Rotary evaporator capable of accurately achieving quantification of concentrated liquid

A technology of rotary evaporator and concentrate, applied in the direction of distillation in a rotary container, distillation separation, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

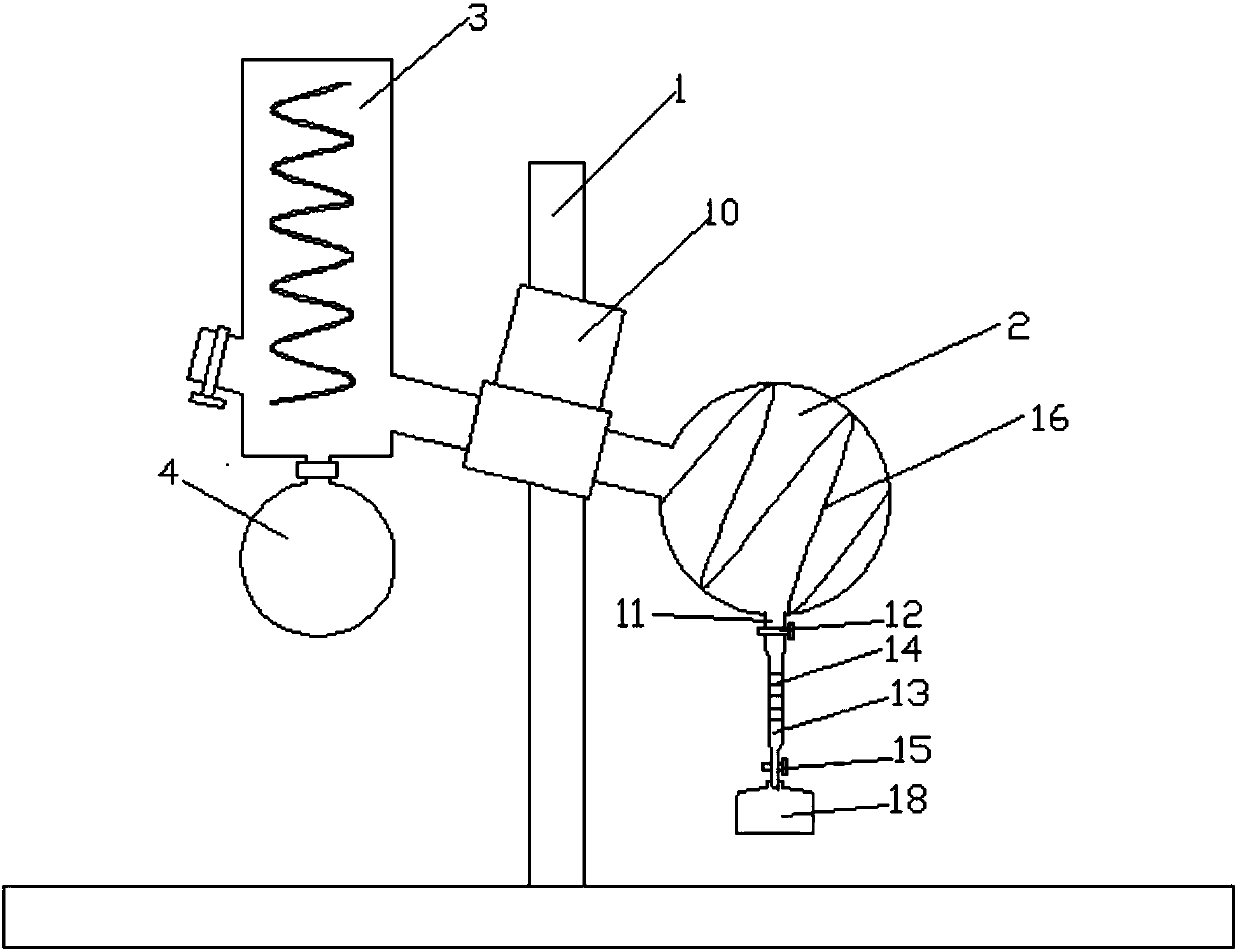

[0022] see figure 1 As shown, the rotary evaporator described in this embodiment that can accurately realize the accurate quantification of concentrated liquid includes: a support 1, a detachable distillation bottle 2 and a condenser 3 are fixed on the support 1, and the distillation bottle 2 is filled with The liquid to be concentrated is heated by a heating assembly to achieve evaporation and concentration; the bottom of the condenser 3 is connected with a collection bottle 4 for collecting fractions; the support is also provided with a rotating motor 10 that controls the rotation of the distillation bottle 2 (The rotary evaporator of the present invention can also be provided with a control panel for controlling the parameter speed of the rotating motor and heating temperature, not shown in the figure), and control components for controlling the rotating speed and heating temperature.

