Rotary evaporator capable of accurately achieving fraction quantification

A technology of rotary evaporator and distillate, which is applied in the direction of distillation in a rotary container, distillation separation, separation method, etc., to achieve the effects of volume reduction, reduction of heating water consumption and oil consumption, and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

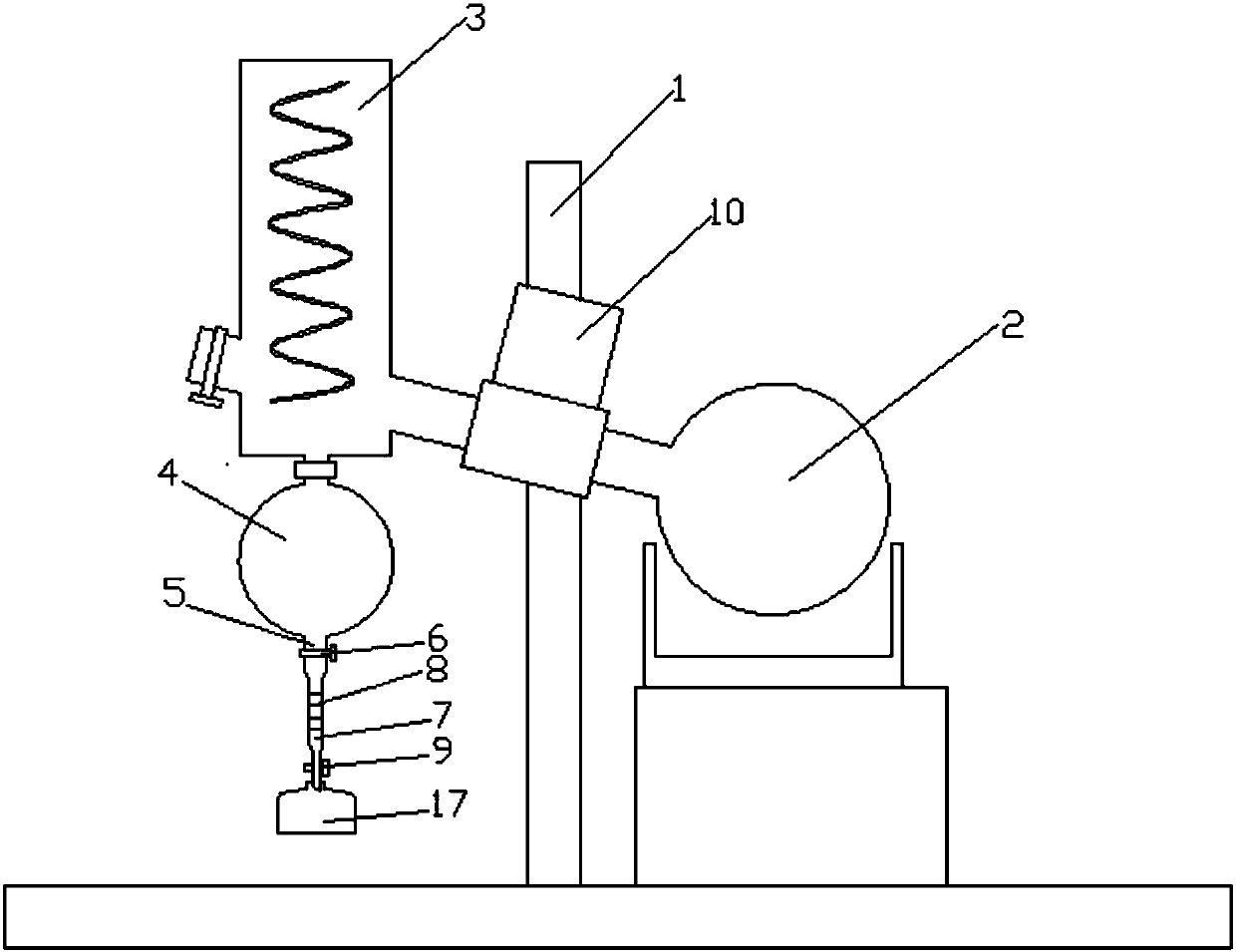

[0023] see figure 1 The structure shown in this embodiment, the rotary evaporator that can accurately realize fraction quantification, includes: a bracket 1, a detachable distillation bottle 2 and a condenser 3 are fixed on the bracket 1, and the distillation bottle 2 is filled with The liquid to be concentrated is heated by a heating assembly to achieve evaporation and concentration; the bottom of the condenser 3 is connected with a collection bottle 4 for collecting fractions; the support is also provided with a rotating motor 10 that controls the rotation of the distillation bottle 2 (The rotary evaporator of the present invention can also be provided with a control panel for controlling the rotating speed, not shown in the figure), and a lifting assembly for controlling the lifting of the distillation bottle 2 and a control assembly for controlling the heating temperature. The heating assembly is a water bath or an oil bath arranged at the bottom of the retort 2, and the l...

