Motor detection device for automobile manufacturing

A detection device and automobile manufacturing technology, which is applied in the direction of measuring devices, measuring device casings, motor generator testing, etc., can solve the problems of inaccuracy, lack of unified standards, low efficiency of manual detection, etc., and achieve rigorous design, convenient and fast use, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

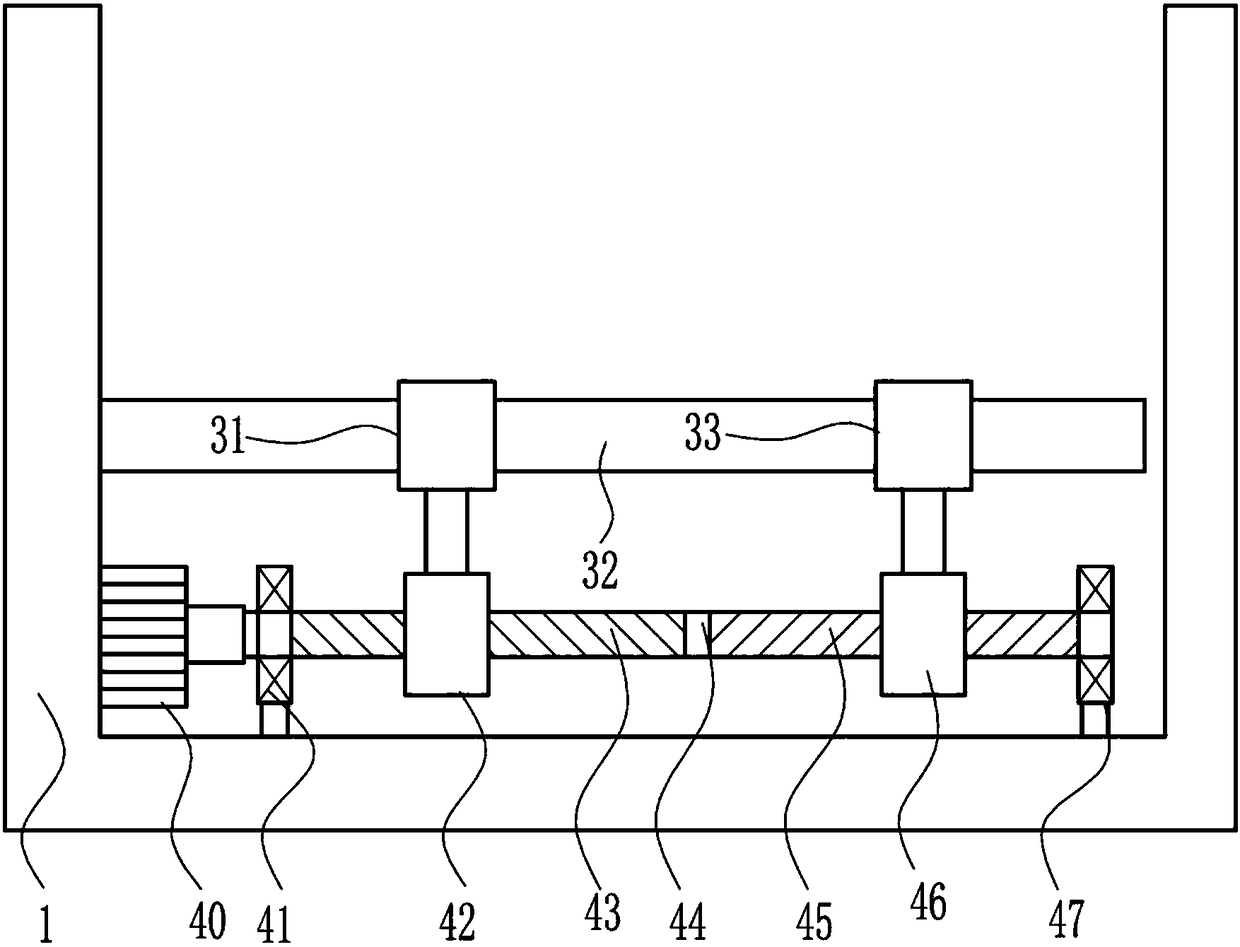

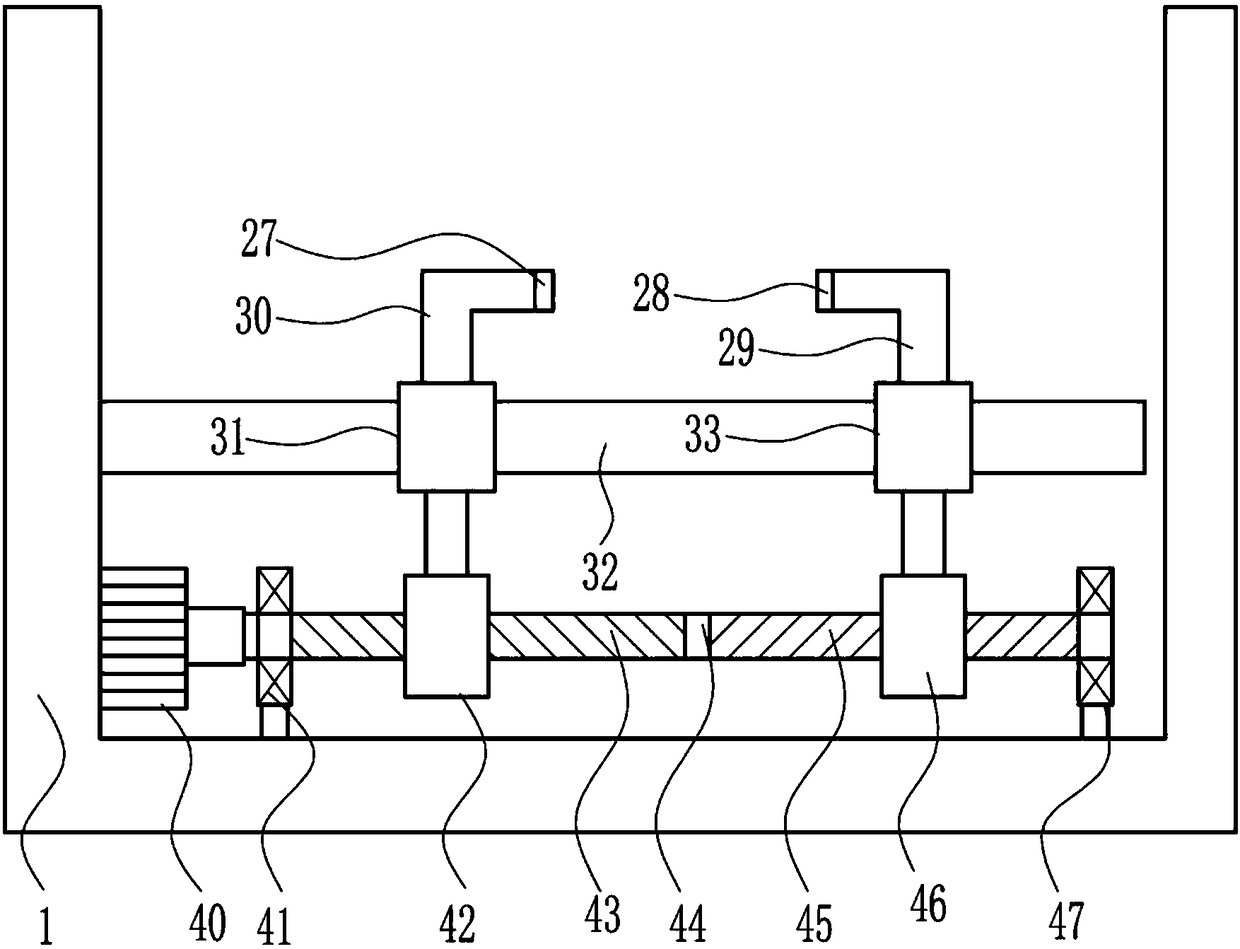

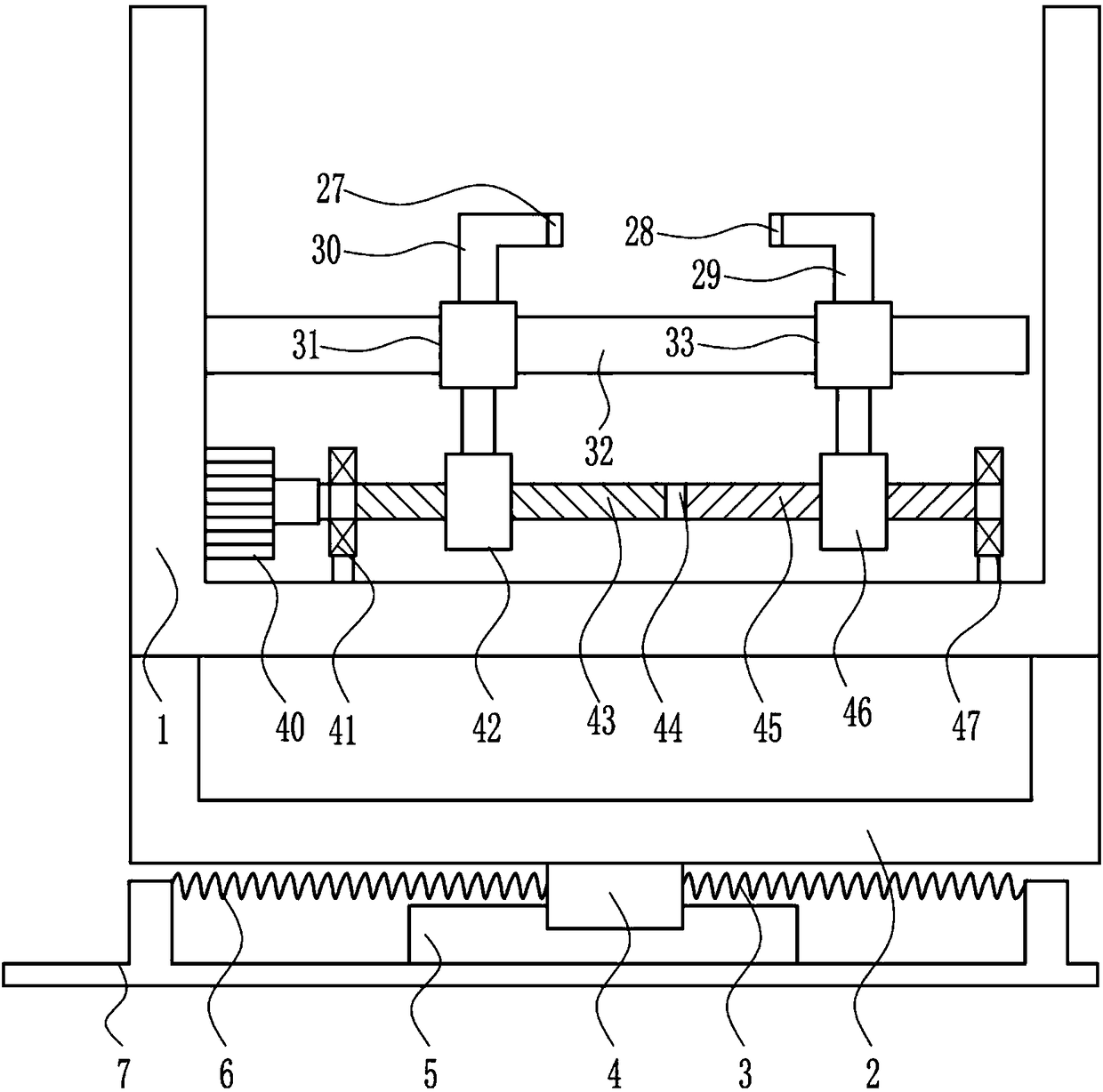

[0025] A motor detection device for automobile manufacturing, such as Figure 1-4 As shown, it includes a fixed frame 1, a first sliding sleeve 31, a sliding rod 32, a second sliding sleeve 33, a second motor 40, a second bearing 41, a first screw nut 42, a first screw rod 43, and a connecting shaft 44 , the second screw mandrel 45, the second screw nut 46 and the seventh bearing 47, the second motor 40 is installed on the right side of the left wall of the fixed frame 1, the first screw mandrel 43 is installed on the output shaft of the second motor 40, the first wire The connecting shaft 44 is installed on the right end of the rod 