Self-test method for LCD display with camera

A camera and display technology, applied in optics, instruments, closed-circuit television systems, etc., can solve the problems of uncertain judgment standards, prone to errors, and easy human fatigue, so as to achieve efficient judgment and testing, and avoid errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

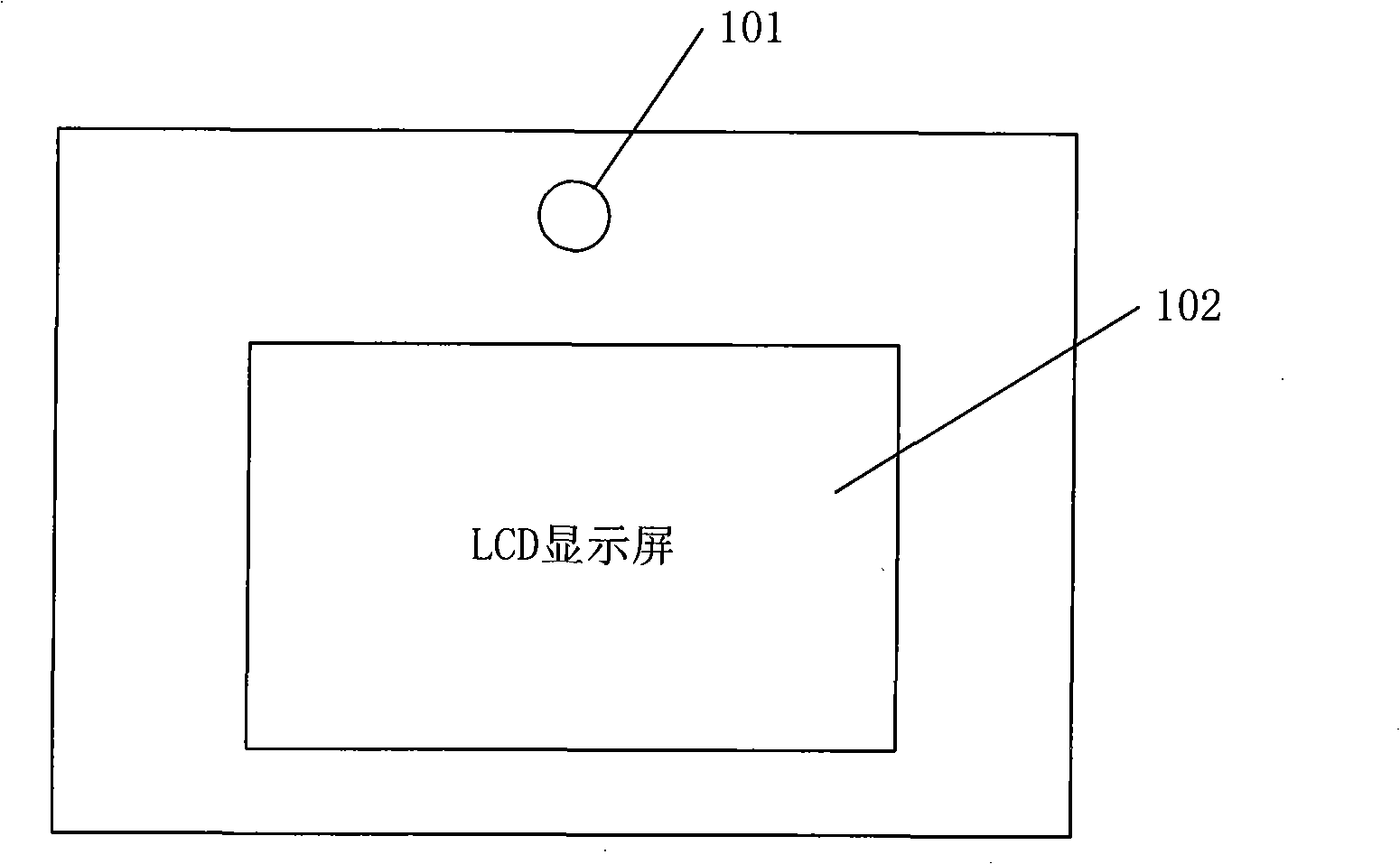

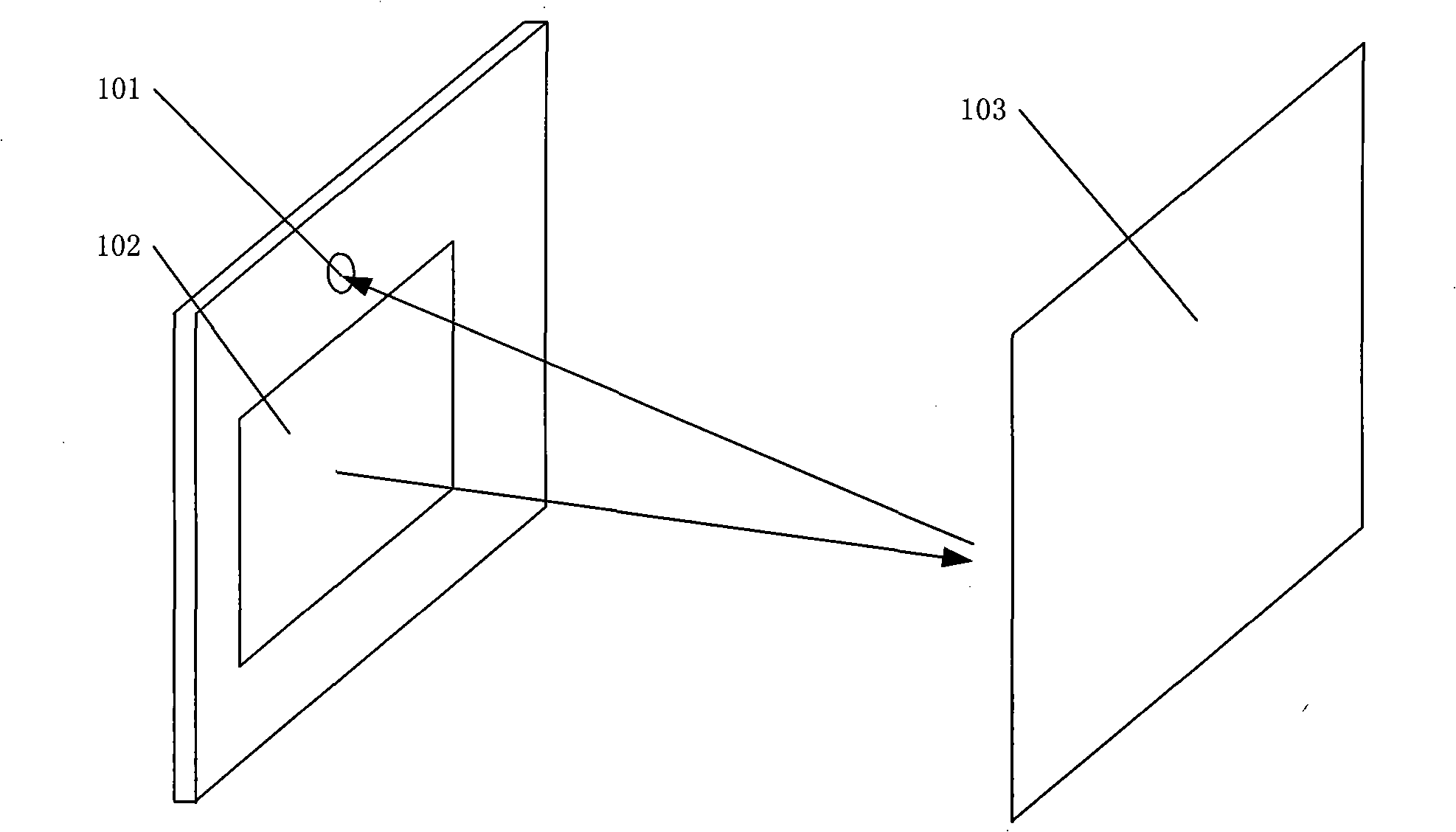

[0056] Such as figure 1 As shown, a product to be inspected includes an LCD display 102 and a camera 101 above it. The present invention utilizes the characteristic that the product to be tested has a camera 101 and an LCD display 102 at the same time, and utilizes simple external equipment, such as figure 2 A mirror 103 is shown as a reflective mirror surface, so that the camera 101 of the device under test can obtain the output image of its LCD display screen 102 through the mirror surface 103 . Here, by adjusting the positions of the product to be inspected and the mirror surface 103 , the camera 101 can completely capture the display area of the LCD display screen 102 . .

