Drum-type ultrasonic cleaning machine and method for cleaning workpieces

An ultrasonic, drum-type technology, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve problems such as inability of elements to diffuse and penetrate, device detachment, and decrease in coating adhesion, and achieve a significant cleaning effect. , Realize automation, eliminate the effect of workpiece lamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

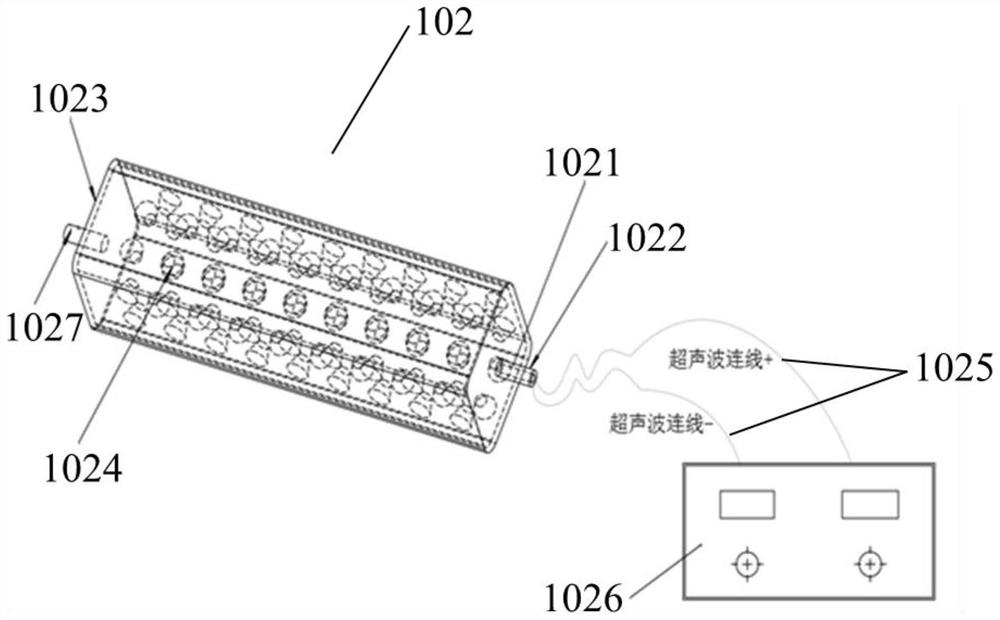

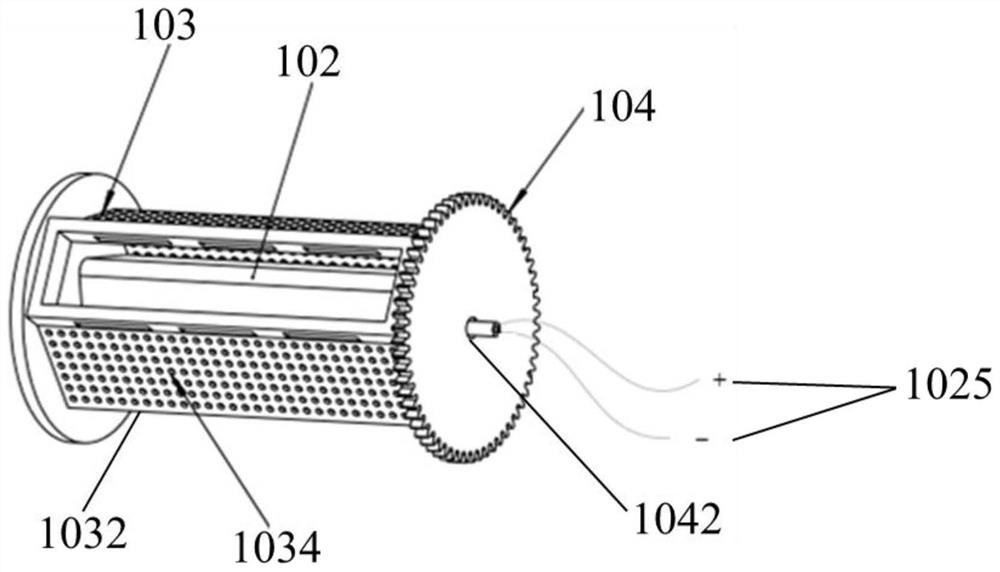

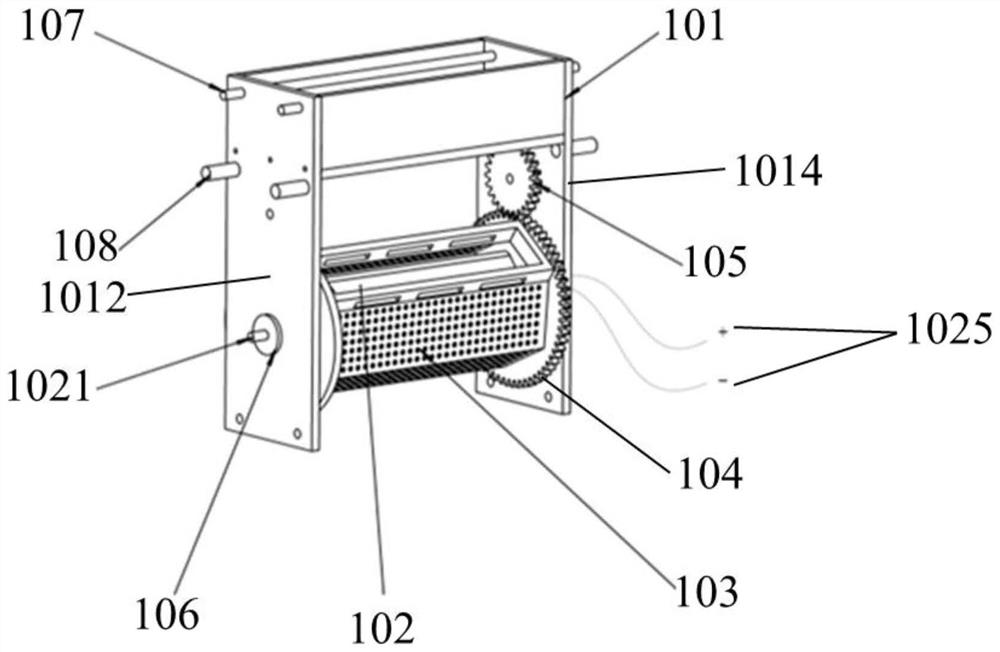

[0018] Combine now figure 1 , figure 2 , image 3 The present invention will be described.

[0019] The object of the present invention is to provide a basic unit device structure that is suitable for degreasing, pickling and water washing of flat workpieces and can be used in a fully automatic electroplating production line or a fully automatic degreasing and derusting production line.

[0020] The present invention provides a drum 103 type ultrasonic cleaner 10, comprising a frame 101, including a first plate 1012 and a second plate 1014 oppositely arranged; an ultrasonic vibration box 102, fixed on the frame 101 and arranged on the second plate Between a plate 1012 and the second plate 1014, the ultrasonic vibration box 102 has a shaft 1021 extending through the first plate 1012 and the second plate 1014; the roller 103 is arranged on the first plate Between 1012 and the second plate 1014 and surrounding the shell 1023 of the ultrasonic vibration box 102 , the roller 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com