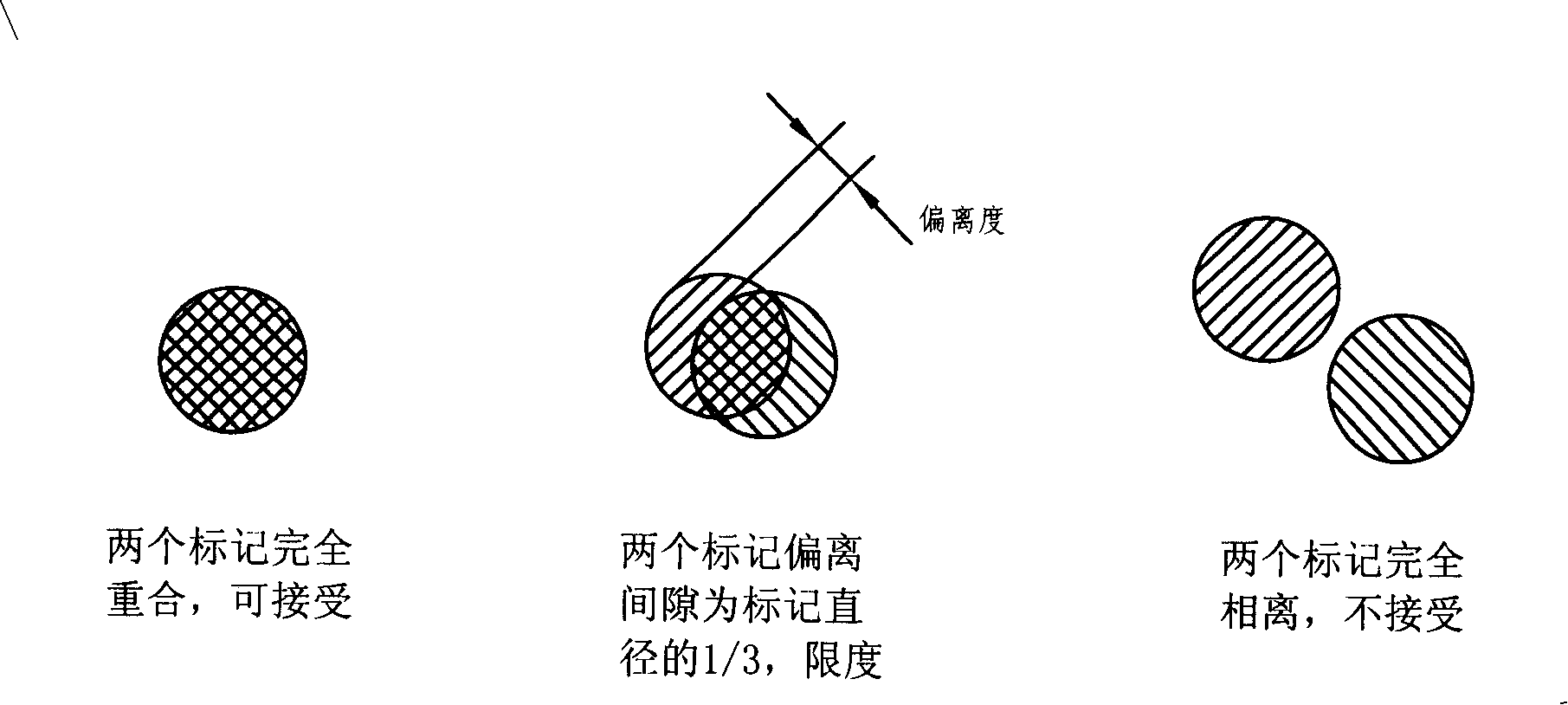

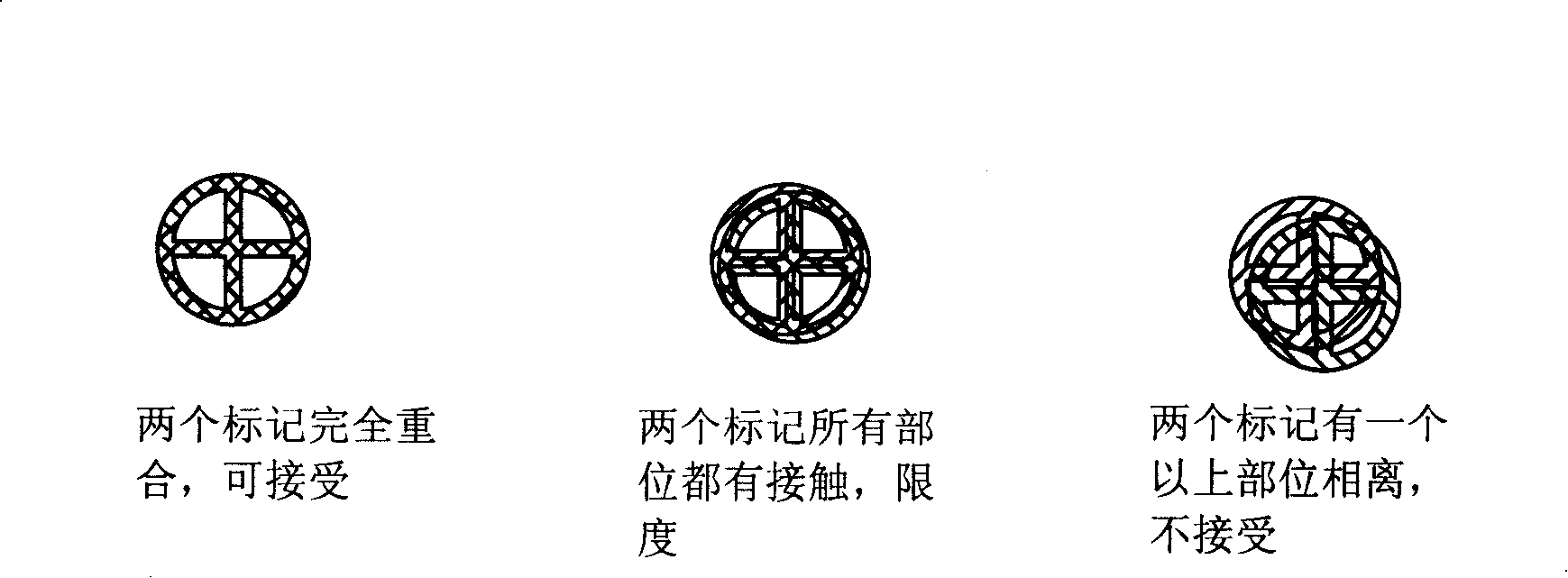

[0019] The present invention respectively etches a circular alignment mark on each layer of the flexible printed circuit board that needs to be aligned, such as image 3 As shown, the alignment mark is a ring-shaped composite mark with a socketed cross. The line width of the cross in the composite mark and the accuracy requirements for the offset between product layers are the same, and the requirements for offset between different product layers Different line widths can be designed, so it can meet the interlayer offset judgment requirements of all products.

[0020] For example, when the pad size of a certain type of multilayer flexible printed circuit board is 0.60mm, and the drilling hole is 0.20mm, then the alignment accuracy should be at least 0.20mm to ensure product quality, but some customers will The accuracy puts f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com