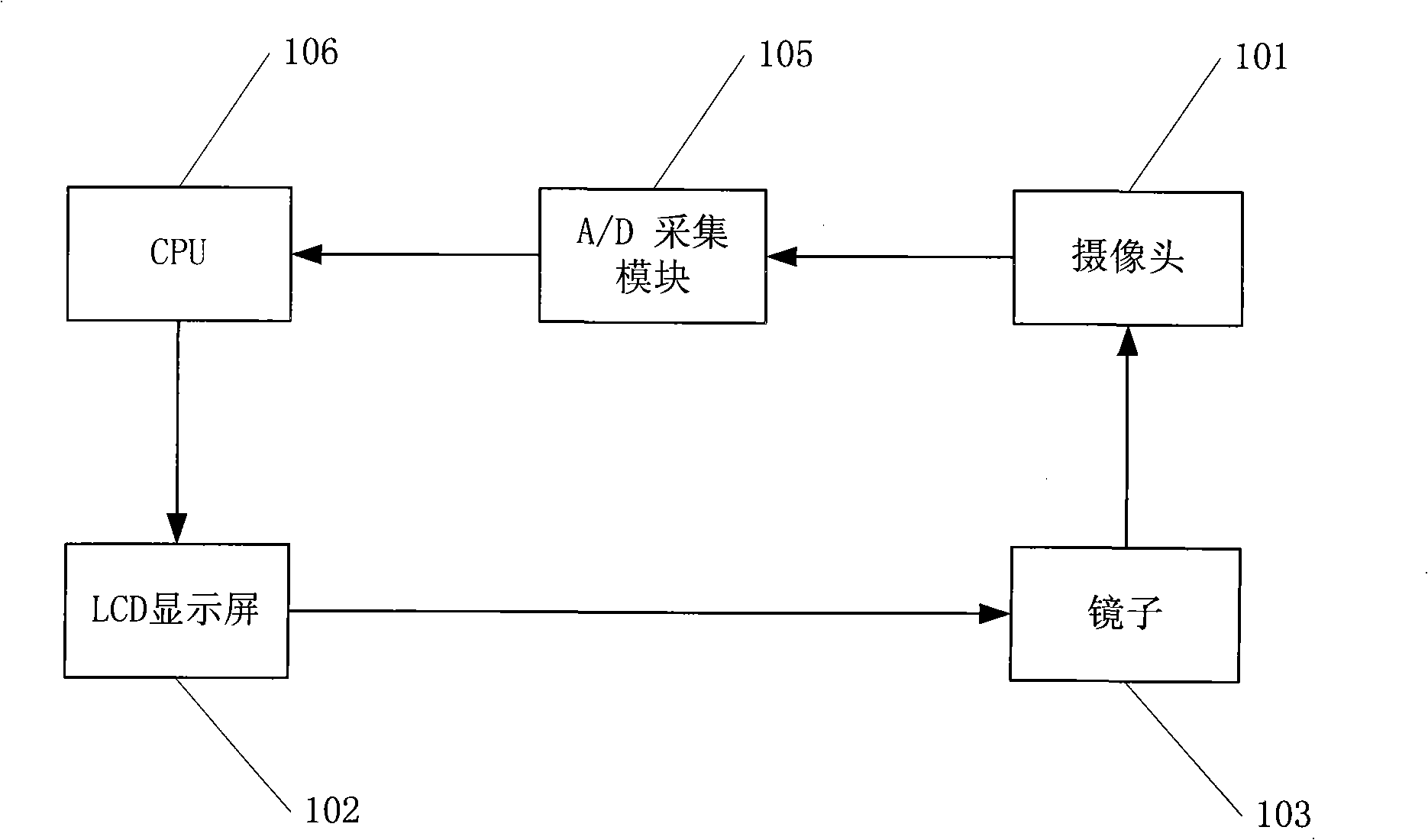

[0057] Such as image 3 As shown, the image output from the LCD display screen 102 fed back from the mirror 103 passes through the camera 101 , the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com