Cross-cut testing machine and method

A detection machine and cross-cutting technology, which is applied in the direction of measuring devices, testing wear resistance, testing machinability, etc., can solve the problems of time-consuming and laborious, manual quality inspection, and large differences in testing standards, and achieve high efficiency and automation High and uniform testing standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

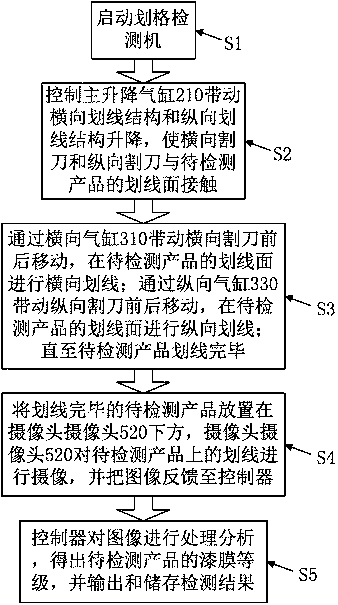

Method used

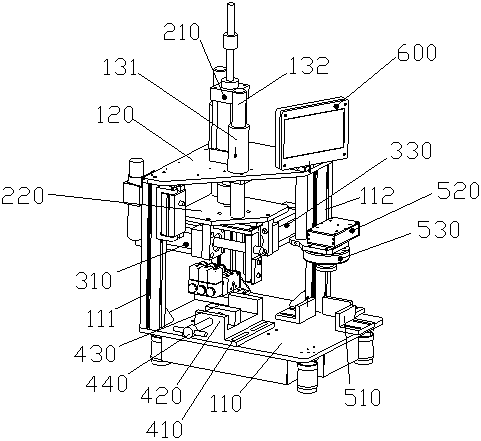

Image

Examples

Embodiment 2

[0053] Specifically, the specific structure of the fixture structure can be set according to the specific needs of the product to be inspected. In this embodiment, the fixture structure is specifically provided with the following two structures: Embodiment 1: The fixture structure includes a fixture mounting seat 410 disposed on the installation base 110 and two vertical limiters disposed on the fixture mounting seat 410 The position plate 420 is provided with a moving guide rod between the two vertical limit plates 420, and the two ends of the mobile guide rod are respectively fixedly connected with the two vertical limit plates 420. Between 420, a fixed clip 430 is arranged, and the fixed clip 430 passes through the moving guide rod and moves back and forth along the moving guide rod. A screw hole is arranged on one of the vertical limit plates 420, and one end of the screw rod 440 is connected with the fixed clip. The block 430 is connected, and the other end of the screw r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com