Cleaning device for roof of plastic greenhouse

A technology for cleaning devices and plastic greenhouses, applied in cleaning methods and appliances, greenhouse cultivation, climate change adaptation, etc., can solve the problems of high risk, limited use conditions, low degree of automation, etc., achieve light weight, ensure the quality of use, The effect of high-efficiency cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

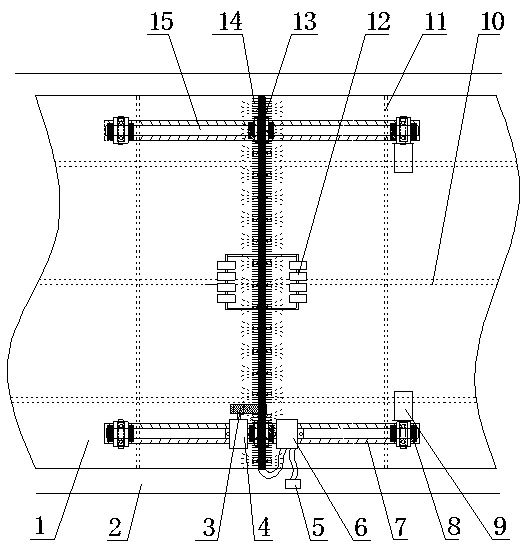

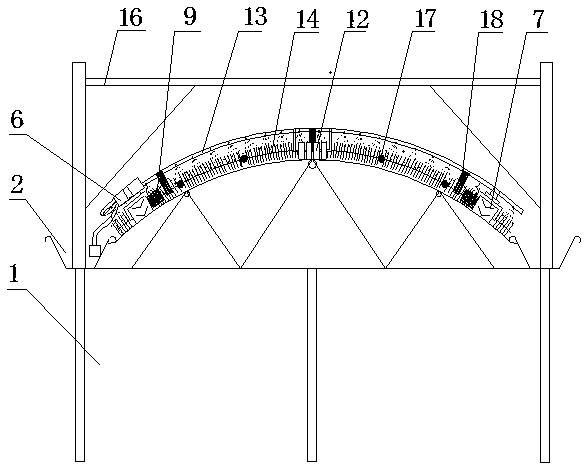

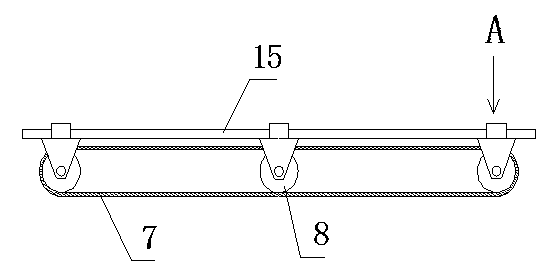

[0021] Such as Figure 1 to Figure 5 As shown, a plastic greenhouse roof cleaning device mainly includes a cleaning mechanism and a walking mechanism. The cleaning mechanism is composed of a water spray pipe 13 and a brush roller 14 arched with the plastic greenhouse 1, and a water pump is installed at one end of the water spray pipe 13. 6. The water pump 6 pumps water directly from the gutter 2 of the greenhouse through the water filter 5 to supply the water spray pipe 13. There are two rows of water spray holes in the front and rear of the water spray pipe 13. The water spray in the front row plays a role of wetting, and the water spray in the rear row plays a role in cleaning . Spray pipe 13 is installed on the support bar 15 of walking mechanism, also is the suspension of whole device simultaneously, and arched hair brush roller 14 is inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com