Detection system of PVDF membrane

A detection system and technology to be detected, applied in measuring devices, optical testing of flaws/defects, material analysis through optical means, etc., can solve problems such as tailing, obvious wrinkles, black spots, etc., achieve low labor costs and improve production The effect of high quality and detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to further understand the present invention, the preferred embodiments of the present invention are described below in conjunction with examples, but it should be understood that these descriptions are only to further illustrate the features and advantages of the present invention, rather than limiting the claims of the present invention.

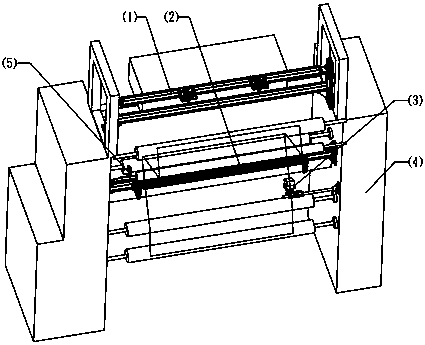

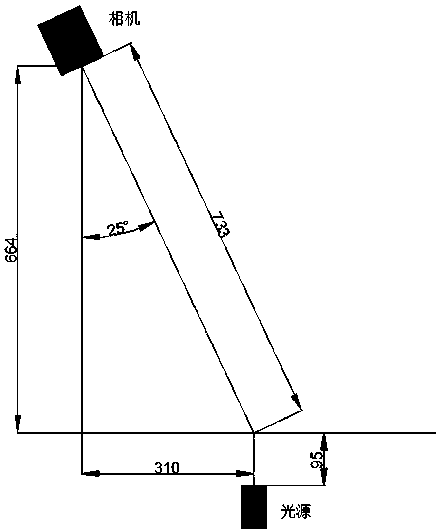

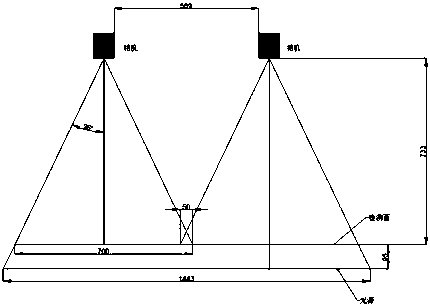

[0033] The embodiment of the present invention provides a PVDF film detection system, such as figure 1 As shown, it includes a light source assembly 2 configured on the PVDF film production line 4 for irradiating the PVDF film to be inspected, a camera assembly 1 for photographing the PVDF film to be inspected, and a marking assembly for marking defect parts on the PVDF film to be inspected. 3 and a meter counter component 5 for detecting the conveying distance of the PVDF film to be detected, and a computer connected to the light source component, camera component, marking component and meter counter component respectively. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com