Embodiment 2

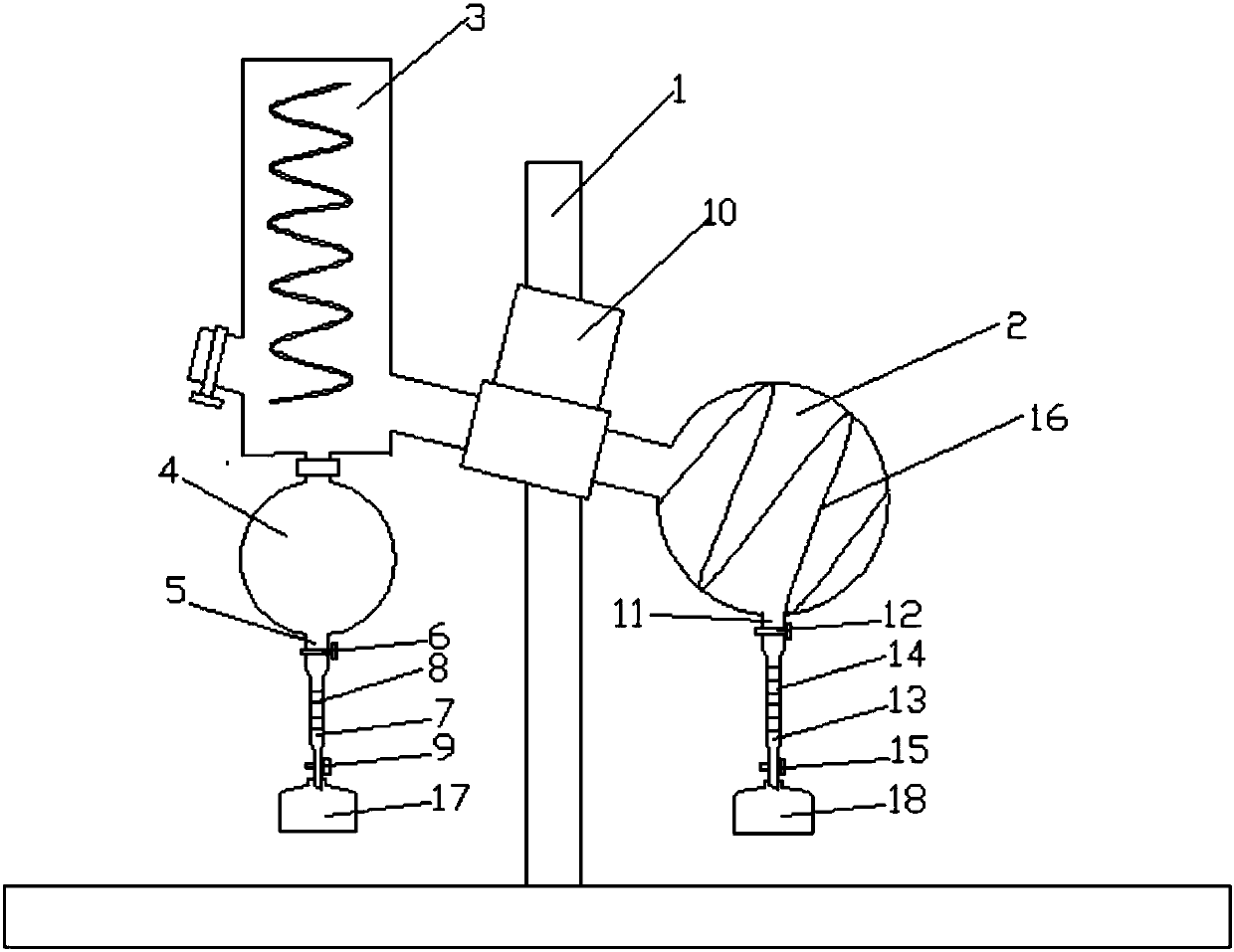

[0030] As a structure that can be transformed, such as figure 2The structure of the rotary evaporator shown in this embodiment, the rotary evaporator that can accurately realize the quantification of fractions described in this embodiment, includes: a bracket 1, a detachable distillation bottle 2 and a condenser 3 are fixed on the bracket 1, and the distillation bottle 2 contains the liquid to be concentrated, and is heated by a heating assembly to realize evaporation and concentration; the bottom of the condenser 3 is connected with a collection bottle 4 for collecting the distillate; the bracket is also provided with a device to control the rotation of the distillation bottle 2 Rotary motor 10 (the rotary evaporator of the present invention can also be provided with a control panel for controlling the rotational speed, not shown in the figure), and a control assembly for controlling the heating temperature, etc.

[0031] Such as figure 2 In the shown rotary evaporator, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com