[0023] like figure 1 In the shown rotary evaporator, the bottom of the distillation bot...

Embodiment 2

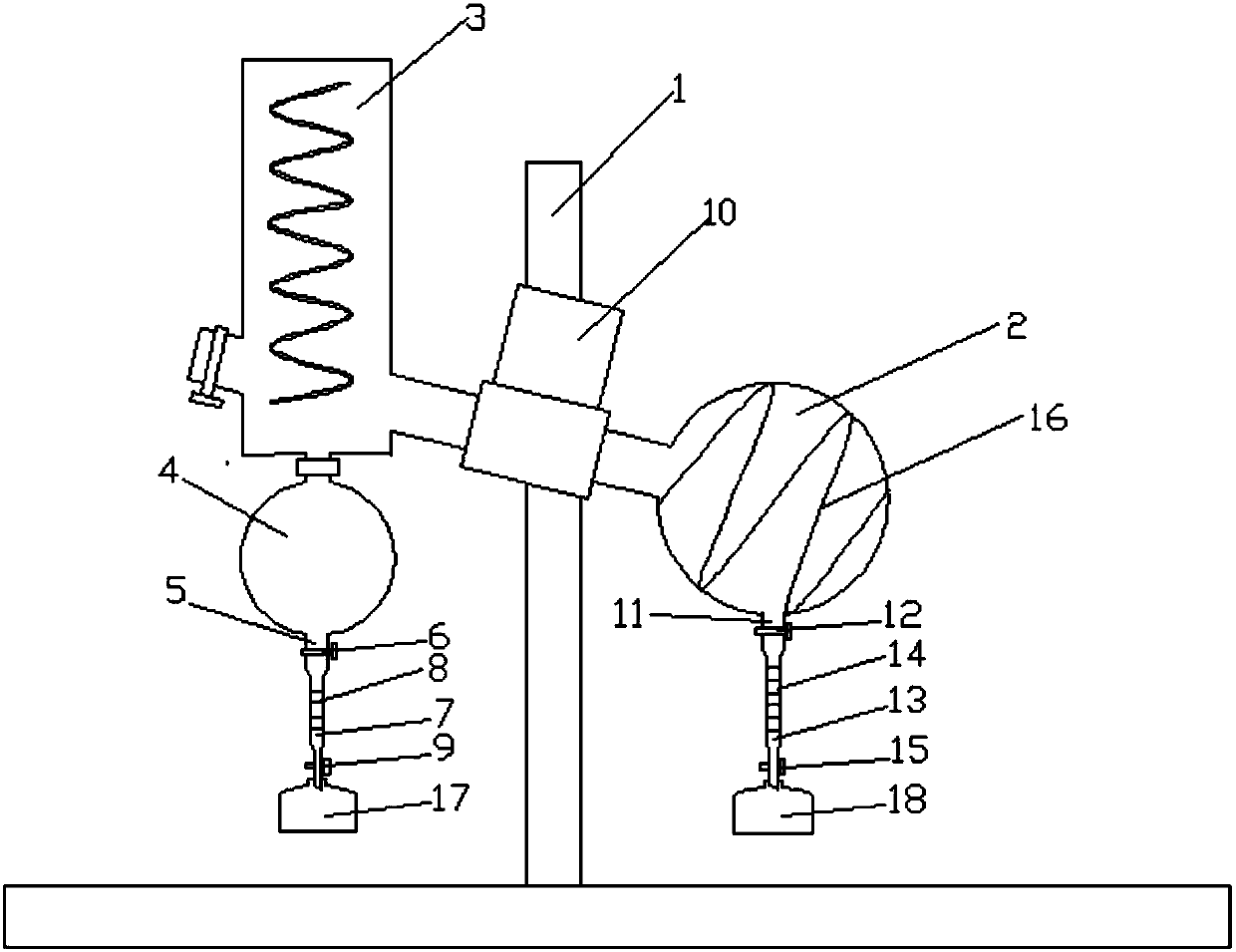

[0030] As a structure that can be transformed, such as figure 2 The structure of the rotary evaporator shown in this embodiment, the rotary evaporator that can accurately realize the quantification of the concentrated liquid described in this embodiment, includes: a support 1, a detachable distillation bottle 2 and a condenser 3 are fixed on the support 1, and the distillation The liquid to be concentrated is contained in the bottle 2, and is heated by a heating assembly to realize evaporation and concentration; the bottom of the condenser 3 is connected with a collection bottle 4 for collecting fractions; The rotary motor 10 (the rotary evaporator of the present invention can also be provided with a control panel for controlling the rotating speed, not shown in the figure), and a control assembly for controlling the heating temperature, etc.

[0031] like figure 2 In the shown rotary evaporator, the bottom of the distillation bottle 2 (based on the position of the working ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com