43, the second screw mandrel 45 is installed on the right end of the connecting shaft 44, the second bearing 41 is installed on the left part of the fixed frame 1, the seventh bearing 47 is installed on the right part of the fixed frame 1, and the second bearing 41 Link to each other with the first screw mandrel 43 through the mode of interference ...

Embodiment 2

[0027] A motor detection device for automobile manufacturing, such as Figure 1-4 As shown, it includes a fixed frame 1, a first sliding sleeve 31, a sliding rod 32, a second sliding sleeve 33, a second motor 40, a second bearing 41, a first screw nut 42, a first screw rod 43, and a connecting shaft 44 , the second screw mandrel 45, the second screw nut 46 and the seventh bearing 47, the second motor 40 is installed on the right side of the left wall of the fixed frame 1, the first screw mandrel 43 is installed on the output shaft of the second motor 40, the first wire The connecting shaft 44 is installed on the right end of the rod 43, the second screw mandrel 45 is installed on the right end of the connecting shaft 44, the second bearing 41 is installed on the left part of the fixed frame 1, the seventh bearing 47 is installed on the right part of the fixed frame 1, and the second bearing 41 Link to each other with the first screw mandrel 43 through the mode of interference ...

Embodiment 3

[0030] A motor detection device for automobile manufacturing, such as Figure 1-4 As shown, it includes a fixed frame 1, a first sliding sleeve 31, a sliding rod 32, a second sliding sleeve 33, a second motor 40, a second bearing 41, a first screw nut 42, a first screw rod 43, and a connecting shaft 44 , the second screw mandrel 45, the second screw nut 46 and the seventh bearing 47, the second motor 40 is installed on the right side of the left wall of the fixed frame 1, the first screw mandrel 43 is installed on the output shaft of the second motor 40, the first wire The connecting shaft 44 is installed on the right end of the rod 43, the second screw mandrel 45 is installed on the right end of the connecting shaft 44, the second bearing 41 is installed on the left part of the fixed frame 1, the seventh bearing 47 is installed on the right part of the fixed frame 1, and the second bearing 41 Link to each other with the first screw mandrel 43 through the mode of interference ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com