Opening strength detector for storage battery

A technology of strength detection and battery shell, which is applied in the direction of applying stable tension/pressure to test the strength of materials, and achieves the effect of uniform detection standards and fast detection speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

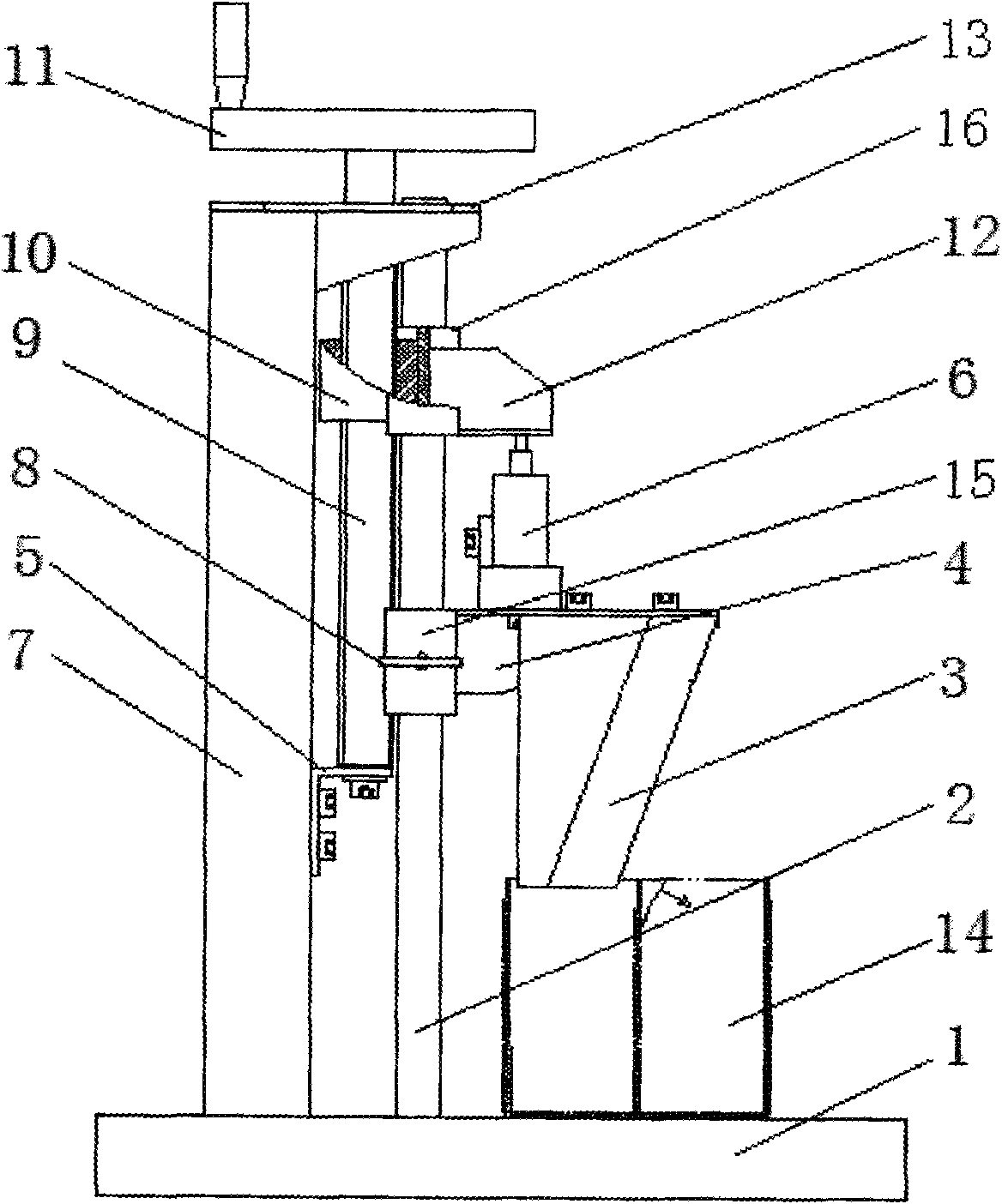

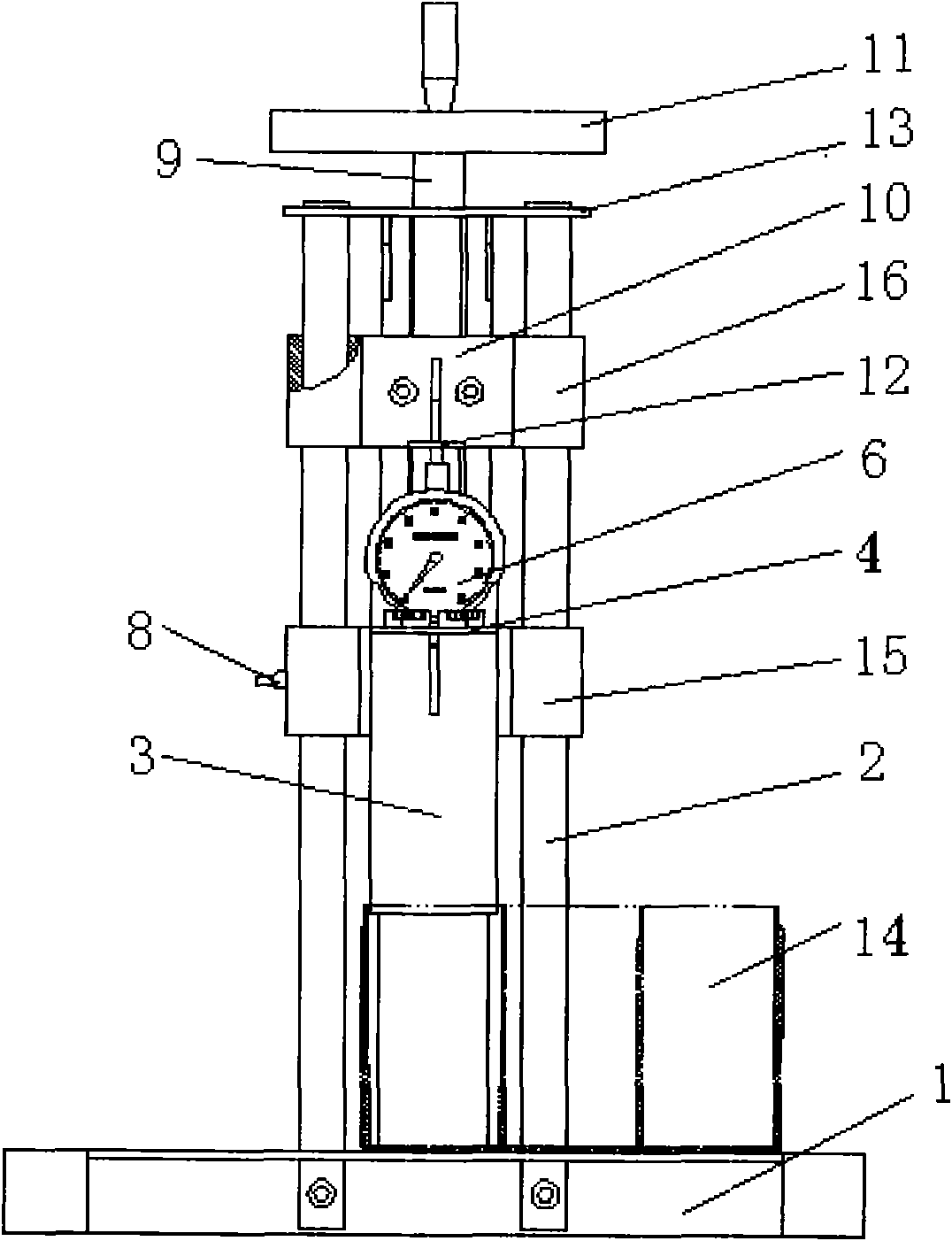

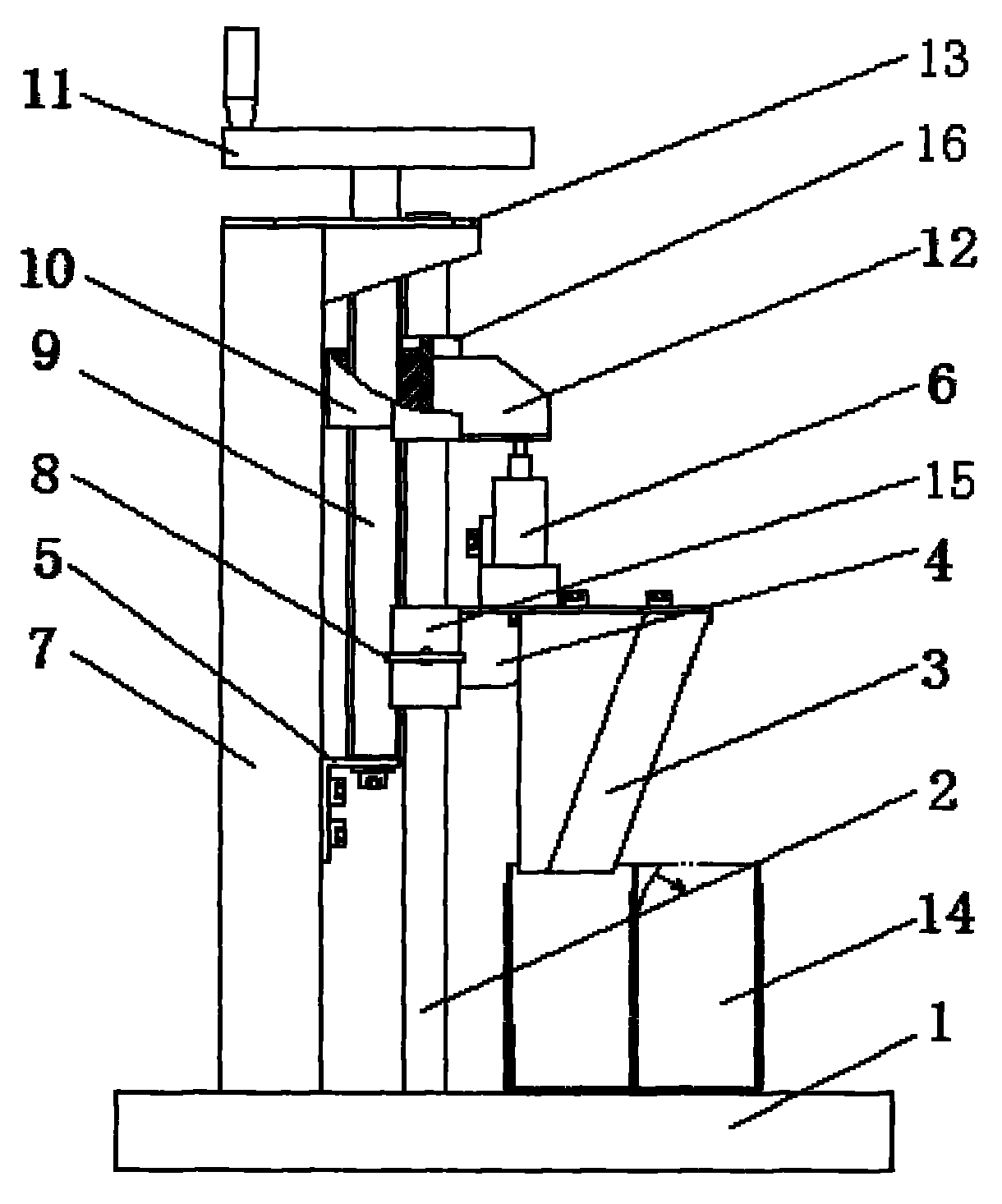

[0014] Such as figure 1 , 2 As shown, a battery case opening strength tester includes a column 7 and a guide column 2 arranged between the upper and lower workbenches 1 and 13, and the guide column 2 is movably connected with an upper sliding pressing block 12 and a lower sliding pressing block. 4. The upper sliding briquetting block 12 is threadedly connected with the lead screw 9 set on the column 7, and the lower sliding briquetting block 4 below the upper sliding briquetting block 12 is provided with a pressure gauge 6, and the upper sliding briquetting block 12 is pressed against the pressure during detection. For the contacts in Table 6, an oblique pressing block 3 is arranged below the lower sliding pressing block 4 . The side of the oblique pressing block 3 facing the guide column 2 is a vertical surface, and the opposite side is a slope, and the vertical angle is 15 degrees.

[0015] still as figure 1 , 2 As shown, the upper sliding pressing block 12 and the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com