Ball seat coating area for spherical hinge and partition detecting method of coating zone fitting degree

A detection method and tee technology, which are applied in image analysis, image data processing, instruments, etc., can solve the problems of large boundary line judgment errors, low efficiency, and low boundary recognition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with the accompanying drawings.

[0045] The present invention adopts the following technical scheme: a method for detecting the painted area of a ball seat of a ball joint, which is characterized in that it includes the following steps:

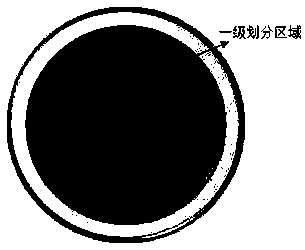

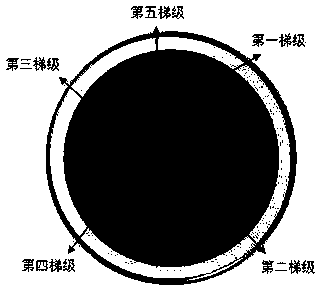

[0046] (a) Evenly paint the outer spherical surface of the ball pin of the ball joint used in automobiles, and assemble the painted ball pin into the ball joint structure. The ball joint structure is the ball pin, ball seat, The ball sleeve, the ball pin in the ball joint structure can freely rotate or swing along the central axis of the spherical surface of the ball seat, wherein the maximum swing angle of the ball pin is determined by the height of the cylinder of the ball sleeve and the size of the inner and outer diameters; The wire cutting method performs wire cutting on the ball sleeve of the ball joint along the section direction where the central axis of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com