High efficiency constant current LED driver

a constant current led driver, high efficiency technology, applied in the direction of electroluminescent light sources, electric lighting sources, semiconductor lamp usage, etc., can solve the problems of narrow operating frequency range, limited modulation capability of the frequency for the gain, and insufficient frequency rang

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

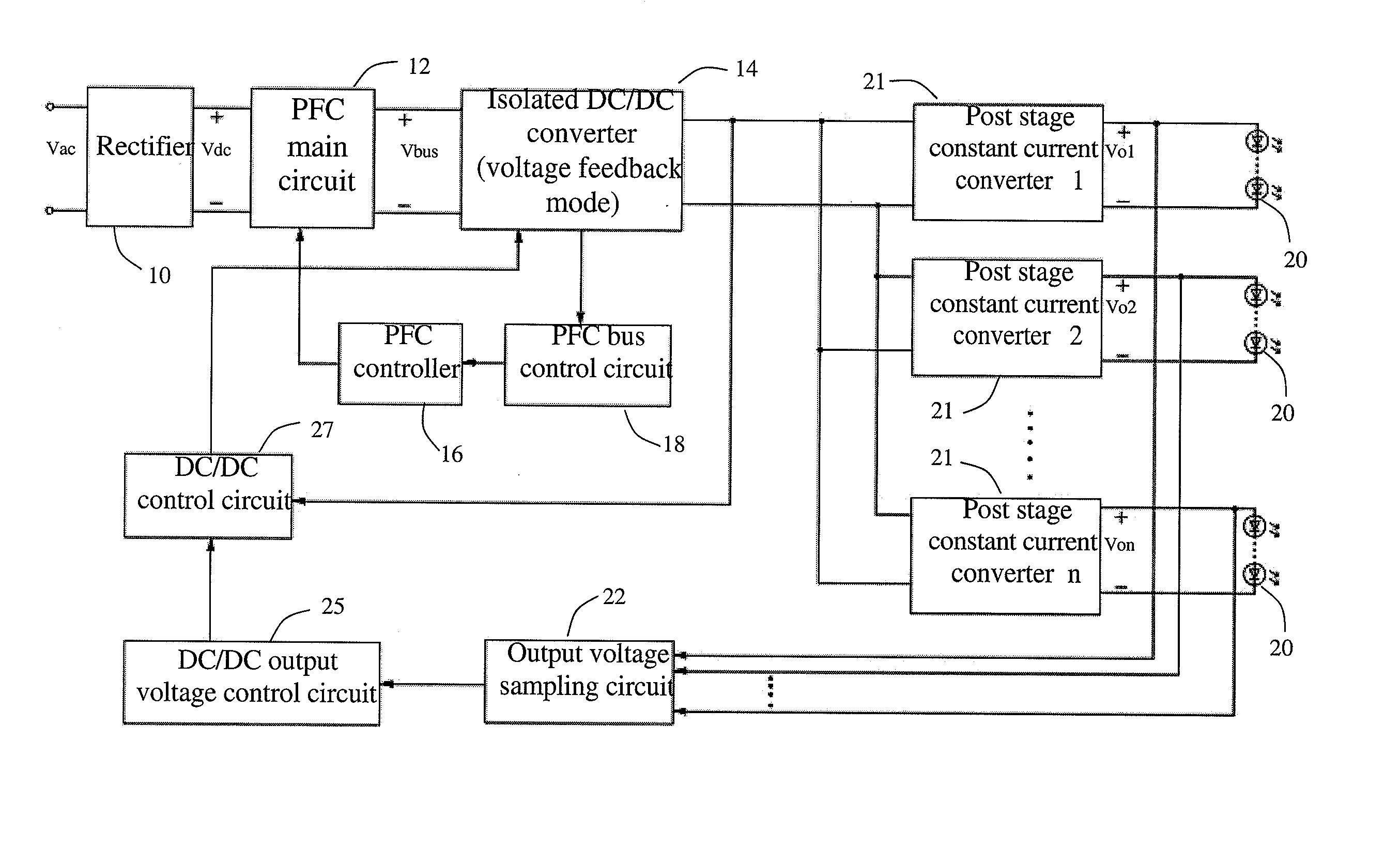

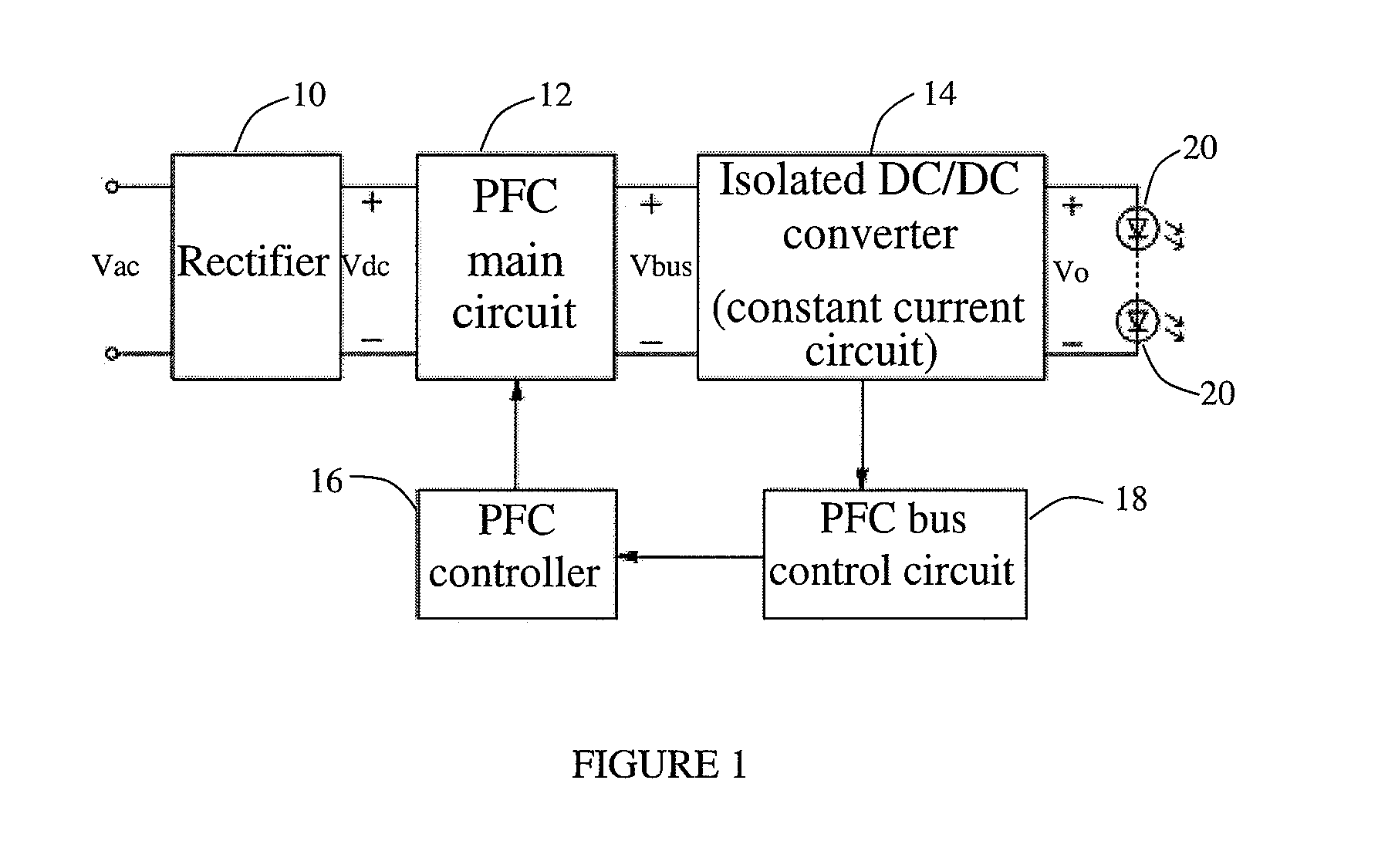

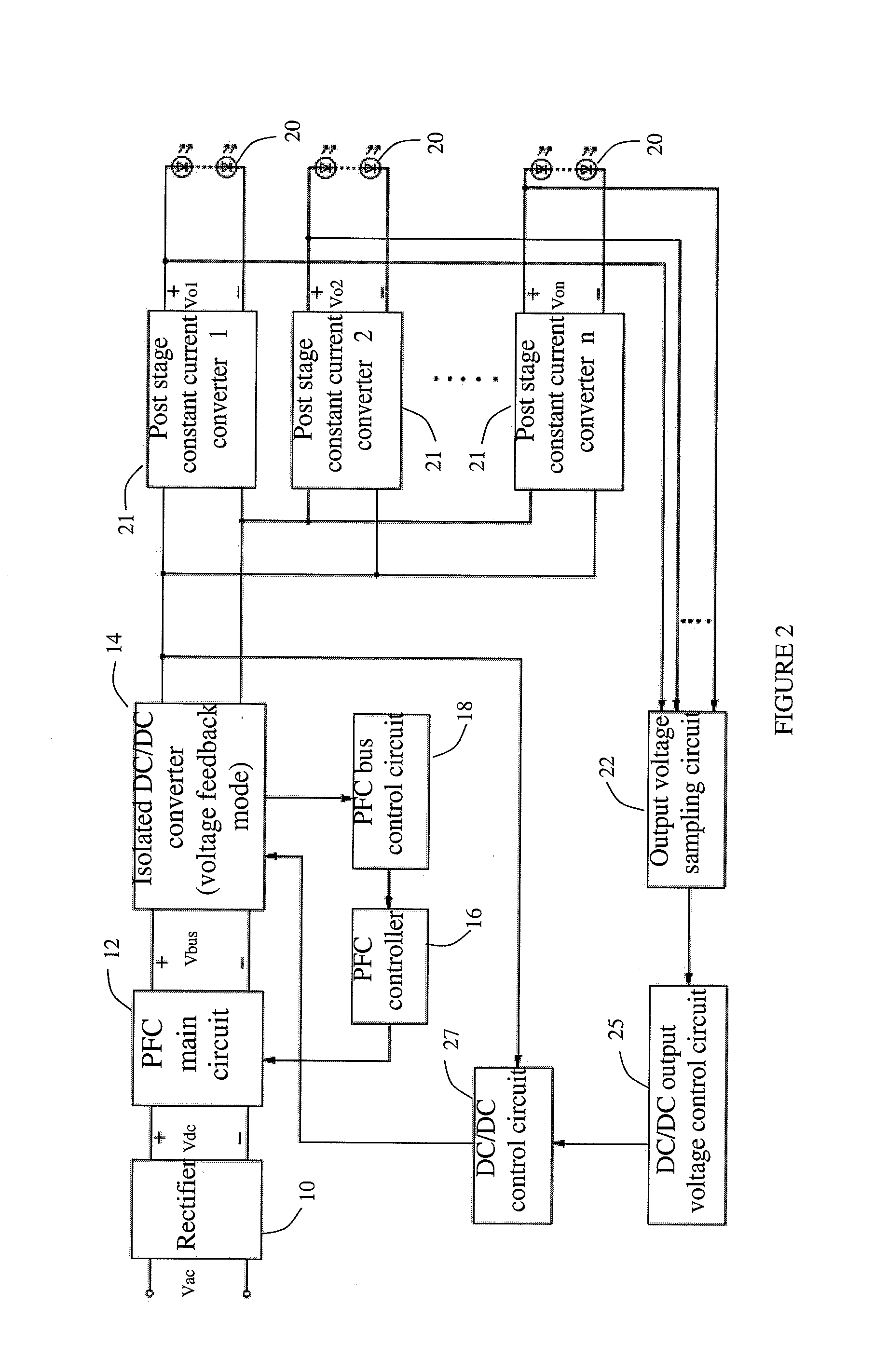

[0017]FIG. 1 discloses a block diagram illustrating an exemplary embodiment of a high efficiency constant current LED driver. The high efficiency constant current LED driver comprises a rectification bridge 10, a PFC main circuit 12, an isolated DC / DC converter 14, a PFC controller 16, and a PFC bus control circuit 18. The rectification bridge 10 rectifies the AC input voltage (Vac) and then outputs the DC voltage (Vdc) to the PFC main circuit 12. The PFC main circuit 12 receives the dc voltage (Vdc) from the rectification bridge 10 and the feedback voltage from the PFC controller 16, and then outputs the DC voltage (Vbus) to the DC / DC converter 14 through a PFC circuit. The isolated DC / DC converter 14 receives the DC voltage (Vbus) from the PFC main circuit 12, and then outputs a DC voltage (Vo) to the LED load 20 through a DC / DC converter and supplies a constant current to the LED load 20. The PFC controller 16 receives the control signal from the PFC bus control circuit 18, and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com