Automatic dredging type coal discharging hopper

A coal hopper and automatic technology, which is applied in the field of coal hoppers with automatic dredging and anti-blocking functions, can solve the problems of wasting manpower and material resources, difficult to clean, and increase the density of coal materials, so as to achieve less use of force and good cleaning effect , strong penetrating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

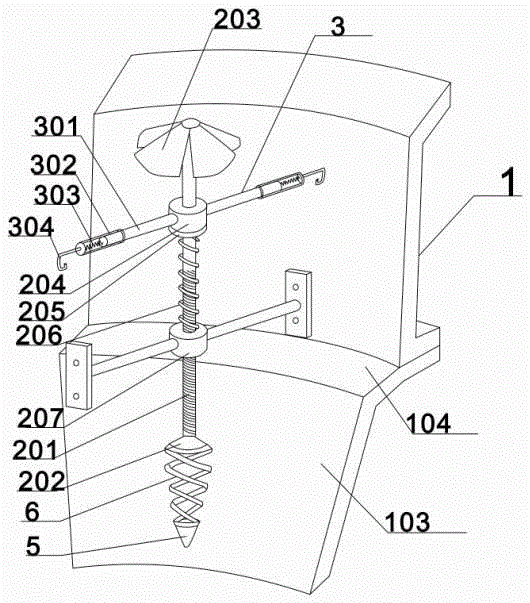

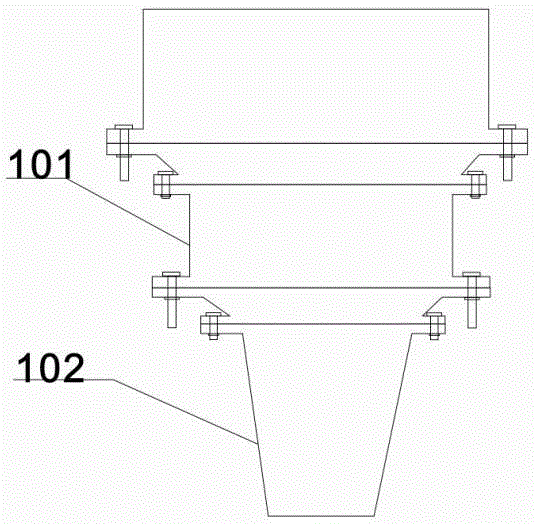

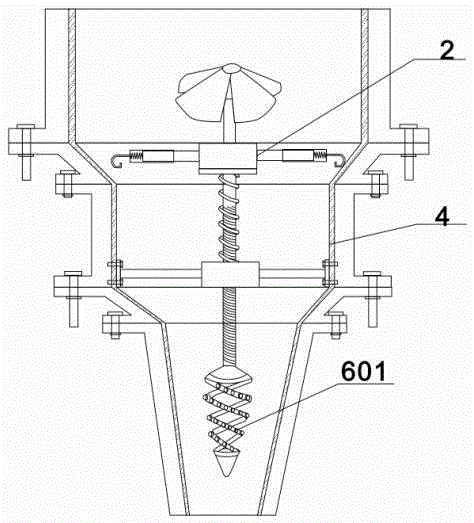

[0021] An automatic dredging type coal falling hopper, which is provided with a stepped bucket body and multi-level steps inside. The bucket body can be composed of multiple cylindrical sections and conical sections, and the cylindrical sections and conical sections are stacked alternately Combined into a complete bucket body, the connection between the cylindrical section and the conical section can be flanged. If a single section needs to be replaced and cleaned, the entire section can be removed for adjustment.

[0022] An automatic dredging device is fixed in the bucket, and the automatic dredging device is provided with a dredging rod with a thread at one end, the threaded end of the dredging rod is connected with a dredging cone, and the other end is connected with a fan blade, which is pushed by the falling coal , to drive the dredging rod to rotate, the upper fixing sleeve, the pressure bearing, the spring, and the lower fixing sleeve are sequentially arranged on the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com