Calibration method for self-adaptive threshold in X-ray on-line detection of joint of wire-cored belt

A technology of adaptive threshold and belt joints, which is applied to measuring devices, material analysis using wave/particle radiation, instruments, etc., can solve problems such as inaccurate joint image calibration, and achieve the effect of reducing calculation load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

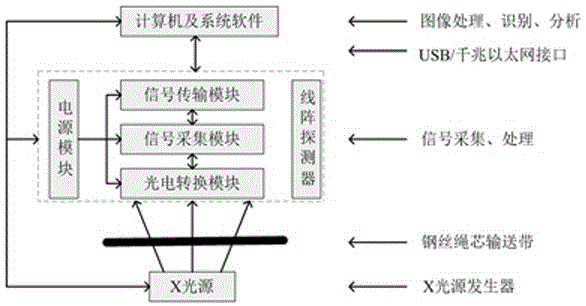

[0053] The self-adaptive threshold calibration method in the X-ray on-line detection of steel wire belt joints comprises the following steps:

[0054] Step 1: Set the connector counter to 0;

[0055] The second step: read each image of the video stream one by one online, if the joint counter is greater than or equal to the given number of joints in the database, then go to the eighth step;

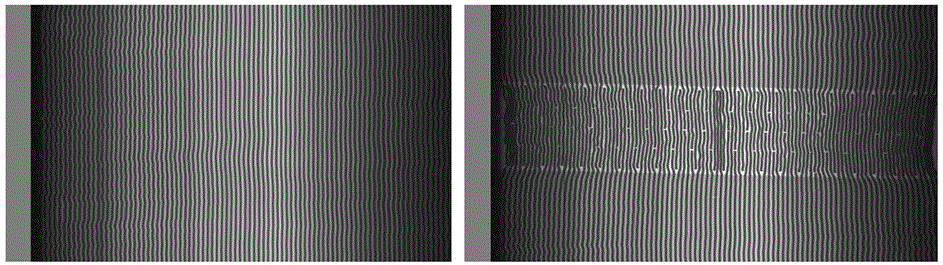

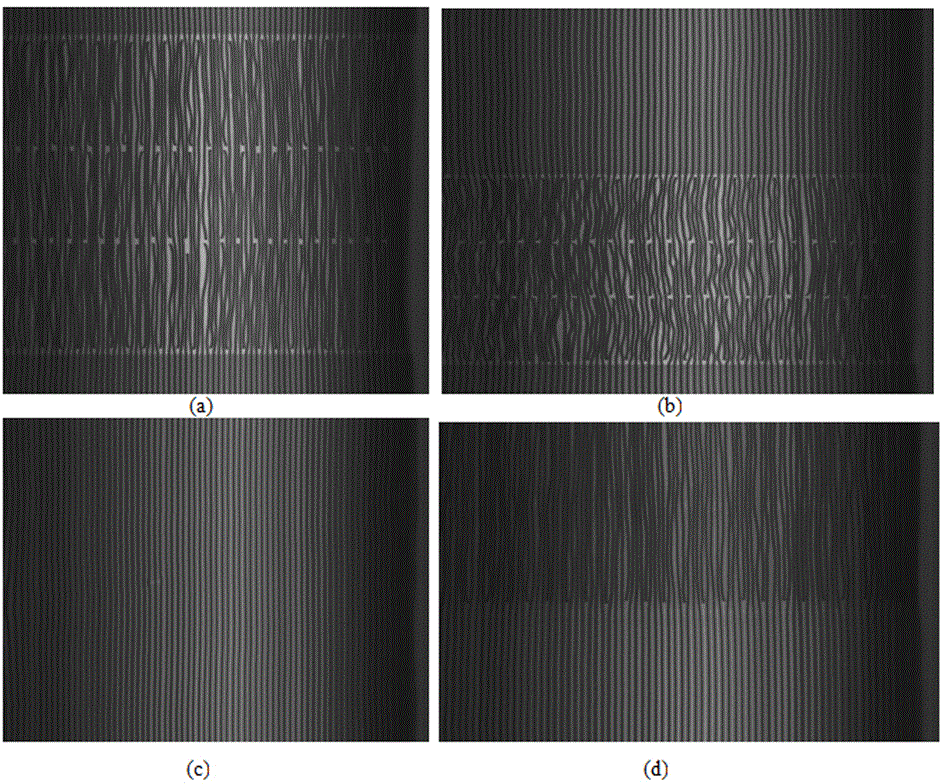

[0056] Step 3: Otherwise, sample one line every 30 lines of the read image, calculate the linear texture code of the sampled line, so as to obtain the number of steel wire cores in the sampled line, and read in the image to obtain the maximum number, minimum number, and average number of steel wire cores and the variance;

[0057] the fourth step: Make a judgment, the read-in image that satisfies the formula is the image that contains the assumed joint area, otherwise go to the second step to read the next image in the video stream;

[0058] Step 5: Count the histogram of the number of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com