A rotary transmission device used for precision detection mechanism of pharmaceutical glass bottle production line

A technology for medicinal glass bottles and testing institutions, which is applied in the directions of transportation and packaging, conveyor objects, etc., can solve the problems of difficulty in ensuring the uniformity of final product quality, large differences in standards, and large labor costs, so as to ensure safety and avoid problems. Safety incidents, accurate and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

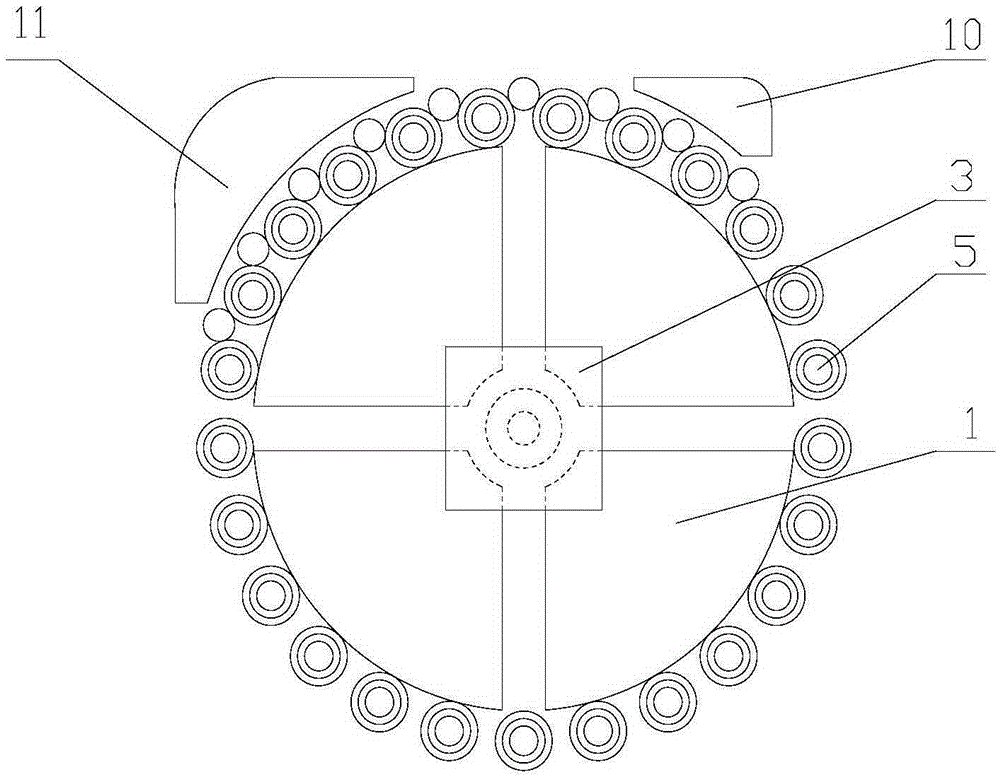

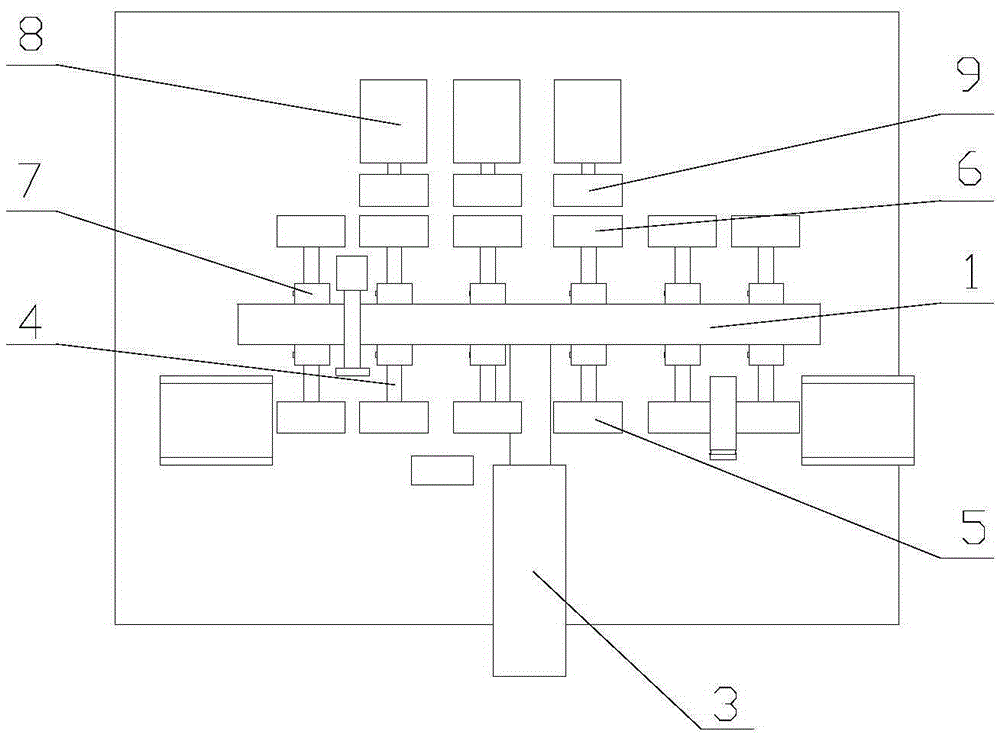

[0035] During operation, the medical glass bottle to be inspected falls into the groove between the front rollers 5 along with the conveying device, and reaches the top of the turntable 1 with the rotation of the turntable 1, when it corresponds to the front roller 5 that blocks the medical glass bottle When the rear roller 6 reaches the position corresponding to the roller 9, the turntable 1 stops rotating, and the roller 9 drives the rear roller 6 to start to rotate in the same direction, and the medicinal glass between the front rollers 5 rotates accordingly, and the camera device detects the bottle Take pictures in person, and transmit the shooting results to the computer inspection system.

[0036] Then the roller 9 and the rear roller 6 stop rotating, the turntable 1 starts to rotate, the rear roller 6 moves forward a position of the roller 9, the turntable 1 stops rotating, and the roller 9 drives the rear roller 6 to start to rotate in the same direction, and is located...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com